Small-capacity master alloy casting system

A technology of casting system and master alloy, which is applied to equipment for feeding molten metal into casting molds, ingot workshops, foundry workshops, etc. The effect of reducing the diversion plug, improving the purity and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with preferred embodiments.

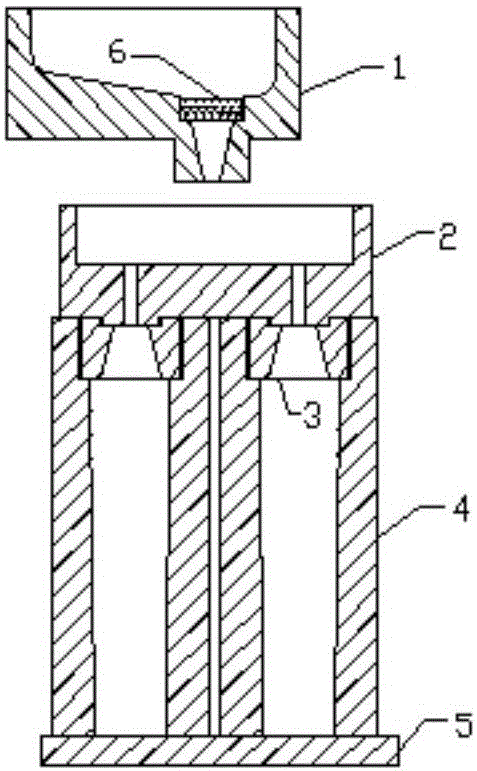

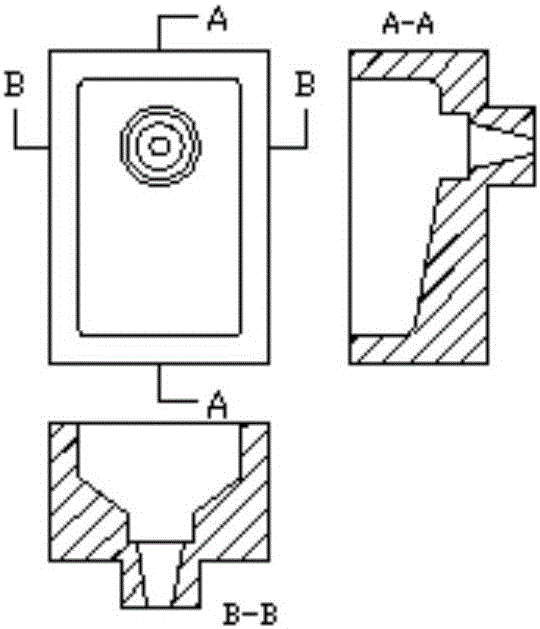

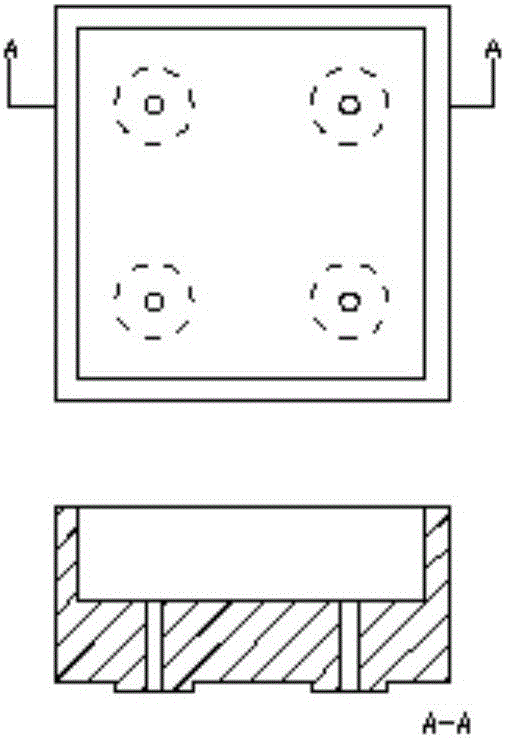

[0023] Such as figure 1 As shown, the present invention can produce the small-capacity master alloy casting system of high-quality master alloy mainly by the prefabricated tundish with zirconia filter sheet and three inclined planes inside, straight face, refractory shunt (such as image 3 shown), embedded heating riser (such as Figure 4 shown), ingot mold (such as Figure 5 shown), refractory floor (such as Figure 6 shown) composition. The square four-hole shunt is connected with the embedded heating riser, and the embedded heating riser and the ingot mold are connected with refractory mud.

[0024] The three surfaces inside the prefabricated tundish away from the nozzle are inclined surfaces, and the side close to the nozzle is a vertical surface, such as figure 2 As shown, the porosity of the zirconia filter in the tundish is 10ppi, su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com