Combined electrode electric desalting dewatering equipment

A combination electrode and electric desalination technology, which is applied in the field of dehydrator and high-efficiency combined electrode electric desalination, can solve the problems of electric dehydration desalter not suitable for large diameter, uneven electric field, limited processing capacity, etc., to achieve increased space and improved Float time, the effect of reducing the backmixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to the drawings and embodiments.

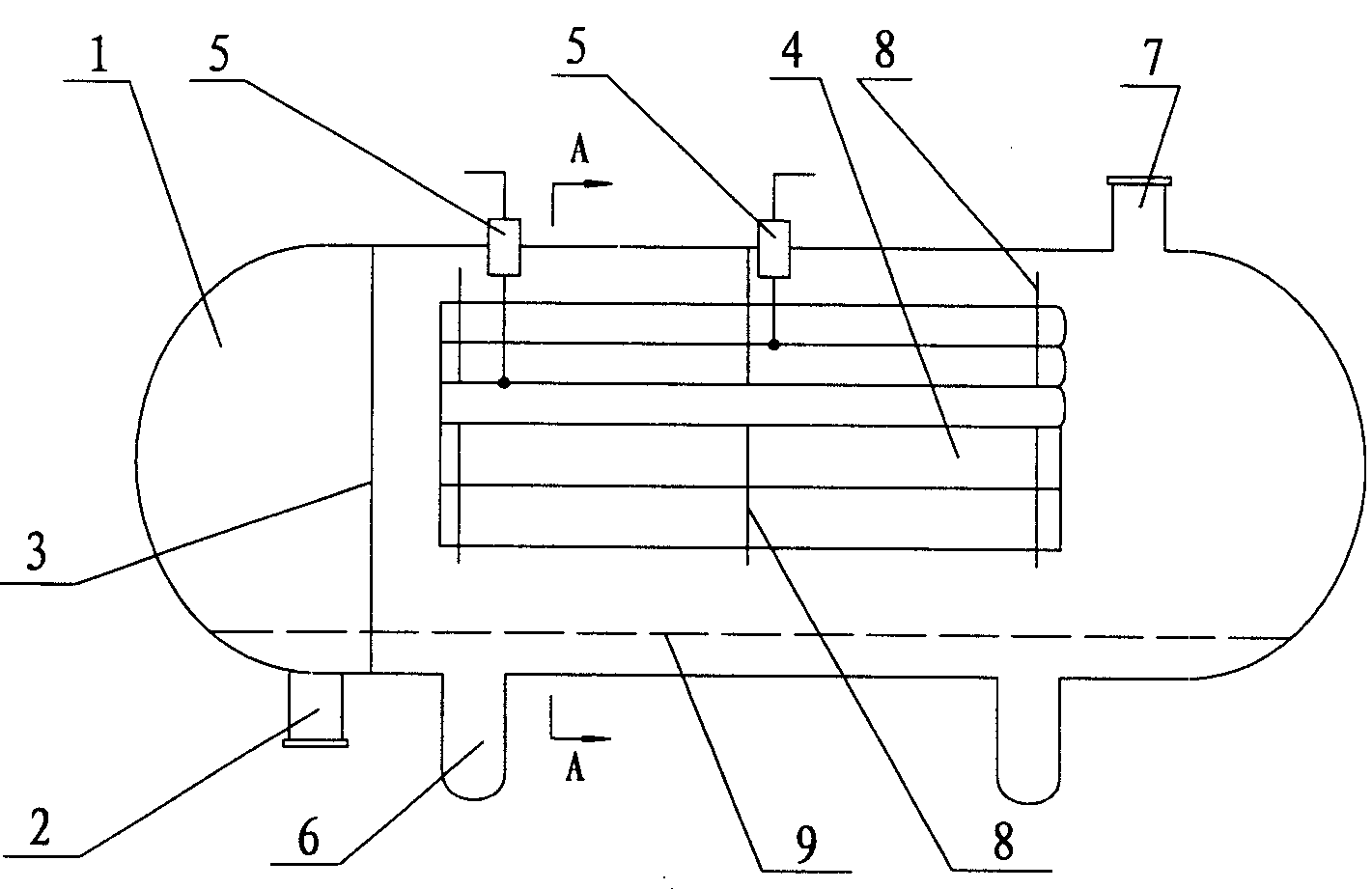

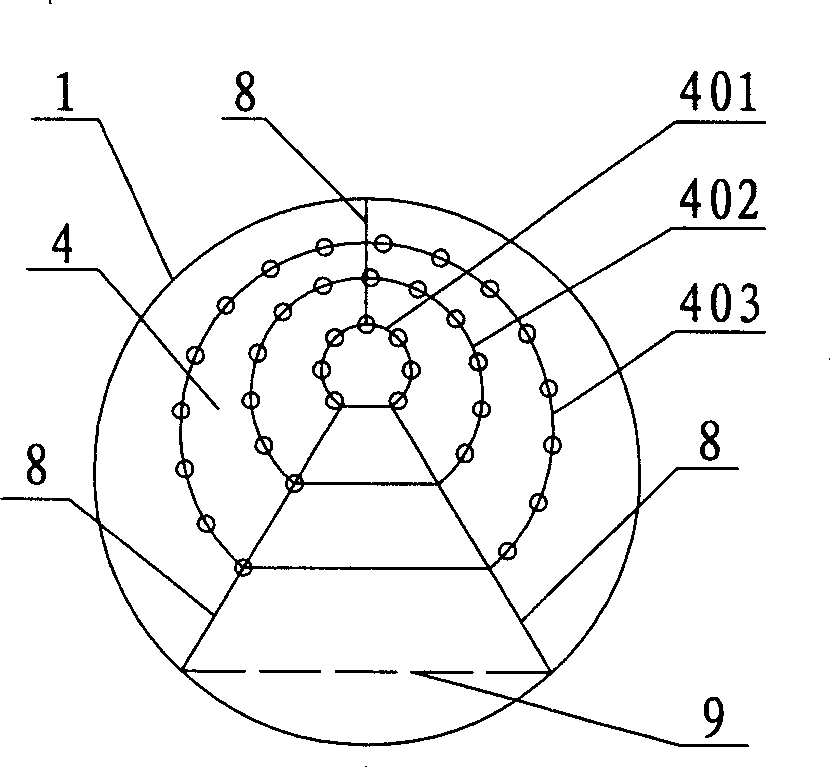

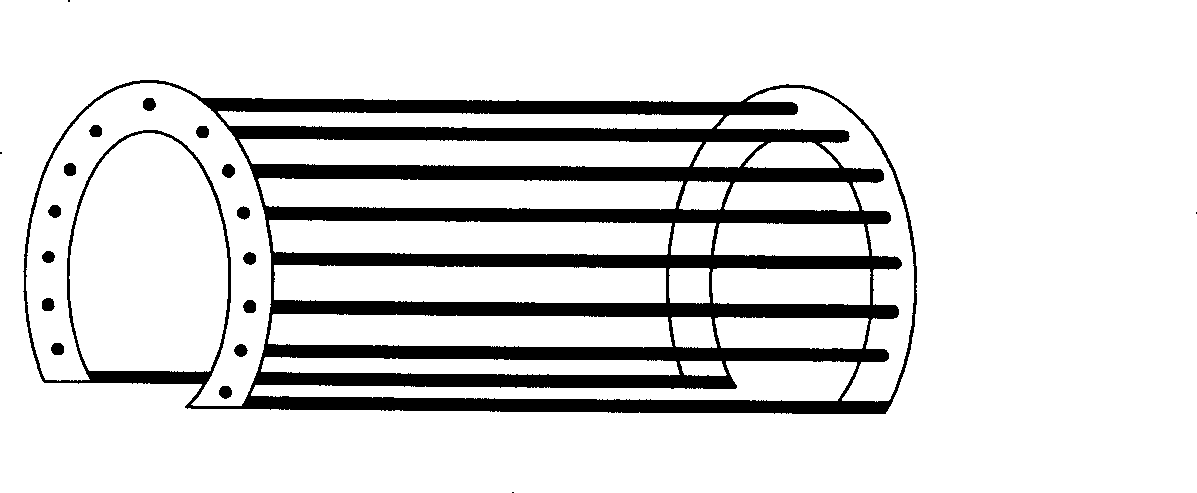

[0025] figure 1 with figure 2 The illustrated electric dehydration desalter of the present invention mainly includes a tank body 1 and an electrode assembly 4 arranged in it. The tank 1 is provided with an inlet pipe 2, a distributor 3, a water bag 6, an outlet pipe 7, and a high-voltage electric introduction device 5. The distributor 3 is located at the inlet end of the oil-water mixture and is a steel plate with square or round holes. The electrode assembly 4 is composed of a first-layer electrode 401, a second-layer electrode 402, and a third-layer electrode 403, all of which are circular in cross-section, combined from the inside to the outside, and is fixed on the tank 1 with an insulating support and hanging 8 On the inner wall; the insulating support and hanging 8 adopt PTFE rods or ceramic rods. The ring electrode assembly 4 is installed between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com