A kind of floating flocculant and preparation method thereof

A flocculant and composite flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water treatment parameter control, etc., can solve the problems of secondary pollution, unfavorable follow-up treatment, etc., and achieve good floating effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

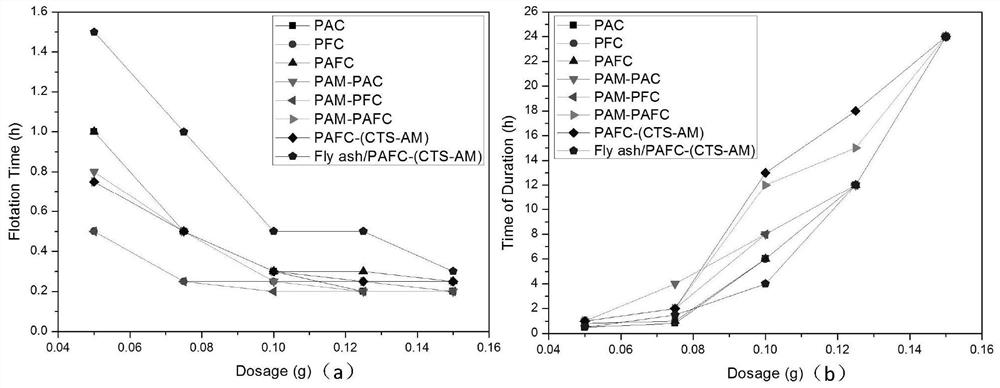

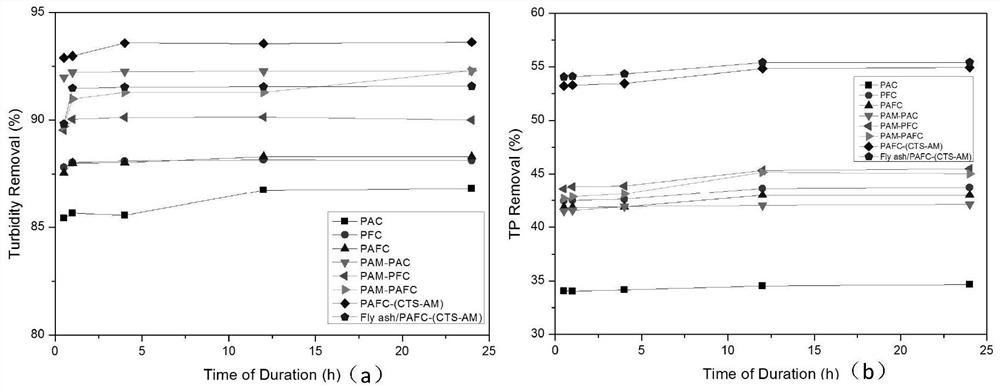

Image

Examples

Embodiment 1

[0025] Embodiment 1: Preparation of floating polyaluminum chloride (PAC) flocculant:

[0026] Simply mix 0.05g of polyaluminum chloride with 0.050g, 0.750g, 0.100g, 0.125g, and 0.150g of sodium percarbonate, and stir evenly to prepare a floating polyaluminum chloride flocculant.

Embodiment 2

[0027] Embodiment 2: the preparation of floating type polyferric chloride (PFC) flocculant:

[0028] Then 0.05g of polyferric chloride solid is mixed with 0.050g, 0.750g, 0.100g, 0.125g and 0.150g of sodium percarbonate respectively, and stirred evenly to prepare a floating polyferric chloride flocculant.

Embodiment 3

[0029] Embodiment 3: Preparation of floating polyaluminum ferric chloride (PAFC) flocculant:

[0030] Preparation of polyaluminum ferric chloride: 2g of FeCl 3 ·6H 2 O and 4.47g AlCl 3 ·6H 2 O into the beaker, add 200ml of distilled water and stir until completely dissolved, slowly add 0.78gNa 2 CO 3 Powder, add 0.04g Na after the foam disappears 2 HPO 4 12H 2 O, continue to stir until completely dissolved. After aging, place it in an oven at 60°C to dry, cool to room temperature, and grind to obtain polyaluminum ferric chloride (PAFC) solid with relatively stable properties.

[0031] Then, 0.05g of the above polyaluminum ferric chloride solid was simply mixed with 0.050g, 0.750g, 0.100g, 0.125g, and 0.150g of sodium percarbonate respectively, and stirred evenly to prepare a floating polyaluminum ferric chloride flocculation agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com