Cavitation and foaming integrated tailing flotation device

A flotation device and cavitation technology, used in flotation, solid separation, etc., can solve the requirements of tailings flotation that cannot meet large volume and high precision, does not have tailings flotation function, and has poor hydraulic cavitation effect. and other problems, to achieve the effect of superior cavitation benefit, high shear force and energy dissipation rate, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

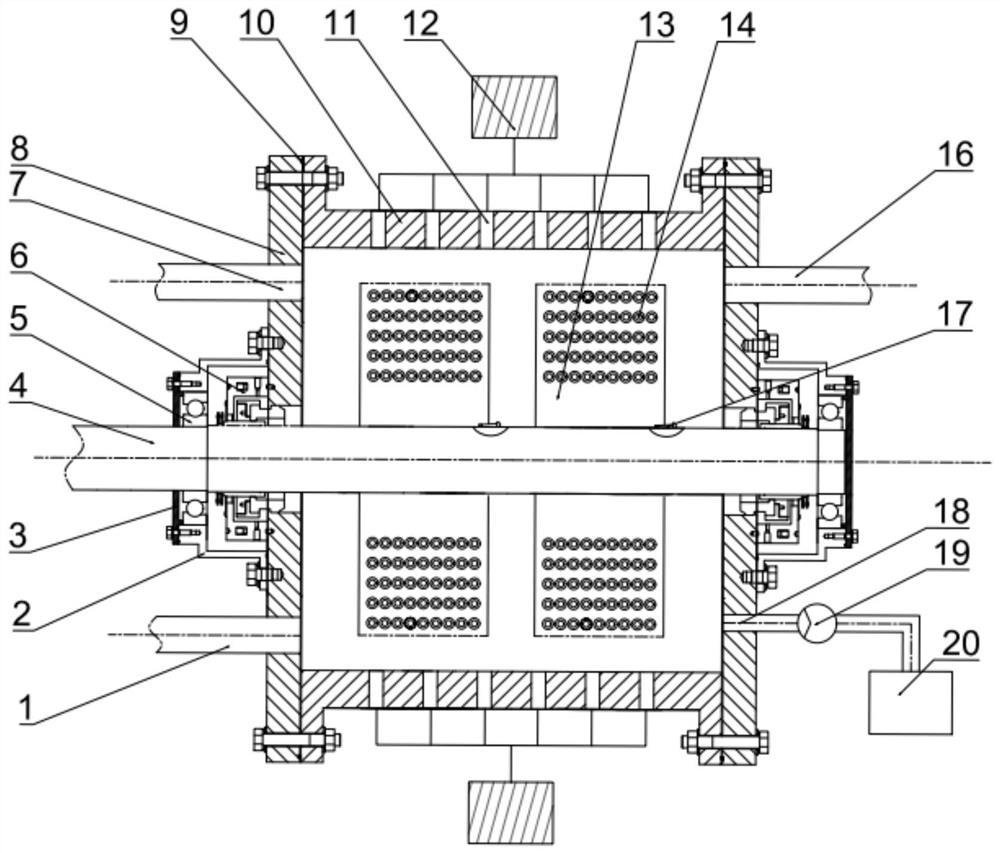

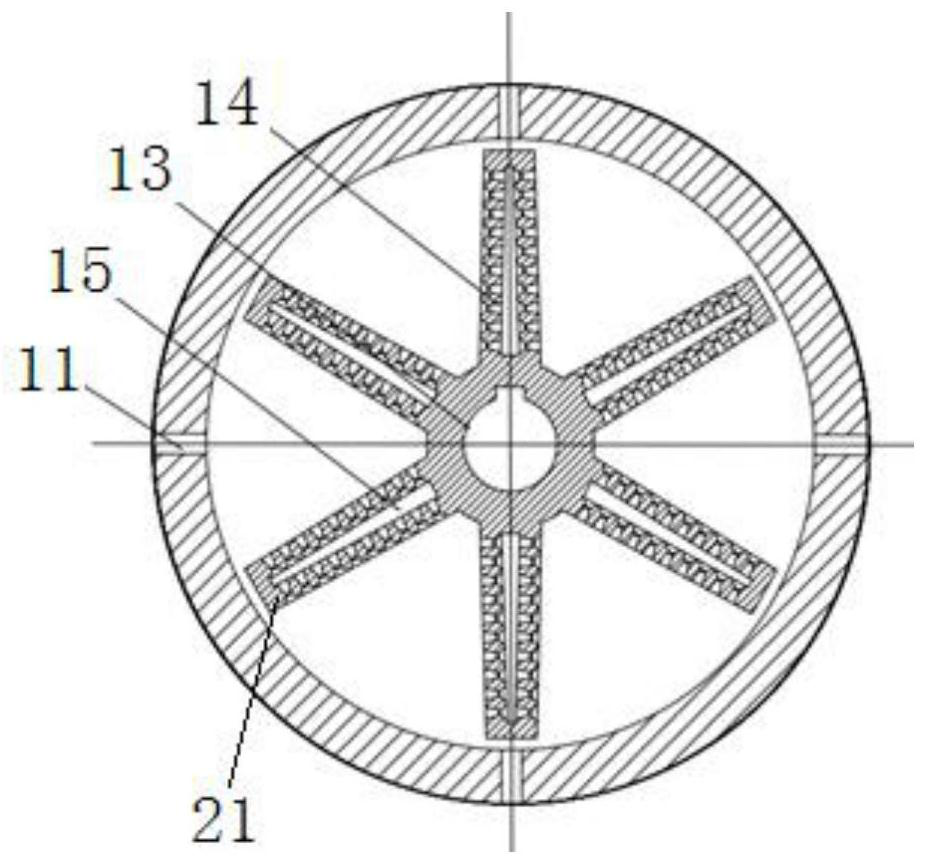

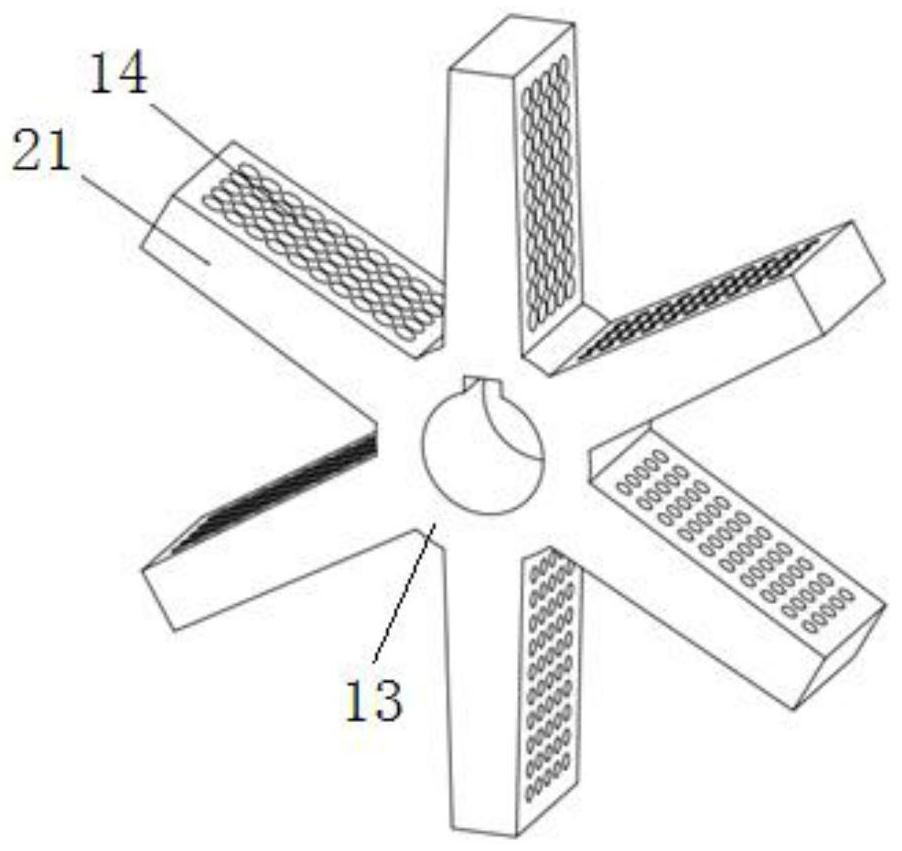

[0053] By performing tailings flotation process on 10kg of tailings slurry after tailings treatment, under the optimal working condition and this structure (parameters: the inner diameter of the stator is 400mm, the width of the stator is 340mm, and the wall thickness is 30mm The length of the blade is 130mm, the width is 60mm, and the thickness is 30mm; the inner diameter of the outlet and inlet of the Venturi-shaped hole is 6mm, the inner diameter of the central throat is 0.7mm, the contraction angle is 45°, and the expansion angle is 11°; the Venturi on the blade The inner-shaped holes are arranged in a 5×4 rectangular array; there are 4 ultrasonic transducers per circle, a total of 6 circles; there are 2 ultrasonic generators, and the power of a single machine is 2000W), and the following conclusions are obtained:

[0054] At a speed of 4500rpm, the flow rate is 4m 3 / h, the ultrasonic frequency is 40kHz, the foaming agent is XP20 ionic foaming agent, and the reaction temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com