Vidp+vhcc dual production method of powder superalloy master alloy and powder superalloy master alloy

A high-temperature alloy and master alloy technology, which is applied in the field of metallurgy, can solve the problems of inability to transplant from multiple processes, complicated operation process, master alloy pollution, etc., and achieve the effect of good floating effect, simple process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

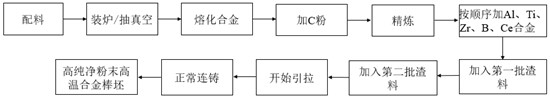

Method used

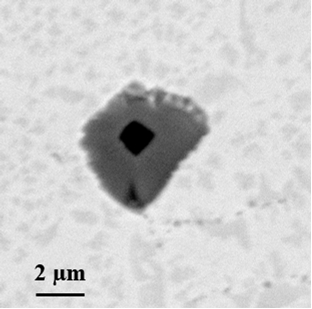

Image

Examples

preparation example Construction

[0068] In an optional embodiment, the preparation method of the slag comprises: melting the raw material of the slag, then water quenching, cooling, and crushing to obtain the slag.

[0069] Specifically, the following operations can be followed: high-purity CaO, MgO, CaF 2 、Al 2 o 3 、TiO 2 , ZrO 2 , CeO 2 The reagents were weighed in proportion and put into a tube furnace, and kept at 1500°C for 30 minutes to ensure complete melting and homogeneity. After the molten slag sample was taken out, it was quenched in water and ground into powder for use.

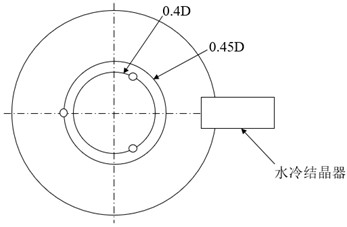

[0070] In an optional embodiment, the bottom air supply element is an annular slot type bottom blowing air supply element;

[0071] In an optional embodiment, the annular slot type bottom blowing air supply element includes a first air supply point, a second air supply point and a third air supply point, and the first air supply point is set at the VIDP The 0.45D circumference of the molten pool of the furnace is arranged a...

Embodiment 1

[0087] Such as figure 1 As shown, the present embodiment provides a kind of smelting equipment, comprises VIDP furnace and continuous casting facility, and VIDP furnace comprises vacuum chamber and is placed in the melting pool of vacuum chamber; The top of vacuum chamber is provided with feeding funnel 1, vacuum valve 2, vacuum meter 3. The feeding funnel 1 is set corresponding to the molten pool, and the upper periphery of the molten pool is provided with an induction coil 4 for inductively heating the material in the molten pool. During the smelting process, the molten metal 5 is placed in the lower part of the molten pool, and the bottom of the molten pool is set There is a bottom gas supply element 6, and the slag 7 is placed on the top of the molten metal 5; a crystallizer is provided on the lower side of the molten pool, and the crystallizer adopts a graphite mold 8 and a water-cooled copper mold 9, and the crystallizer is along the direction of the molten metal flow A ...

Embodiment 2

[0118] (1) Ingredients:

[0119] The components of the vacuum horizontal continuous casting slag system and their mass percentages are CaO: 24%, Al 2 o 3 : 20%, MgO: 3%, CaF 2 : 48%, TiO 2 : 2%, ZrO 2 : 2%, CeO 2 :1%. High purity CaO, MgO, CaF 2 、Al 2 o 3 、TiO 2 , ZrO 2 , CeO 2 The reagents were weighed in proportion and put into a tube furnace, and kept at 1500°C for 30 minutes to ensure complete melting and homogeneity. After the molten slag sample was taken out, it was quenched in water and ground into powder for use.

[0120] The powdered superalloy material is made of high-quality raw materials, the purity of the raw materials is ≥99.99%, and the components and mass percentages are C: 0.05%, Cr: 16.50%, Co: 13.00%, W: 4.10%, Mo: 4.10%, Al: 2.30%, Ti: 3.90%, Nb: 0.70%, B: 0.015%, Zr: 0.050%, Ce: 0.010%, Ni according to the balance, all raw materials are washed with alcohol and then baked.

[0121] (2) Loading:

[0122] Put pre-dried Cr, Co, W, Mo, Nb, Ni and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com