Slag retaining ring for cast iron quantitative seat bag pouring and preparation method thereof

A slag retaining ring and seat bag technology, which is applied in casting equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of weakening the buoyancy of molten iron upward, reducing the working life of the slag retaining ring, and the slag retaining ring cannot float up in time, etc. To achieve the possible effect of improving the buoyancy, improving the slag blocking effect and reducing the brokenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention provides a slag retaining ring in a slag retaining mechanism when pouring large iron castings with a quantitative seat ladle. It can effectively prevent the scum on the surface of the molten iron in the seat bag from entering the mold.

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention should not be limited thereby.

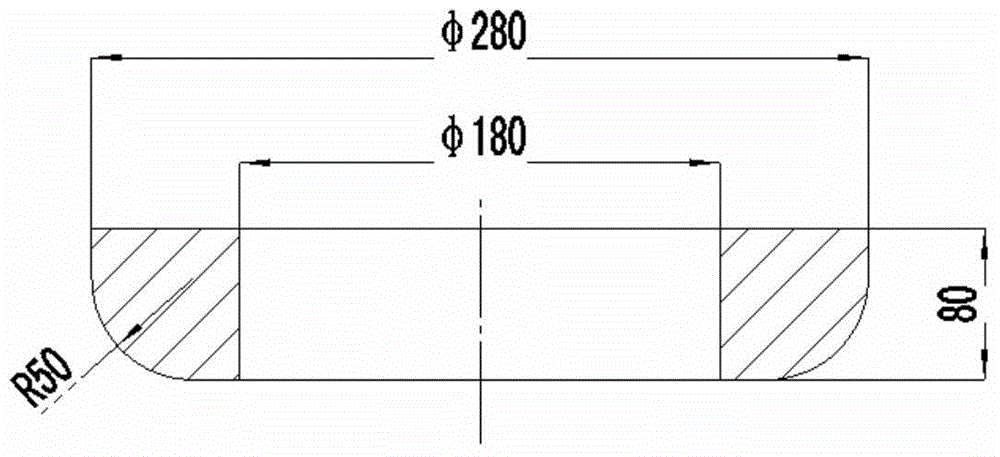

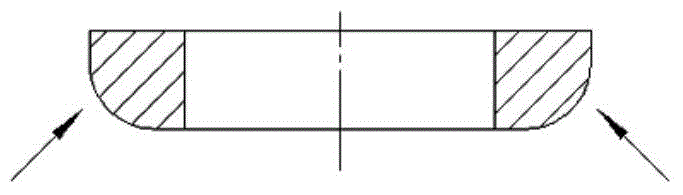

[0029] Please see first figure 2 , as shown in the figure, the slag retaining ring for pouring cast iron quantitative seat bag is a torus, and the lower peripheral part of the section passing through the central axis of the torus is arc-shaped. In other words, the lower part of the torus-shaped slag retaining ring The cross-section of the outer circumference is arc-shaped; the resultant force of the molten iron buoyancy on the lower outer circumference points to the central axis above the torus, see image 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com