Aeration-free waste water air floatation complexing agent and its preparation method, use method and use device

An applicator and composite agent technology, applied in chemical instruments and methods, food industry wastewater treatment, natural water treatment, etc., can solve the problem of high operating cost of the treatment process, achieve good floating effect, facilitate application and promotion, and reduce operating costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An aeration-free waste water air flotation composite agent, the composite agent includes, by mass fraction, coagulant, 20-50%, which includes iron salt, magnesium salt and polyaluminum chloride; cross-linking agent, 3-5%.

[0040] The cross-linking agent is water-soluble epoxy cross-linking agent or cross-linking agent EH or cationic water-soluble epoxy cross-linking agent EPTA.

[0041] The iron salt is ferric sulfate or ferric chloride or ferrous sulfate, and the magnesium salt is magnesium sulfate or magnesium chloride.

[0042] The coagulant also includes Mn ions and perchlorate.

Embodiment 2

[0044] In conjunction with Example 1, a method for preparing an aeration-free waste water air flotation composite agent, the preparation method includes the pretreatment of the coagulant, and the pretreatment includes the coagulant containing iron salt, magnesium salt and polyaluminum chloride, MnCl 2 and potassium perchlorate are dissolved in water, heated and stirred, and finally dried at 500 degrees Celsius to form powder.

Embodiment 1 and Embodiment 2

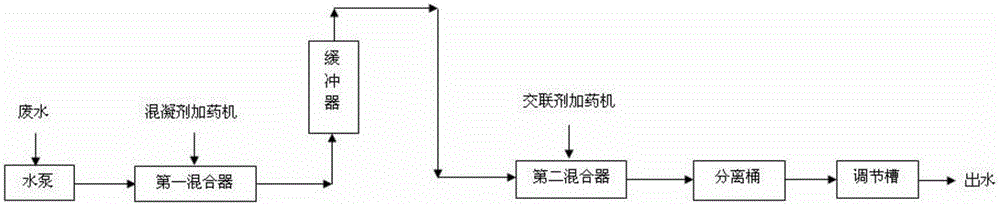

[0046] In combination with Example 1 and Example 2, an application method of an aeration-free waste water air flotation compound agent, the steps of the application method are as follows:

[0047] In the first step, the coagulant and crosslinking agent are dissolved in water respectively for later use;

[0048] In the second step, a coagulant is first added to the waste water to cause oxidation and coagulation reaction with the suspended particles in the waste water, and the injection amount of the coagulant is 0.25% of the waste water volume;

[0049] In the third step, a cross-linking agent is finally added to the waste water, and the injection amount of the cross-linking agent is 0.1% of the waste water, thereby forming loose flocs in the waste water;

[0050] In the fourth step, after the reaction, the solid flocs can float up without aeration, and then the floating solid flocs are subjected to solid-liquid separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com