Method for depriving solvent for cis-polybutadiene

A butadiene rubber and solvent removal technology, which is applied in the field of butadiene rubber solvent removal, can solve the problems of large water vapor consumption and high solvent oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

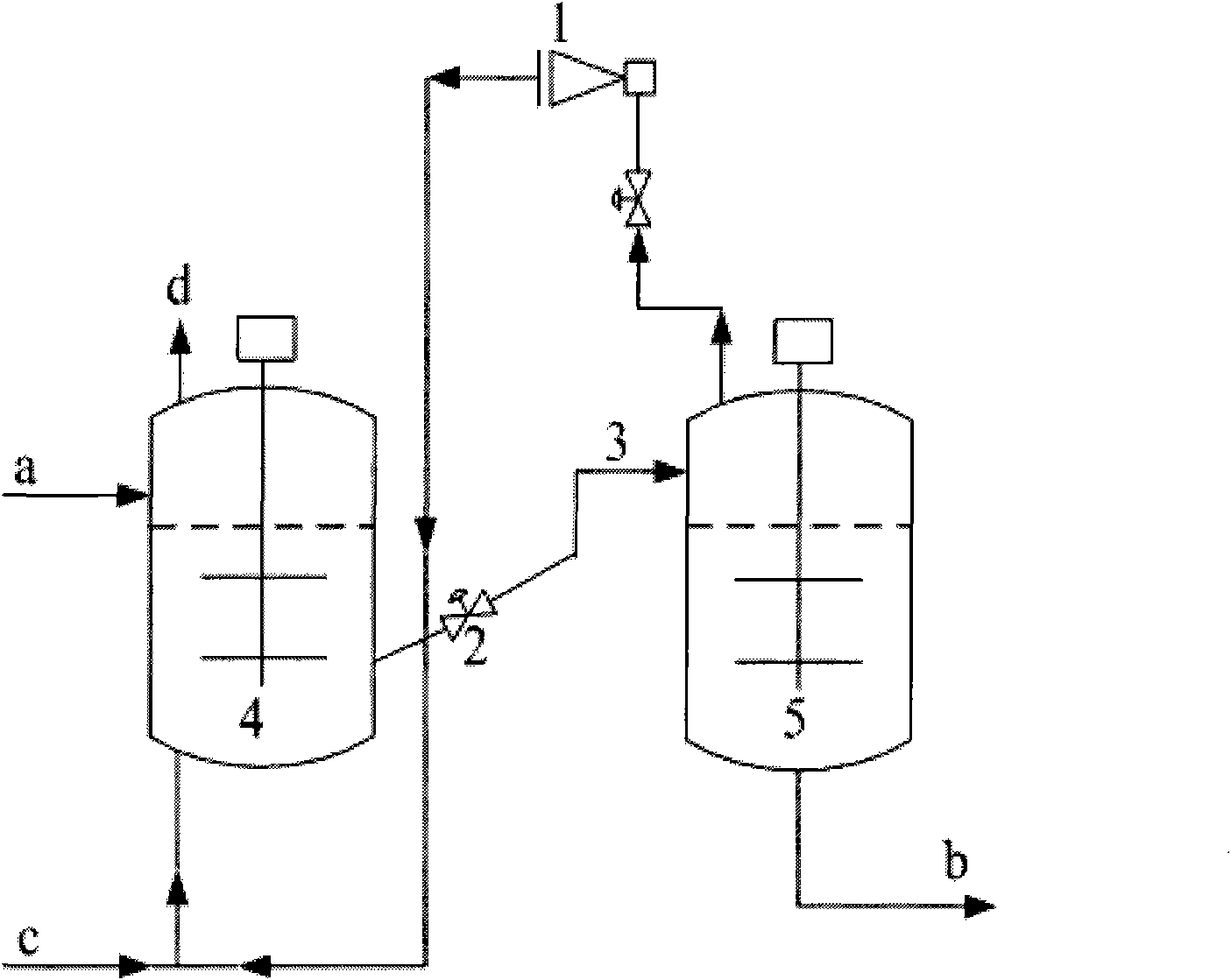

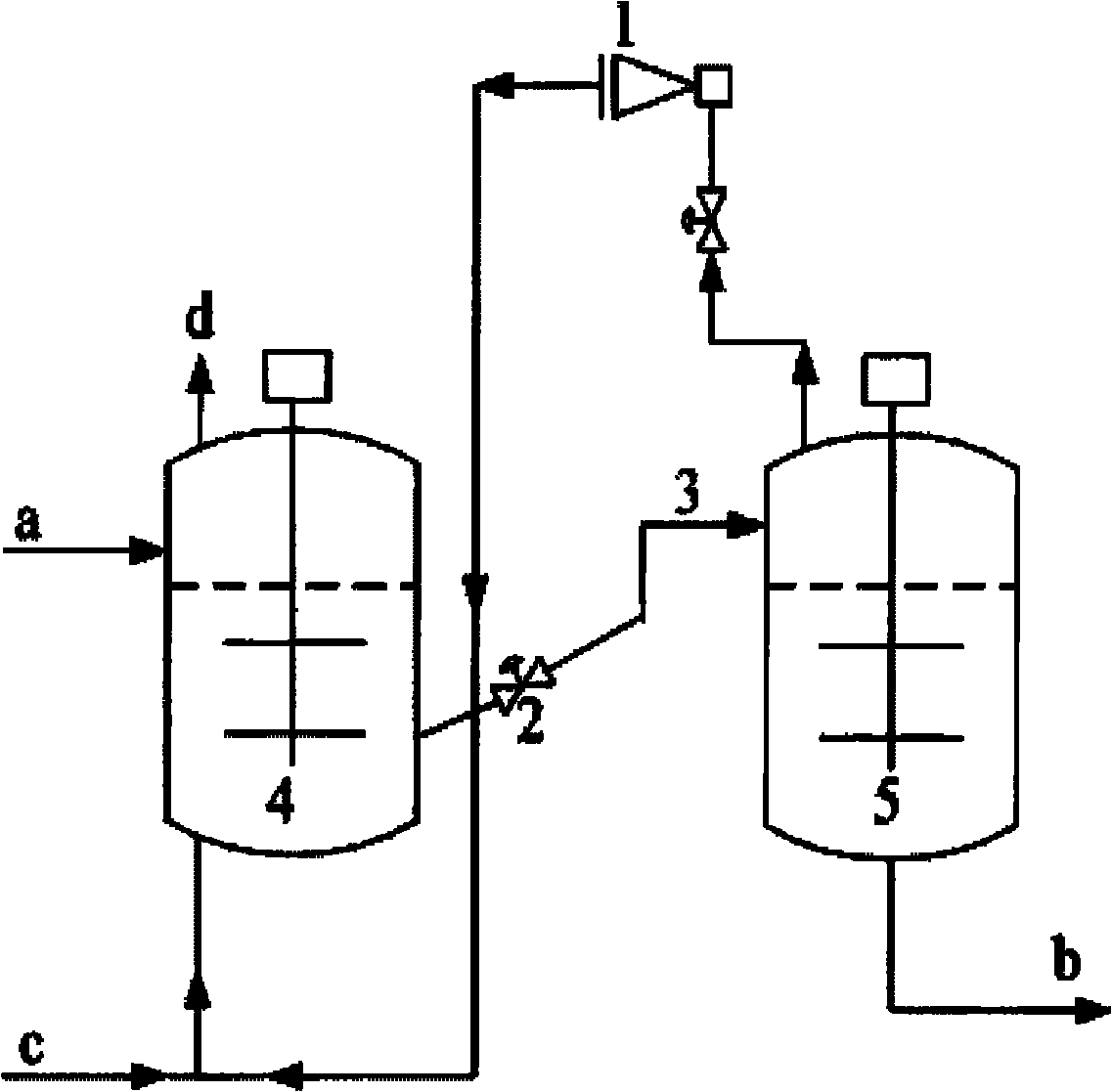

[0022] use figure 1As shown in the process, the stream I containing rubber glue and hot water is injected from the upper part of the first coagulation tank, the stream II containing water and solvent is discharged from the top of the first coagulation tank, and the overflow pipe on the side of the first coagulation tank Exhaust stream III, wherein the flow rate of stream III is controlled by the liquid level control system; stream III enters from the gas phase space position in the second condensation tank, and the stream containing water and solvent is extracted through Venturi, and then enters the first stream together with supplementary fresh steam At the bottom of the coagulation tank; at the bottom of the second coagulation tank, the condensed stream containing butadiene rubber is obtained; after the stream II containing water and solvent is separated, the solvent is obtained. Wherein the weight ratio of rubber glue solution and hot water in logistics I is 1: 2; In parts ...

Embodiment 2

[0025] With [Example 1], only the weight ratio of rubber glue solution and hot water in the logistics I is 1: 4; In parts by weight, the rubber glue solution comprises 20 parts of butadiene rubber, 79.99 parts of solvent and 0.01 parts The antioxidant 264 of part; The temperature of described hot water is 87 ℃; The described solvent is 61~65 ℃ distillation range oil; In described stream II, the volume ratio of water and solvent is 1:4. The operating conditions of the first condensation tank are: temperature T 1 =99°C, pressure P 1 =91KPa; the operating condition of the second condensation tank is: temperature T 2 =98°C, pressure P 2 = 40KPa.

[0026] The result is: solvent oil consumption is 74 kg / ton of rubber, water vapor consumption is 1.7 tons / ton of rubber.

Embodiment 3

[0028] With [embodiment 1], just the weight ratio of rubber glue solution and hot water in logistics I is 1: 4; In parts by weight, described rubber glue solution comprises the solvent of 20 parts of butadiene rubber and 80 parts; The temperature of the hot water is 90°C; the solvent is hexane with a distillation range of 60-75°C; in the stream II, the volume ratio of water to solvent is 1:5. The operating conditions of the first condensation tank are: temperature T 1 =101°C, pressure P 1 =88KPa; the operating condition of the second condensation tank is: temperature T 2 =100°C, pressure P 2 = 30KPa.

[0029] The result is: solvent oil consumption is 61 kg / ton of rubber, water vapor consumption is 1.6 tons / ton of rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com