Graphene with porous structure and preparation method of graphene

A porous structure, multi-layer graphene technology, applied in the field of graphene and its preparation, can solve the problems of unsuitable large-scale and low-cost production of graphene, high process control requirements, loss of physical and chemical properties, etc., to achieve convenience The effect of low-cost mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the present embodiment, adopt MgO / Mg(OH) respectively 2 and Al 2 o 3 / Al(OH) 3 As a catalyst, hydrothermal treatment is used to make the morphology of the catalyst into a porous sheet, and the adsorption of the porous structure of the catalyst is used to catalyze the cracking of carbon-containing hydrocarbons, thereby generating porous graphene.

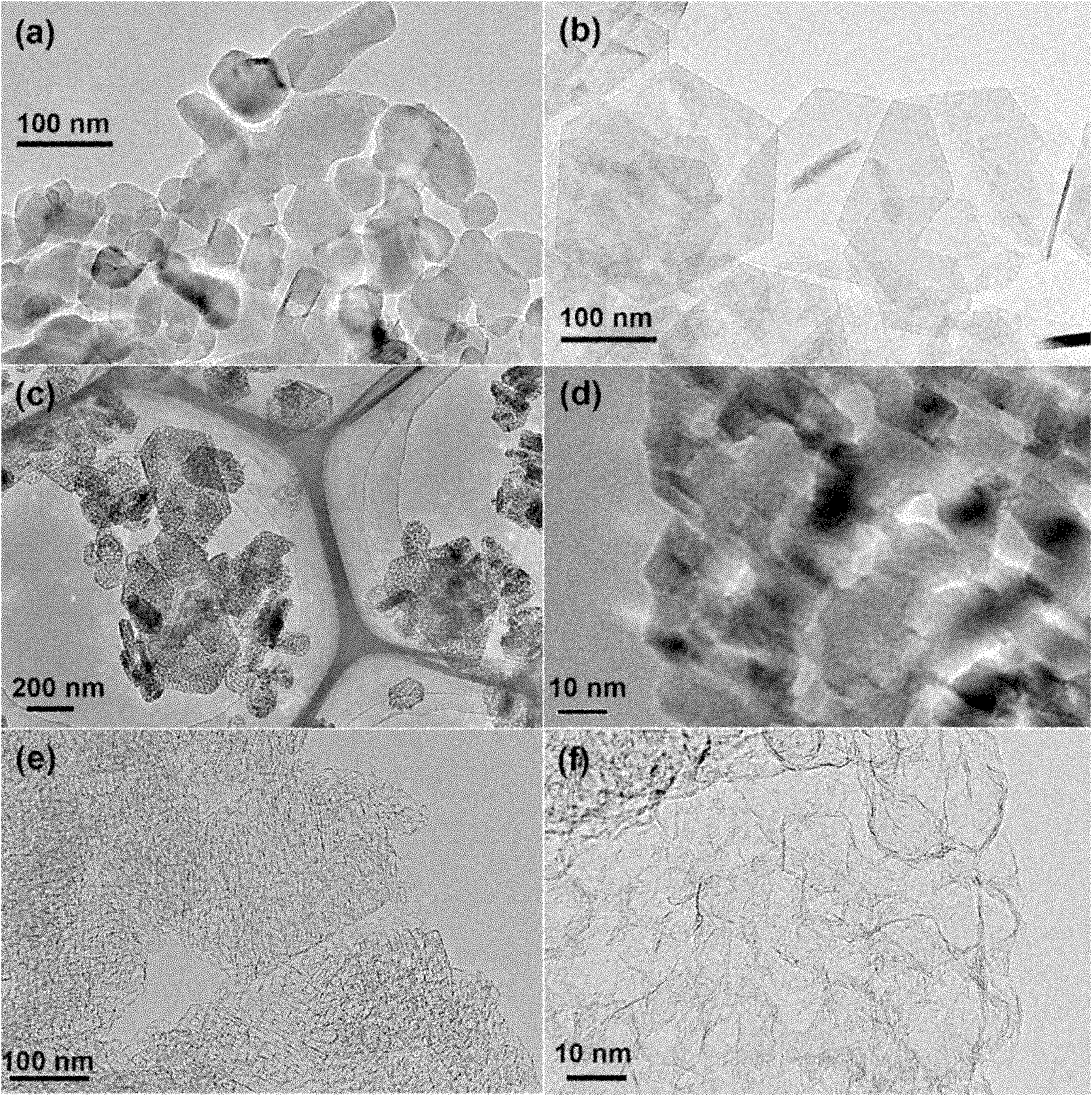

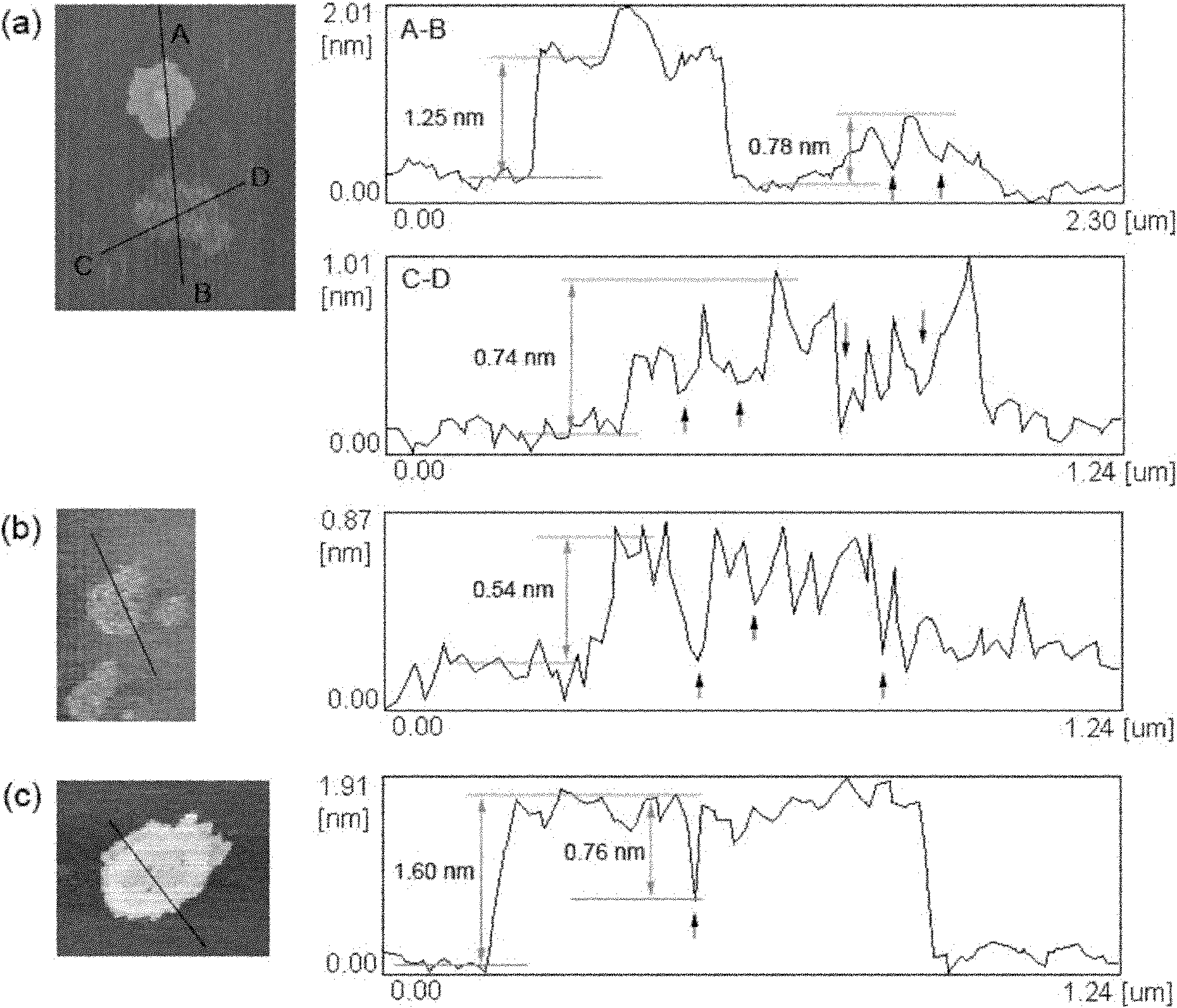

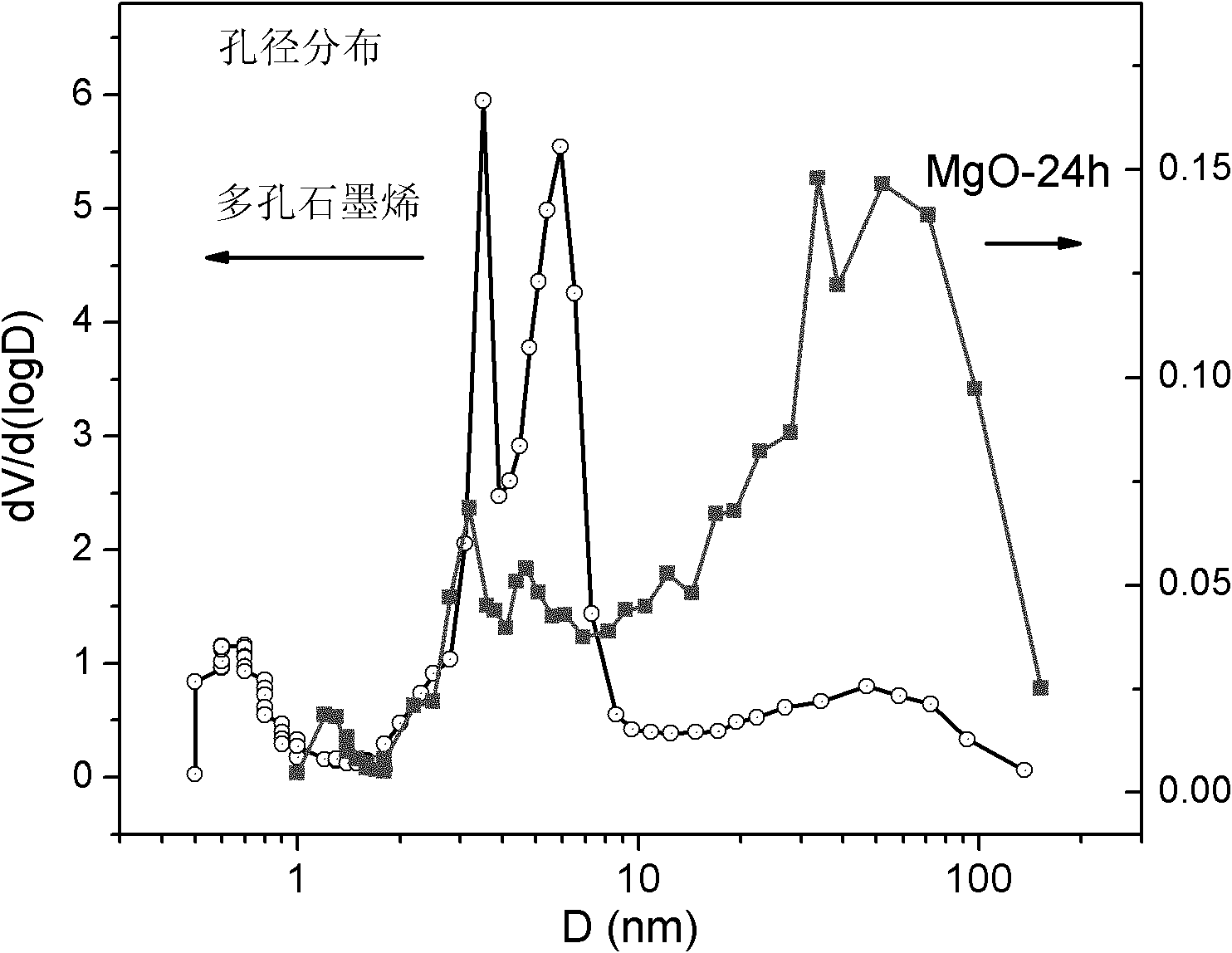

[0024] With MgO / Mg(OH) 2 The preparation of the catalyst is taken as an example. The initial MgO powder used is a light MgO commodity, which mainly contains particles with a diameter of tens of nanometers. For the transmission electron microscope pictures, please refer to figure 1 Middle (a). Disperse MgO powder in deionized water, boil (about 100° C.) and reflux for 24 hours in a flask connected to a condensation column, and then filter and dry with suction after cooling to obtain boiled catalyst powder. After hydrothermal treatment, MgO combines with water to form Mg(OH) 2 , the catalyst consists of granular ( figu...

Embodiment 2

[0032] In this example, MgO was used as the carrier to support Fe components to prepare the catalyst, and the Fe / MgO catalyst prepared by the impregnation method was hydrothermally treated to obtain a catalyst with excellent performance with a sheet-like porous structure, and the catalyst was used to prepare porous Graphene.

[0033] First prepare Fe / MgO catalyst by impregnation method, then disperse Fe / MgO catalyst powder in deionized water, carry out hydrothermal treatment at 80-300°C for 2h, then heat and boil the obtained mixture in a beaker (about 100°C), about 20 The water is evaporated to dryness in 10 minutes, and the catalyst powder after hydrothermal treatment is obtained. The XRD analysis of the catalyst obtained by the above method shows that MgO combines with water to form Mg(OH) 2 , the catalyst consists of granular ( Figure 6 In (a)) transformed into flakes ( Figure 6 In (b)), the iron component is very uniformly dispersed in the flake-like Mg(OH) 2 In , n...

Embodiment 3

[0036] In this example, porous graphene products were prepared by using hydrotalcite compounds with different components.

[0037] Taking the FeCoMo / MgAl hydrotalcite compound as an example, a lamellar catalyst with a ratio of Fe: Co: Mo: Mg: Al = 0.2: 0.2: 0.02: 3: 1 was prepared by the urea method ( Figure 8 middle (a)). The preparation method is as follows: Weigh Fe(NO 3 ) 3 9H 2 O, Co(NO 3 ) 2 .6H 2 O, (NH 4 ) 6 Mo 7 o 24 .4H 2 O, Mg(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O and a certain amount of urea are dissolved in water, the concentration of urea is 3mol / L, and the total concentration of metal ions is 0.08mol / L. Heat the obtained solution to 95-105°C while stirring, keep reflux for 12h, and then statically crystallize at 95°C for 20h, filter and dry the obtained precipitate to obtain FeCoMo / MgAl hydrotalcite compound, which can be decomposed by calcination at 500°C In addition to OH - and CO 3 2- The oxide structure is formed, and a more porous struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com