High-performance oil-absorbing polyacrylate resin and preparation method thereof

A polyacrylate, high oil-absorbing resin technology, used in petrochemical, environmental and military fields, can solve the problems of poor oil absorption and discharge reversibility, difficult to control product form, complex preparation process, etc., achieve good application prospects, reduce Surface stickiness, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] For this reason, the invention provides a kind of preparation method of polyacrylate super oil-absorbing resin, comprises the steps:

[0024] a. The dispersant is completely dissolved in the dispersed phase;

[0025] b. Mix the long and short chain alkyl acrylate monomers and acrylate monomers, and add them to the belt together with the initiator, crosslinking agent, porogen, dispersant and dispersant solution in step a. In a reaction vessel with a stirrer, a thermometer, and a condenser;

[0026] c. If an elastomer with oil absorption capacity is added, a certain amount of elastomer is added to the toluene solution in advance to make it swell until dissolved, and the addition method is the same as other components in step b.;

[0027] d. Under the protection of nitrogen, raise the temperature of the mixed system to 30~40°C, stir until the mixture is uniform, then raise the temperature to 70°C for 4 hours, raise the temperature to 80°C for 2 hours, and finally raise th...

Embodiment 1

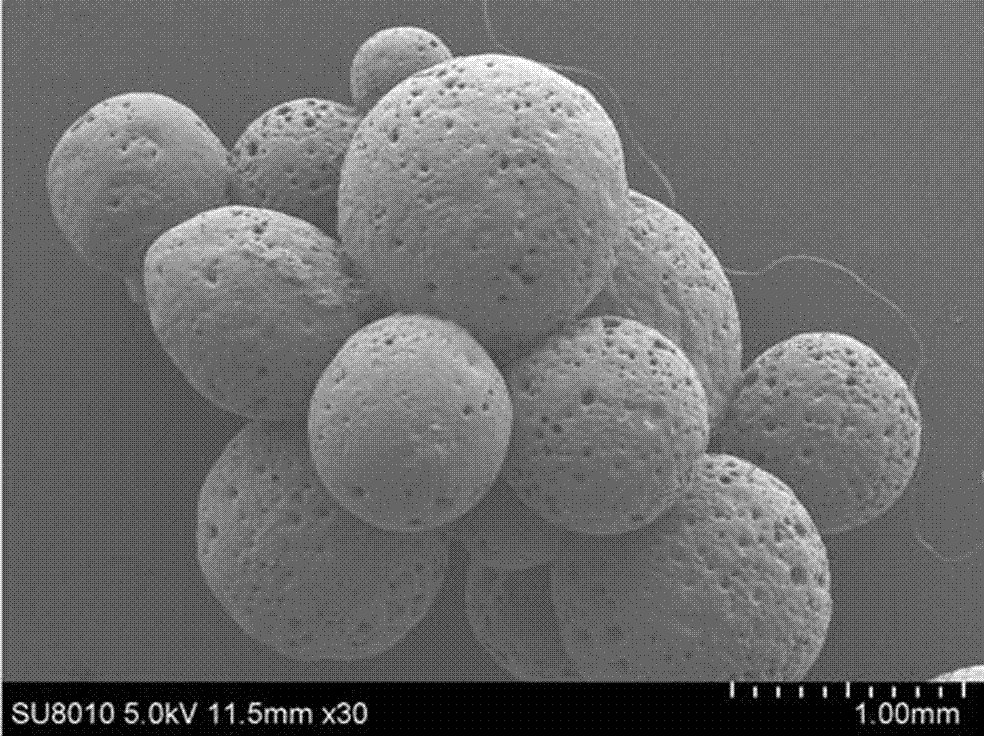

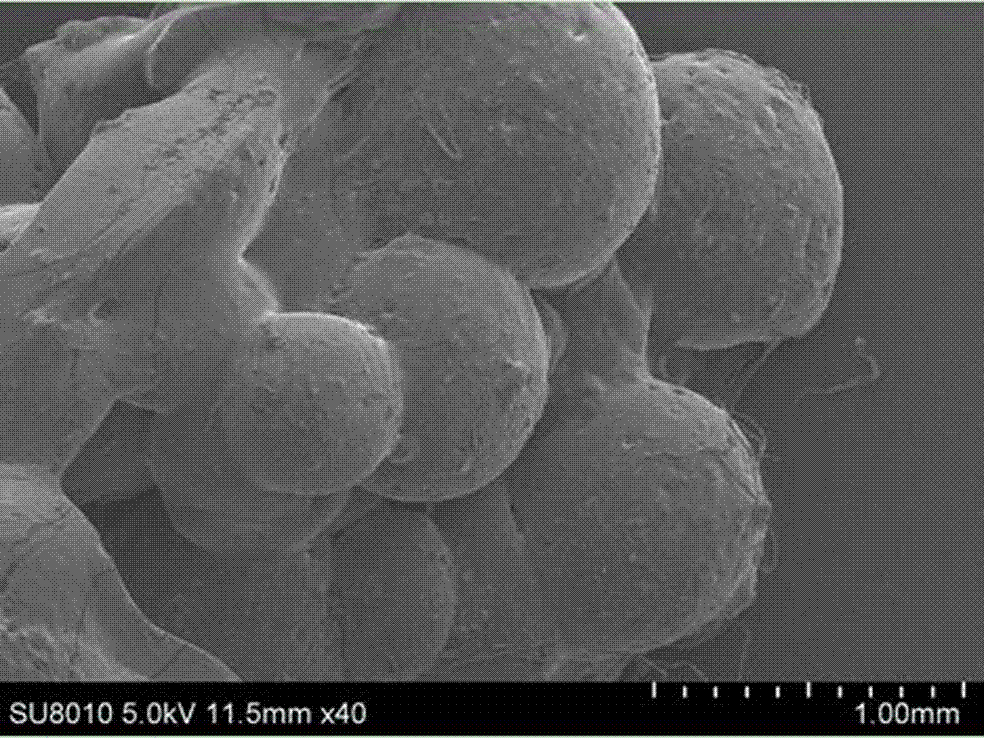

[0041] Introduce nitrogen into the three-necked flask to remove all the oxygen in the flask, and add the monomer mixture into the flask, including 2.31 g of methyl methacrylate, 17.79 g of butyl acrylate, and 120 g of distilled water; the crosslinking agent N, N' -Methylenebisacrylamide 0.0214g and initiator dibenzoyl peroxide 0.16g are dissolved in porogen ethyl acetate 10.0g; The above-mentioned mixed solution is added in the three-necked flask, and the main and auxiliary dispersants are polymerized Vinyl alcohol 0.18g, CaCO 3 Add 0.03g into a three-necked flask; raise the temperature to 30-40°C, stir until completely dissolved; raise the temperature to 70°C for 4 hours, then raise the temperature to 80°C for 2 hours, and finally, raise the temperature to 90°C for 1 hour, and the reaction is over; After the reaction, cool to room temperature, wash with ethanol 2 to 3 times, filter with suction, and dry naturally at room temperature for 12 hours to obtain the product. The m...

Embodiment 2

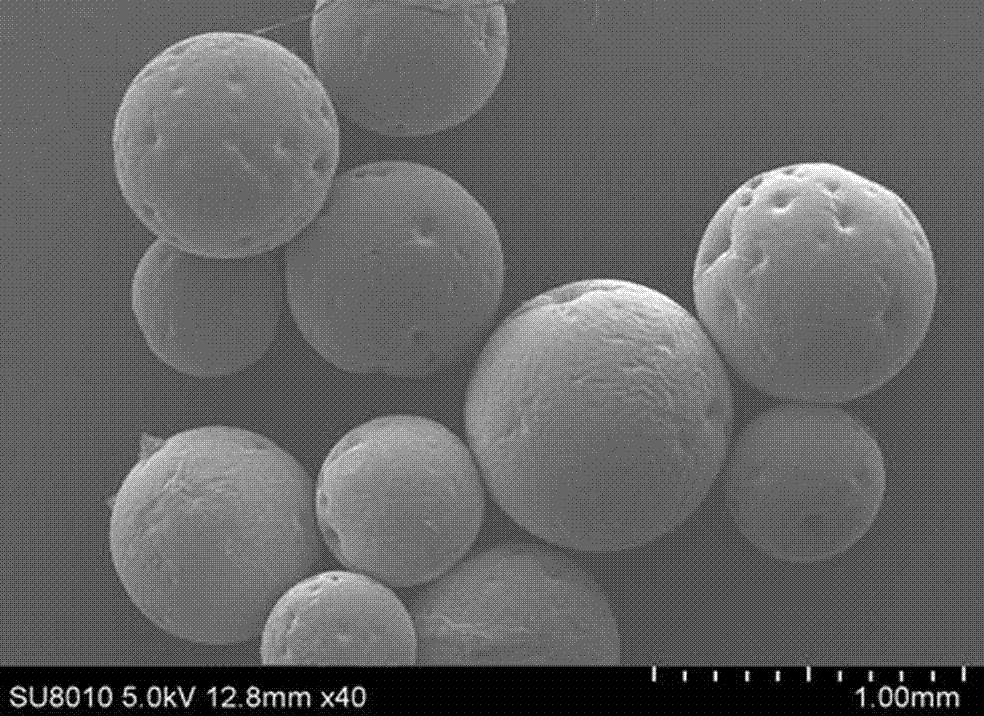

[0046] Introduce nitrogen gas into the three-necked flask to remove all the oxygen in the flask, and add monomer mixture liquid into the flask, including 4.00 g of methyl methacrylate, 16.00 g of butyl acrylate, and 120 g of distilled water; the crosslinking agent N, N' -Methylenebisacrylamide 0.0214g and initiator dibenzoyl peroxide 0.16g are dissolved in porogen ethyl acetate 10.0g; The above-mentioned mixed solution is added in the three-necked flask, and the main and auxiliary dispersants are polymerized Vinyl alcohol 0.18g, CaCO 3 Add 0.03g into a three-necked flask; raise the temperature to 30~40°C, stir until completely dissolved; raise the temperature to 70°C for 4 hours, then raise the temperature to 80°C for 2 hours, and finally, raise the temperature to 90°C for 1 hour, and the reaction is over; After finishing, cool to room temperature, wash with ethanol 2~3 times, filter with suction, and dry naturally at room temperature for 12 hours to obtain the product. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com