Patents

Literature

40results about How to "Ensure long-term stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

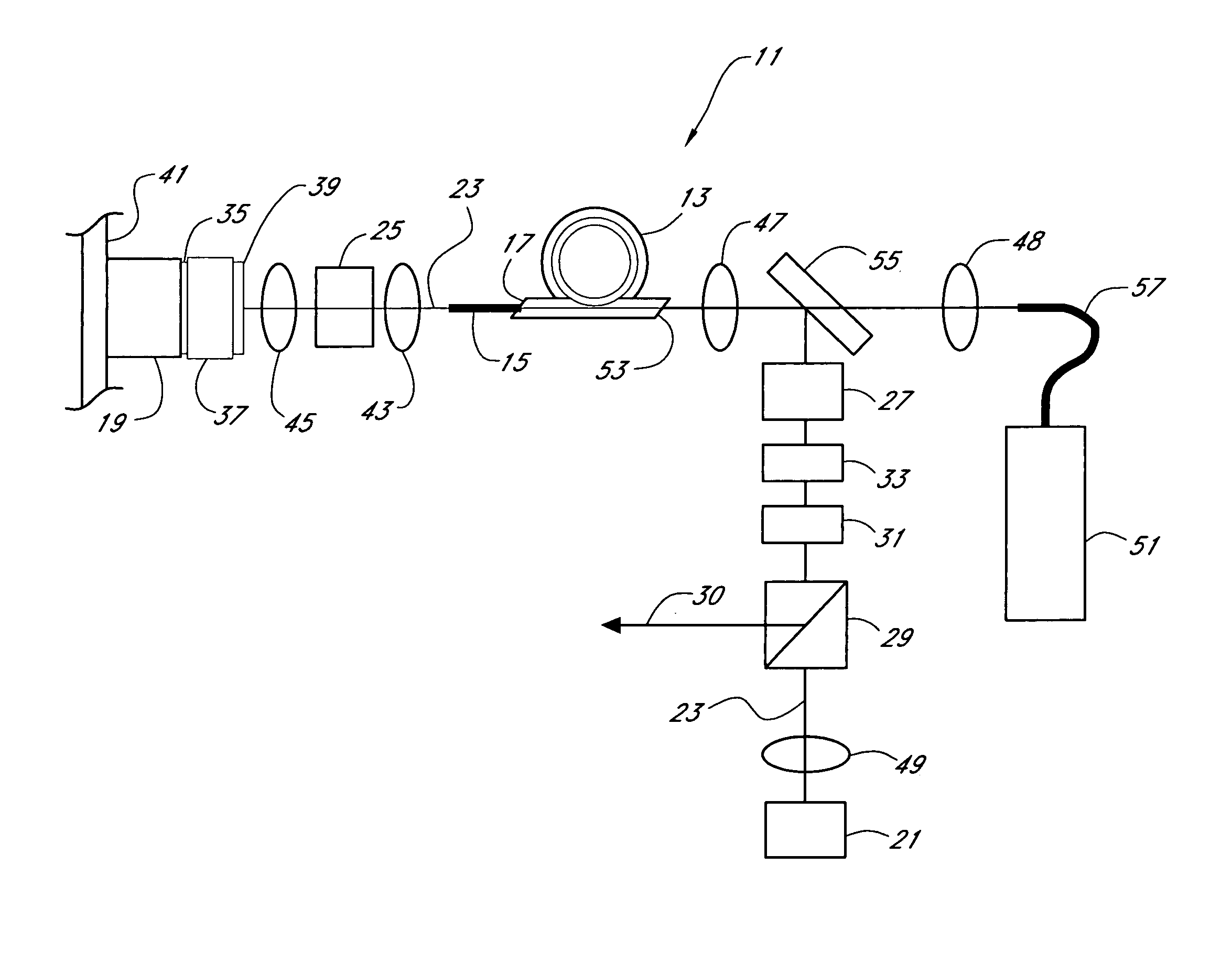

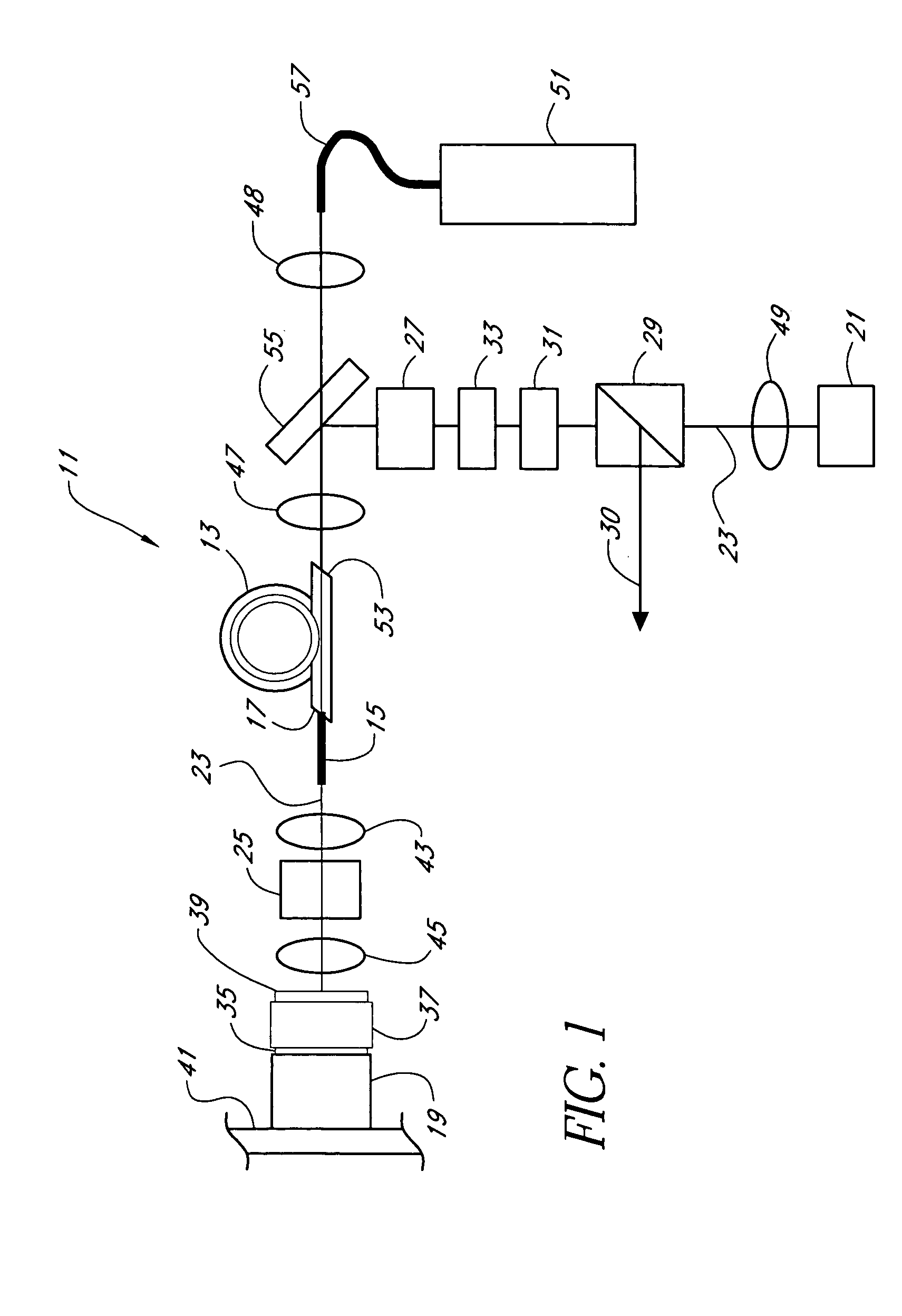

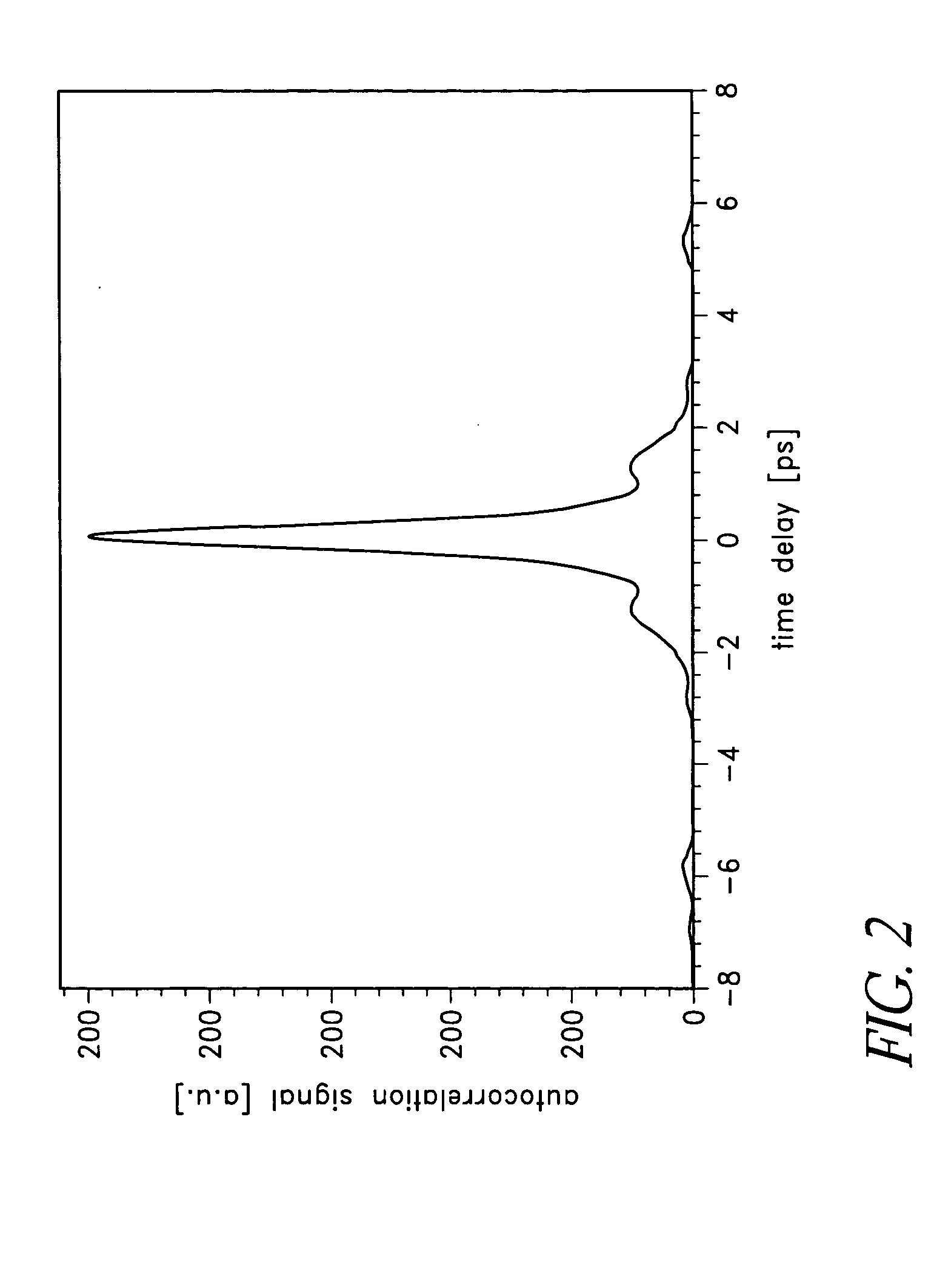

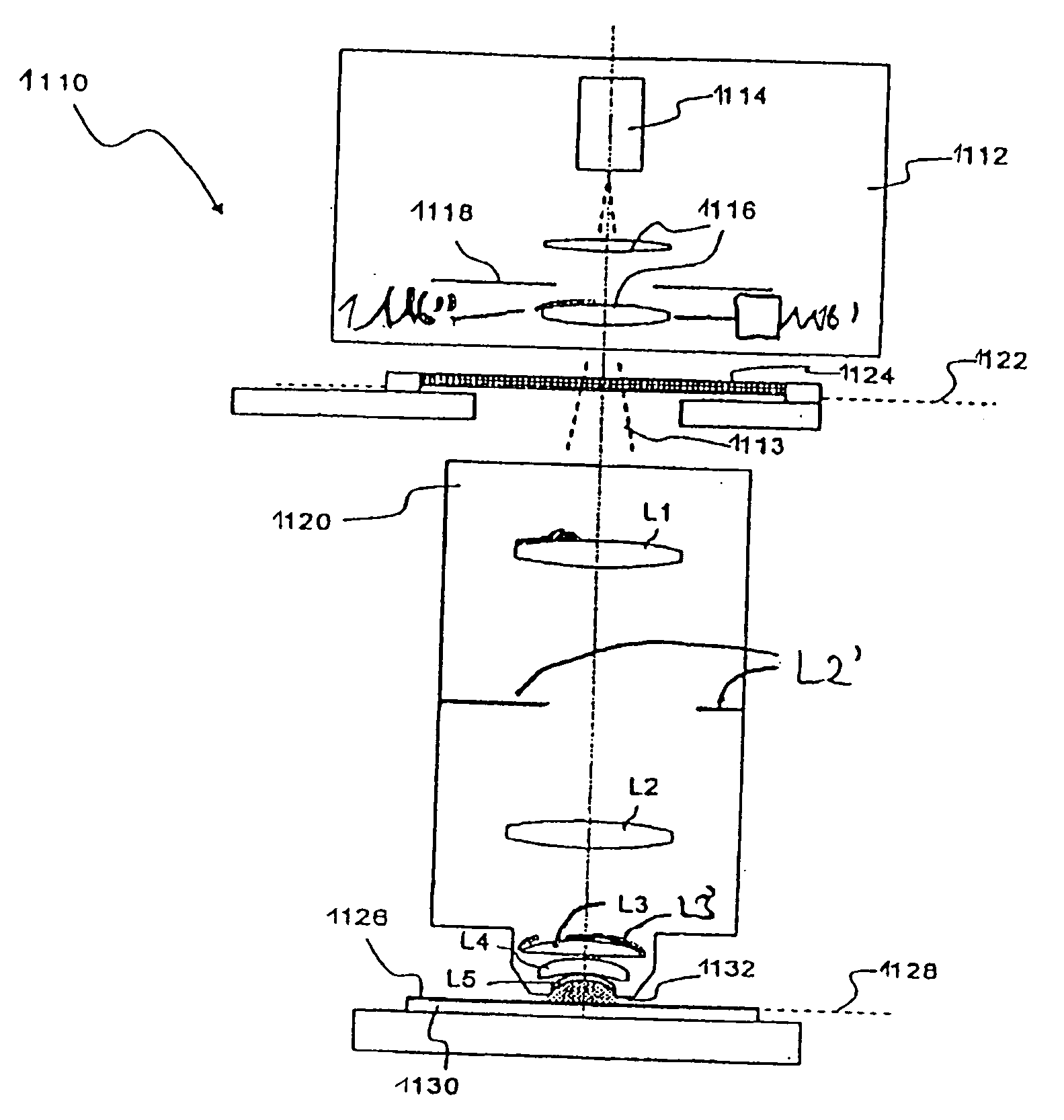

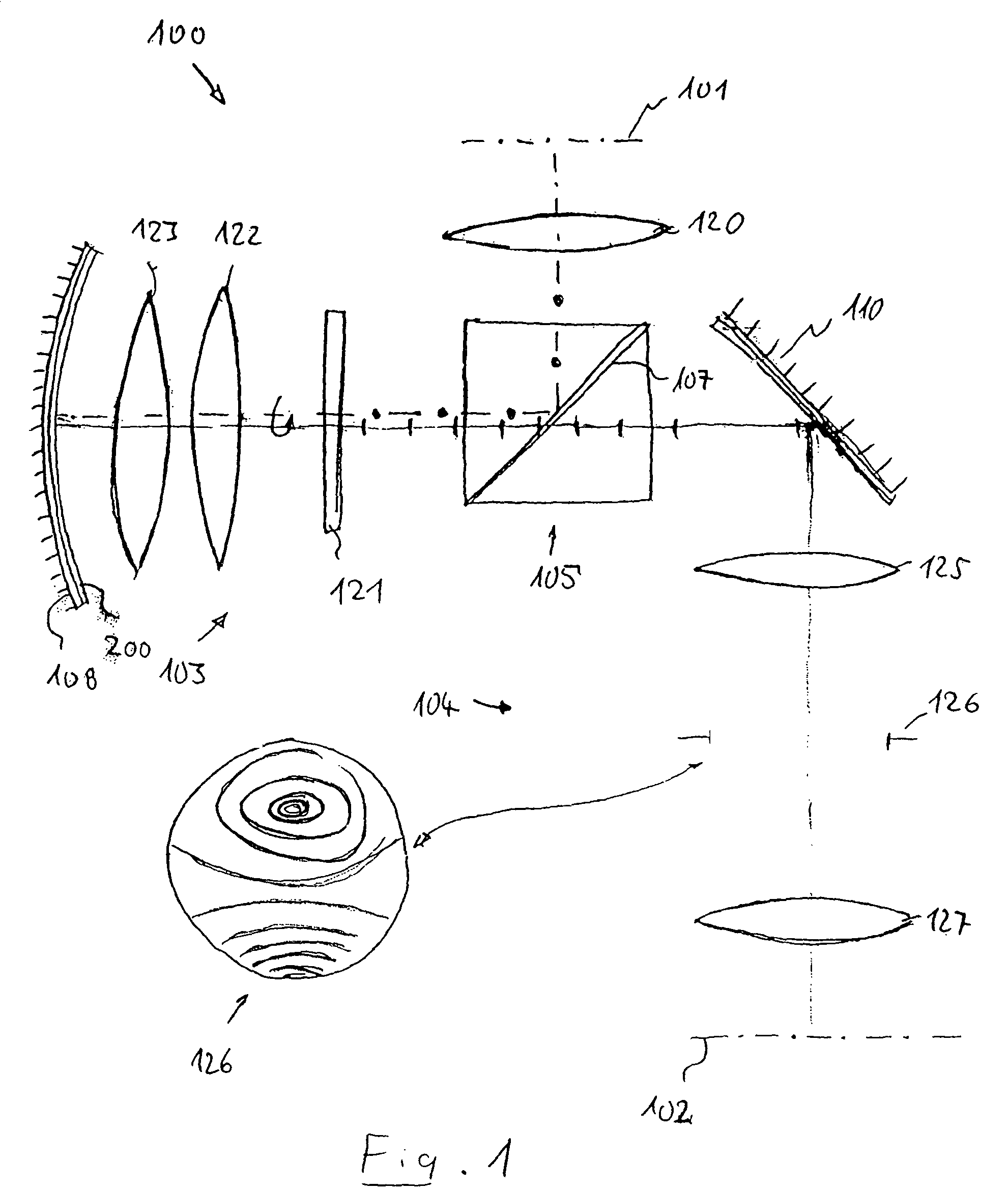

Mode-locked multi-mode fiber laser pulse source

InactiveUS20050008044A1High energy storageIncrease the sectionCoupling light guidesActive medium shape and constructionHigh power lasersPeak value

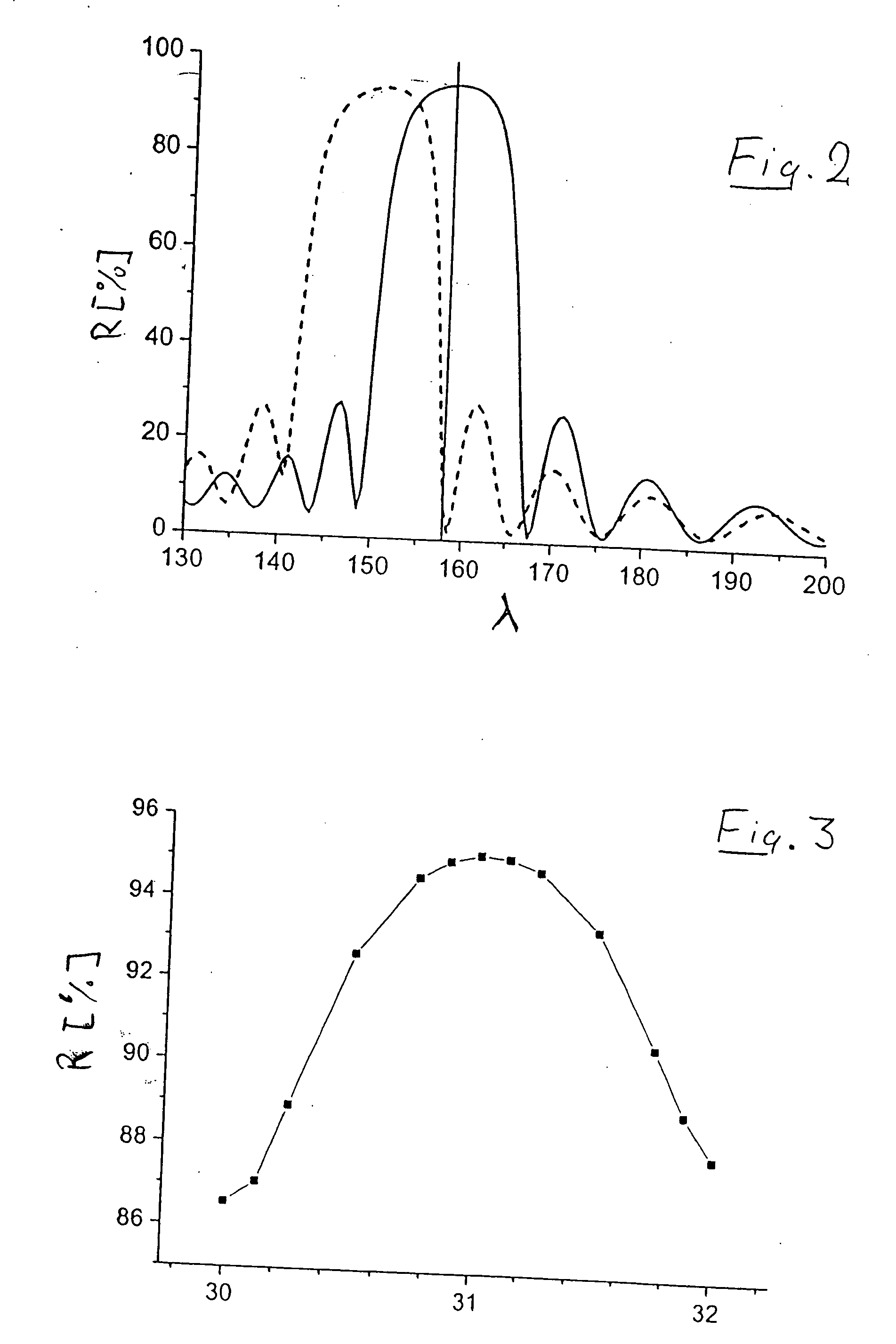

A laser utilizes a cavity design which allows the stable generation of high peak power pulses from mode-locked multi-mode fiber lasers, greatly extending the peak power limits of conventional mode-locked single-mode fiber lasers. Mode-locking may be induced by insertion of a saturable absorber into the cavity and by inserting one or more mode-filters to ensure the oscillation of the fundamental mode in the multi-mode fiber. The probability of damage of the absorber may be minimized by the insertion of an additional semiconductor optical power limiter into the cavity. To amplify and compress optical pulses in a multi-mode (MM) optical fiber, a single-mode is launched into the MM fiber by matching the modal profile of the fundamental mode of the MM fiber with a diffraction-limited optical mode at the launch end, The fundamental mode is preserved in the MM fiber by minimizing mode-coupling by using relatively short lengths of step-index MM fibers with a few hundred modes and by minimizing fiber perturbations. Doping is confined to the center of the fiber core to preferentially amplify the fundamental mode, to reduce amplified spontaneous emission and to allow gain-guiding of the fundamental mode. Gain-guiding allows for the design of systems with length-dependent and power-dependent diameters of the fundamental mode. To allow pumping with high-power laser diodes, a double-clad amplifier structure is employed. For applications in nonlinear pulse-compression, self phase modulation and dispersion in the optical fibers can be exploited. High-power optical pulses may be linearly compressed using bulk optics dispersive delay lines or by chirped fiber Bragg gratings written directly into the SM or MM optical fiber. High-power cw lasers operating in a single near-diffraction-limited mode may be constructed from MM fibers by incorporating effective mode-filters into the laser cavity. Regenerative fiber amplifiers may be constructed from MM fibers by careful control of the recirculating mode. Higher-power Q-switched fiber lasers may be constructed by exploiting the large energy stored in MM fiber amplifiers.

Owner:FERMANN MARTIN E +1

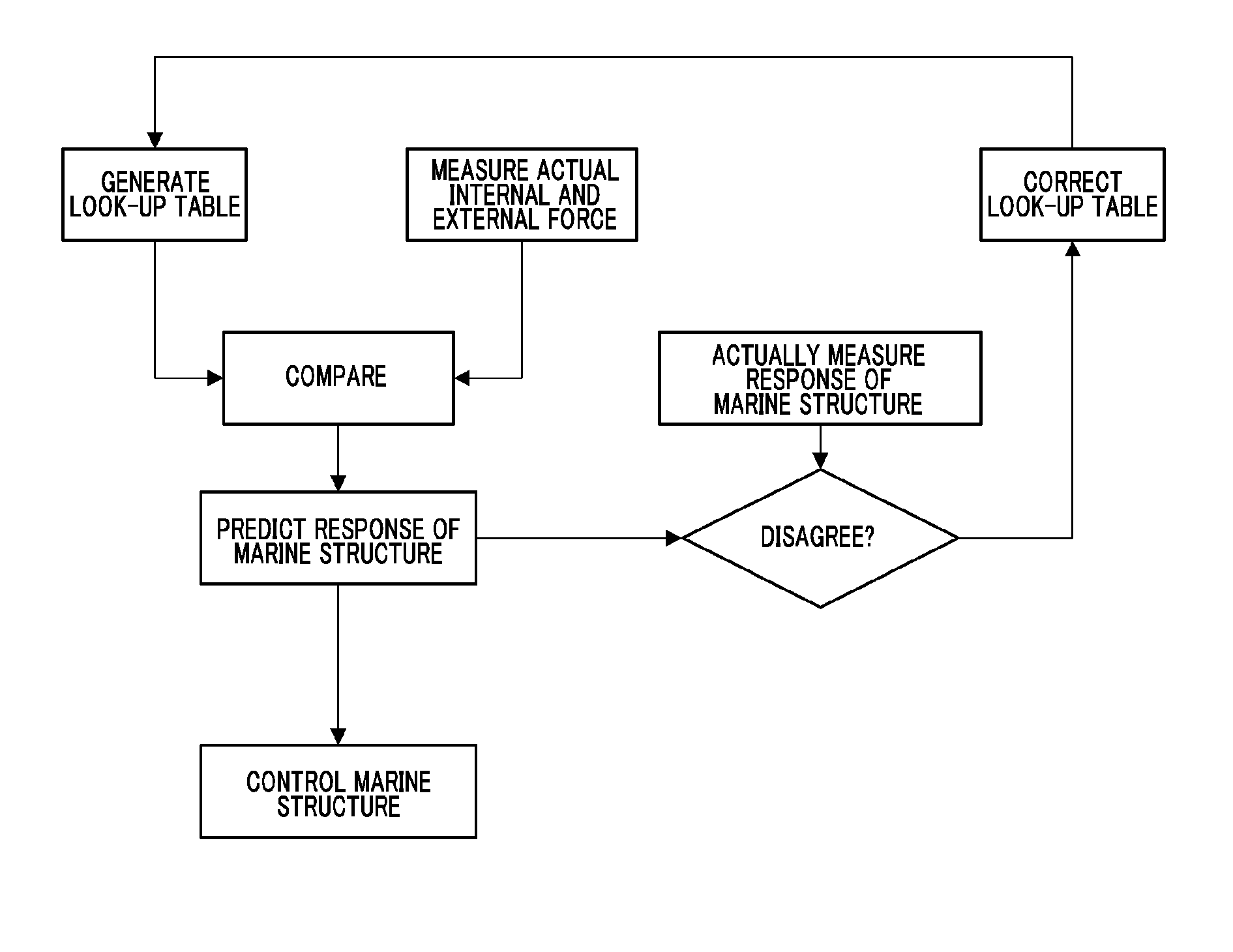

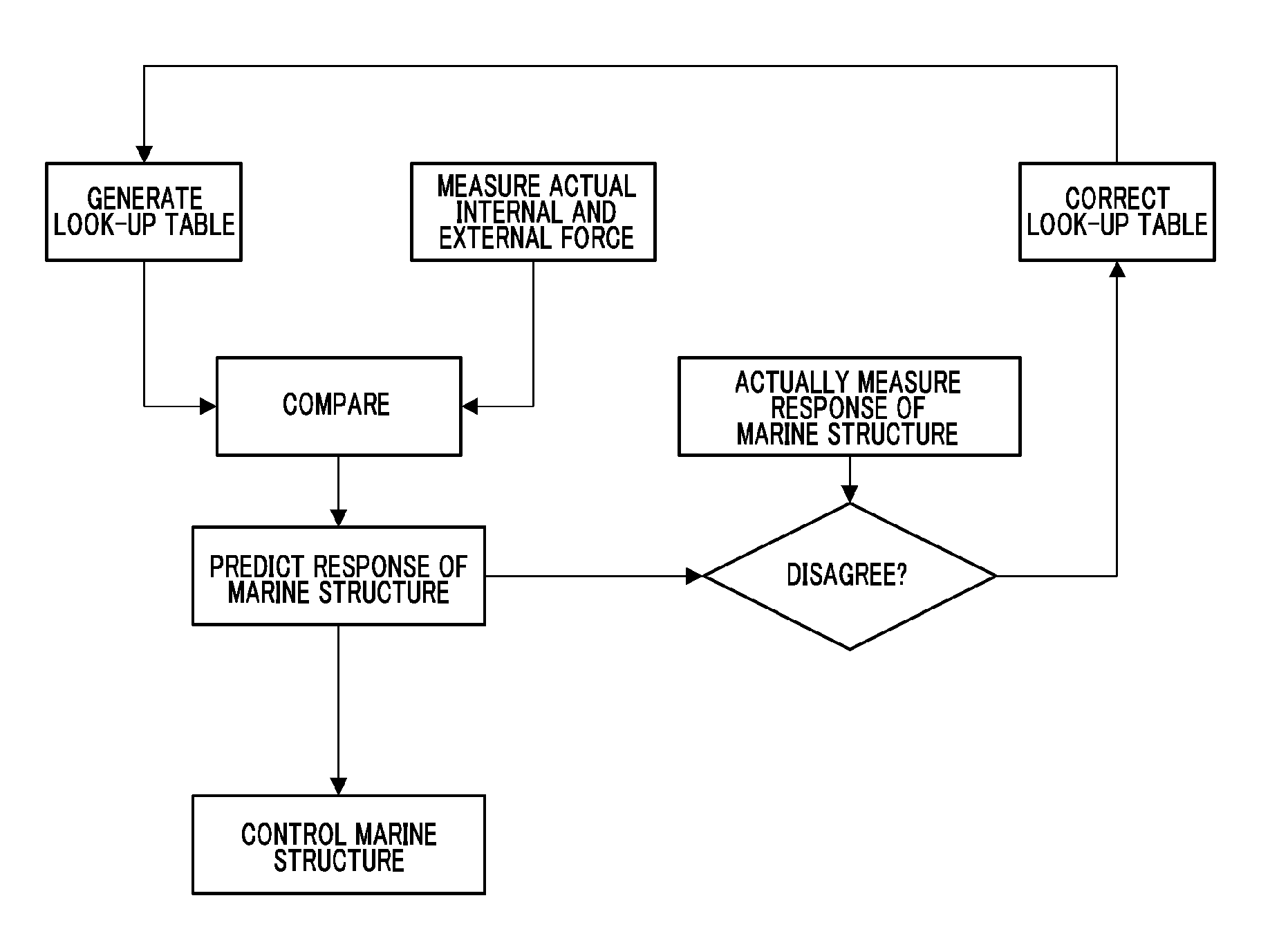

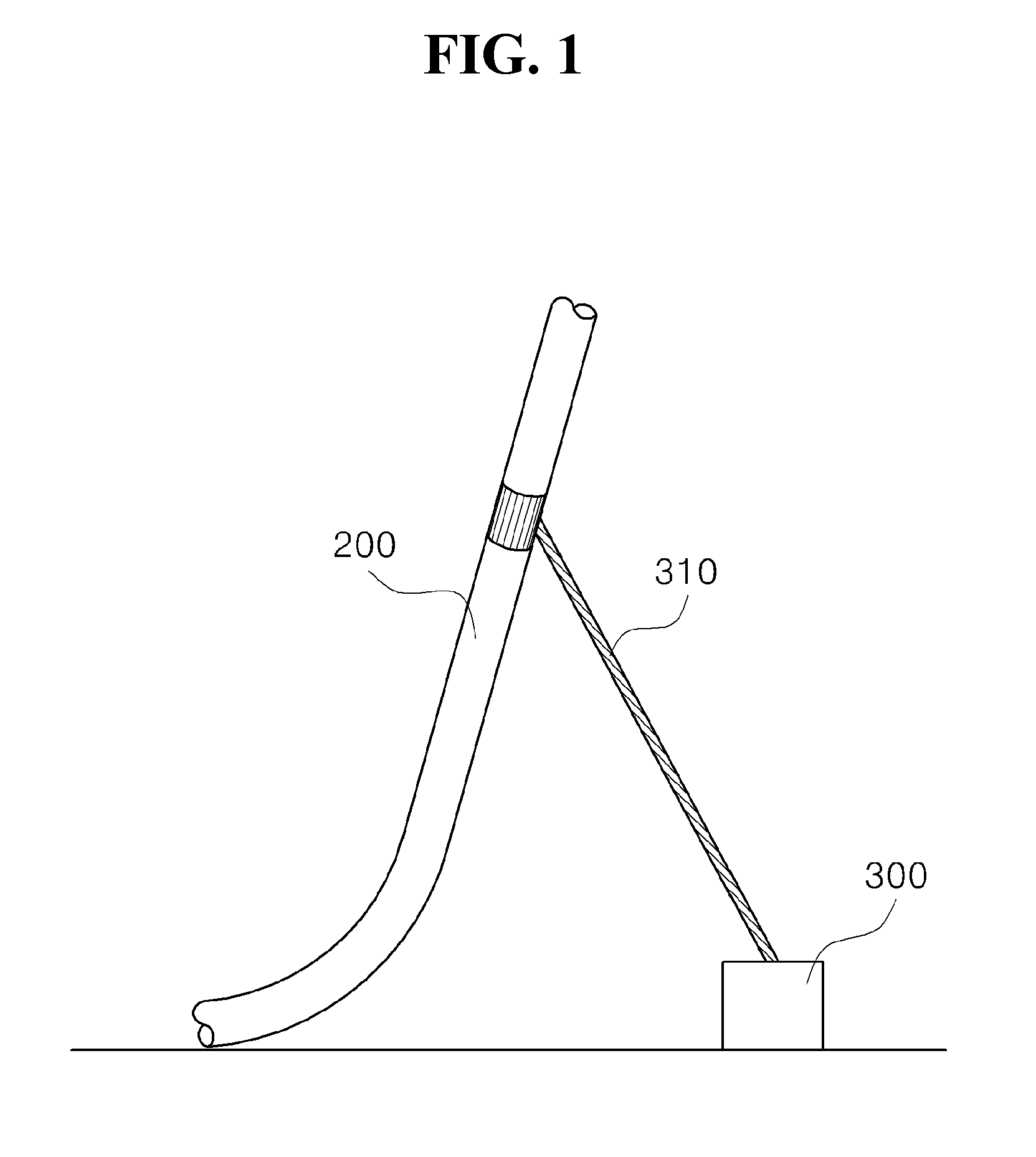

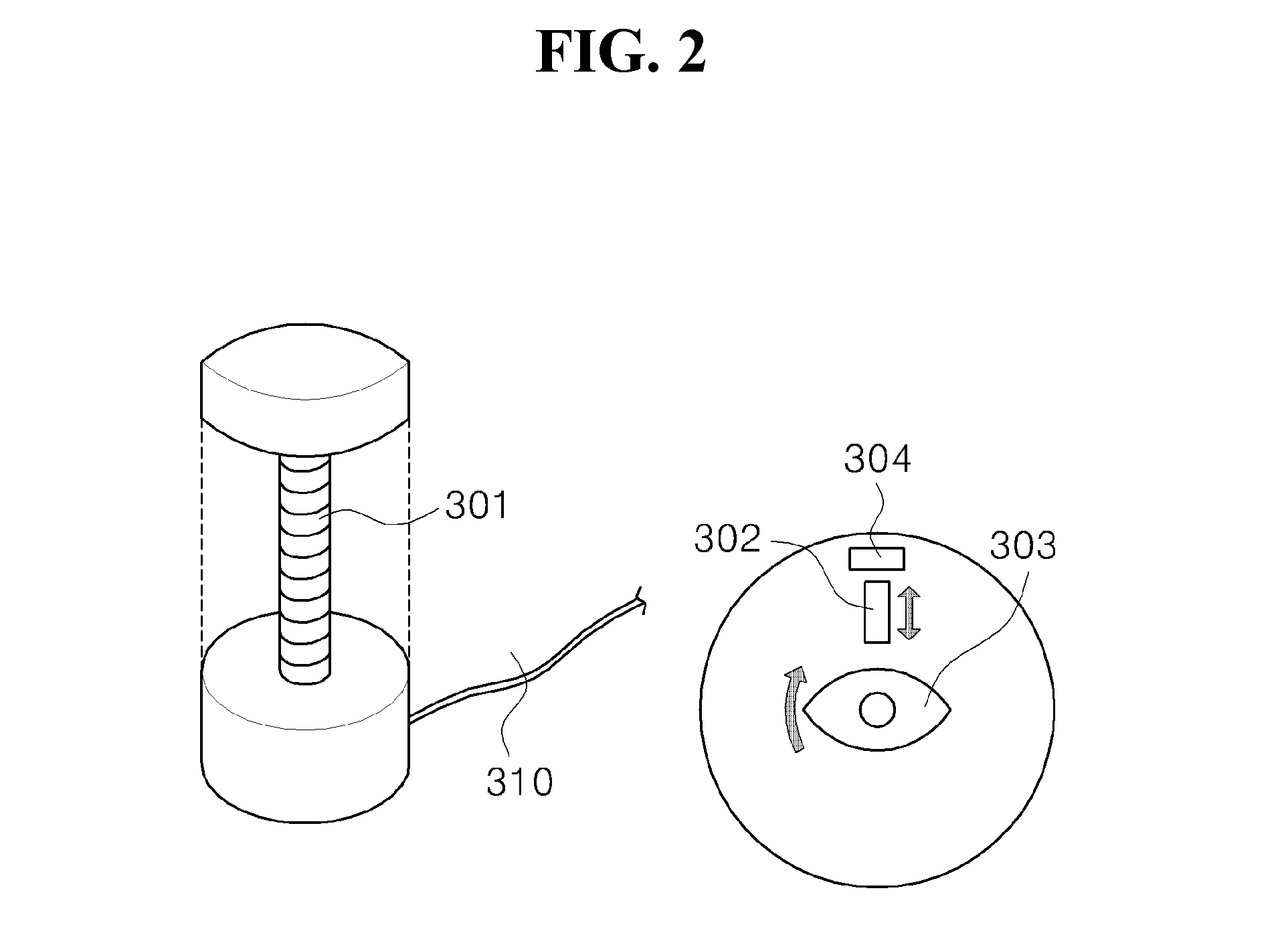

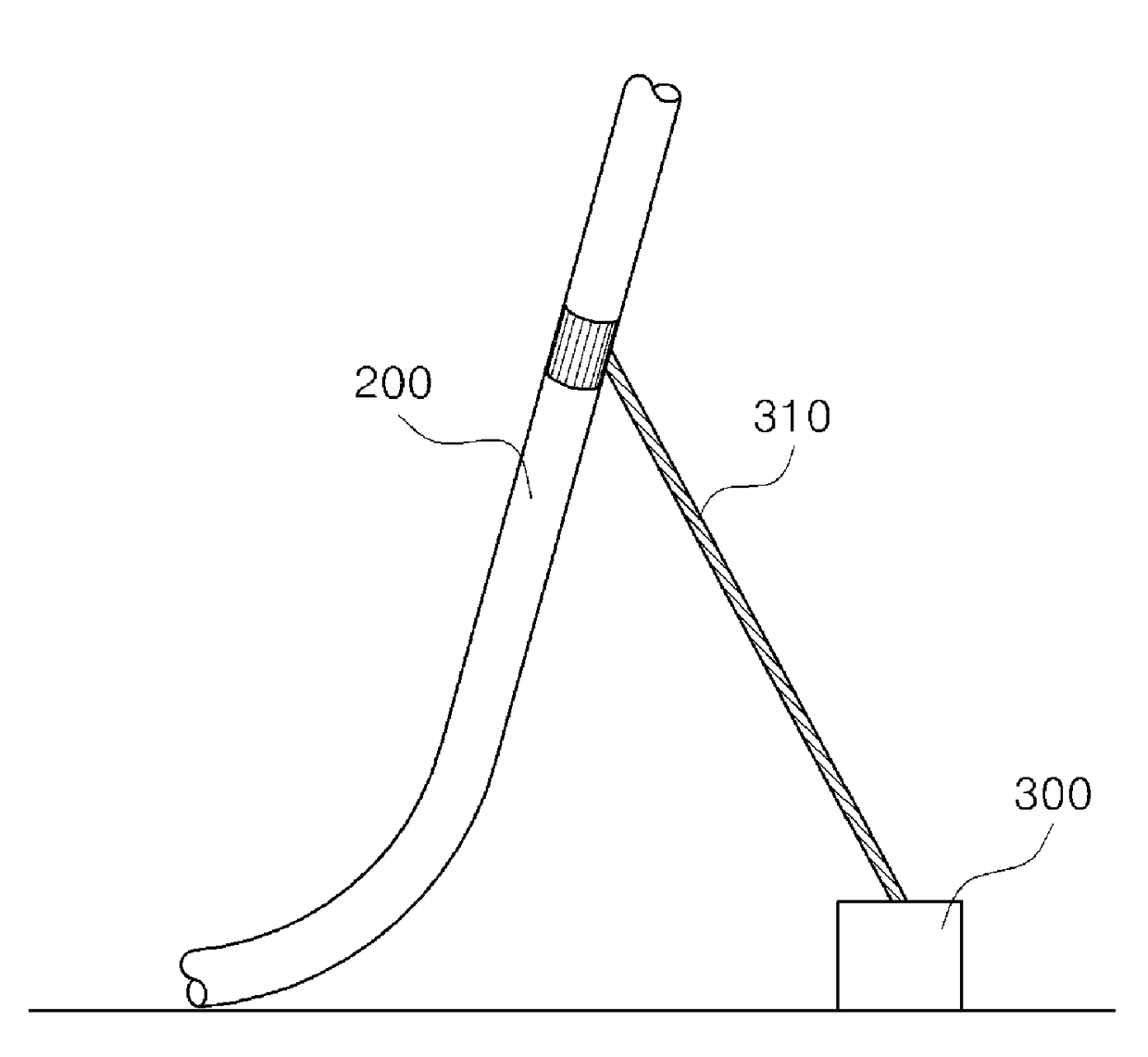

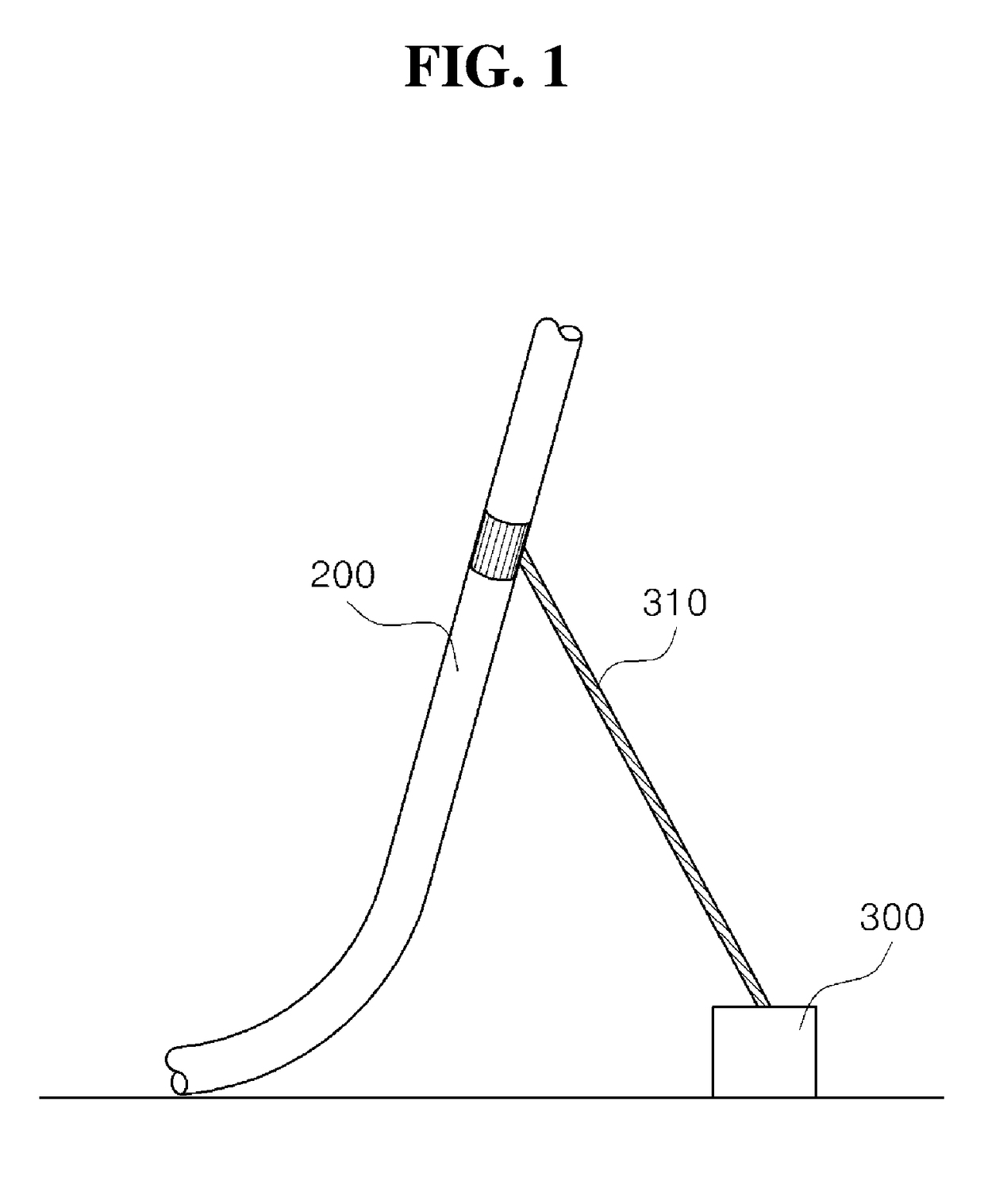

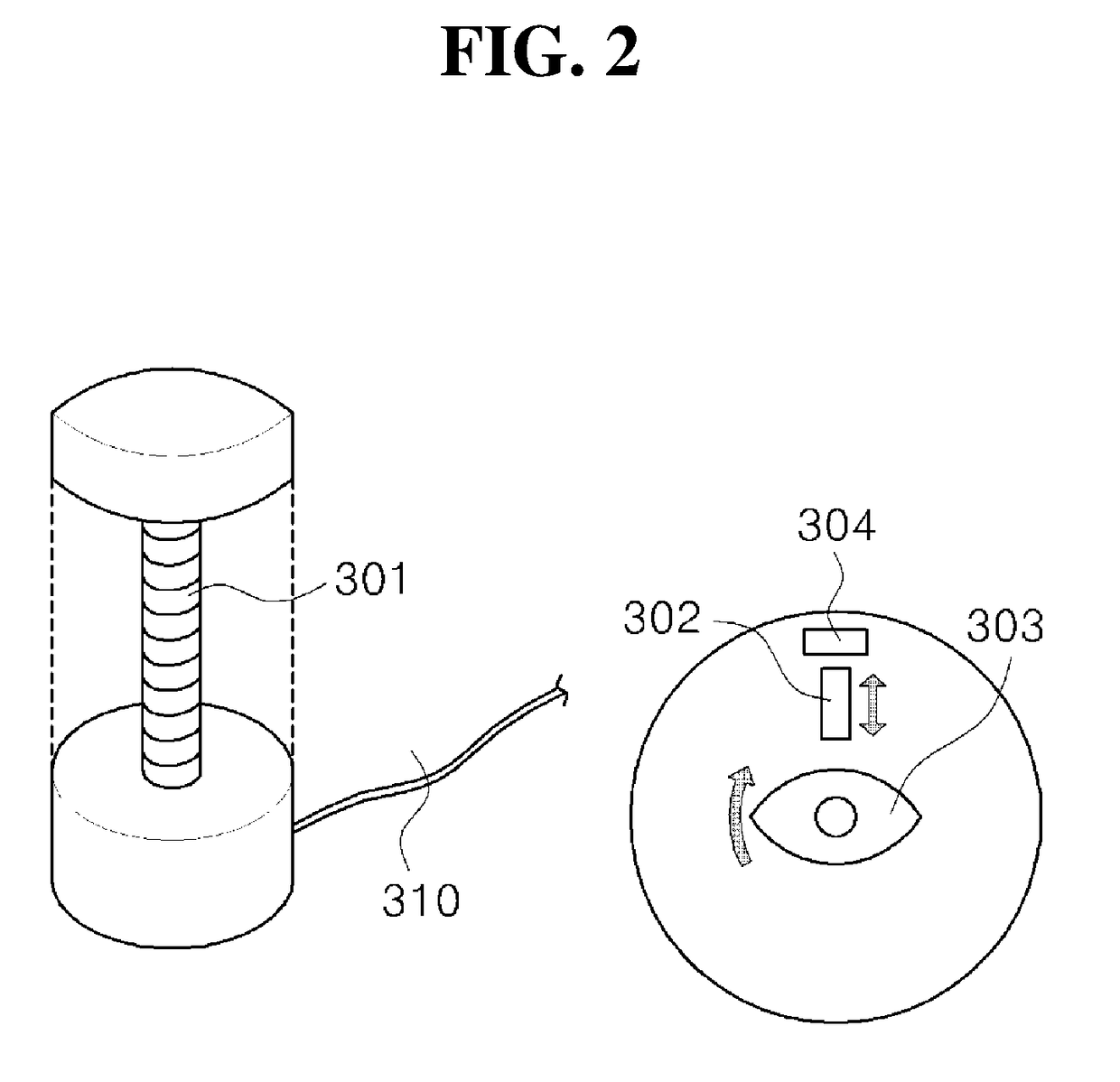

System and method for providing information on fuel savings, safe operation, and maintenance by real-time predictive monitoring and predictive controlling of aerodynamic and hydrodynamic environmental internal/external forces, hull stresses, motion with six degrees of freedom, and the location of marine structure

ActiveUS20150088346A1Easy to installGuaranteed uptimeDigital data processing detailsForce measurement by measuring optical property variationGratingFiber Bragg grating

A system for monitoring a physical change of a marine structure includes a complex optical measuring instrument configured to detect a behavior and structural change of the marine structure by using at least one optical sensor by means of optical fiber Bragg grating.

Owner:CYTRONIQ

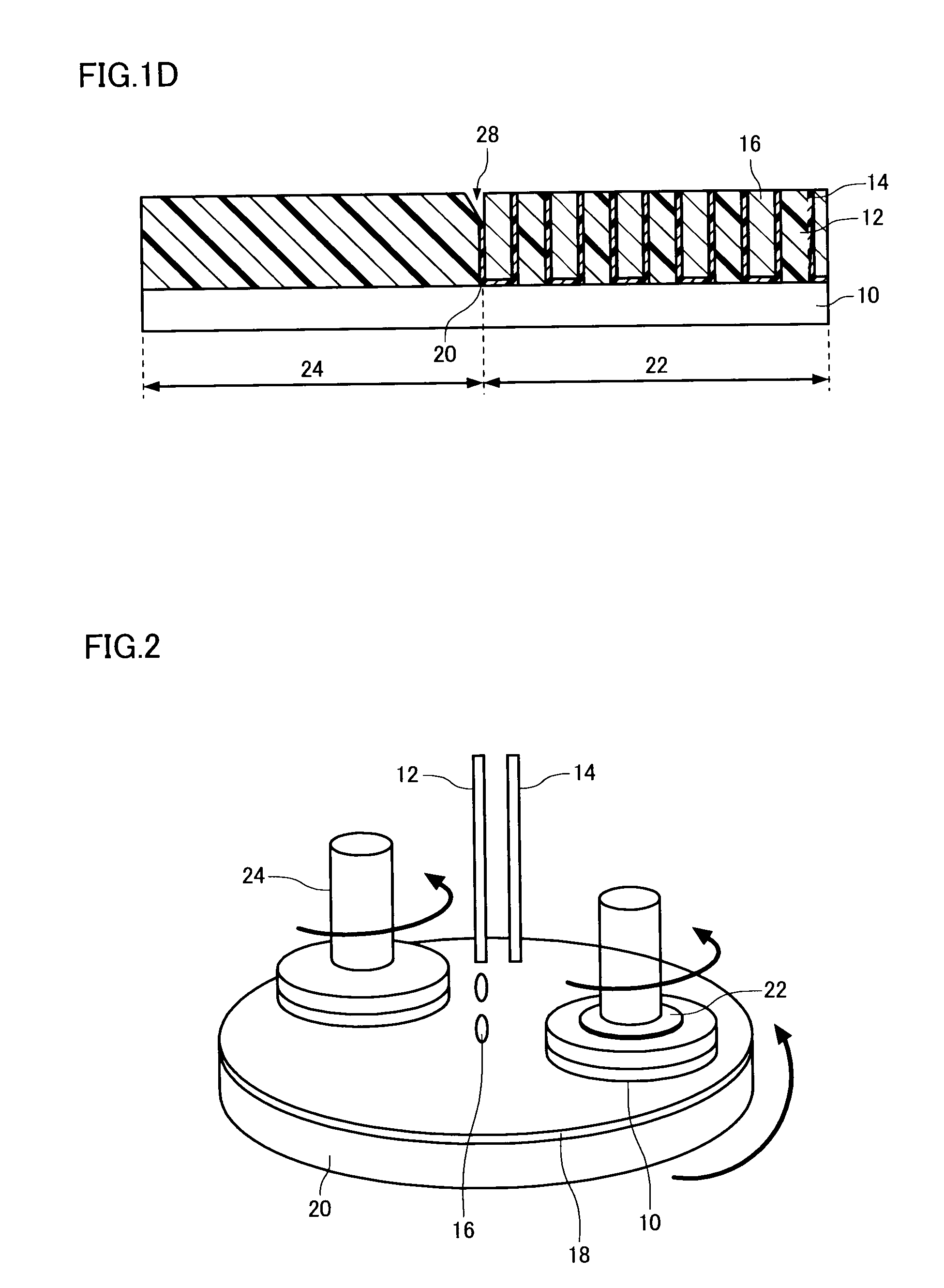

Chemical mechanical polishing aqueous dispersion preparation set, method of preparing chemical mechanical polishing aqueous dispersion, chemical mechanical polishing aqueous dispersion, and chemical mechanical polishing method

InactiveUS20080318427A1Long-term storage stability be excellentExcellent long-term storage stabilityOther chemical processesNanoinformaticsColloidal silicaOrganic acid

A chemical mechanical polishing aqueous dispersion preparation set including: a first composition which includes colloidal silica having an average primary particle diameter of 15 to 40 nm and a basic compound and has a pH of 8.0 to 11.0; and a second composition which includes poly(meth)acrylic acid and an organic acid having two or more carbonyl groups other than the poly(meth)acrylic acid and has a pH of 1.0 to 5.0.

Owner:JSR CORPORATIOON

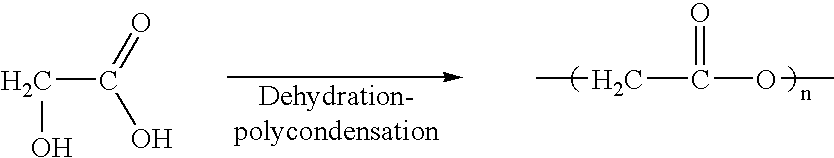

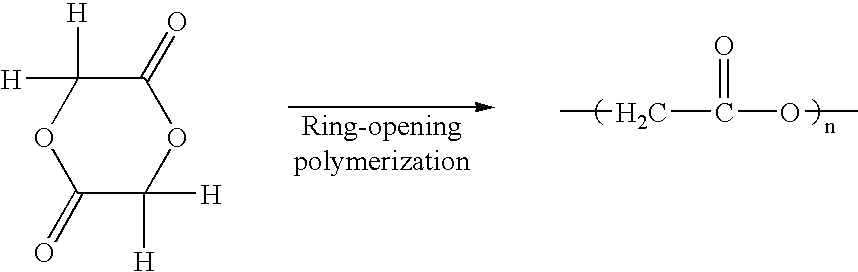

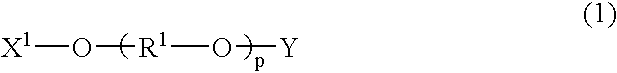

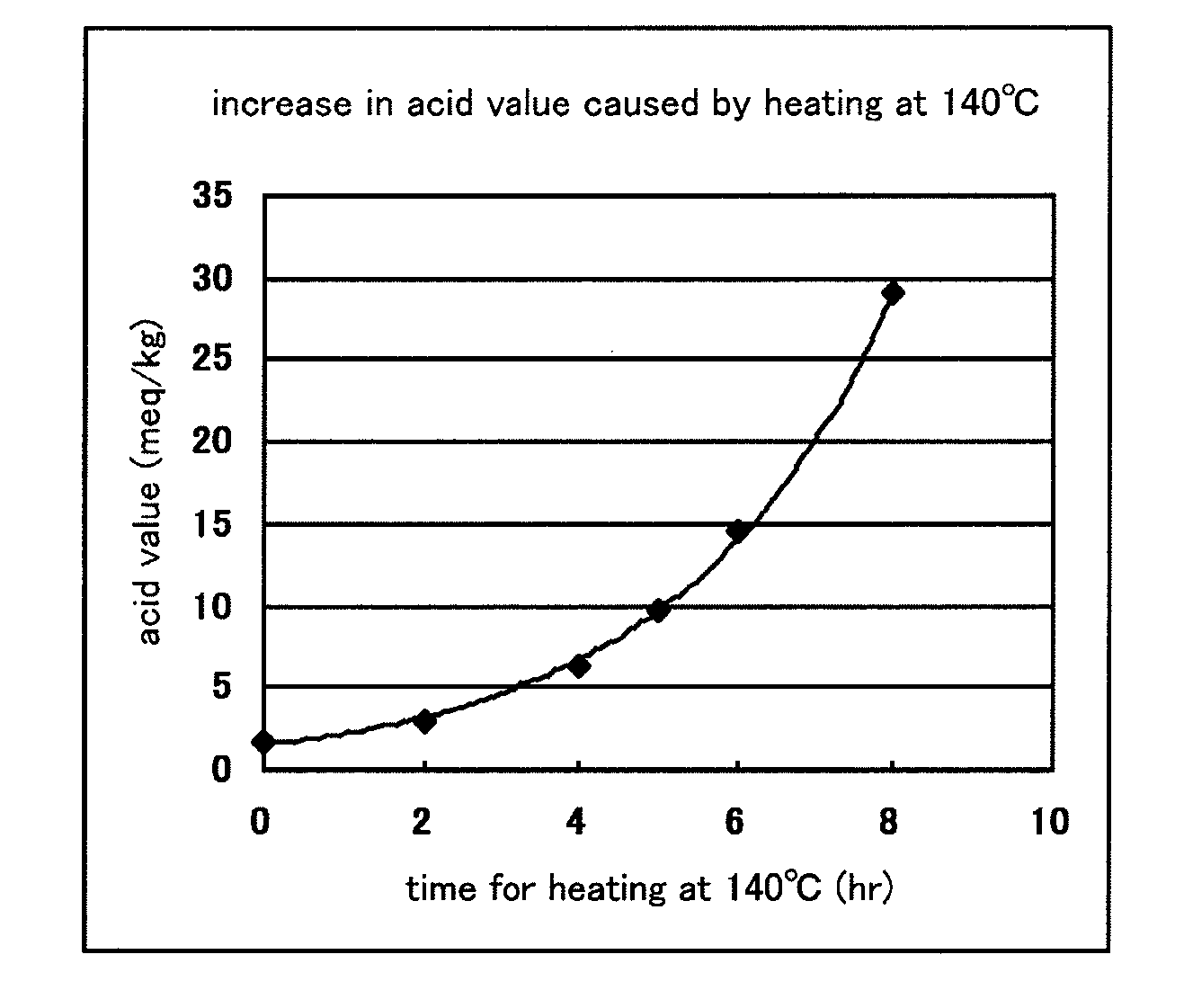

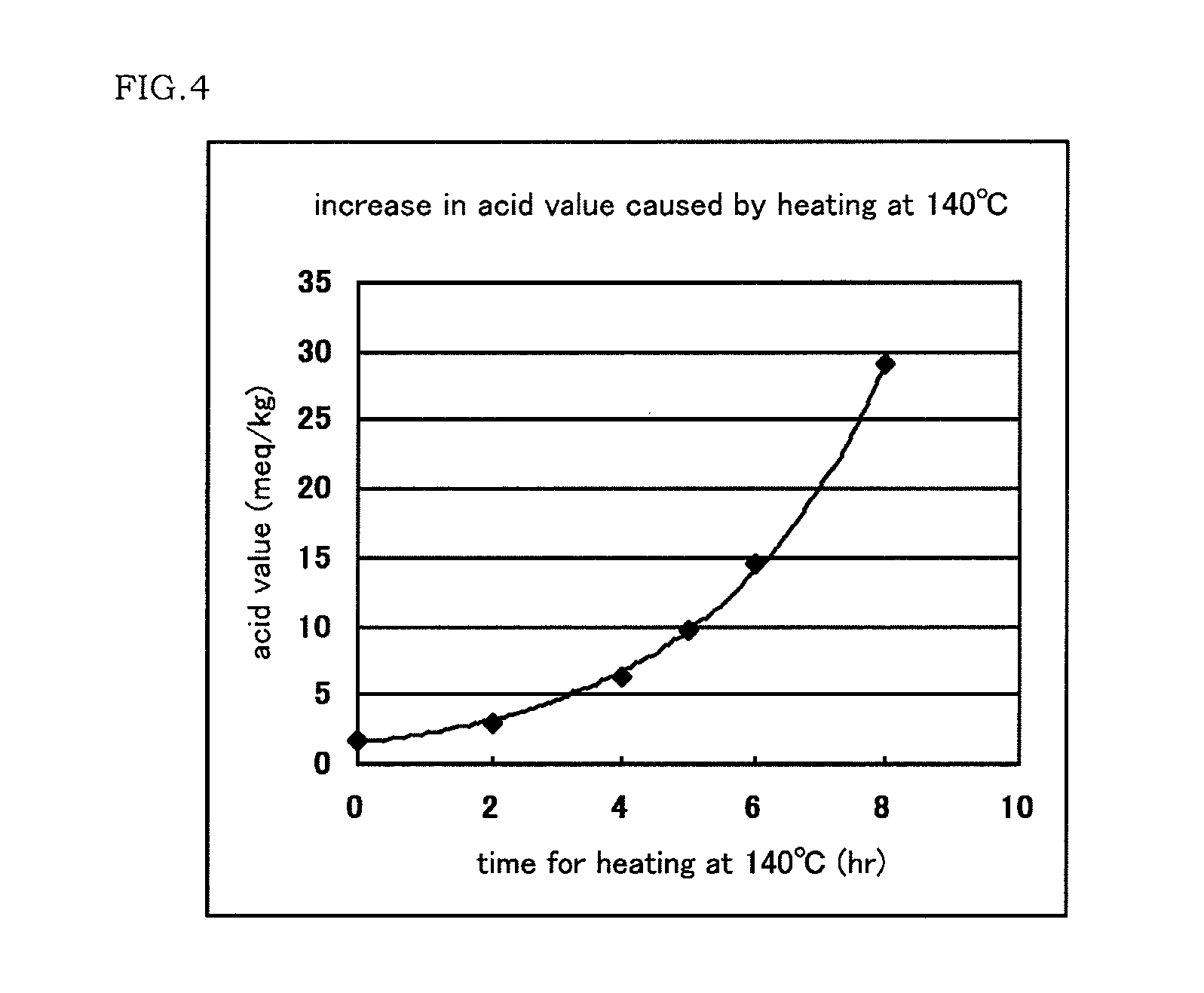

Glycolide production process, and glycolic acid composition

InactiveUS6891048B2Efficient productionLow ion contentOrganic chemistry methodsOrganic acidDepolymerization

The invention provides a process for producing glycolide by depolymerization by heating of a glycolic acid oligomer in the presence or absence of a solvent, which process ensures stable depolymerization. The depolymerization reaction is carried out while the content of alkaline metal ions in a glycolic acid oligomer-containing depolymerization reaction system is controlled to 0.001% by mass or lower; a sulfate or an organic acid salt, each in the form of di- or poly-valent cations, or a mixture thereof is allowed to be present as a stabilizer in the depolymerization reaction system; or the content of alkaline metal ions in the depolymerization reaction system is controlled to 0.001% by mass or lower, and a sulfate or an organic acid salt, each in the form of di- or poly-valent cations, or a mixture thereof is allowed to be present as a stabilizer in the depolymerization reaction system.

Owner:KUREHA KAGAKU KOGYO KK

Ultrafine polyester fiber

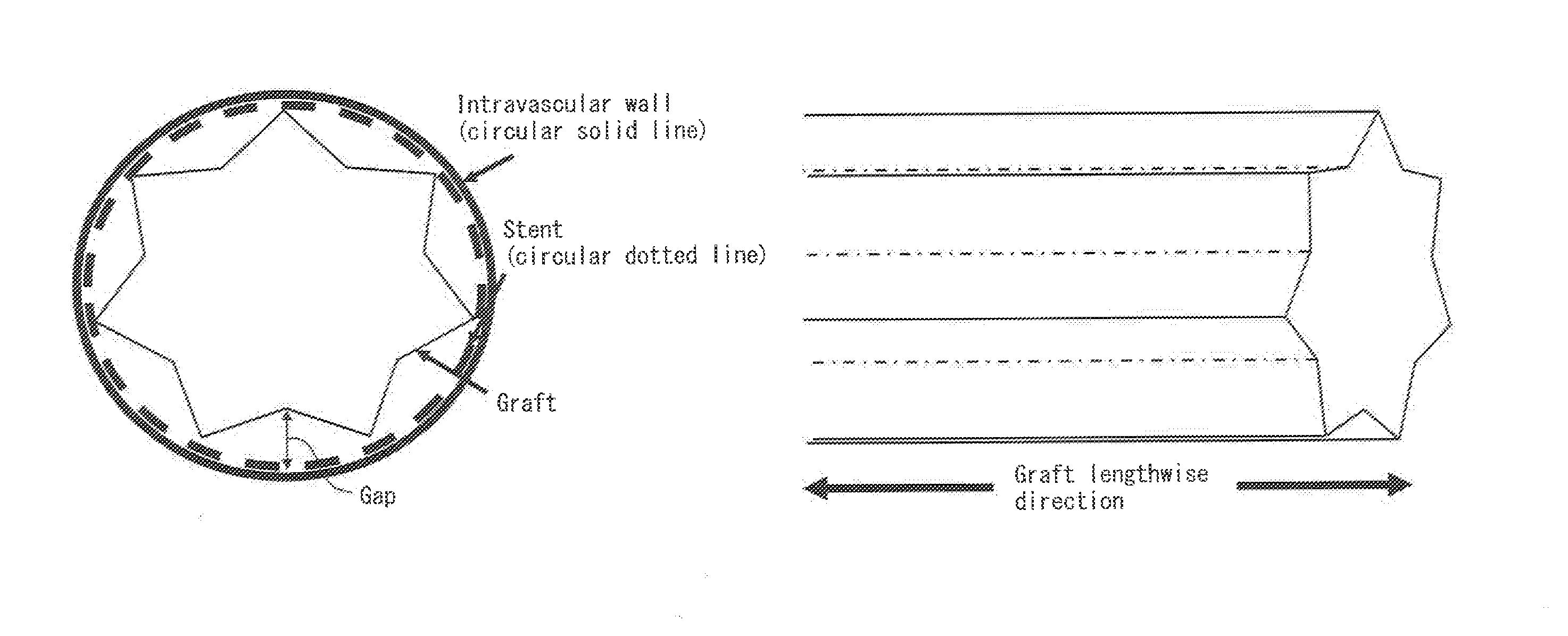

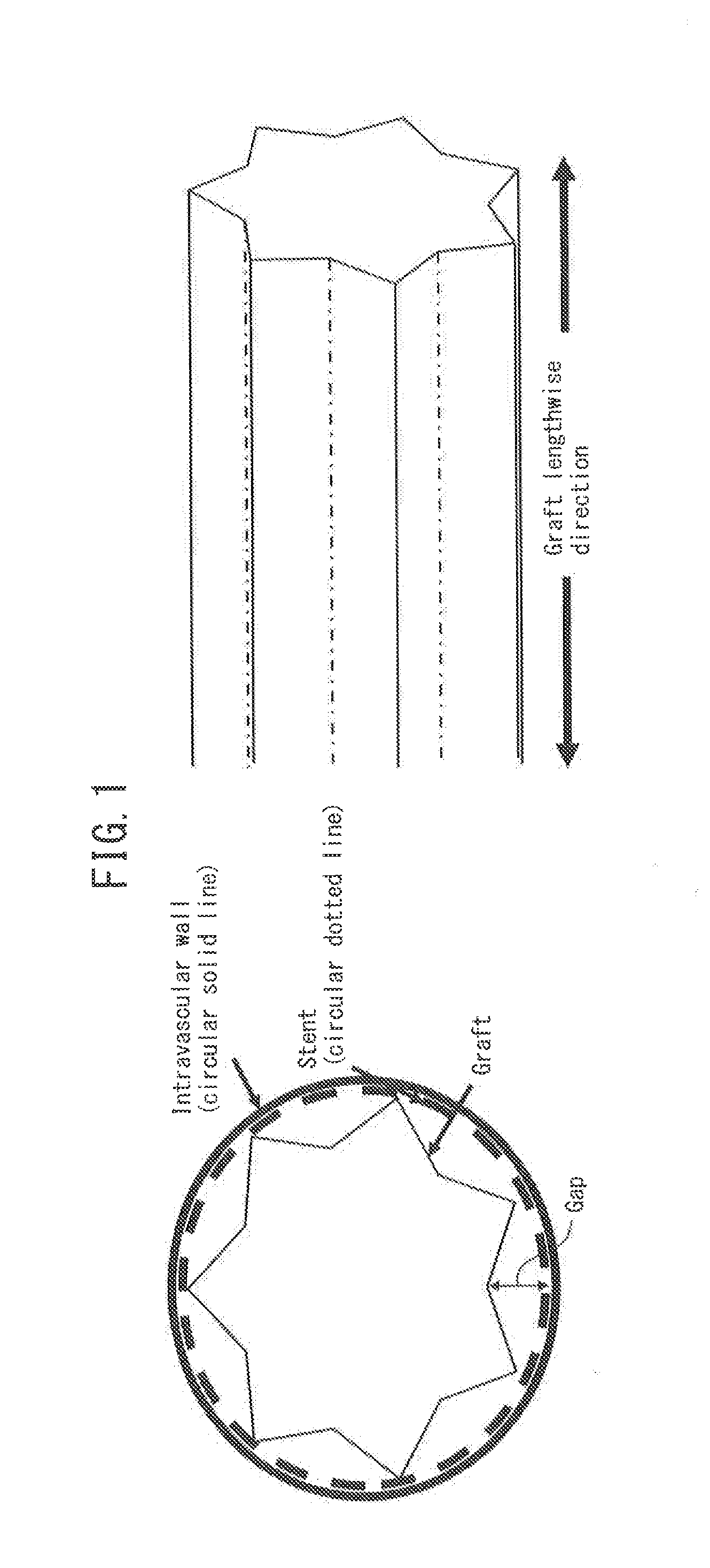

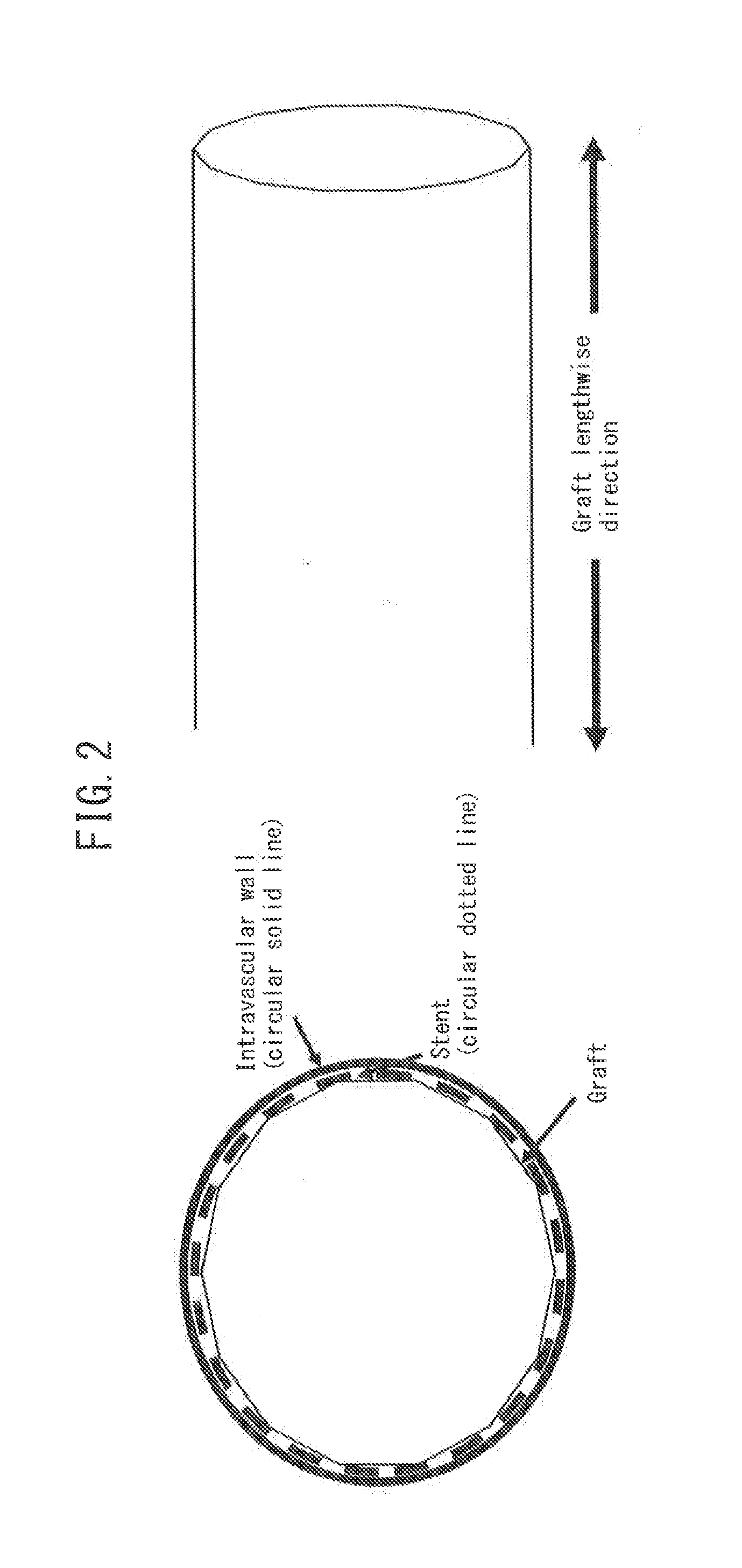

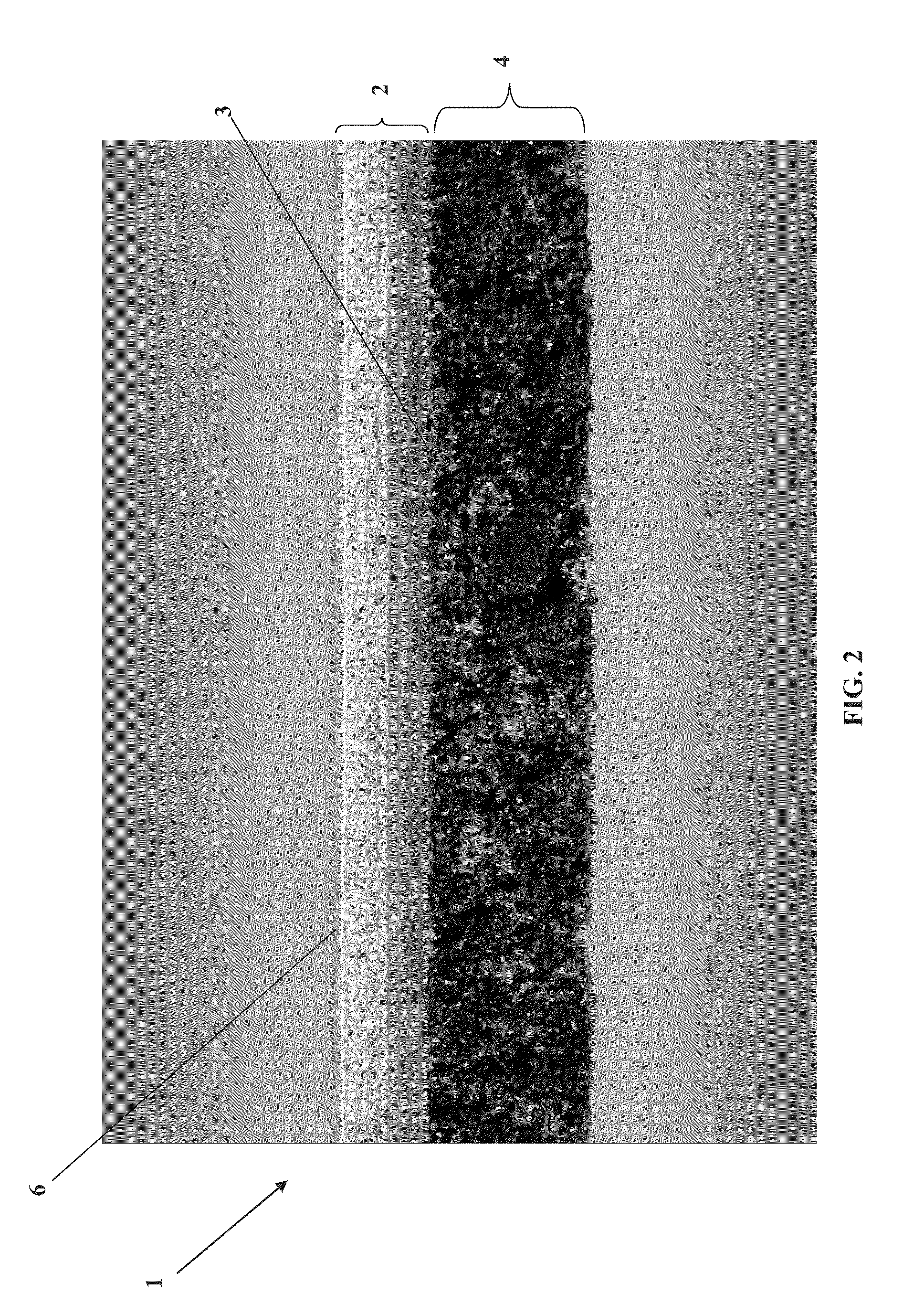

InactiveUS20160184488A1Highly integratedEnsure long-term stabilityStentsSurgeryPolyesterPolyethylene terephthalate glycol

Provided is an ultrafine polyester fiber which is useful as a constituent material for a cloth for a stent graft or other medical device that is to be implanted in the body and which can simultaneously solve both a clinical need (diameter reduction) and a clinical challenge (integration of a stent with a stent graft). An ultrafine polyester fiber which has a polyethylene terephthalate content of 98 wt % or more, characterized by: having (1) a reduced viscosity (ηsp / c) of 0.80 dl / g or higher and (2) a total fineness of 7 to 120 dtex and a single-fiber fineness of 0.5 dtex or less; and exhibiting (3) a maximum thermal shrinkage stress of 0.05 cN / dtex or more in a temperature range of 80 to 200° C. or (4) a degree of crystallinity of 35% or more in a region spreading from the surface of the fiber to a depth of 0.1 μm.

Owner:ASAHI KASEI FIBERS CORPORATION

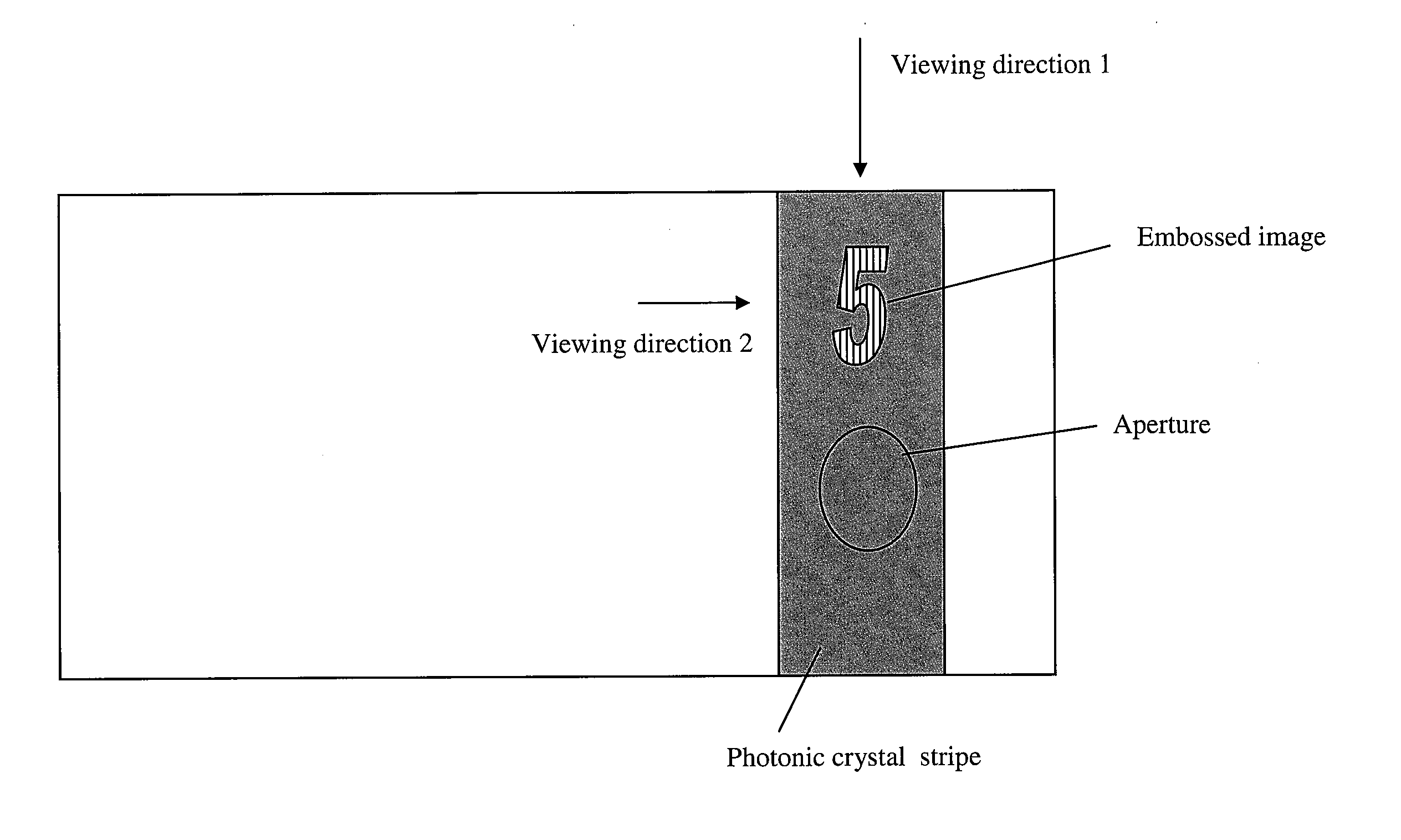

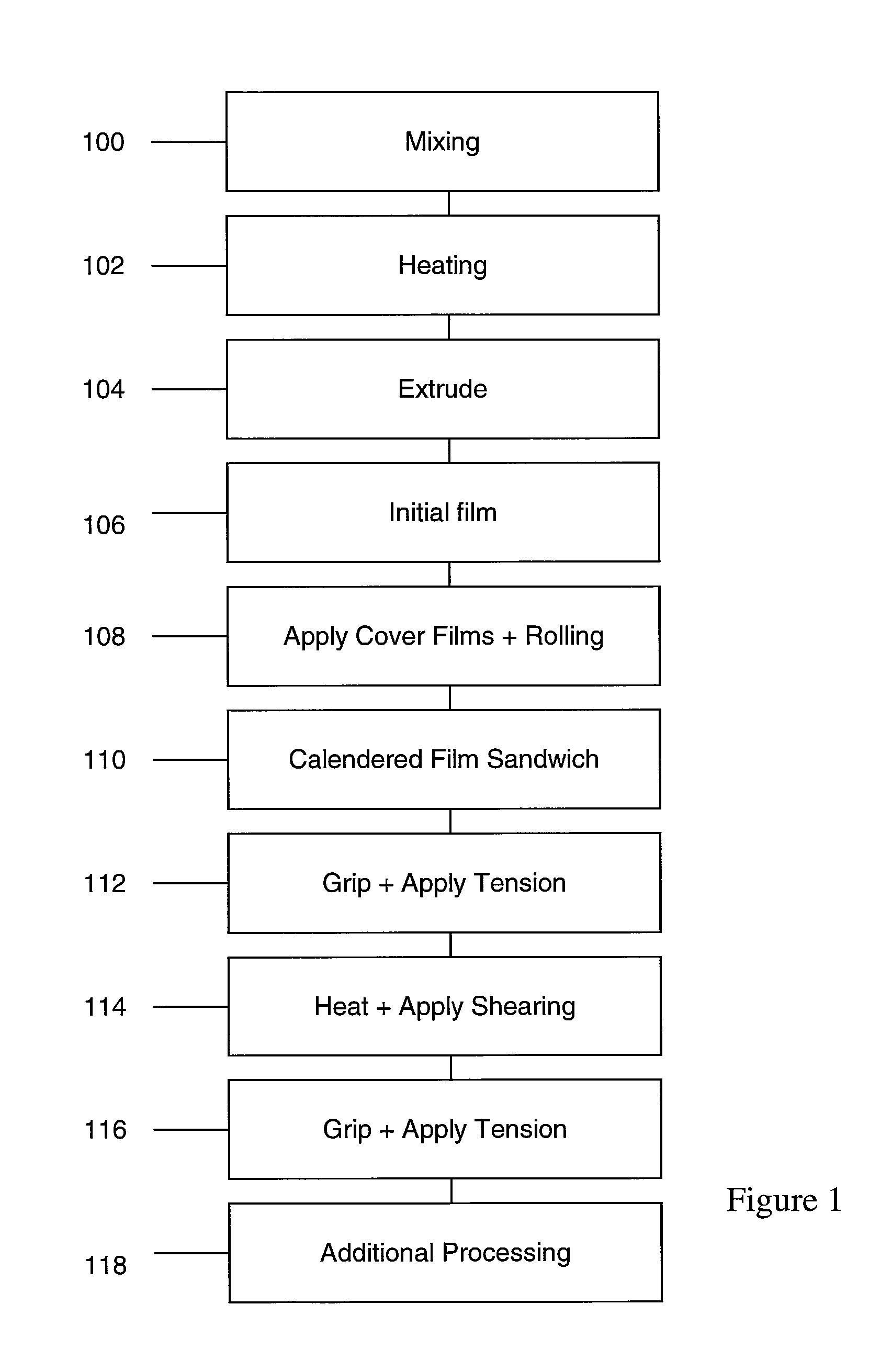

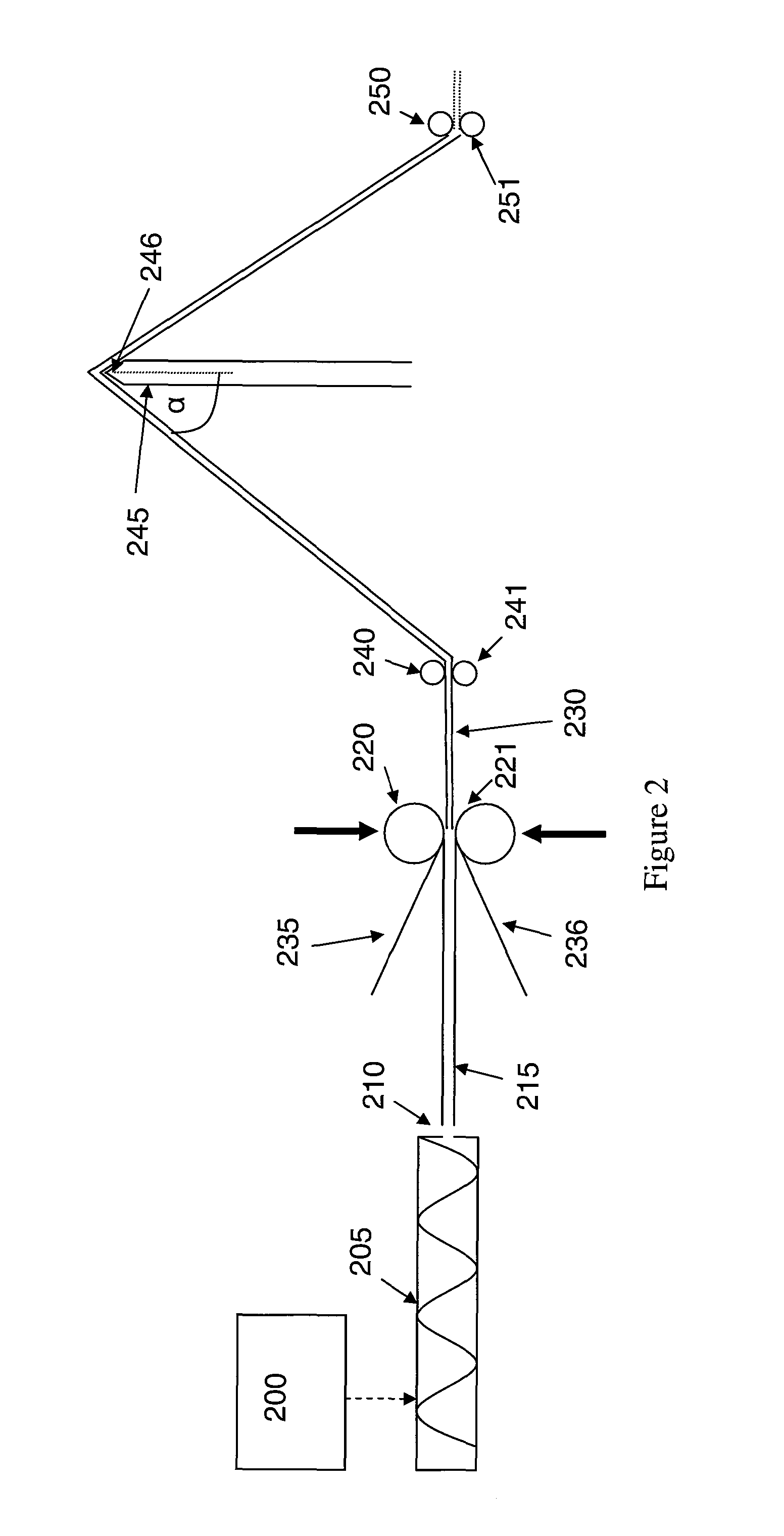

Method of forming a photonic crystal material

InactiveUS20120161431A1Efficient productionEnsure long-term stabilityDiffusing elementsConfectioneryShear stressPhotonic crystal structure

A method of forming a film of photonic crystal material. A first process is performed upon a material capable of having a photonic crystal structure, this process causing deformation of the material so as to form a film in which incident light received by the material is selectively reflected or transmitted to generate a first optical effect in the film. A second process is performed upon substantially all of the film which applies a shear stress to the film. This causes a change in the material structure so as to generate a second optical effect in the film, different from the first optical effect, in response to incident light. Security films, devices, articles and documents formed using the method are also discussed.

Owner:DE LA RUE INT LTD

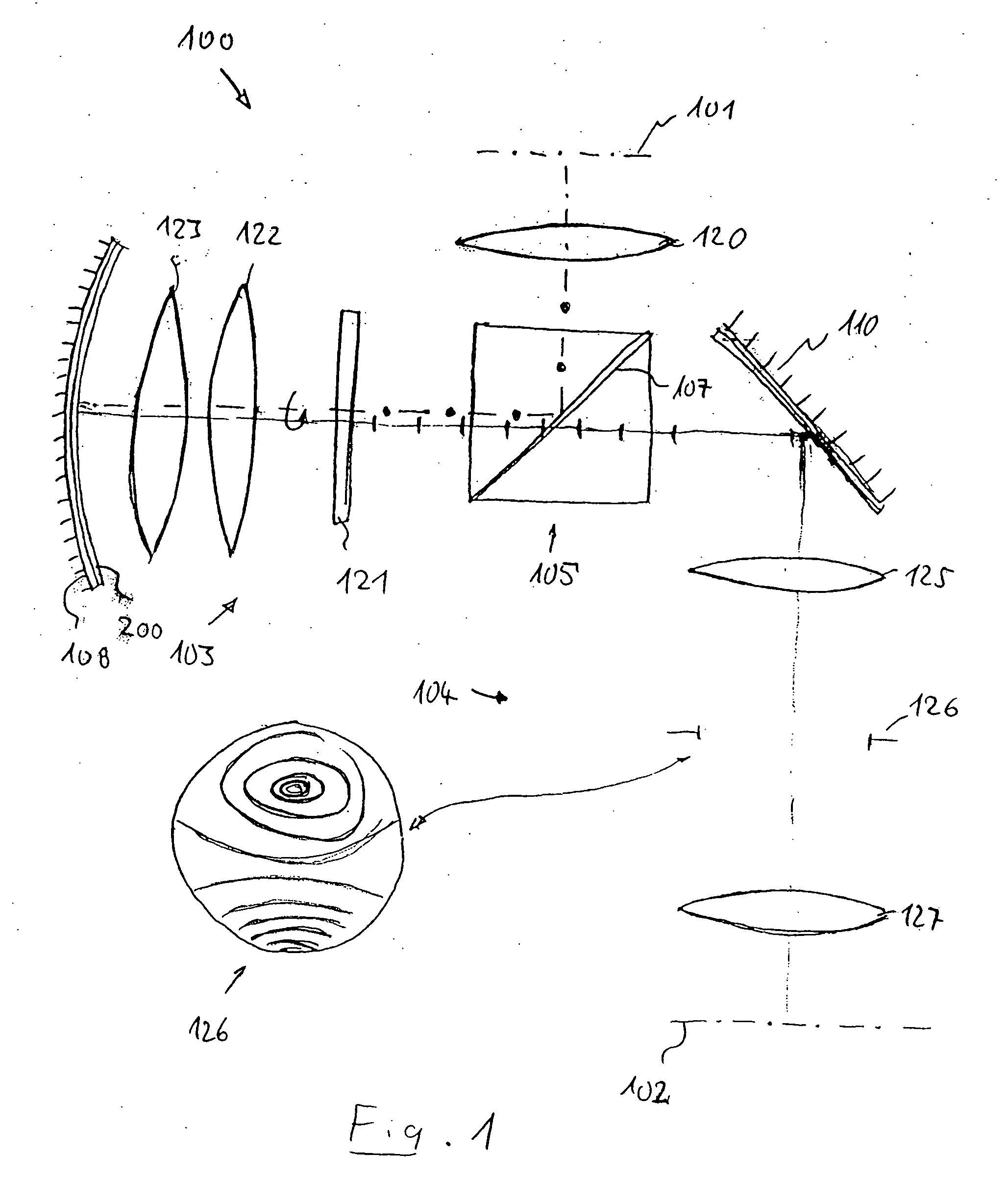

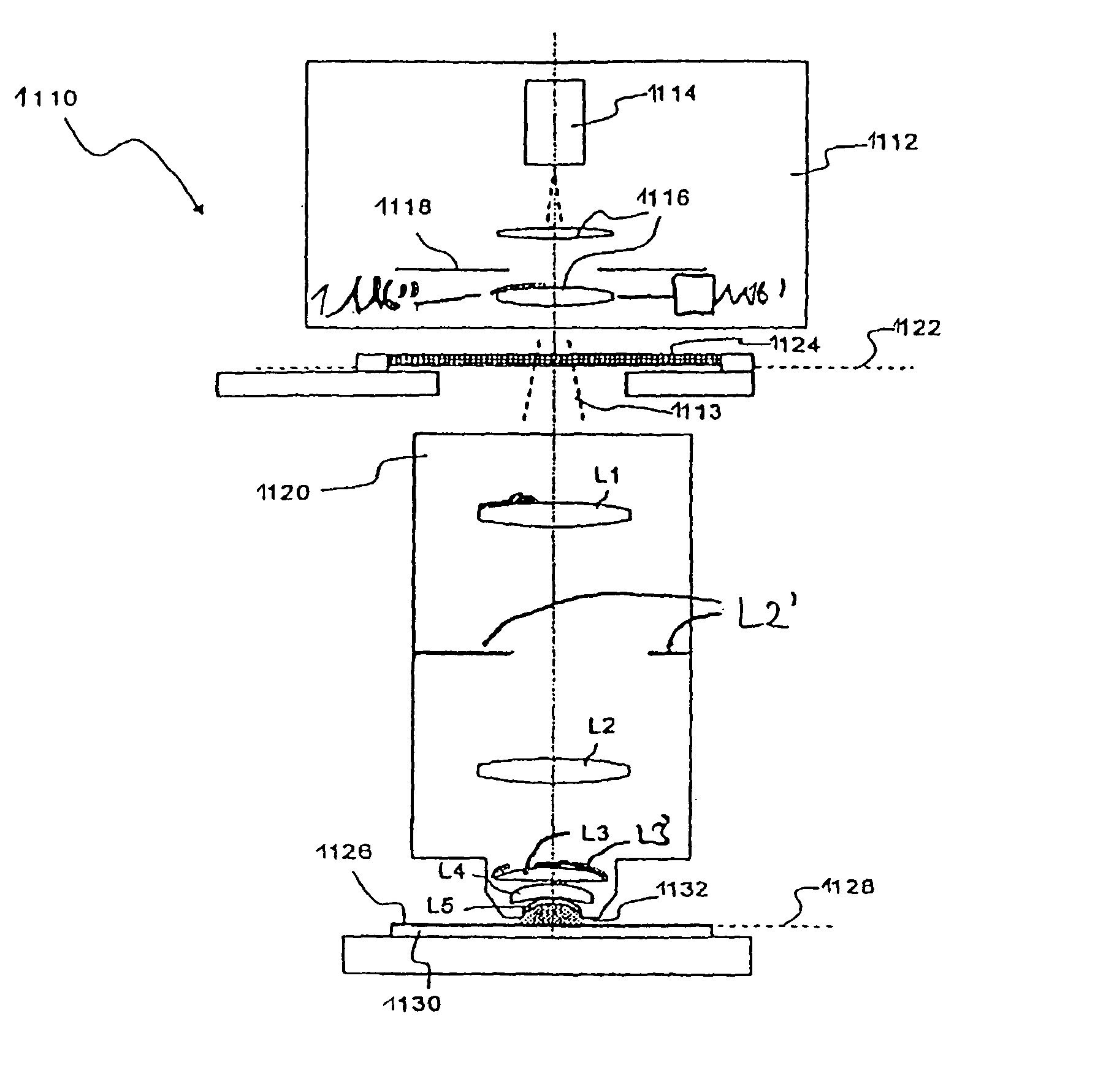

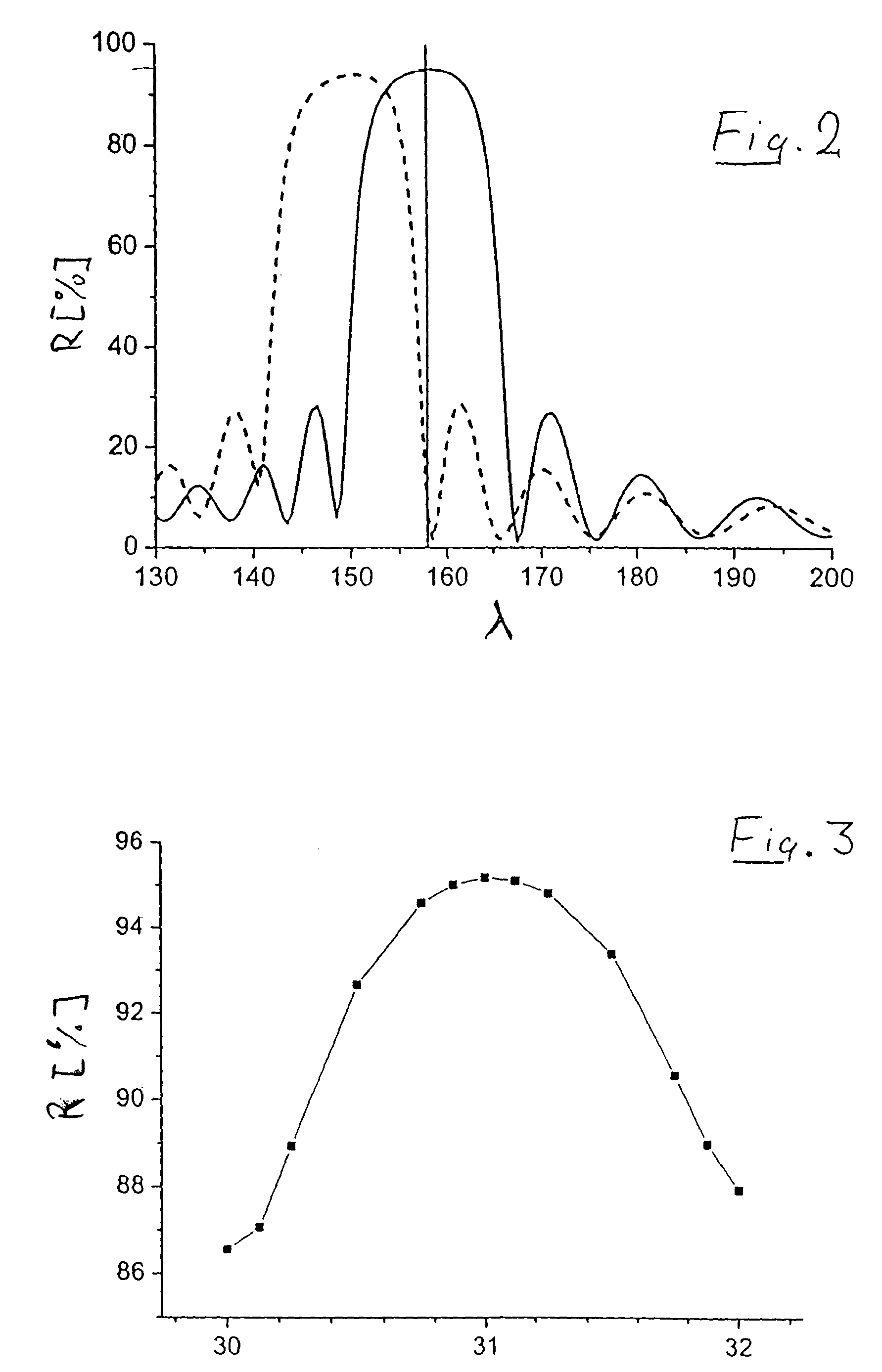

Projection System with Compensation of Intensity Variations and Compensation Element Therefor

InactiveUS20080094599A1High refractive indexLow refractive indexSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusTransmittanceComputational physics

In a projection objective for imaging a pattern arranged in the object plane of the projection objective into the image plane of the projection objective, at least one optical component is provided which has a substrate in which at least one substrate surface is covered with an interference layer system having a great spatial modulation of the reflectance and / or of the transmittance over a usable cross section of the optical component, the modulation being adapted to a spatial transmission distribution of the remaining components of the projection objective in such a way that an intensity distribution of the radiation that is measured in a pupil surface has a substantially reduced spatial modulation in comparison with a projection objective without the interference layer system.

Owner:CARL ZEISS SMT GMBH

Polyvinyl acetal film and uses thereof

ActiveUS20130074910A1Reduce yellownessGood lookingPV power plantsGlass/slag layered productsPolyvinyl alcoholOxygen

A polyvinyl acetal film as an intermediate film for a laminated glass, can provide a laminated glass that exhibits a low degree of yellowness and excellent surface appearance, and is useful as a sealing material or intermediate film that can prolong the life of a laminated glass provided with a solar cell or functional unit. The content of corrosion-causing substance in the polyvinyl acetal film is low, so that the polyvinyl acetal film permits high-temperature lamination and ensures excellent productivity. A solar cell module and a laminated glass are prepared using the polyvinyl acetal film. A plasticized polyvinyl acetal film which comprises 15 to 60 parts by mass of a plasticizer having a total number of 28 or more of carbon atoms and oxygen atoms constituting a molecule based on 100 parts by mass of a polyvinyl acetal resin, and which has an acid value of 5.0 meq / kg or less.

Owner:KURARAY CO LTD

Camera

InactiveUS20070292124A1Reduce manufacturing costHarden fastTelevision system detailsColor television detailsImage sensorVideo camera

A camera in particular for a motor vehicle having at least one image converting element. The image converting element includes at least one image sensor and is connected to at least one additional element of the camera, e.g., the housing of the camera, by at least one interlock.

Owner:ROBERT BOSCH GMBH

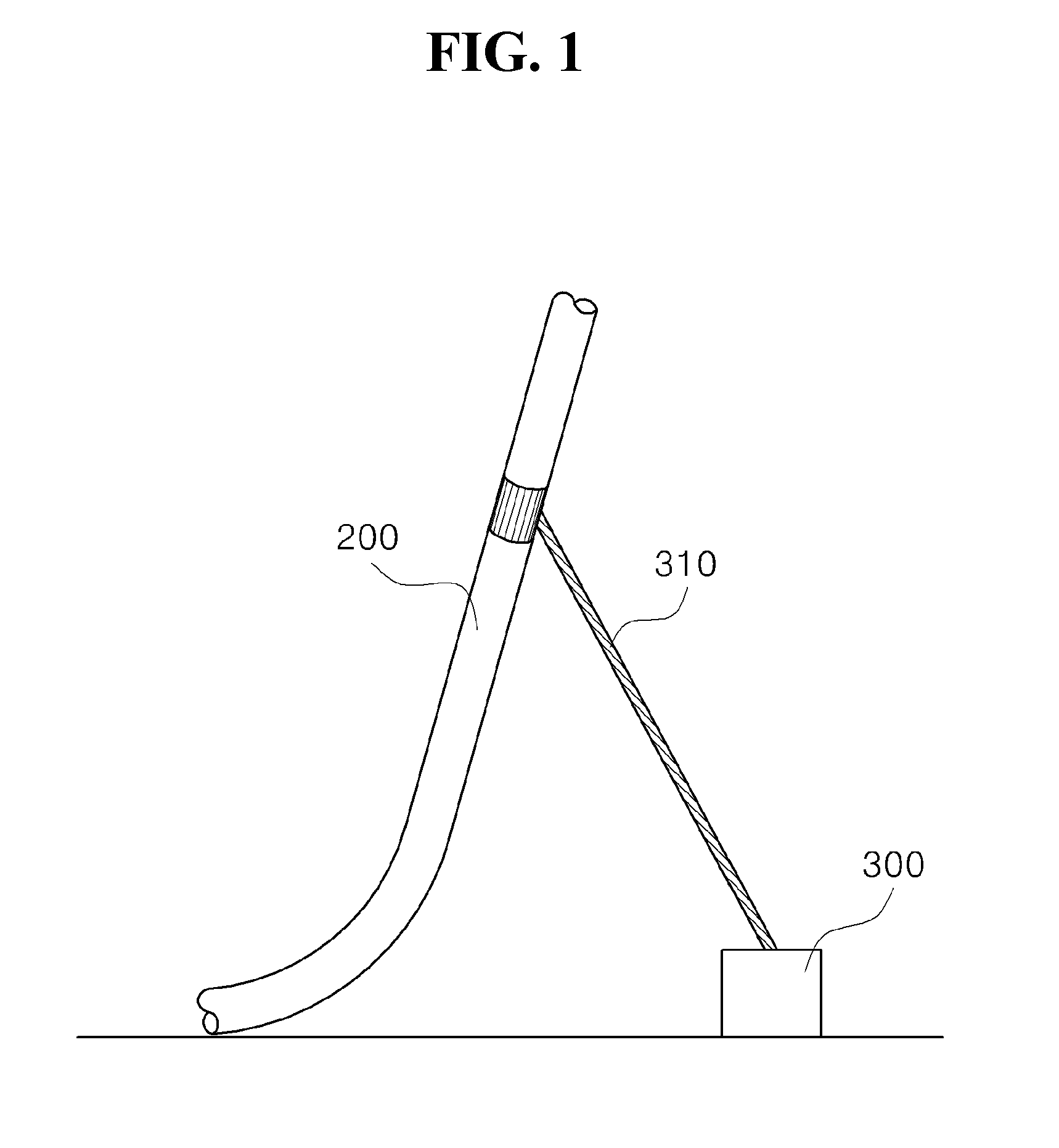

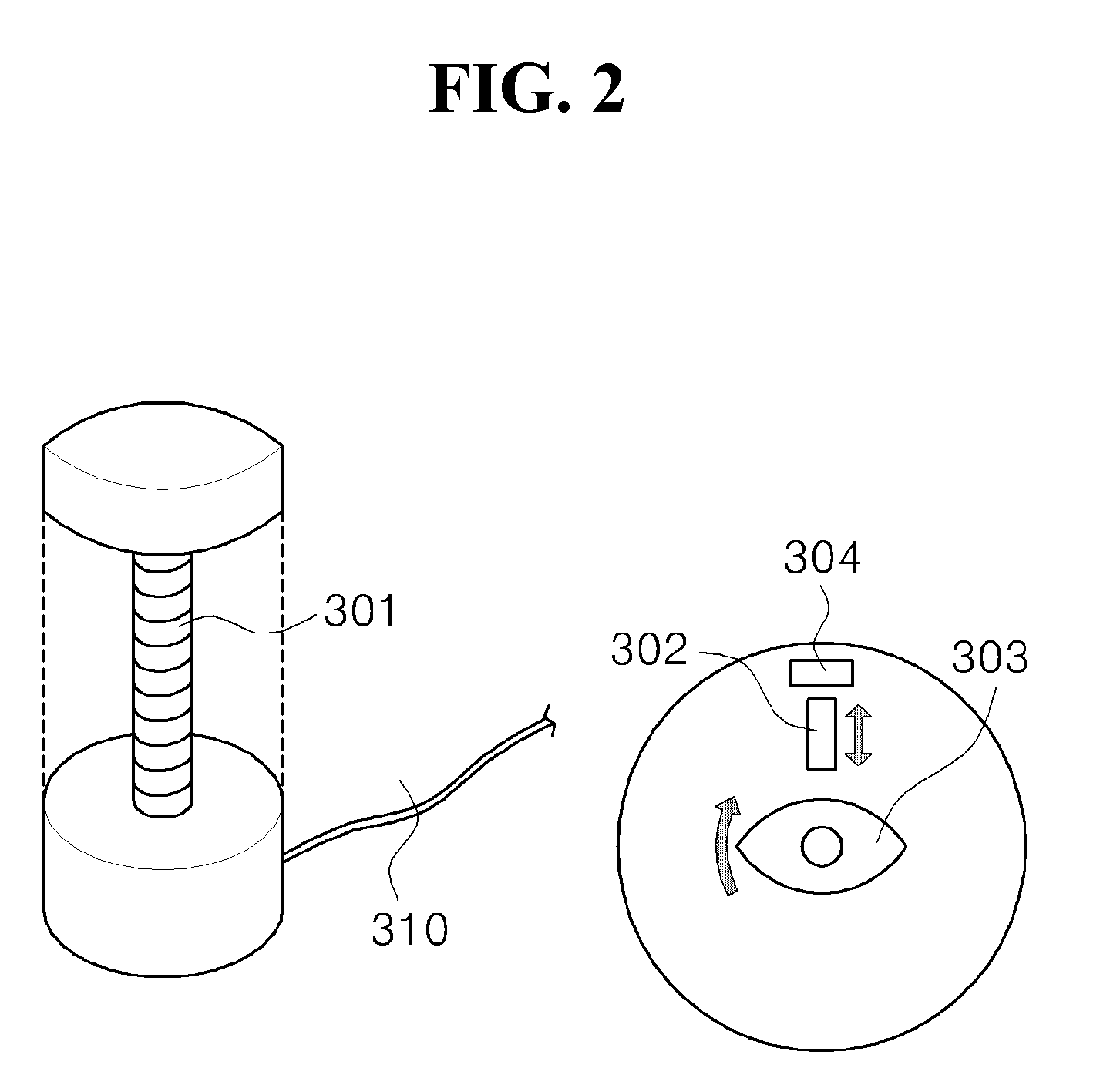

System and method for fuel savings and safe operation of marine structure

A system for monitoring a physical change of a marine structure includes a complex optical measuring instrument configured to detect a behavior and structural change of the marine structure by using at least one optical sensor by means of optical fiber Bragg grating.

Owner:CYTRONIQ

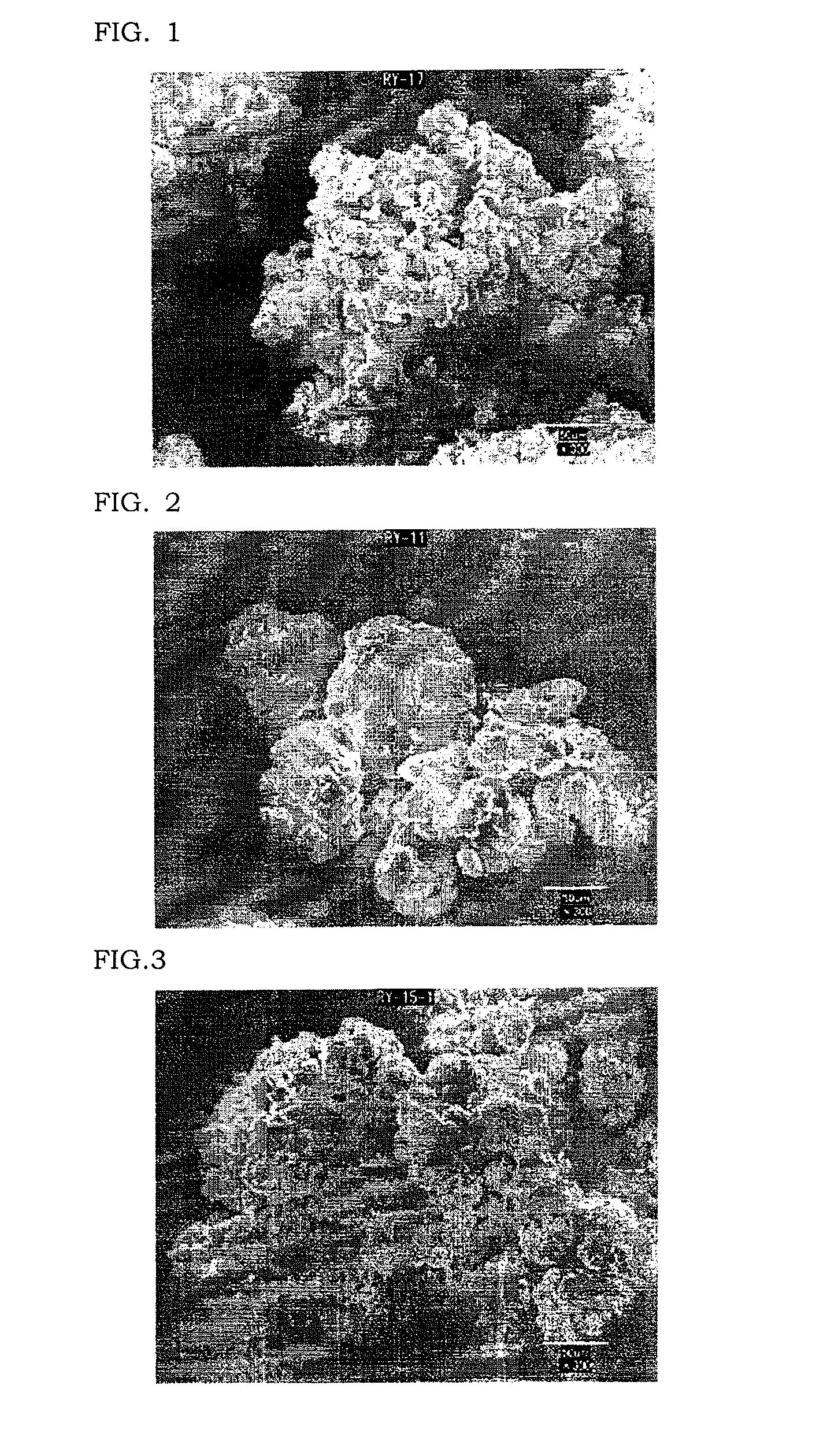

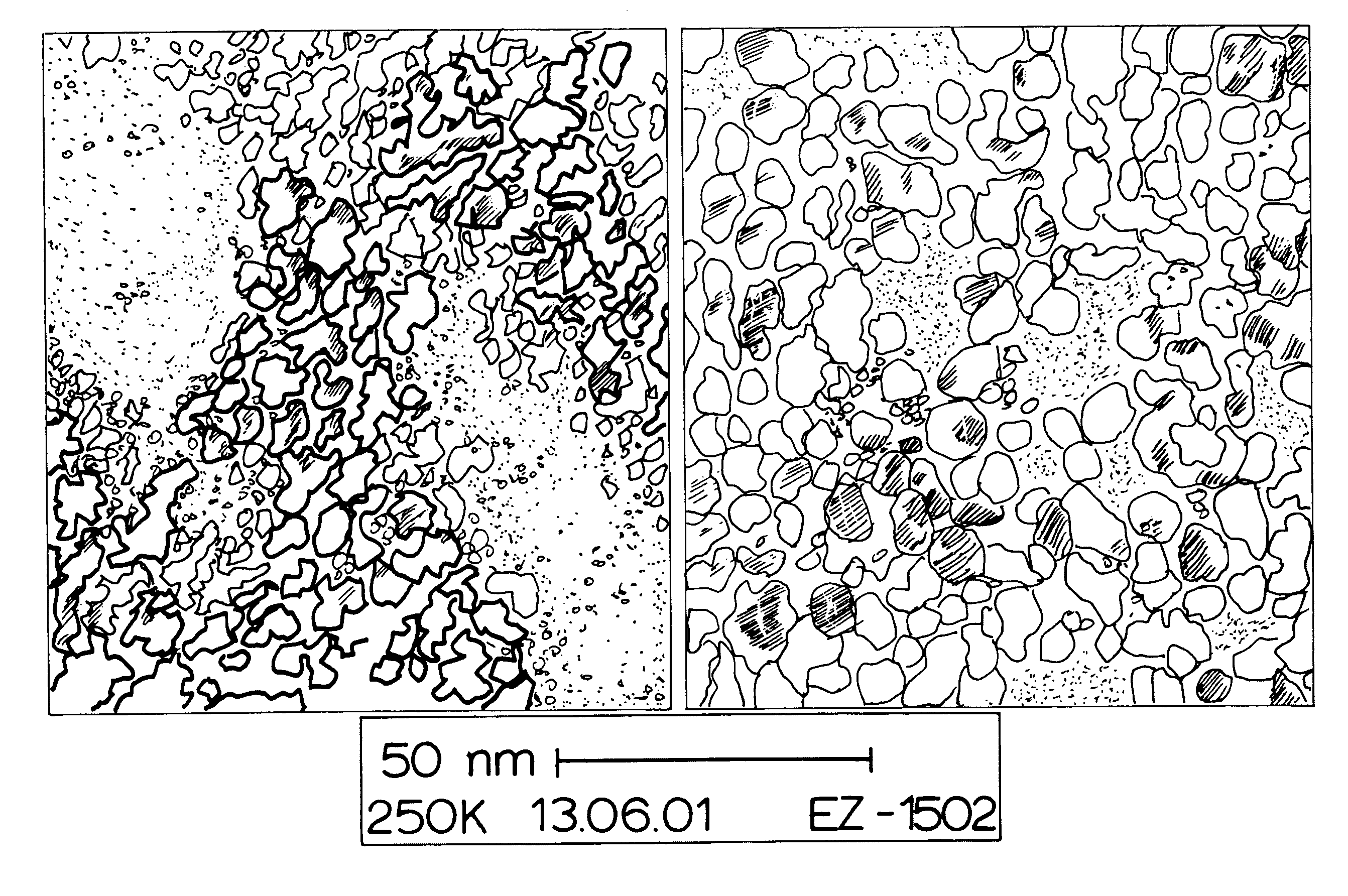

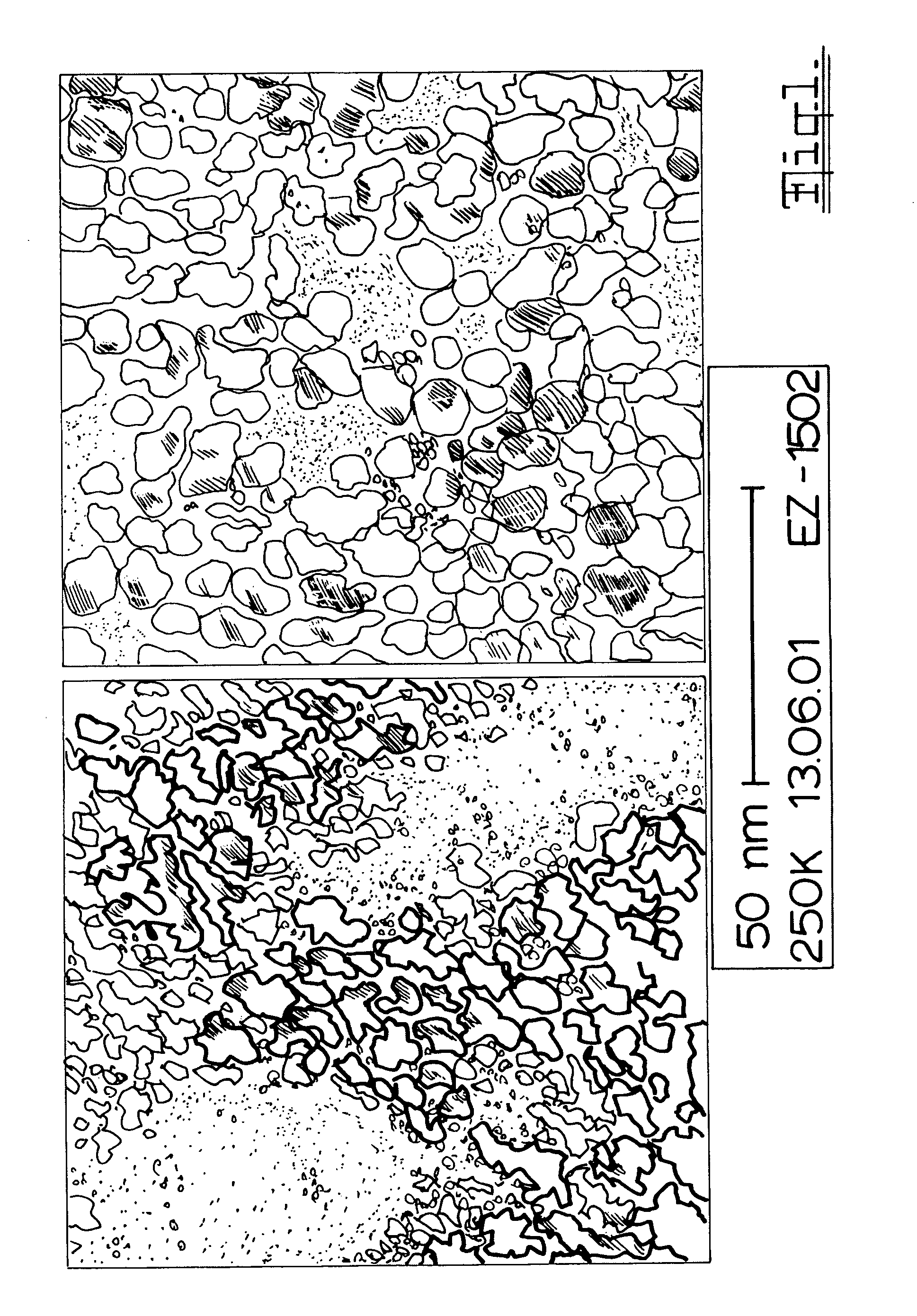

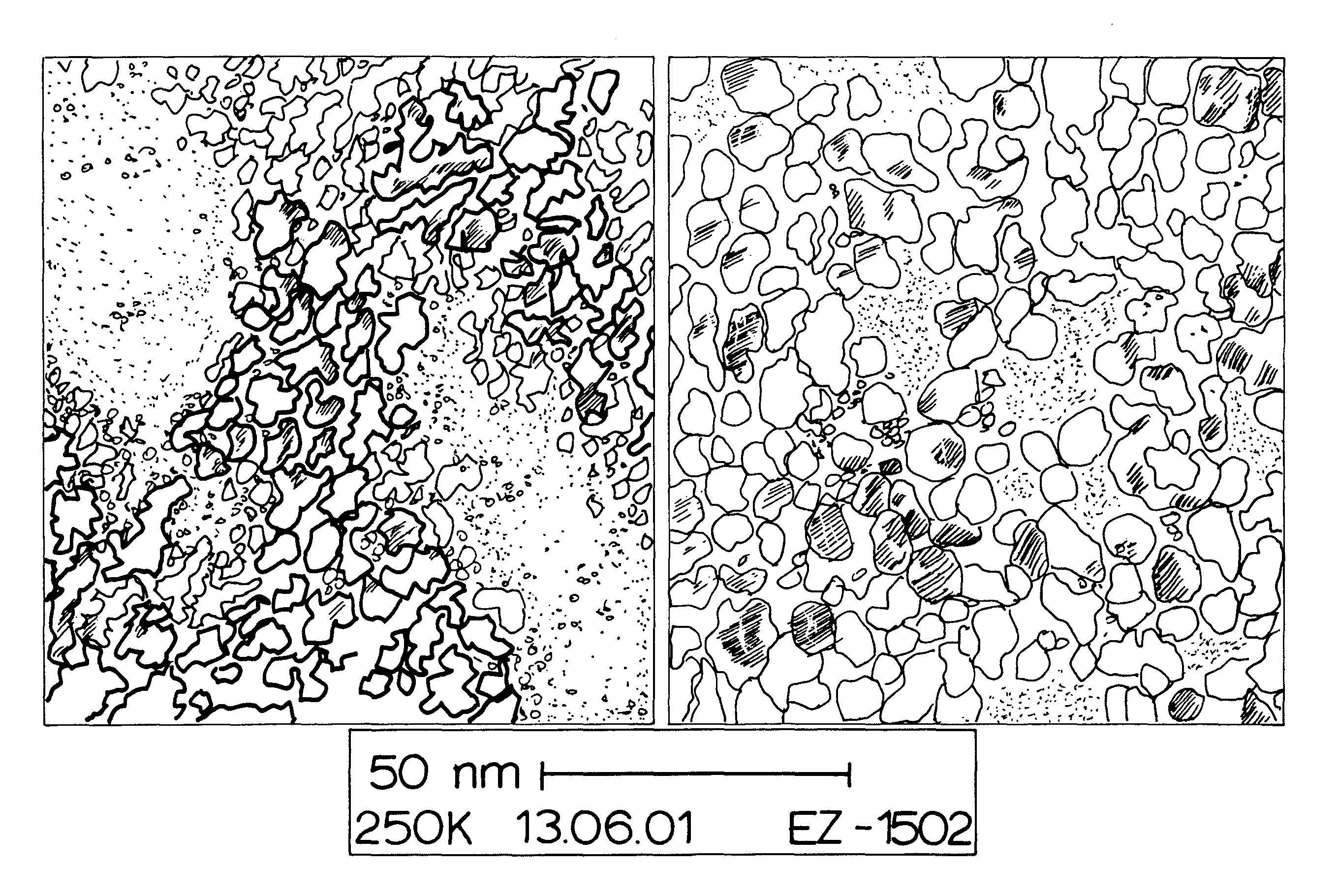

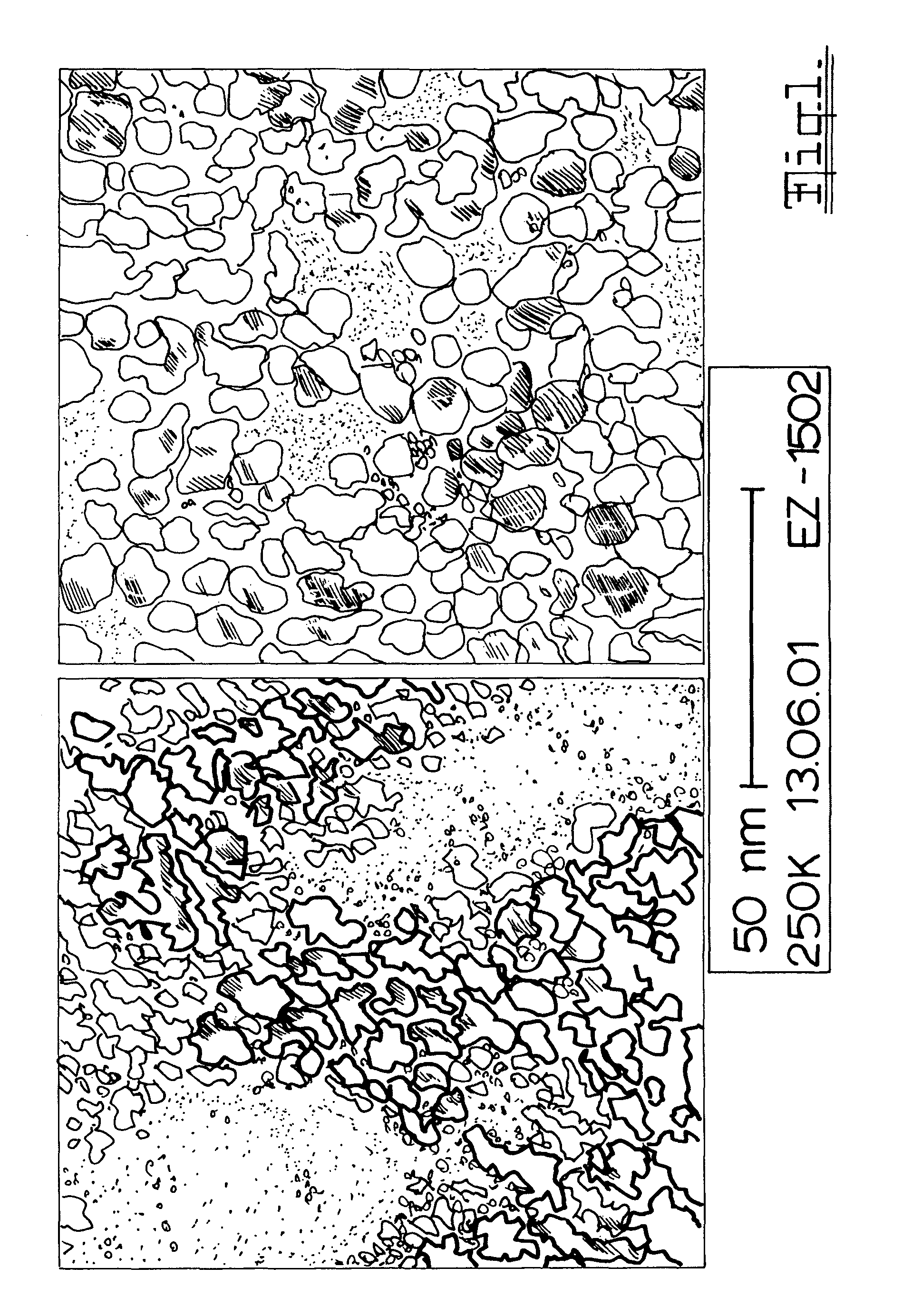

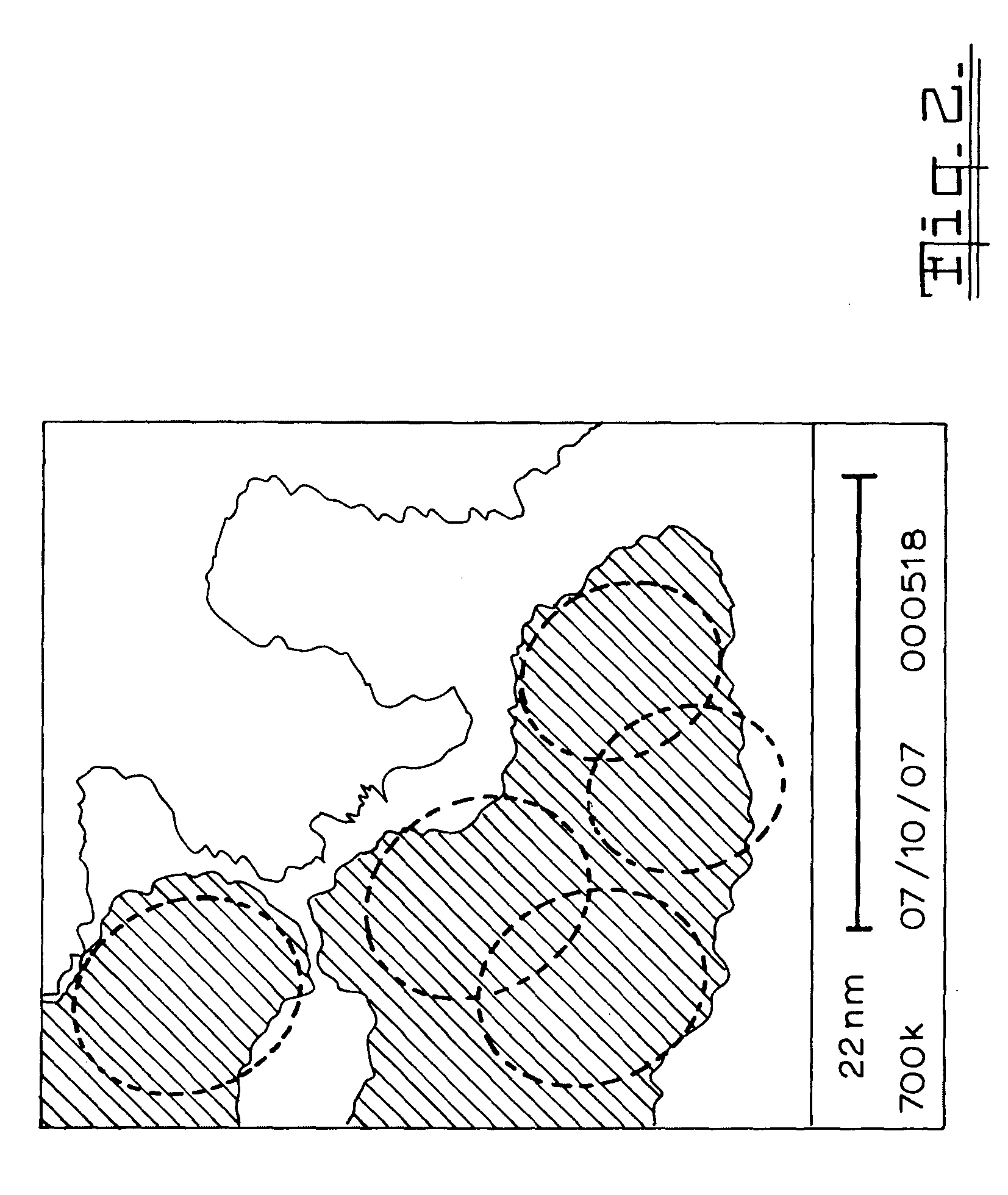

Photo electrodes

ActiveUS20120010068A1High mechanical strengthSimple reaction conditionsMaterial nanotechnologyCatalyst protectionNanoparticleCrystallinity

Methods of fabricating nano particulate Titanium dioxide photocatalysts onto a conducting substrate are disclosed. The methods include hydrothermal fabrications with heat treatment steps to increase the crystallinity and photoactivity of the titanium dioxide layers.

Owner:579453 ONTARIO INC

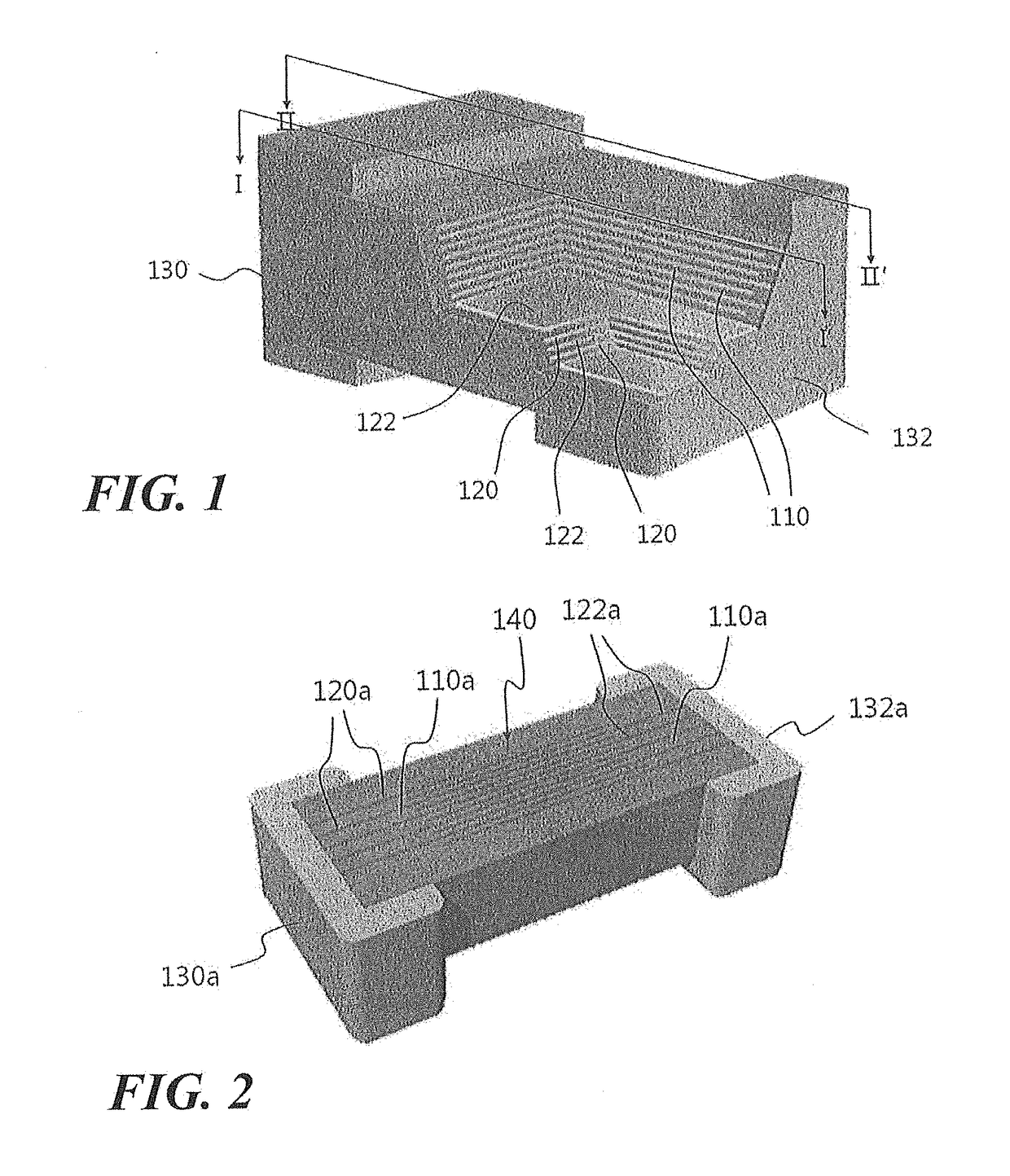

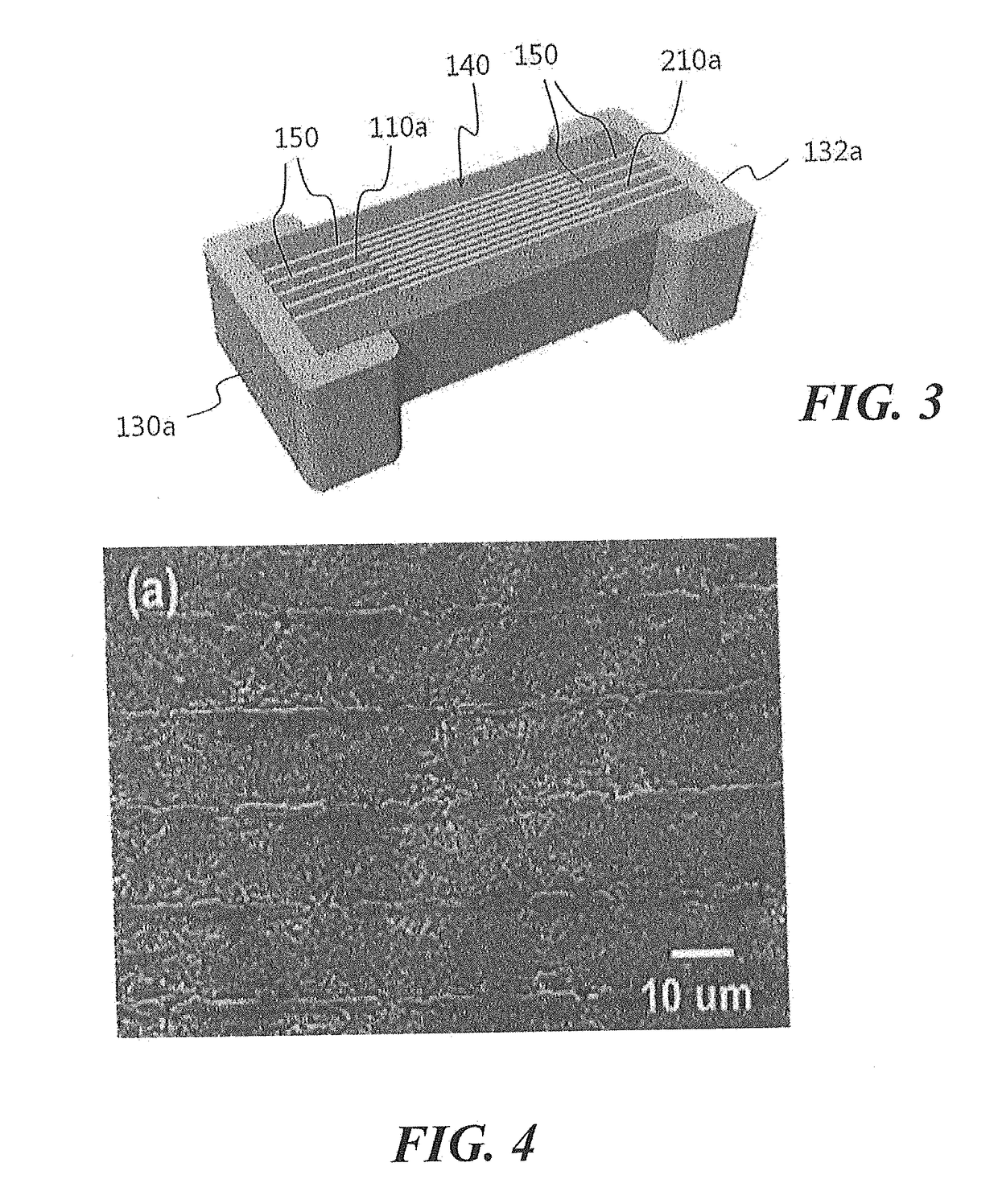

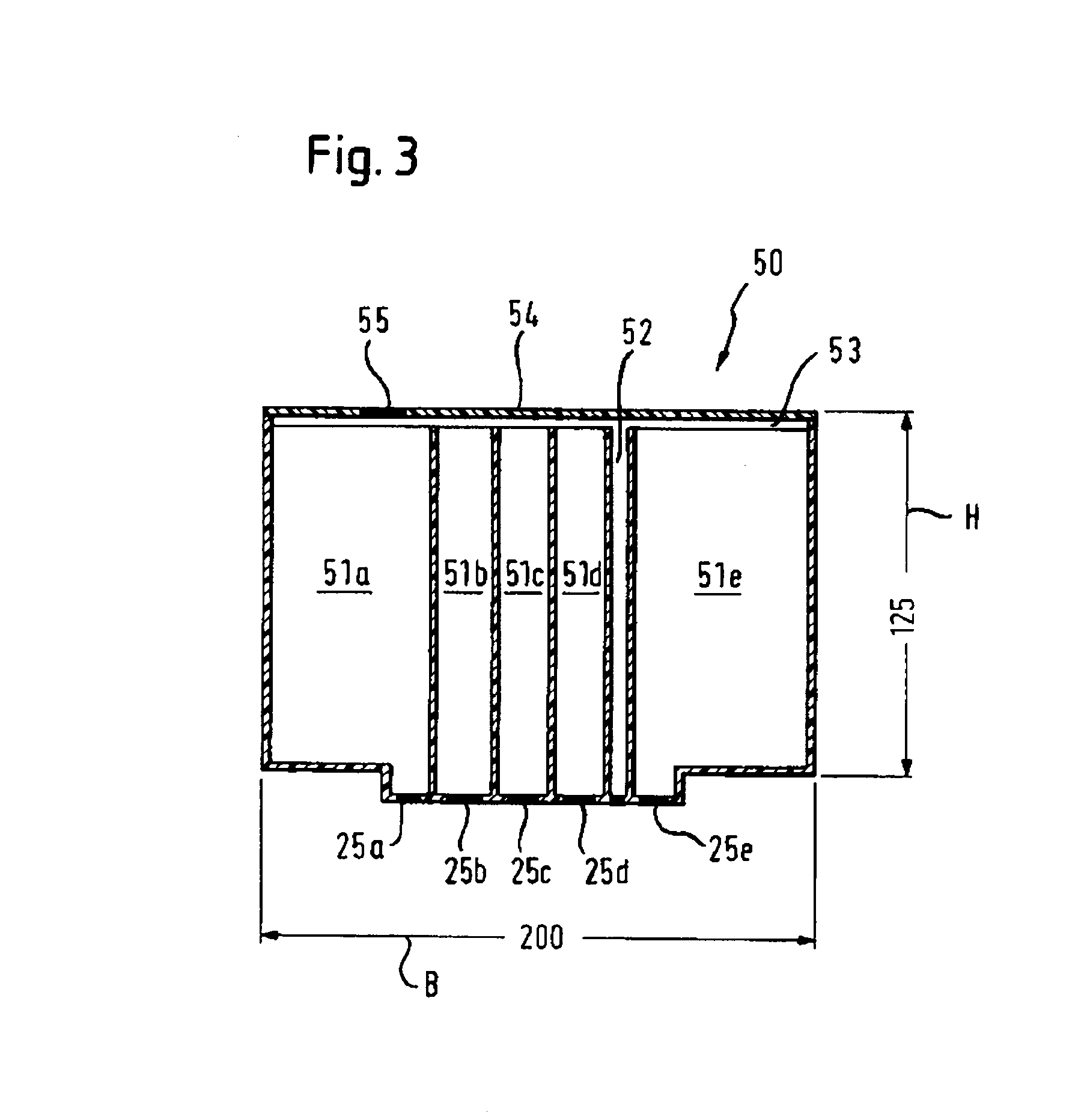

Multi-Layer Ceramic/Metal Type Gas Sensor And Manufacturing Method Of The Same

ActiveUS20180224391A1Low costEasy to adjustSpecific nanostructure formationIndividual molecule manipulationElectricityCeramic

The present invention relates to a gas sensor and a manufacturing method thereof. A sensor body of the gas sensor is formed by cutting a multi-layered ceramic / metal platform where a plurality of sequential layer structures of a ceramic dielectric material and metal are layered in a layering direction. The sensor body includes at least one layered body wherein a ceramic dielectric material, a first internal electrode, a ceramic dielectric material, and a second internal electrode are sequentially layered. The first internal electrode and the second internal electrode are exposed through a cut surface by cutting. The first internal electrode is electrically connected to a first electrode terminal disposed on a first side of the sensor body, and the second internal electrode is electrically connected to a second electrode terminal disposed on a second side of the sensor body facing the first side. The first and the second internal electrode are exposed to form a sensing surface on at least one side of the sensor body excluding a side where the first and the second electrode terminal are installed. A gas sensing material layer for gas detection is formed on a portion or an entire upper portion of the sensing surface, or a metal film whose contact resistance with the gas sensing material layer is lower than the first and the second internal electrode is formed on upper portions of the first and the second internal electrode which are exposed and a gas sensing material layer for gas detection is formed on a portion or an entire upper portion of the sensing surface where the metal film is formed.

Owner:IND UNIV COOPERATION FOUND HANYANG UNIV ERICA CAMPUS

System and method for fuel savings and safe operation of marine structure

ActiveUS20170183062A1Easy to installGuaranteed uptimeDrilling rodsForce measurement by measuring optical property variationGratingMeasuring instrument

A system for monitoring a physical change of a marine structure includes a complex optical measuring instrument configured to detect a behavior and structural change of the marine structure by using at least one optical sensor by means of optical fiber Bragg grating.

Owner:CYTRONIQ

Projection system with compensation of intensity variations and compensation element therefor

InactiveUS8605257B2Ensure long-term stabilityLarge spacingSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusTransmittancePupil

In a projection objective for imaging a pattern arranged in the object plane of the projection objective into the image plane of the projection objective, at least one optical component is provided which has a substrate in which at least one substrate surface is covered with an interference layer system having a great spatial modulation of the reflectance and / or of the transmittance over a usable cross section of the optical component, the modulation being adapted to a spatial transmission distribution of the remaining components of the projection objective in such a way that an intensity distribution of the radiation that is measured in a pupil surface has a substantially reduced spatial modulation in comparison with a projection objective without the interference layer system.

Owner:CARL ZEISS SMT GMBH

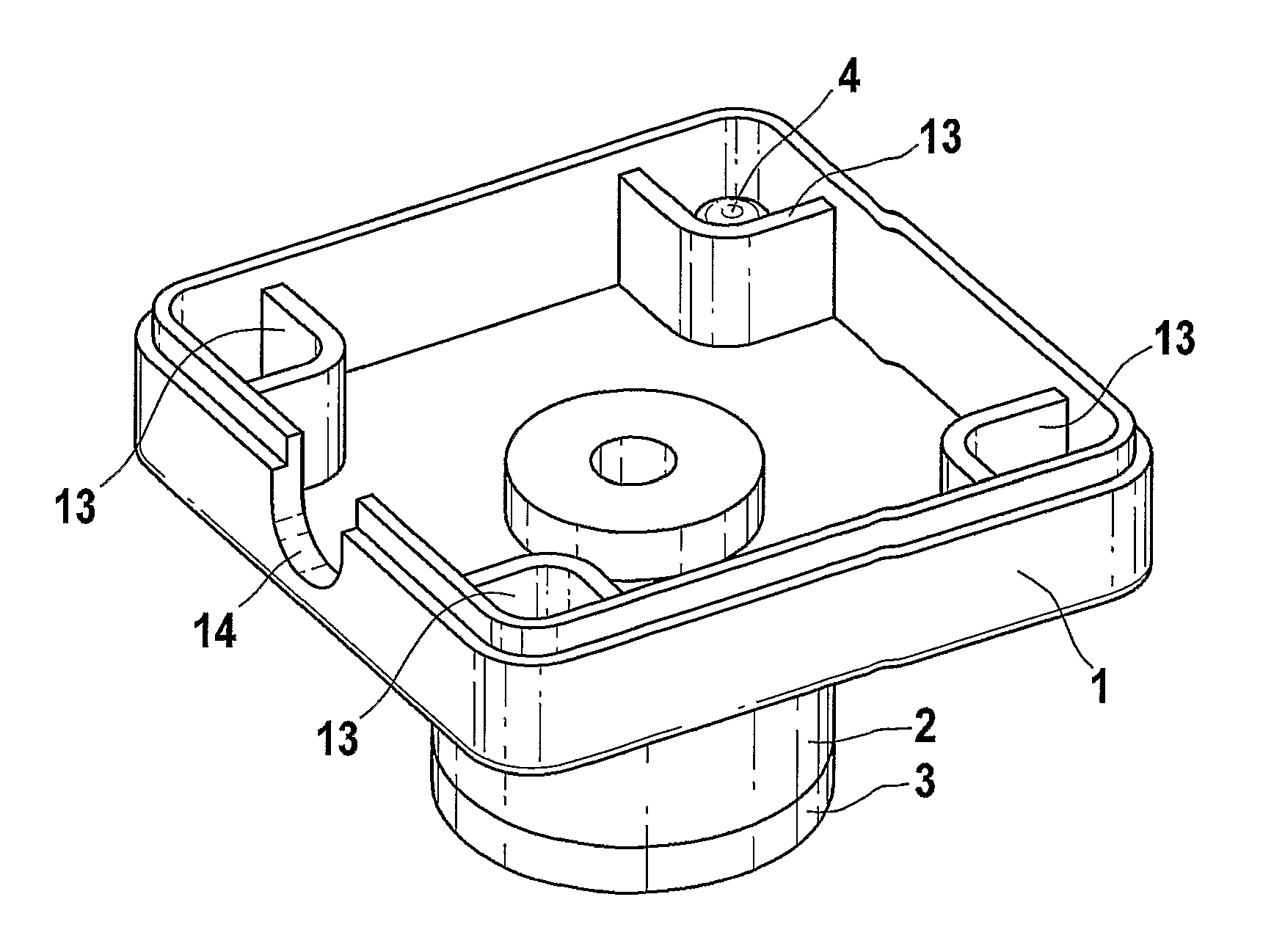

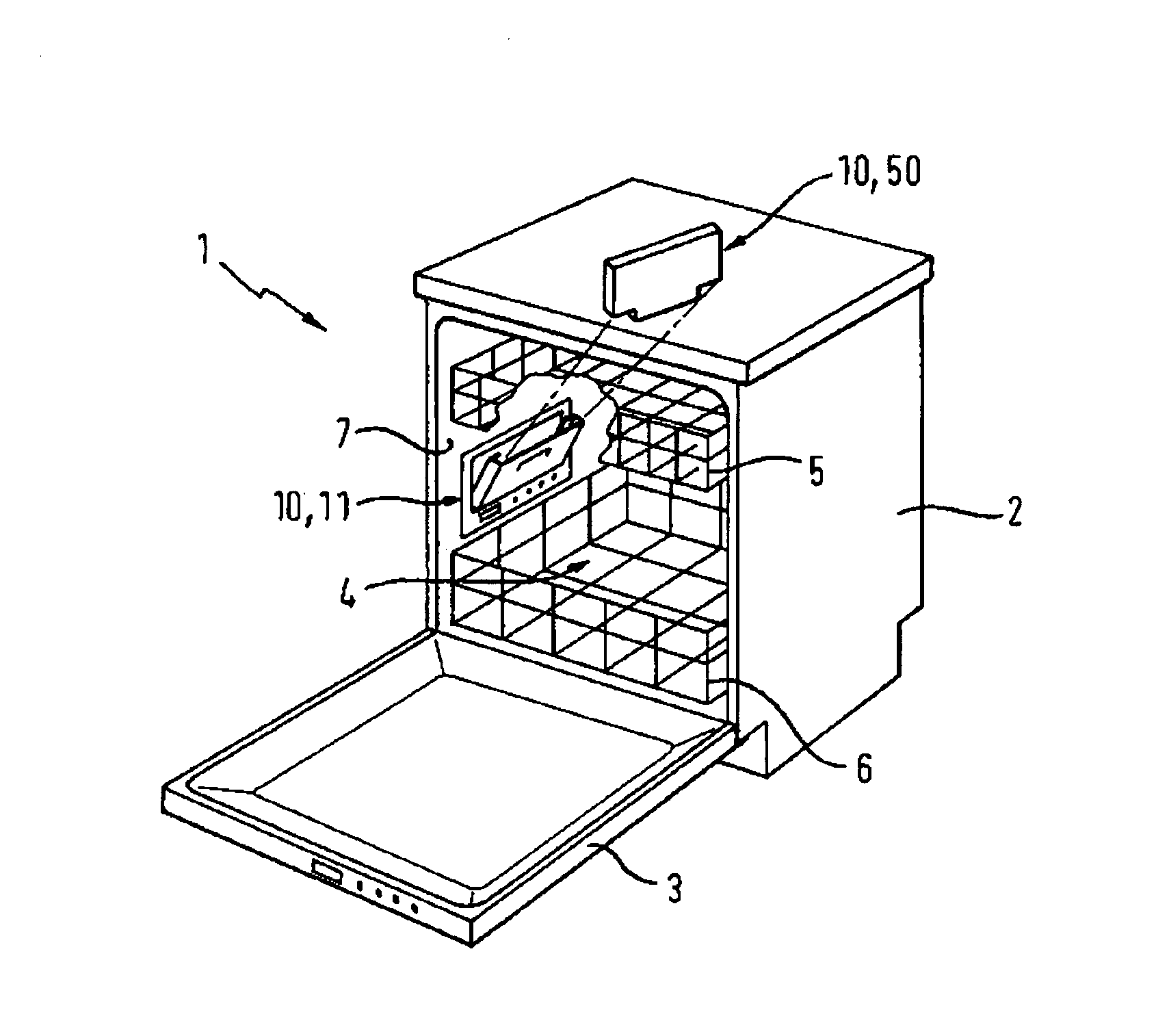

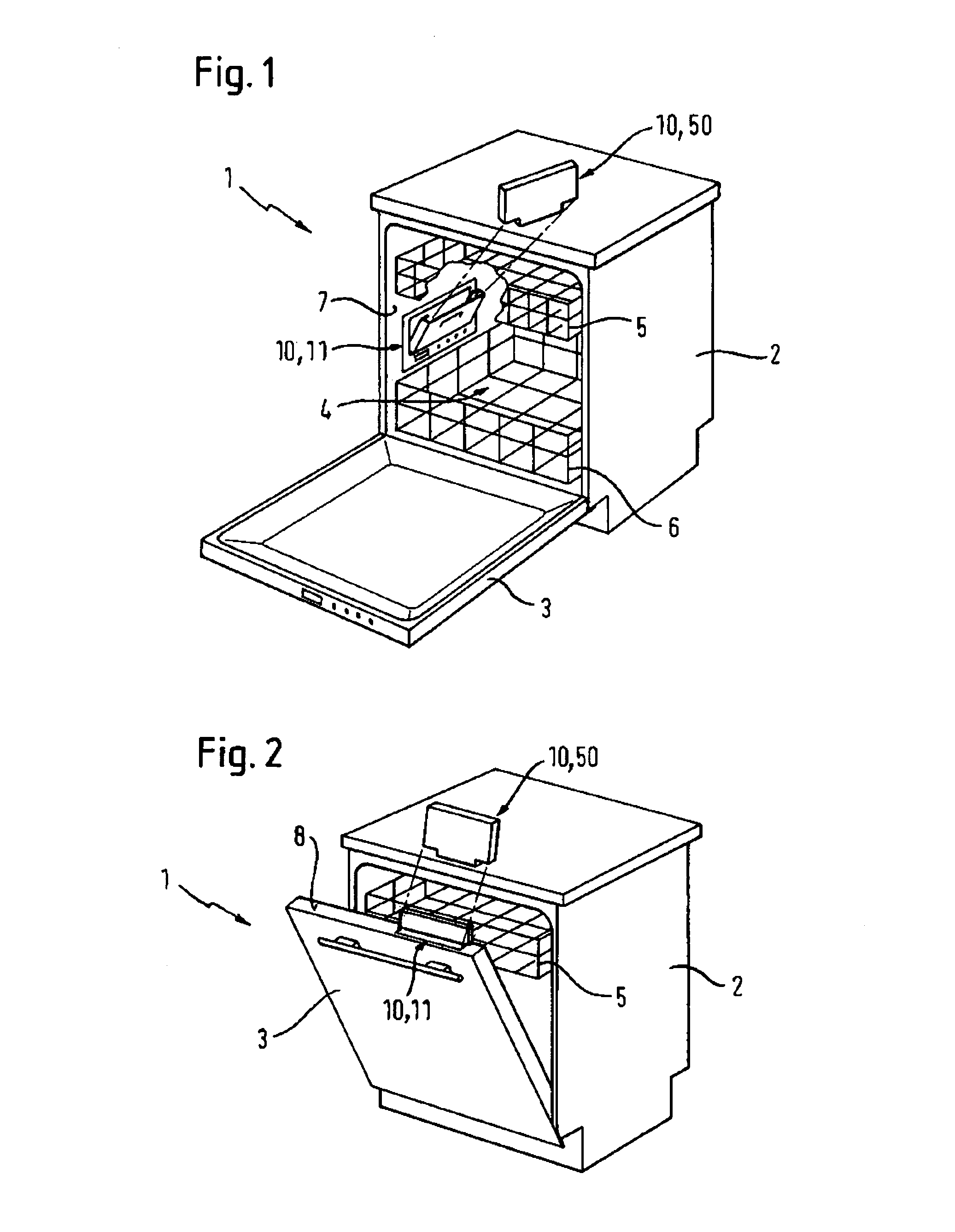

Water-conducting domestic appliance comprising a detergent dosing system and cartridge therefor

ActiveUS8696828B2Reduce deliverySimple configurationAutomatic washing/rinsing machine detectionHollow article cleaningEngineering

A water-conducting domestic appliance, in particular a domestic dishwasher, the water-conducting domestic appliance including a washing compartment for receiving items therein that are to be subjected to a washing cycle by the water-conducting domestic appliance; a detergent dosing system, the detergent dosing system having a detergent dispenser with a receiving compartment, the receiving area for receiving at least one cartridge that is configured to hold at least one detergent; and a cartridge having separate chambers for storing at least two detergents, each chamber having a storage capacity for storing detergent that is greater than a quantity of detergent required for one washing cycle.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

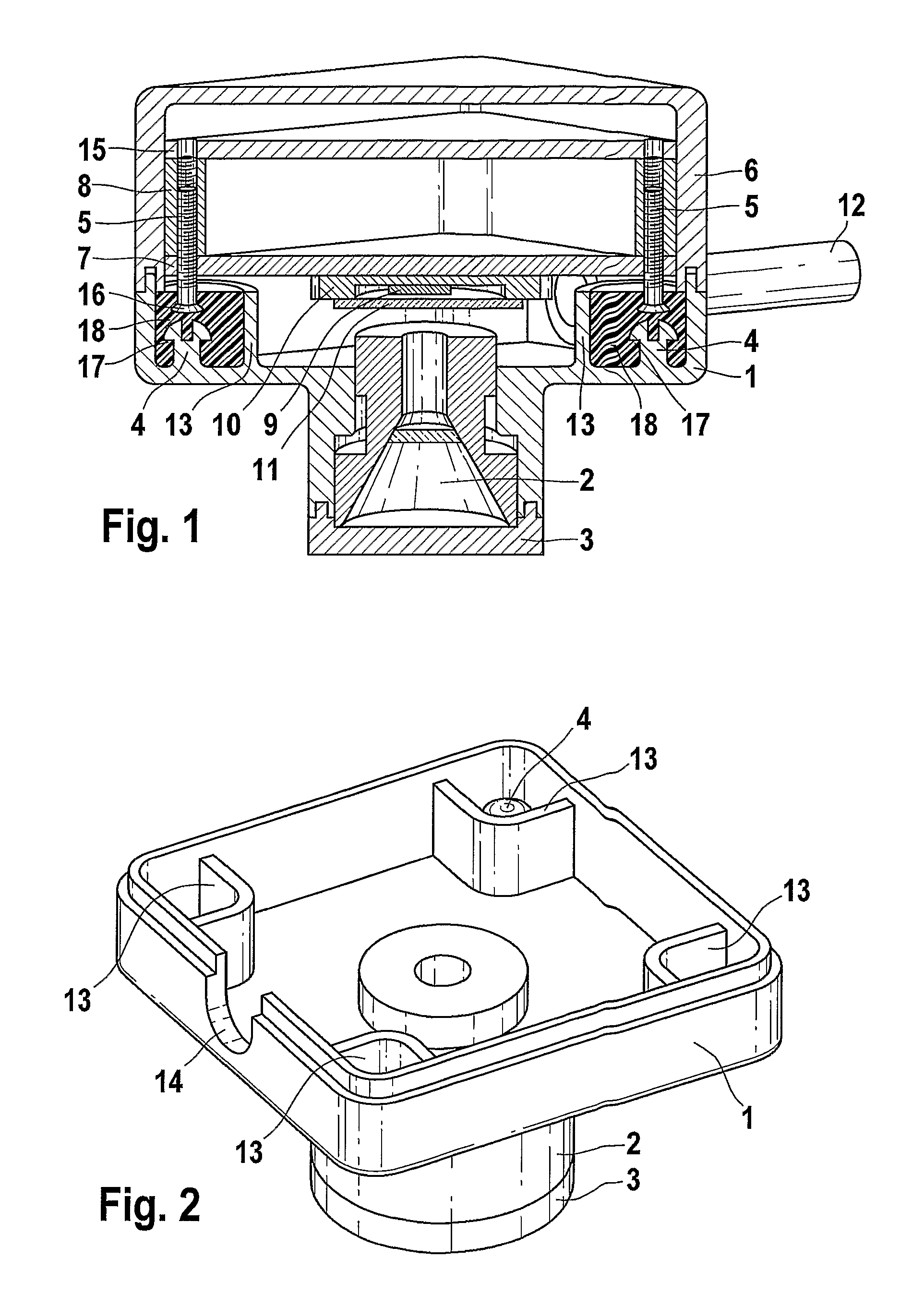

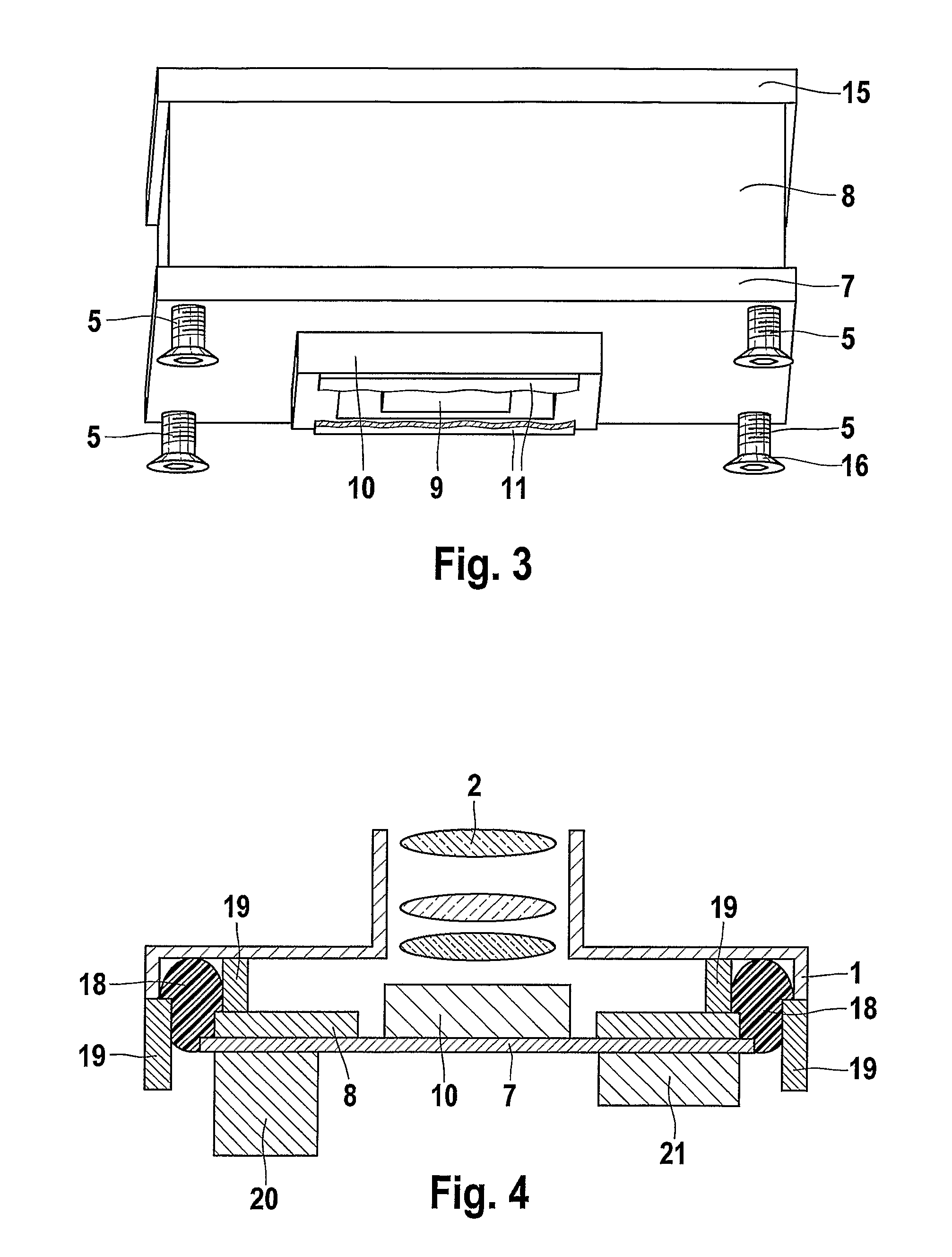

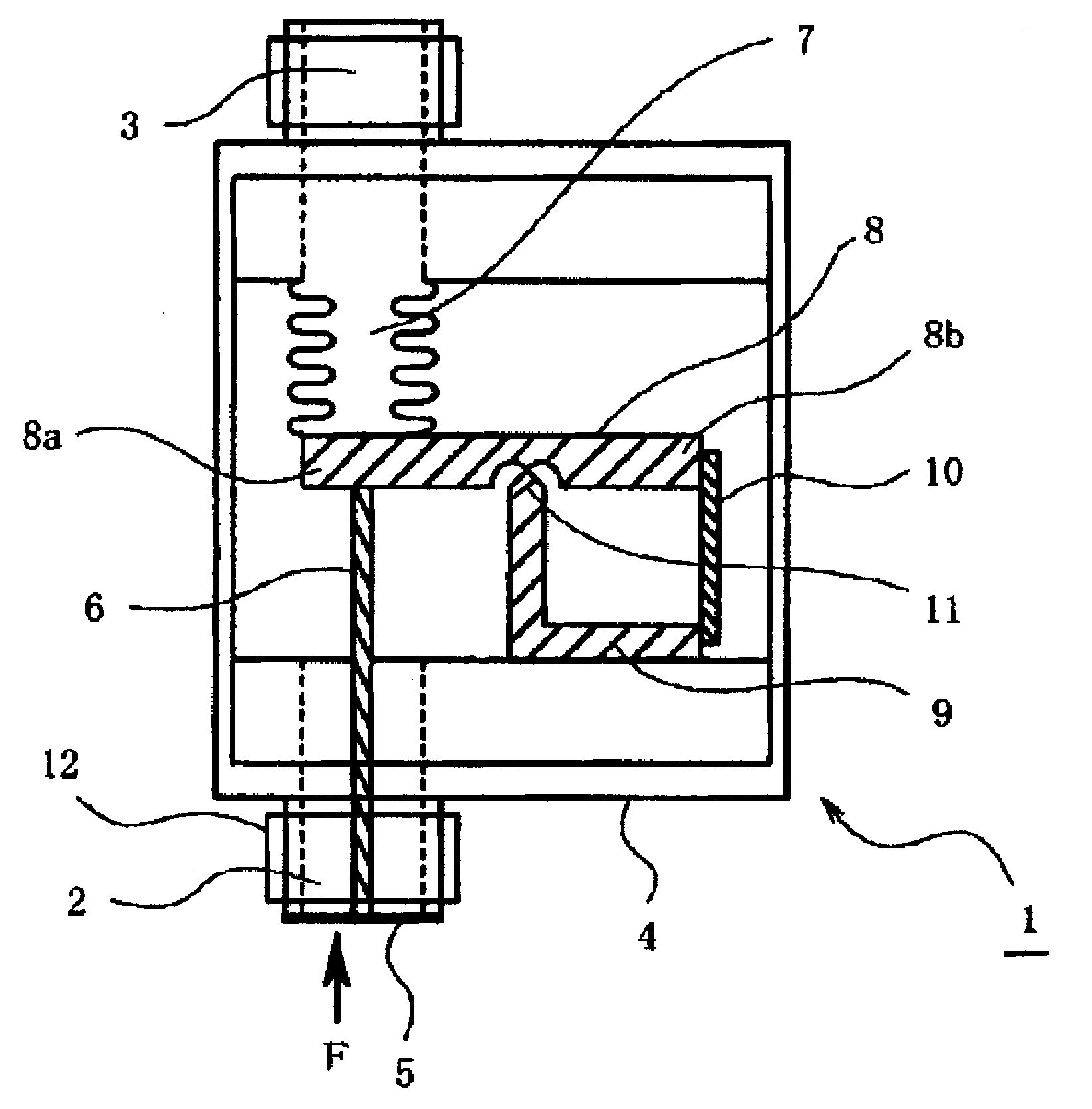

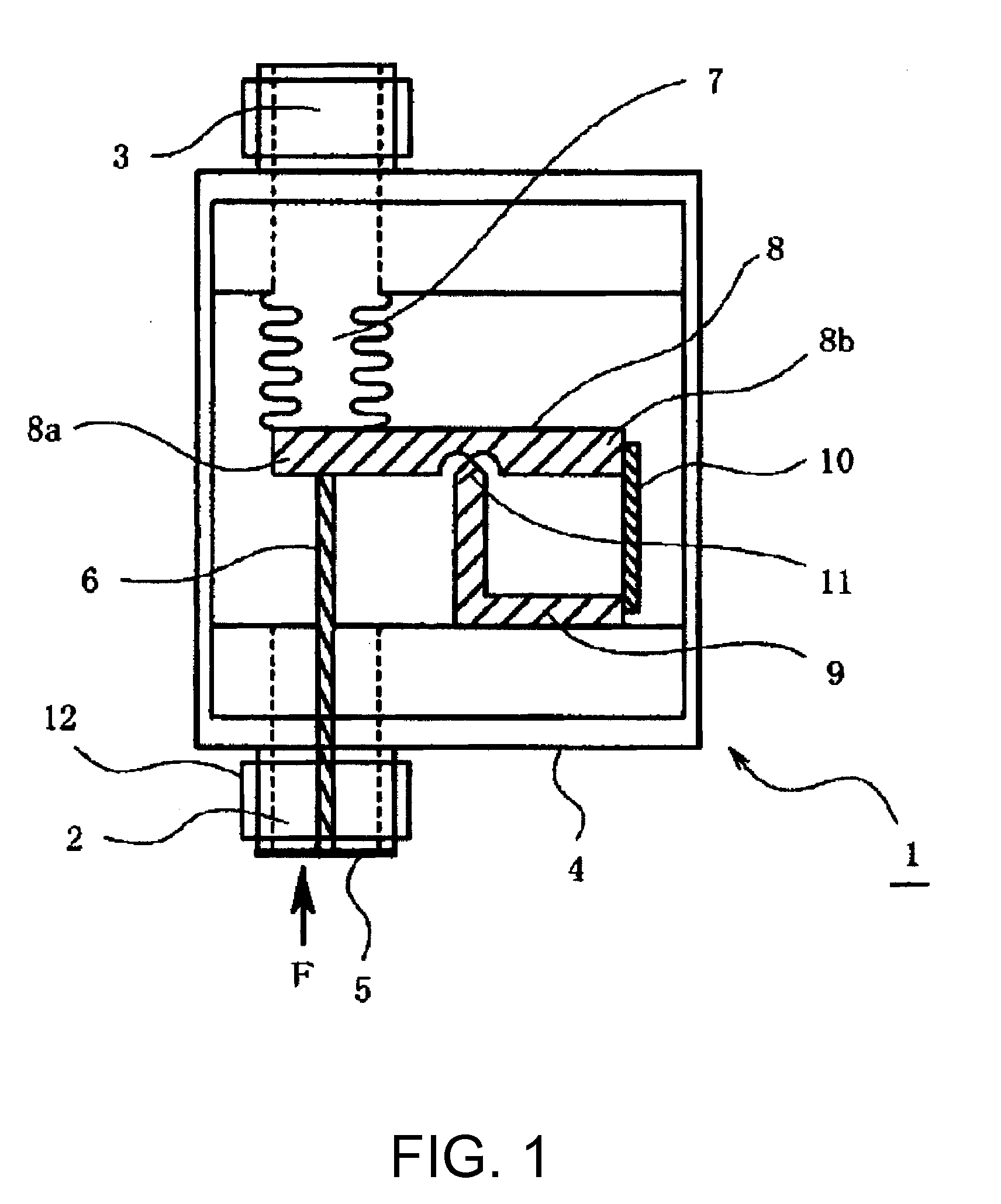

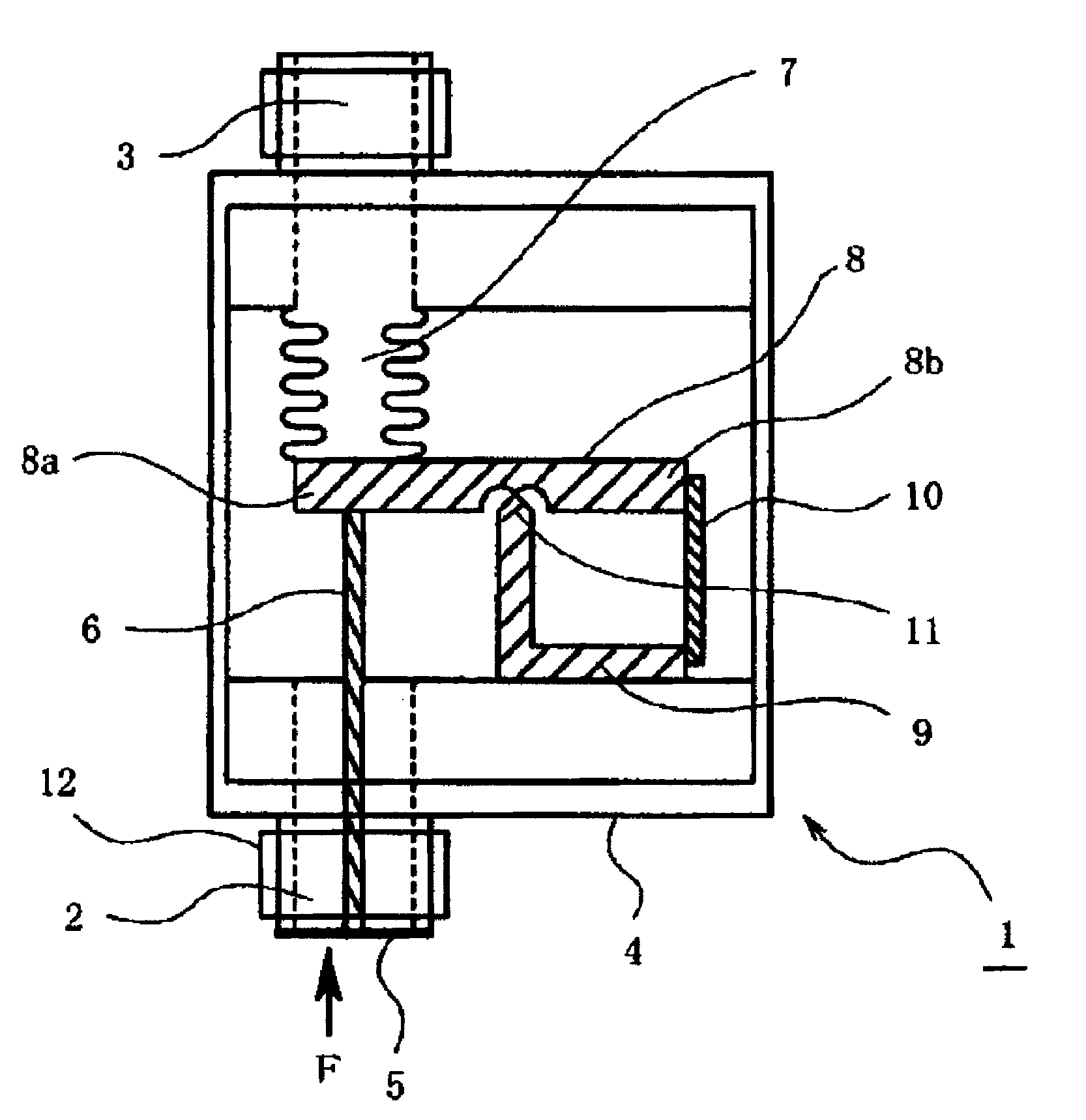

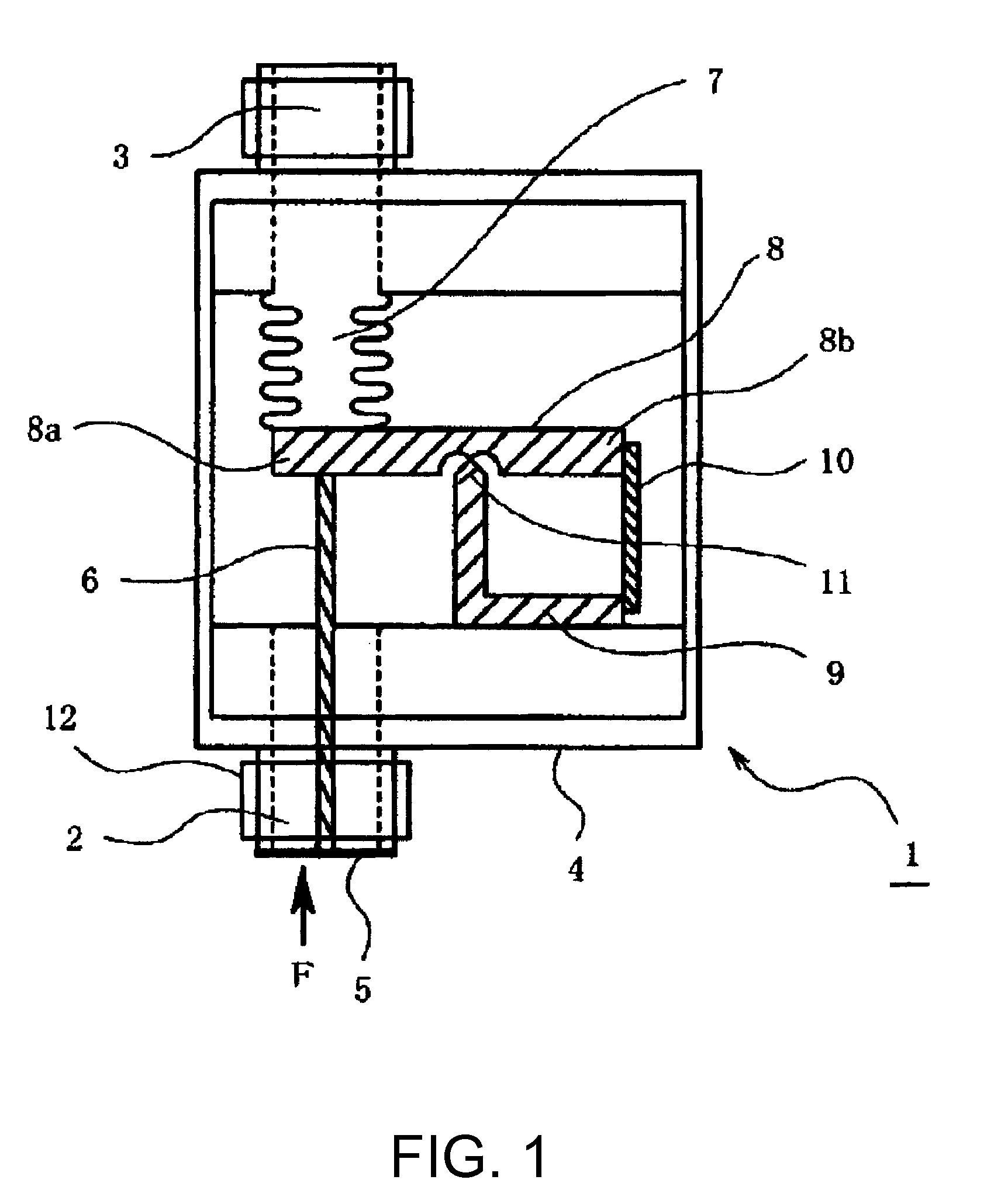

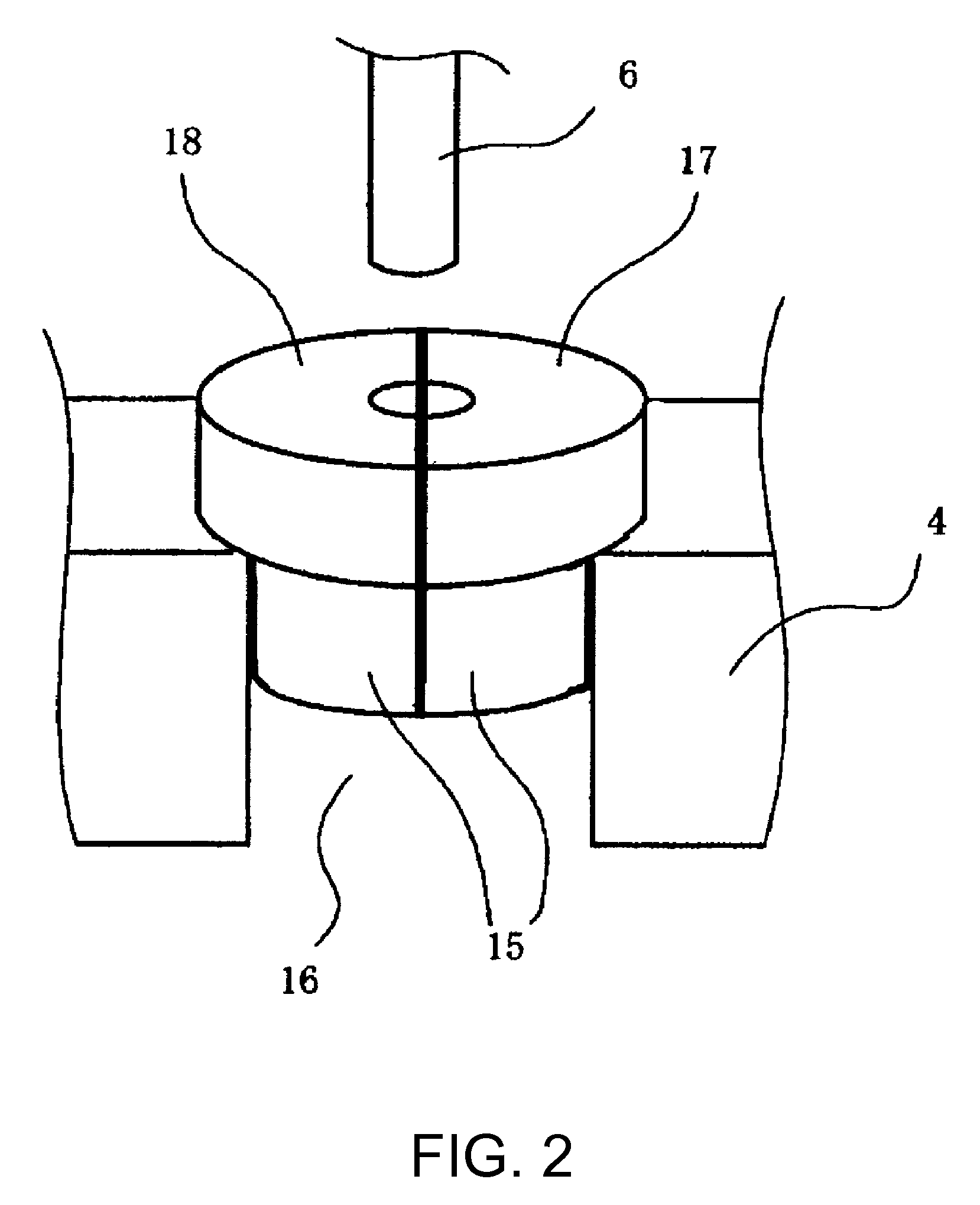

Pressure sensor and method for manufacturing the same

InactiveUS20090241678A1Eliminate needQ-factor can be increasedFluid pressure measurement using piezo-electric devicesFluid pressure measurement using elastically-deformable gaugesPressure senseEngineering

A pressure sensor includes: a housing; an attachment having a pressure input orifice communicating with an interior of the housing; a first diaphragm that seals an opening of the pressure input orifice of the attachment, an external surface of the first diaphragm being a pressure receiving surface; a force transmitting member having an end which is coupled approximately perpendicular to a main surface of the first diaphragm, the main surface being opposite from the pressure receiving surface; a swing arm which is joined to the force transmitting member and is held to a retainer at a pivoting point as a fulcrum; and a pressure sensing element having a first end coupled to the retainer and a second end coupled to the swing arm, so that a displacement direction of the force transmitting member is the same direction as a line joining the first end and the second end. In this pressure sensor, the force transmitting member, the swing arm, the pressure sensing element, and the retainer are housed inside the housing, and the retainer is fixed to an inner wall of the housing.

Owner:SEIKO EPSON CORP

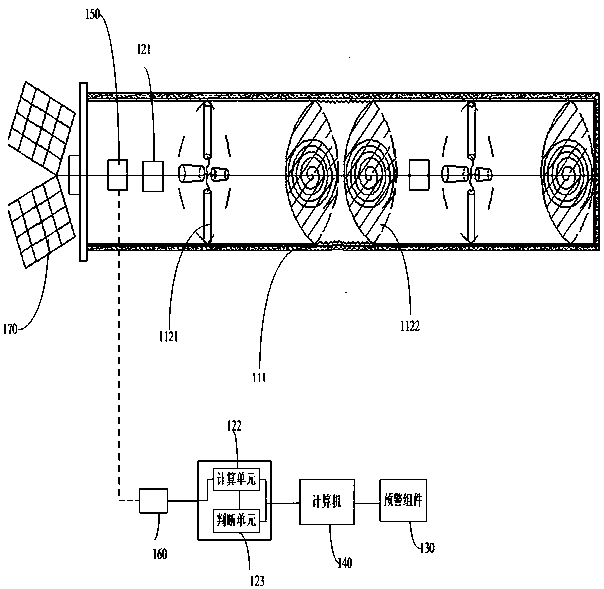

Monitoring early-warning device for slope deformation

InactiveCN108106595AEnsure long-term stabilityEnsure safetyBatteries circuit arrangementsMeasurement devicesContinuous/uninterruptedDeformation monitoring

The invention discloses a monitoring early-warning device for slope deformation. Through performing integrated comprehensive observation on the surface and the inner deformation developing condition of a slope, large measuring range and wide application range are realized, and the monitoring early-warning device can be used for safety early-warning of various slope projects. Through uninterruptedall-weather automatic monitoring, relatively high continuous observing capability, high precision and high durability are realized; the monitoring early-warning device is not limited by sighting condition, geological condition of the project, weather condition, observing range, time and the like; low effect of man factors to the observing precision is realized; the monitoring early-warning deviceis particularly suitable for long-term deformation monitoring of the large-size complicated slope; the monitoring early-warning device realizes automatic observing, automatic acquisition, automatic storage and automatic data analysis; the abnormities such as small deformation and relatively large crack of the slope can be monitored at a relatively early period, thereby realizing in-time and effective monitoring information feedback, reducing conditions such as mis-judgment and judgment omission; a sufficient scientific technology ensuring basis is supplied for researching the deformation characteristic, the evolution rule and project reinforcing treatment of the slope, thereby ensuring long-term stability and safety of a slope project.

Owner:TAIYUAN UNIV OF TECH

Fluorescence-method dissolved oxygen sensor

PendingCN111678899AImprove stabilityHigh precisionThermometers using physical/chemical changesFluorescence/phosphorescenceSignal processing circuitsPhotovoltaic detectors

The invention discloses a fluorescence-method dissolved oxygen sensor, which comprises a measuring light path, a signal processing circuit, a shell body, an outgoing cable and a temperature sensor, wherein the measurement light path comprises a fluorescent film, an optical filter, a photoelectric detector, an excitation light source and a reference light source; the fluorescent film comprises a waterproof breathable film, a fluorescent layer and a colorless transparent glass sheet, the inner surface of the waterproof breathable film is coated with the fluorescent layer, and the colorless transparent glass sheet is bonded to the inner surface of the fluorescent layer; the fluorescent film is located at the head part of the shell body, the optical filter is located between the fluorescent film and the photoelectric detector, and the photoelectric detector is located behind the optical filter and connected with the signal processing circuit; the reference light source and the excitation light source are fixed on two sides in the shell body and are positioned on the same horizontal plane with the optical filter; and the temperature sensor is arranged on the inner wall of the shell bodyand is fixed between the optical filter and the fluorescent film. According to the fluorescence-method dissolved oxygen sensor, the fluorescent film can be prevented from falling off, much diffused light and secondary reflection are avoided, and the measurement precision and stability are improved.

Owner:HAINAN UNICAN SCI & TECH INNOVATION INST CO LTD

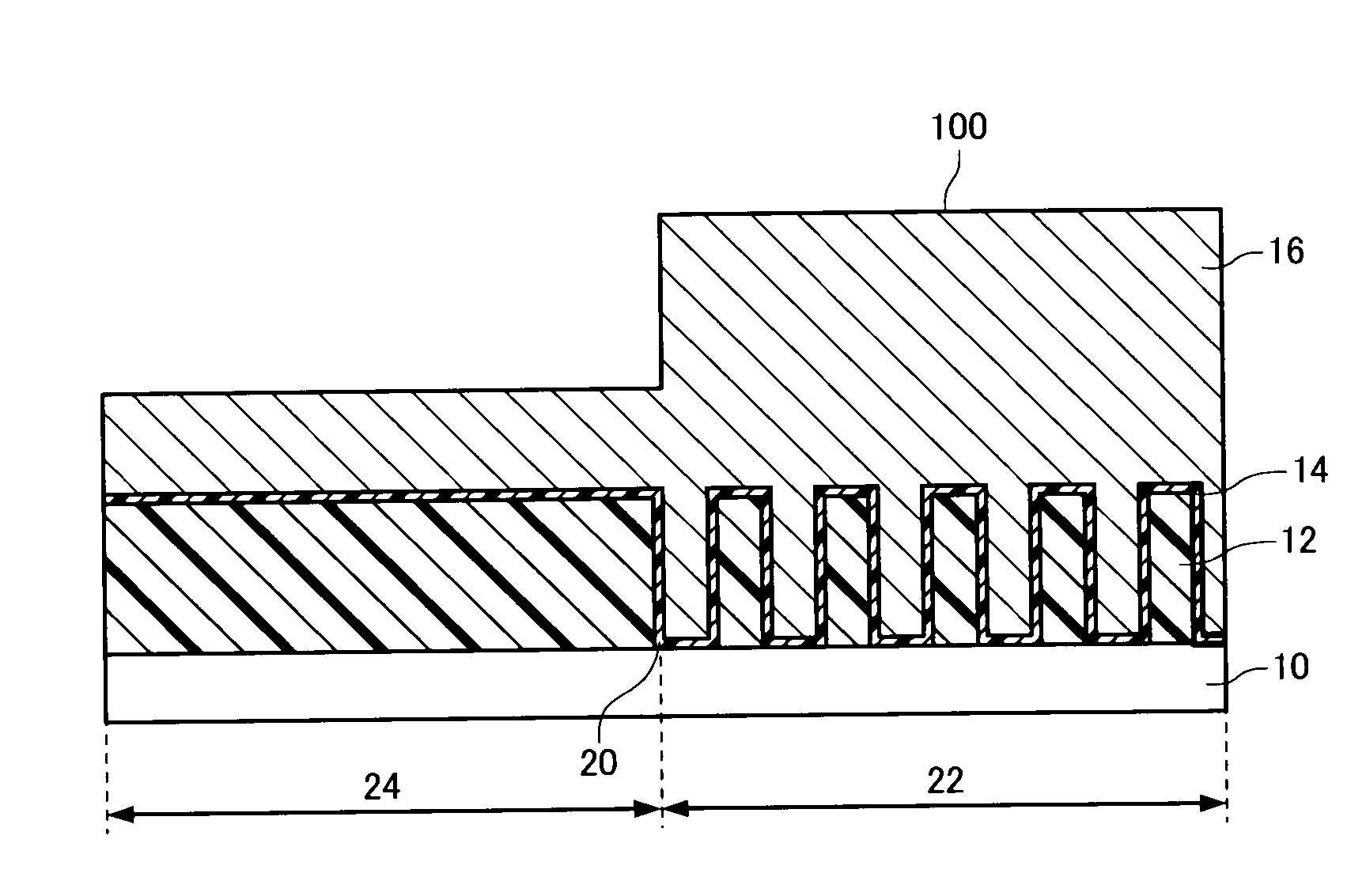

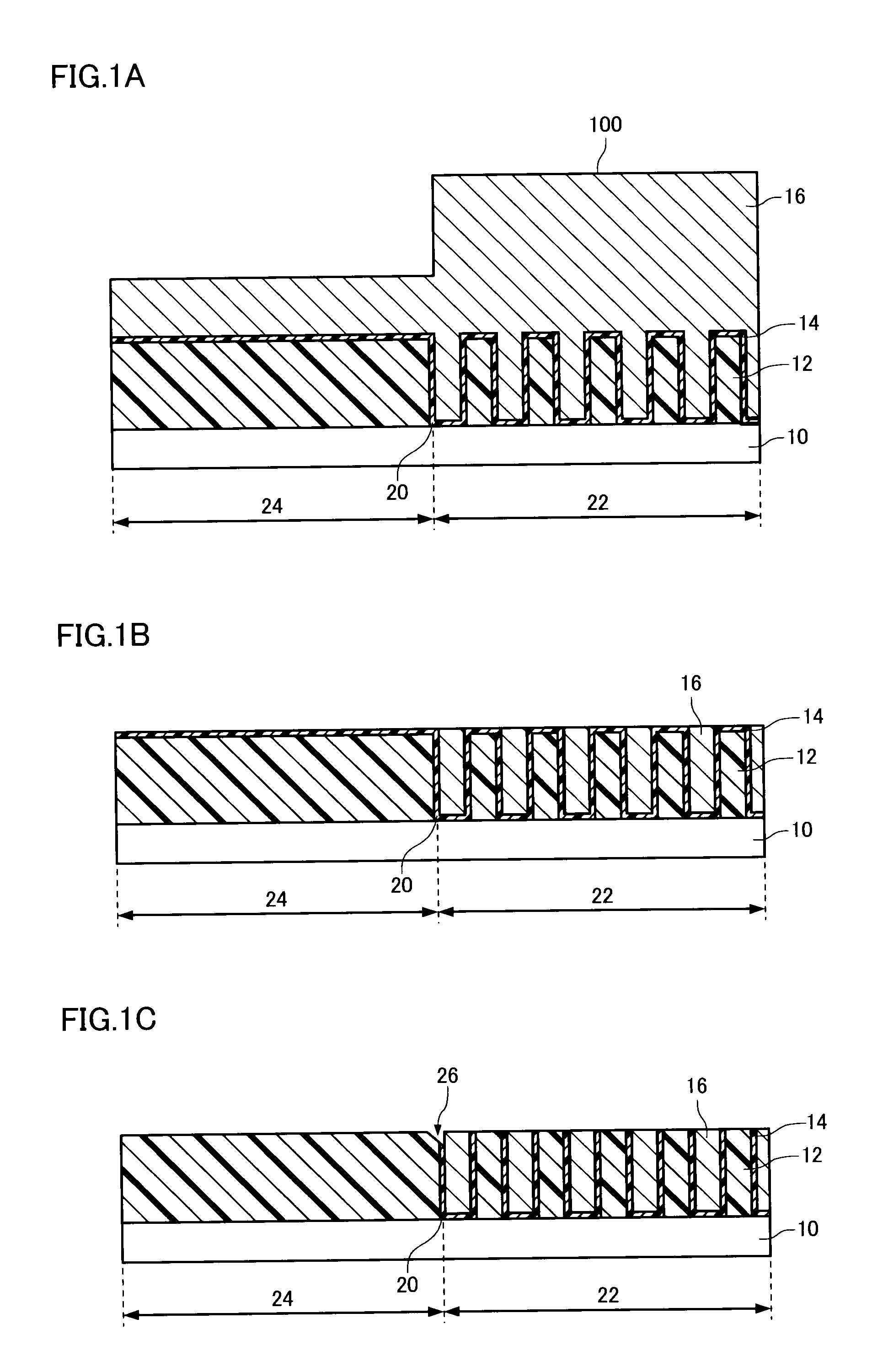

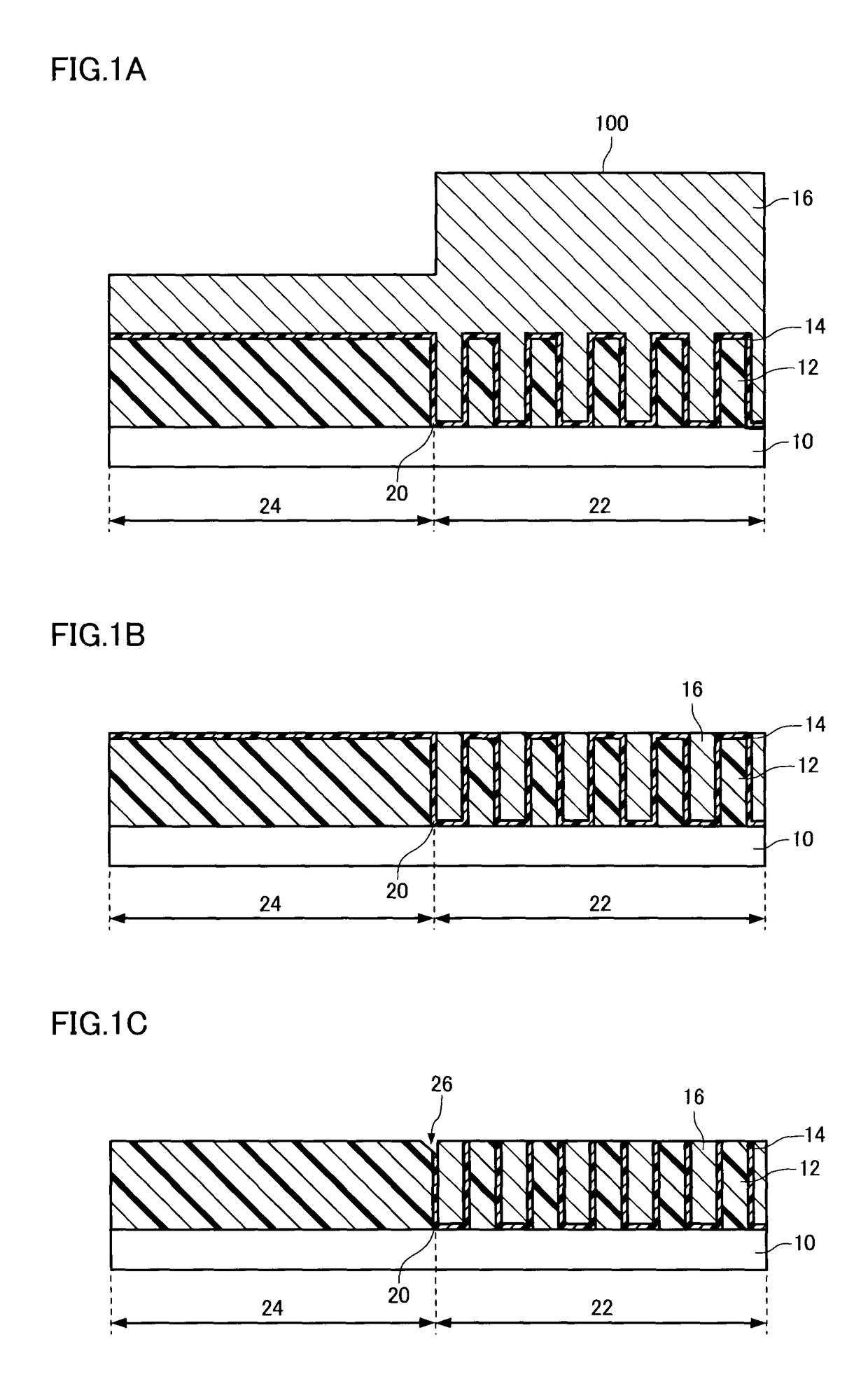

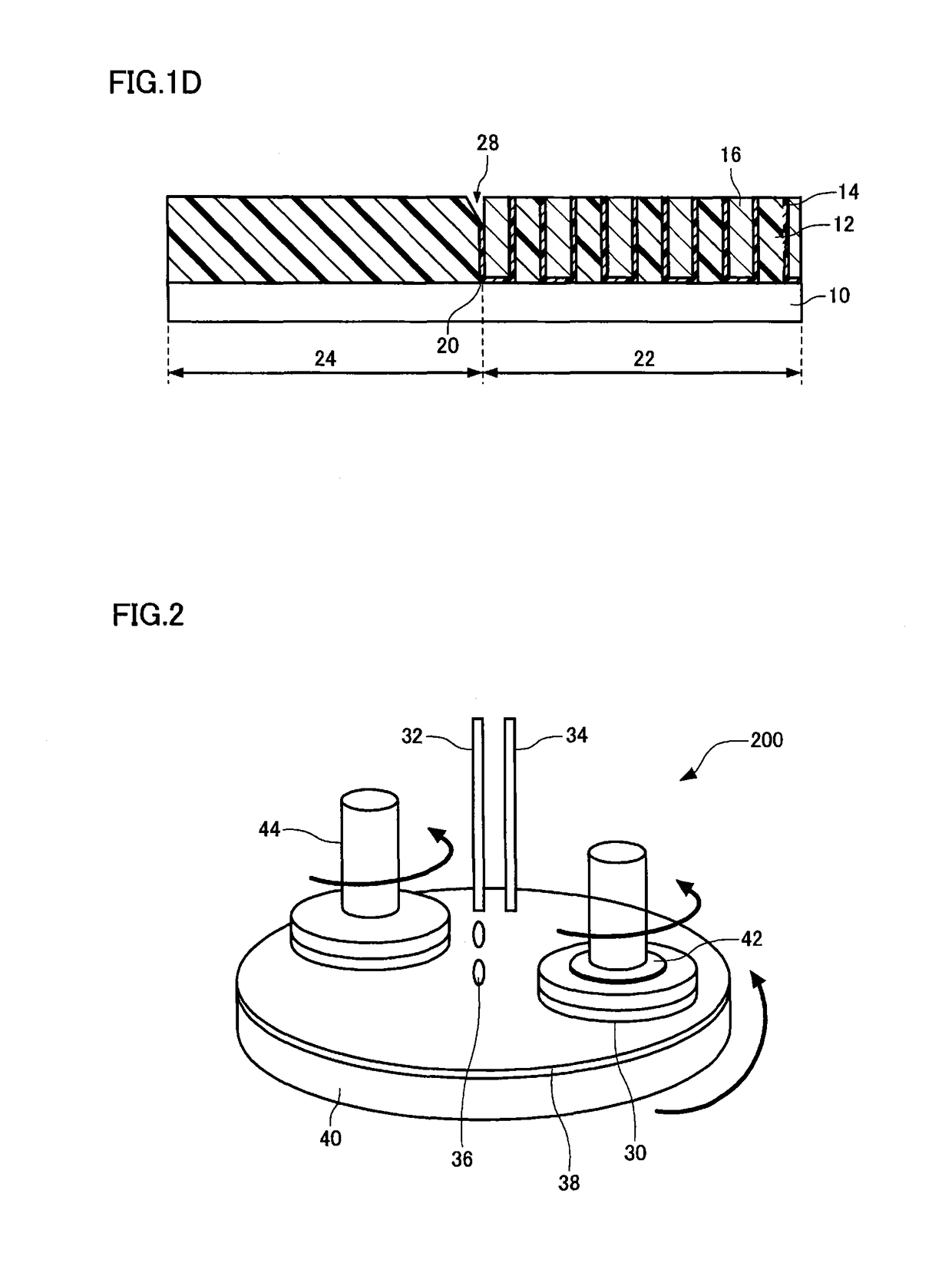

Conductive paste for multilayer electronic components and multilayer electronic component using same

ActiveUS7423220B2More freedomReduce the amount requiredSemiconductor/solid-state device detailsConductive materialConductive pasteElectricity

A conductive paste for multilayer electronic components which is to be directly printed on a ceramic green sheet, the conductive paste contains a conductive powder, a resin and an organic solvent, wherein the organic solvent contains at least one solvent selected from an alkylene glycol diacetate and an alkylene glycol dipropionate. A multilayer electronic component is obtained by firing at high temperature an unfired laminate prepared by alternately stacking ceramic green sheets and internal electrode paste layers in which each of the internal electrode paste layers is formed by the above conductive paste. The conductive paste has appropriate viscosity characteristics and long-term stability, which allows manufacturing highly reliable multilayer electronic components having excellent electrical characteristics, without causing sheet attack.

Owner:SHOEI CHEM IND CO LTD

Pressure sensor and method for manufacturing the same

InactiveUS7942062B2Eliminate needGood temperature characteristicsFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsPressure senseEngineering

A pressure sensor includes: a housing; an attachment having a pressure input orifice communicating with an interior of the housing; a first diaphragm that seals an opening of the pressure input orifice of the attachment, an external surface of the first diaphragm being a pressure receiving surface; a force transmitting member having an end which is coupled approximately perpendicular to a main surface of the first diaphragm, the main surface being opposite from the pressure receiving surface; a swing arm which is joined to the force transmitting member and is held to a retainer at a pivoting point as a fulcrum; and a pressure sensing element having a first end coupled to the retainer and a second end coupled to the swing arm, so that a displacement direction of the force transmitting member is the same direction as a line joining the first end and the second end. In this pressure sensor, the force transmitting member, the swing arm, the pressure sensing element, and the retainer are housed inside the housing, and the retainer is fixed to an inner wall of the housing.

Owner:SEIKO EPSON CORP

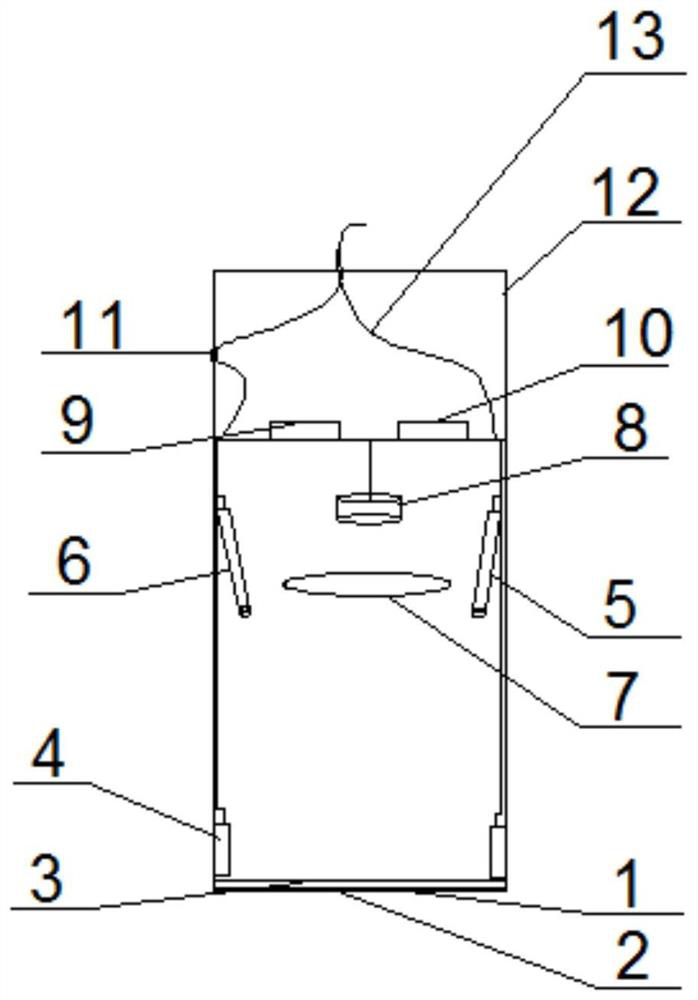

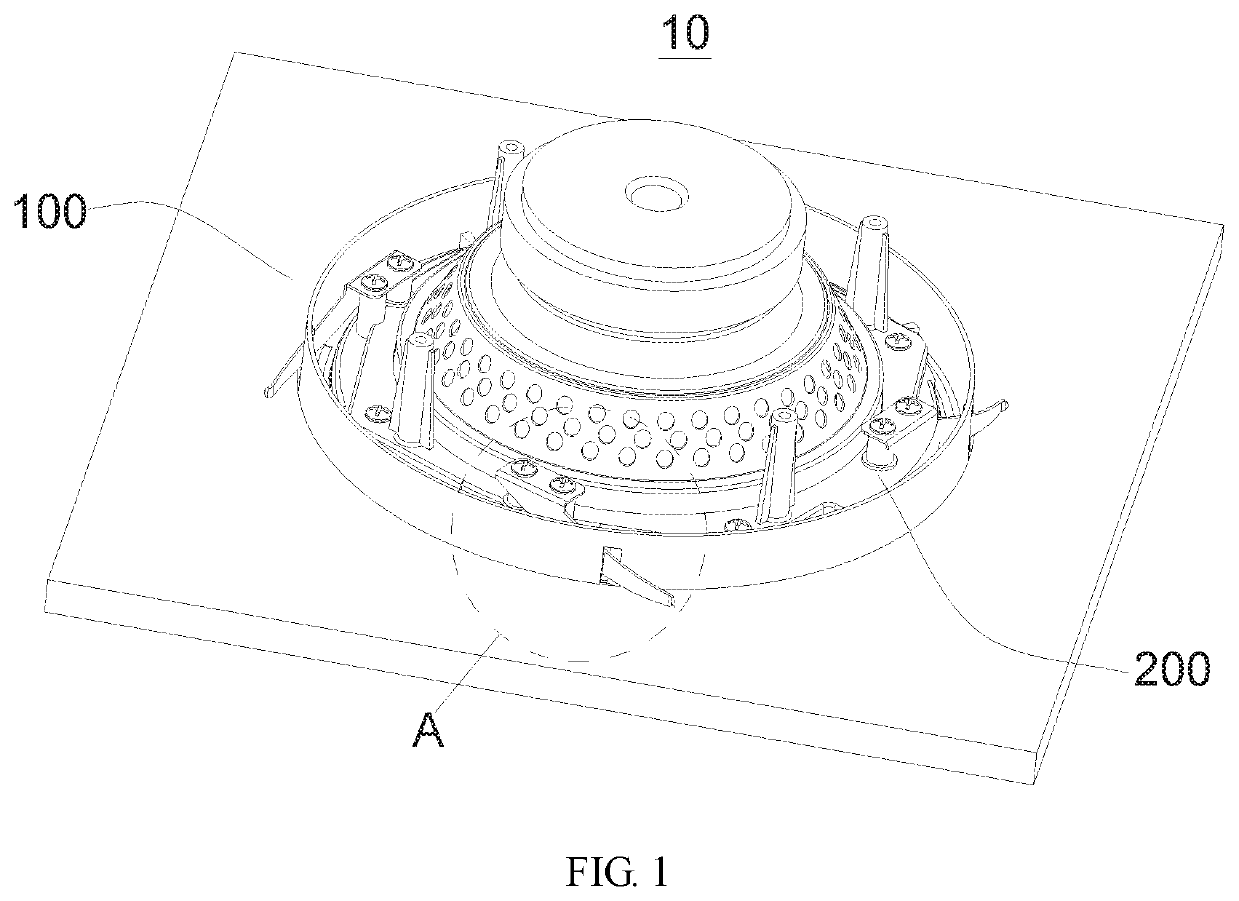

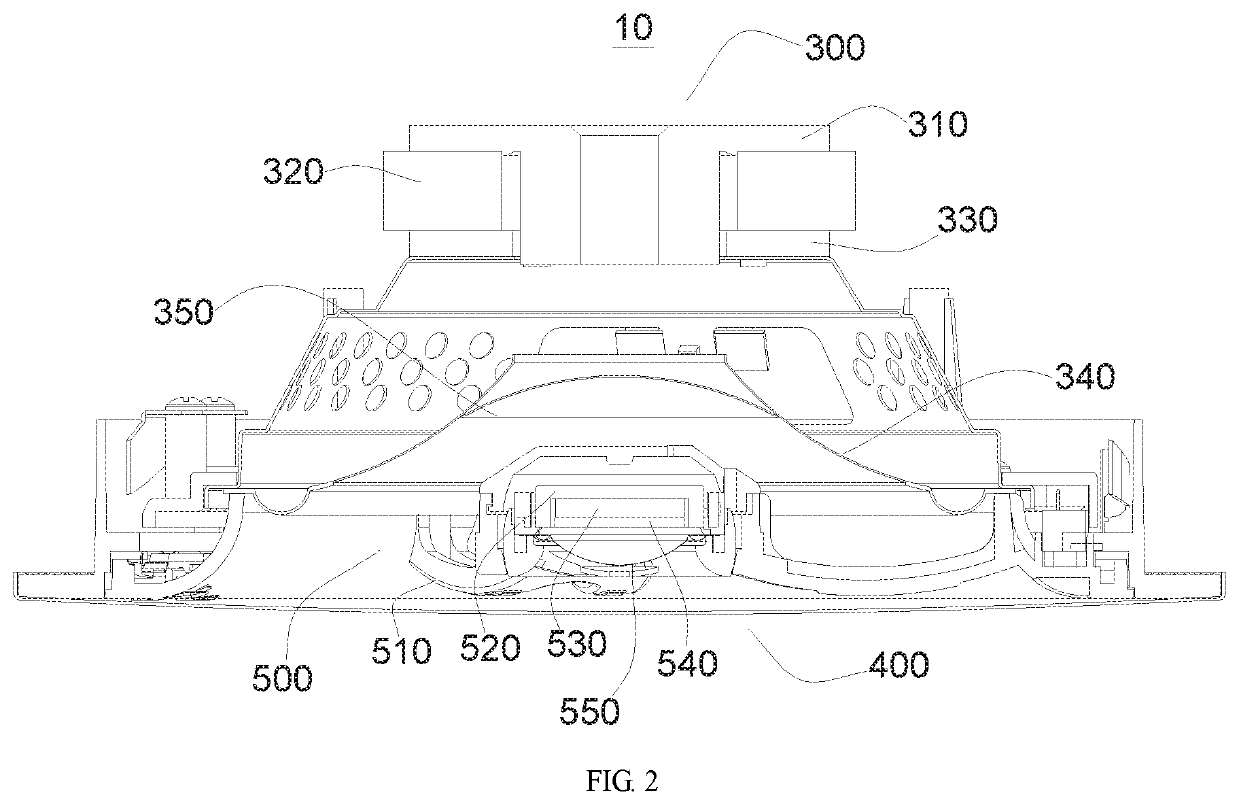

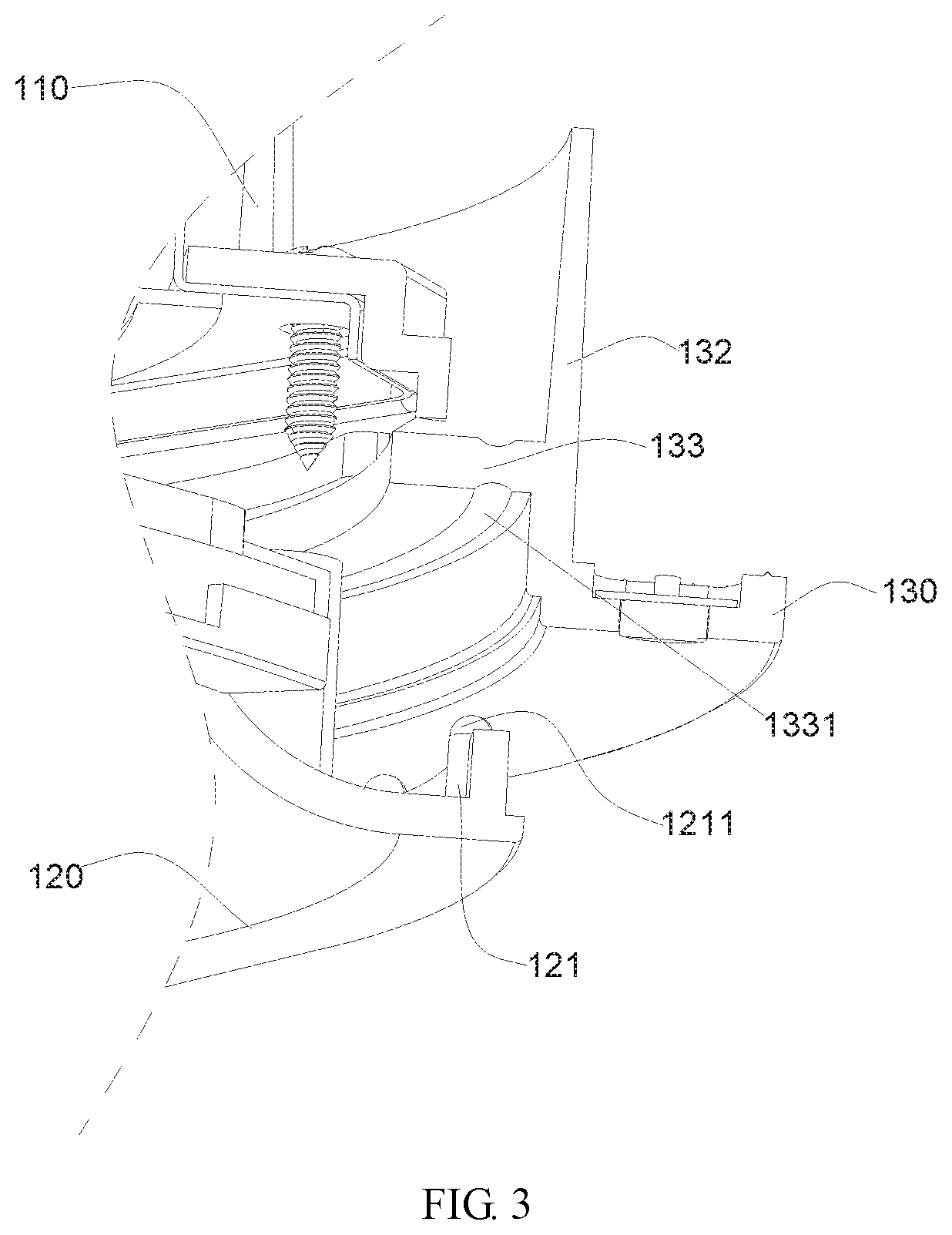

Rapidly mountable ceiling loudspeaker device

ActiveUS10659857B1Efficient disassemblyEndangering personal safetyMicrophonesLoudspeaker transducer fixingWooferMechanical engineering

The invention discloses a rapidly mountable ceiling loudspeaker device comprising a loudspeaker housing, a ceiling locking assembly, a woofer module and a dustproof assembly. The loudspeaker housing comprises a basket, a speaker inner frame and a surface frame ring body; the ceiling locking assembly comprises a locking sleeve body, a ceiling locking piece and a locking member; the woofer module is arranged in the basket; and the dustproof assembly is arranged on the speaker inner frame. After the scheme is employed, the ceiling loudspeaker device can be efficiently assembled and disassembled without the aid of a mounting tool.

Owner:HUIZHOU INNOVATIVE AUDIO PROD CO LTD

Photo electrodes

ActiveUS8673810B2Improve uniformityImprove adhesionMaterial nanotechnologyCatalyst protectionNanoparticleEngineering

Methods of fabricating nano particulate Titanium dioxide photocatalysts onto a conducting substrate are disclosed. The methods include hydrothermal fabrications with heat treatment steps to increase the crystallinity and photoactivity of the titanium dioxide layers.

Owner:579453 ONTARIO INC

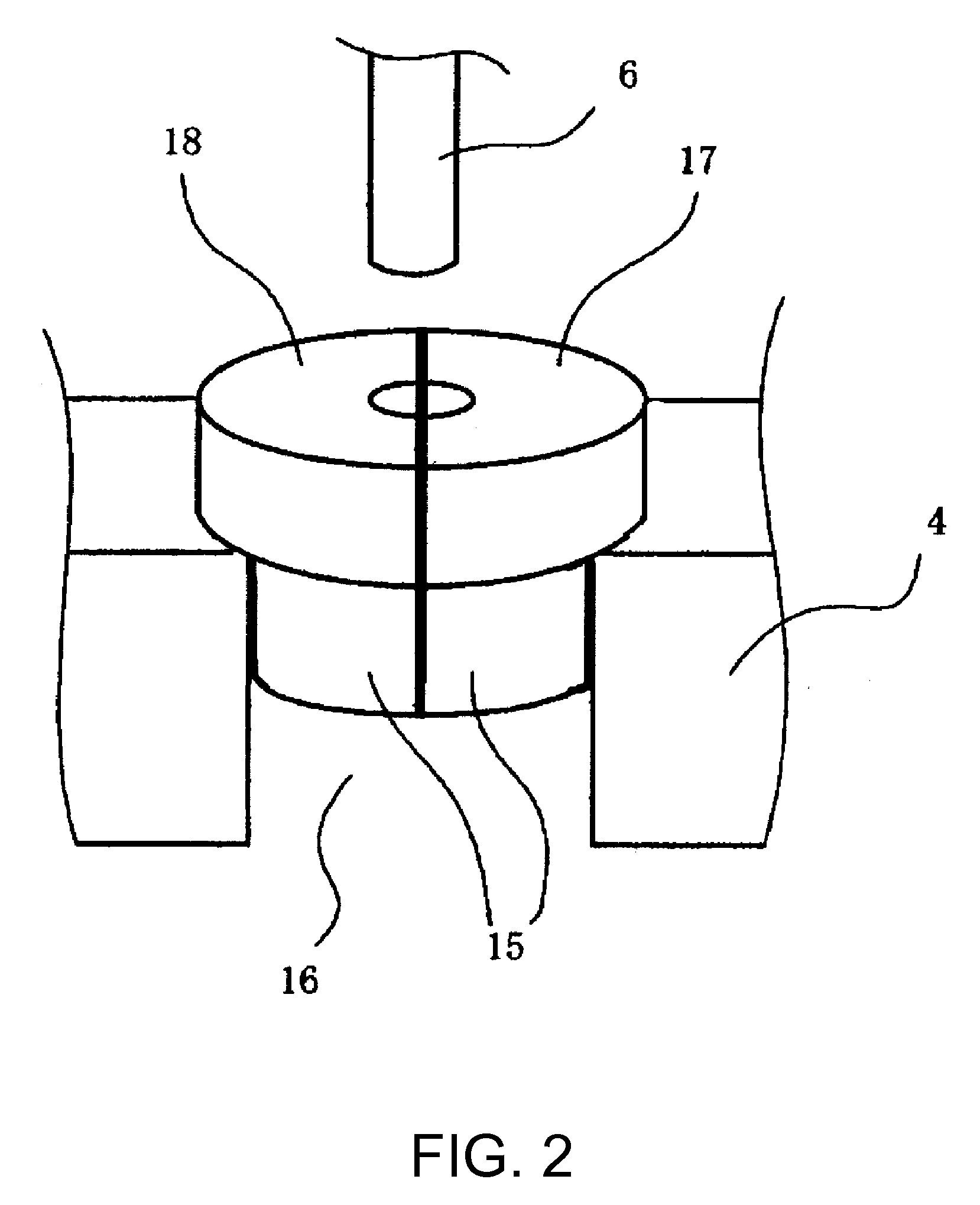

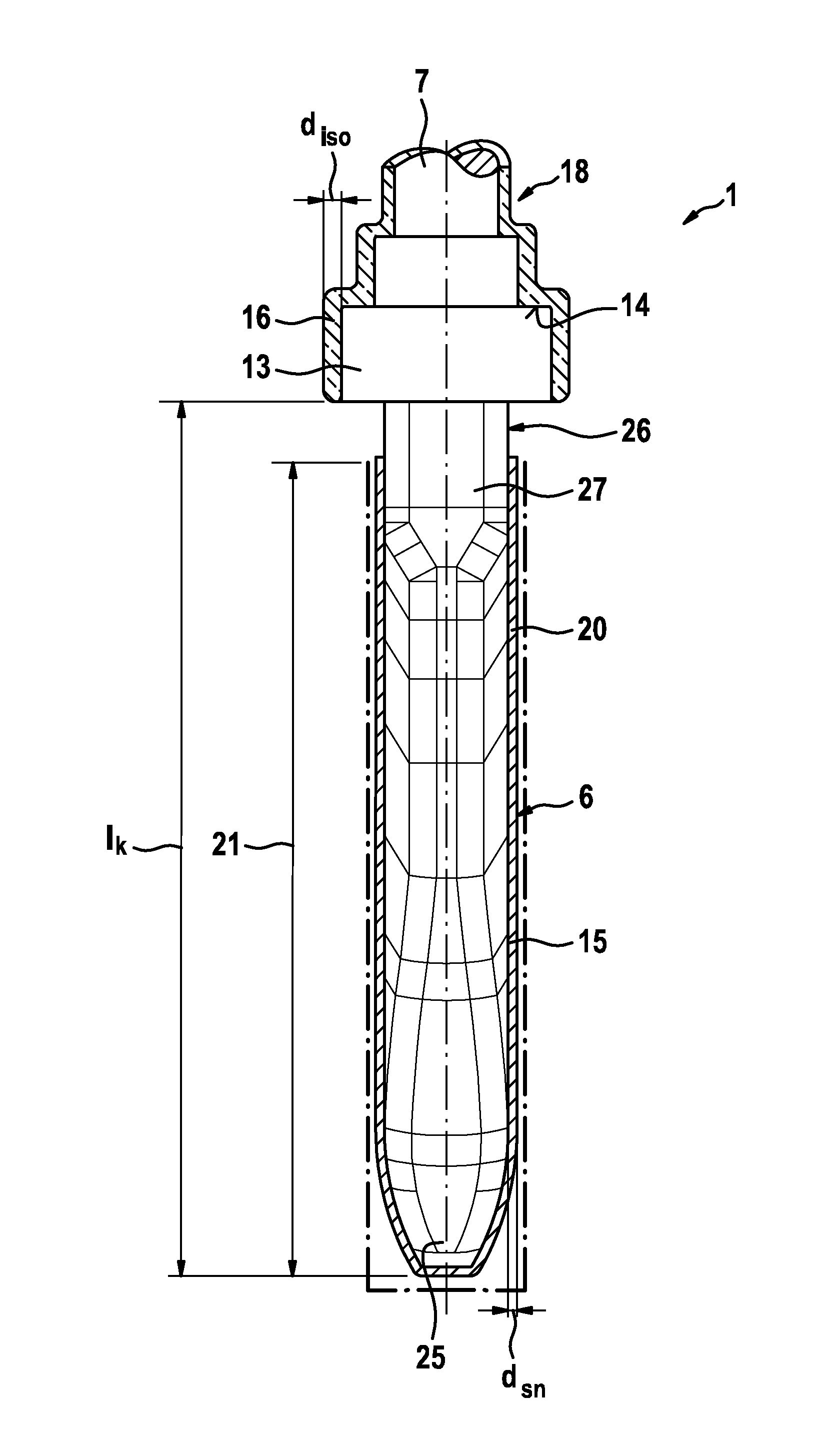

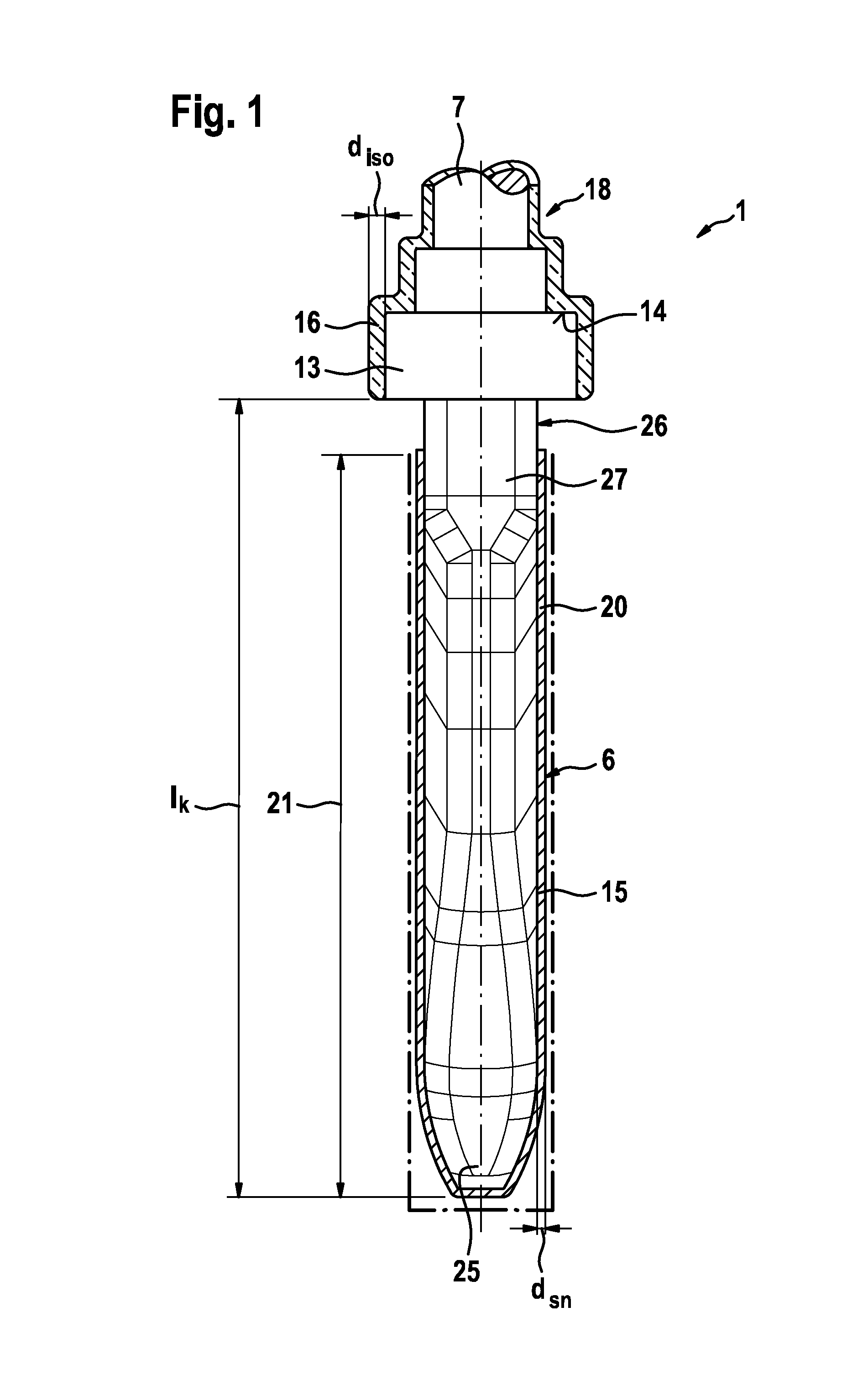

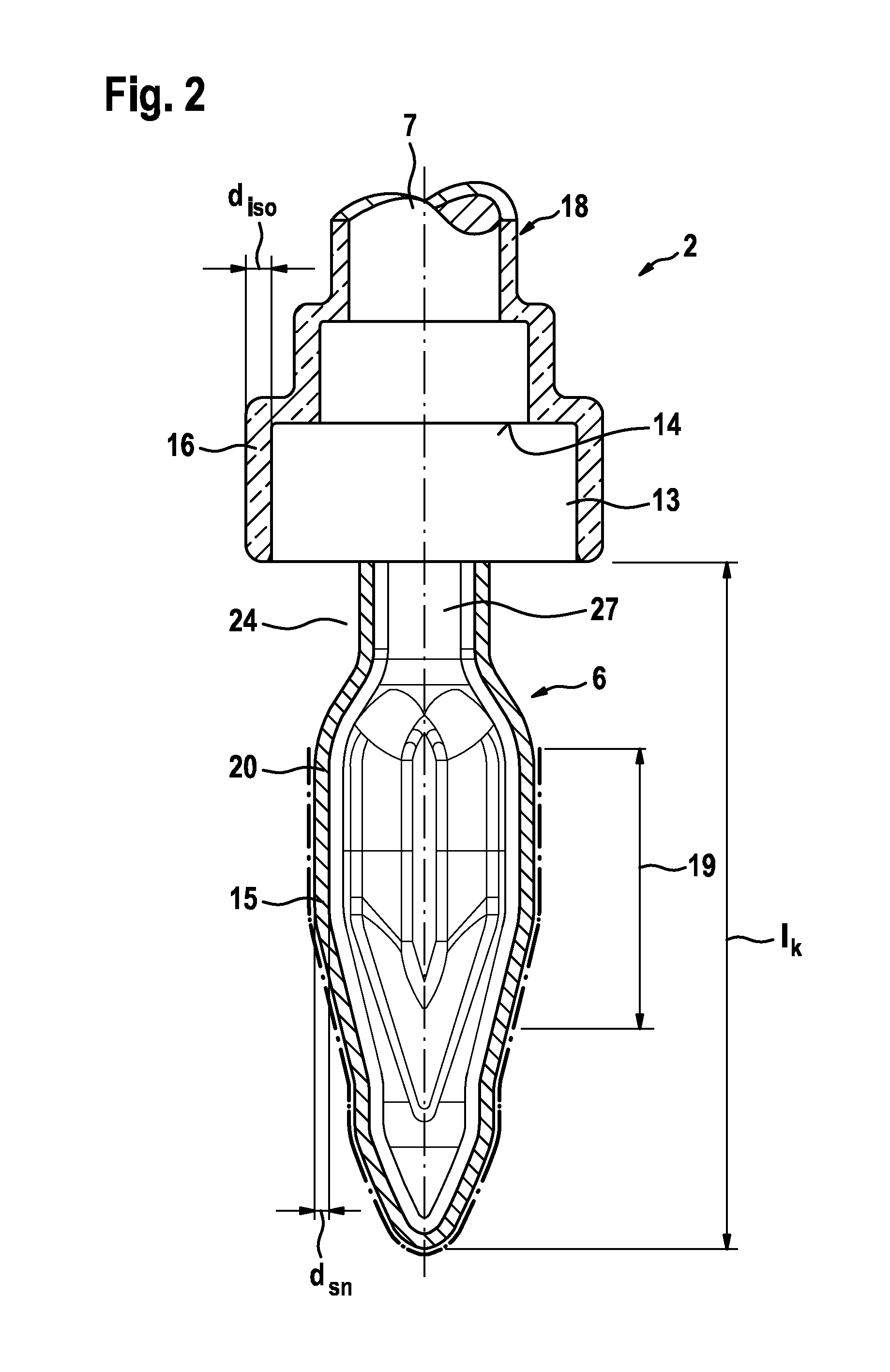

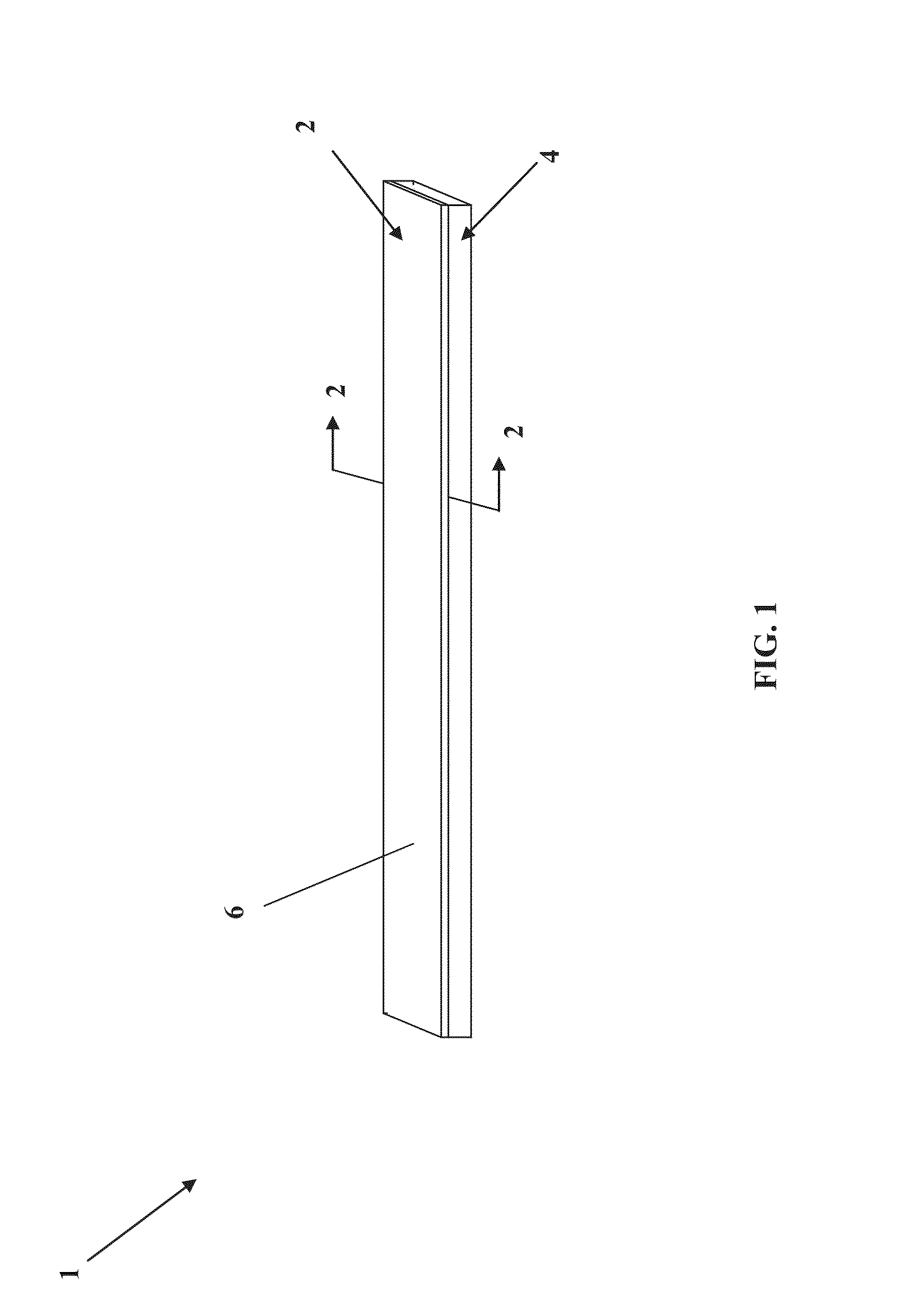

Press-in pin for an electrical press-in connection between an electronic component and a substrate plate

ActiveUS9331412B2Ensure long-term stabilitySecuring/insulating coupling contact membersCoupling contact membersAlloyEngineering

The invention relates to a press-in pin (1, 2) for an electrical press-in connection between an electronic component (3) and a substrate plate (4) with an electrical contact hole (5). The press-in pin (1, 2) has a press-in pin head (6) which has a press-in head length (IK) which is matched to a thickness (d) of the substrate plate (4). A press-in pin leg (7) extends between the electronic component (3) and the press-in pin head (6). A press-in pin collar (13) forms a transition between the press-in pin leg (7) and the press-in pin head (6) and has a locking projection (14). The press-in pin head (6) is coated with a layer (20) of a lead-free tin alloy (15). At least the press-in pin collar (13) with the locking projection (14) has an electrically insulating coating (16).

Owner:ROBERT BOSCH GMBH

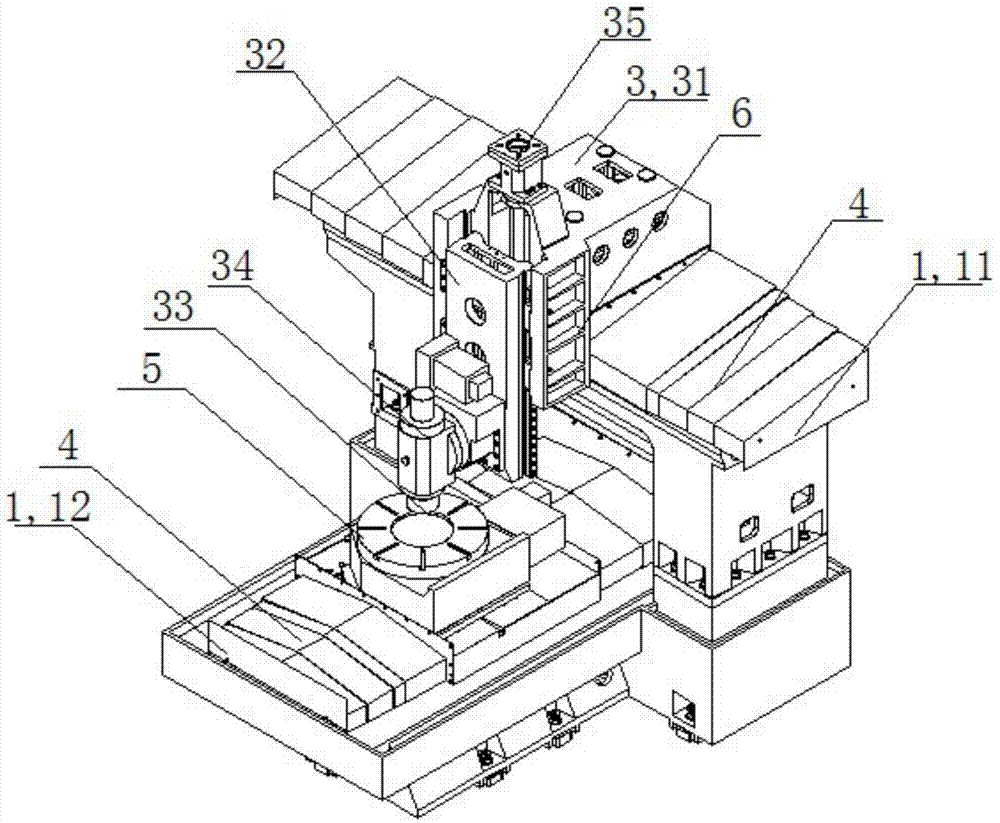

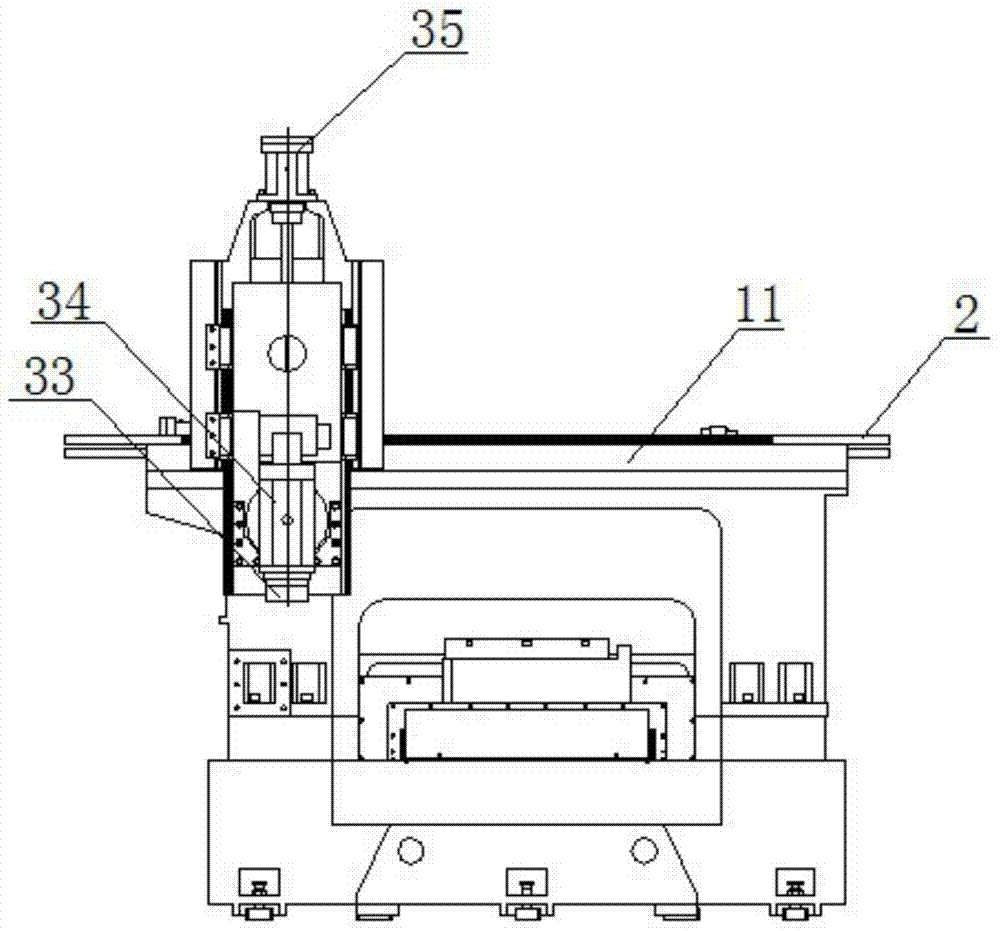

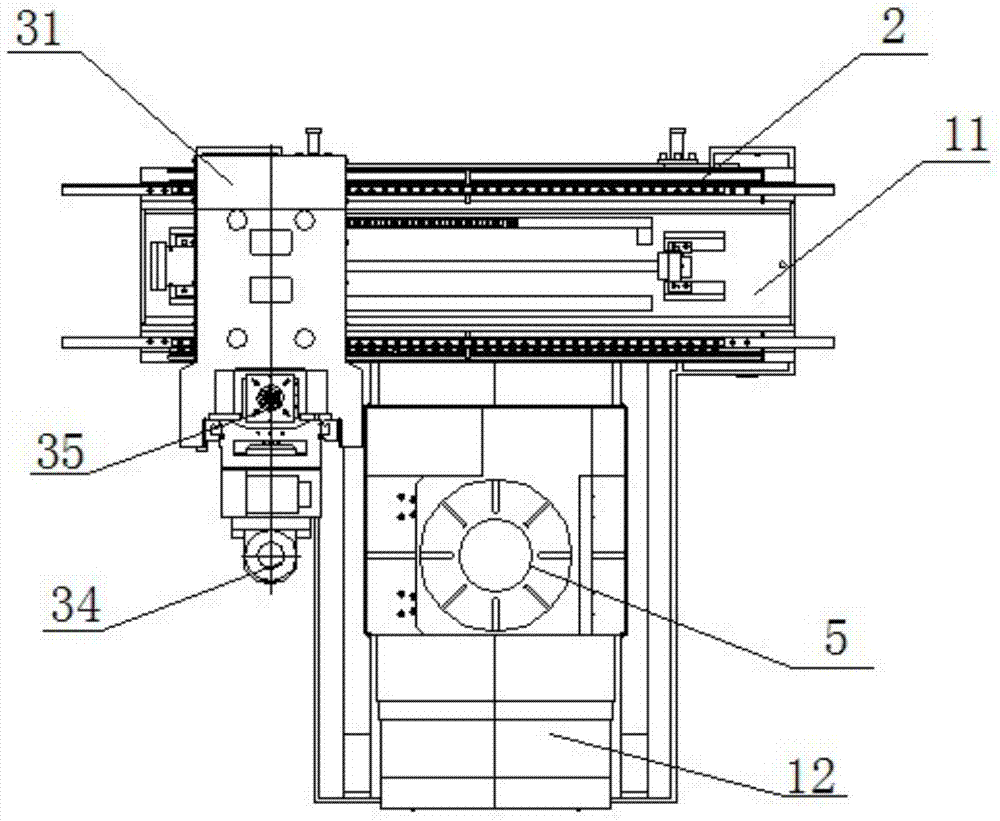

Five-axis high-speed precision-machining numerical control machine tool

InactiveCN104723117AImprove rigidityEnsure machining accuracyLarge fixed membersMaintainance and safety accessoriesLow noiseNumerical control

The invention relates to the field of machining, in particular to a five-axis high-speed precision-machining numerical control machine tool. The five-axis high-speed precision-machining numerical control machine tool comprises a T-shaped machine tool bed, the machine tool bed comprises a transverse machine tool bed body in an X-axis direction and a vertical machine tool bed body in a Y-axis direction, slide rails are arranged on both of the transverse machine tool bed body and the vertical machine tool bed body, and high-precision roller linear guide rails are adopted to serve as the slide rails. The five-axis high-speed precision-machining numerical control machine tool has the advantages that the machine tool is arranged in a high-reinforcement structure and subjected to multiple times of artificial aging treatment so as to achieve high vibration resistance and high rigidity and ensure machining precision and long-term stability; the high-precision roller linear guide rails are adopted on the machine tool bed bodies in the X-axis direction, the Y-axis direction and a Z-axis direction to achieve high rigidity, low noise, small frictional characteristic, precise positioning and the like, quick movement is achieved, machining efficiency and part size precision are improved substantially, and yield of machine tool products is increased.

Owner:CHANGZHOU TRANSCEND CNC MACHINE TOOL

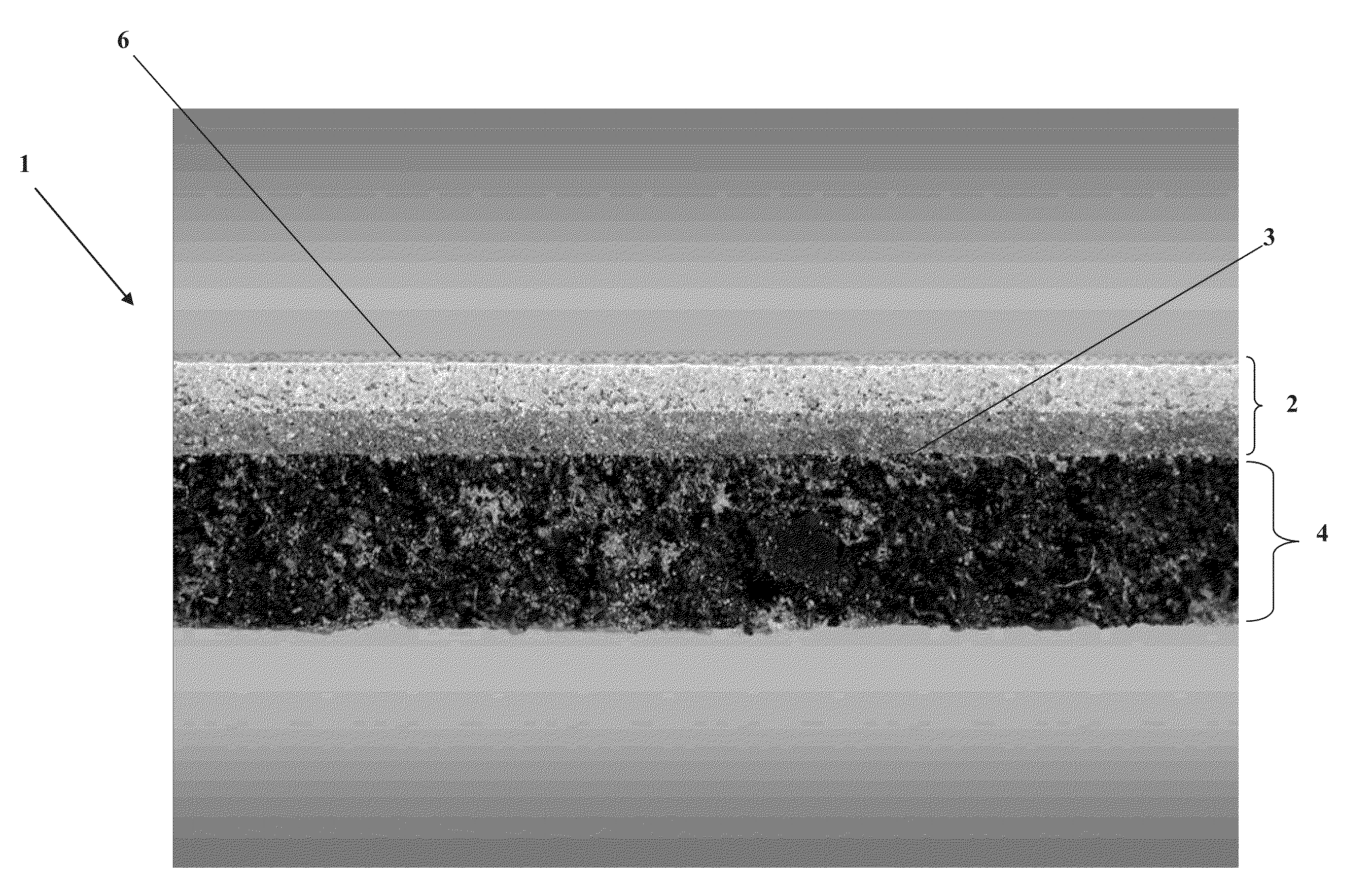

Acoustical Vinyl Flooring and Methods of Manufacture

An acoustical vinyl tile having an integral acoustical layer is disclosed. The vinyl tile includes a vinyl portion, an acoustical portion, and an adhesive layer for fixing the vinyl portion to the acoustical portion. The acoustical portion comprises a crumb rubber component and a polyurethane foam component. The acoustical portion can include 10-40% crumb rubber and 60-90% polyurethane foam. The resulting vinyl tile meets ASTM E 2179 IIC sound requirements. A method of making a vinyl tile meeting the ASTM sound requirements is also disclosed. The method includes providing a vinyl slab portion, providing an acoustical slab portion comprising crumb rubber, polyurethane foam and a resin binder; and bonding the vinyl slab portion to the acoustical portion. Other embodiments are described and claimed.

Owner:MICHAEL FREEDMAN & ASSOC

Methods for stabilizing heavy metal containing material for disposal in saturated zone

InactiveUS7374367B2Cost-effectiveLong-term remobilization potential of the heavy metal is reducedSolid waste disposalContaminated soil reclamationChemistryAcid neutralizing capacity

A leaching-stabilized heavy metal-contaminated matrix can be stored in a subsurface saturated zone by contacting the matrix with an amount of an agent for increasing acid-neutralization capacity sufficient to provide the stored matrix a preselected permanence level.

Owner:RMT

Communication waveband 1.5 micrometer laser wavelength standard generating method and device thereof

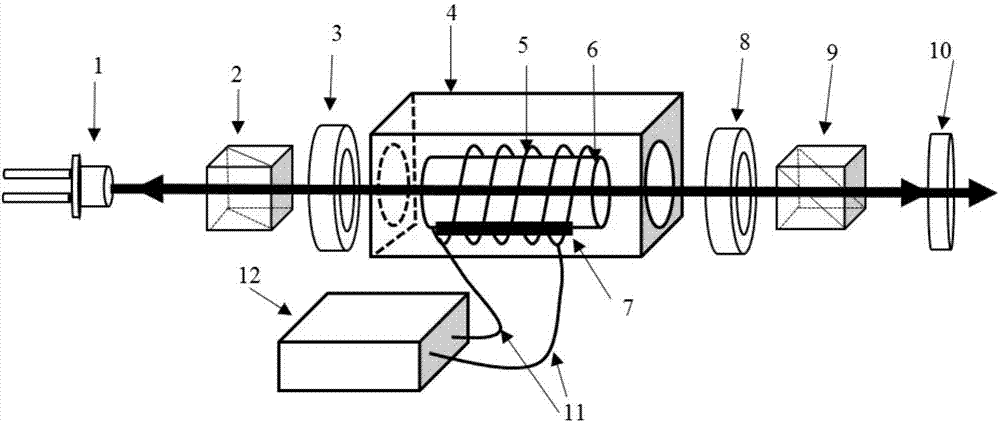

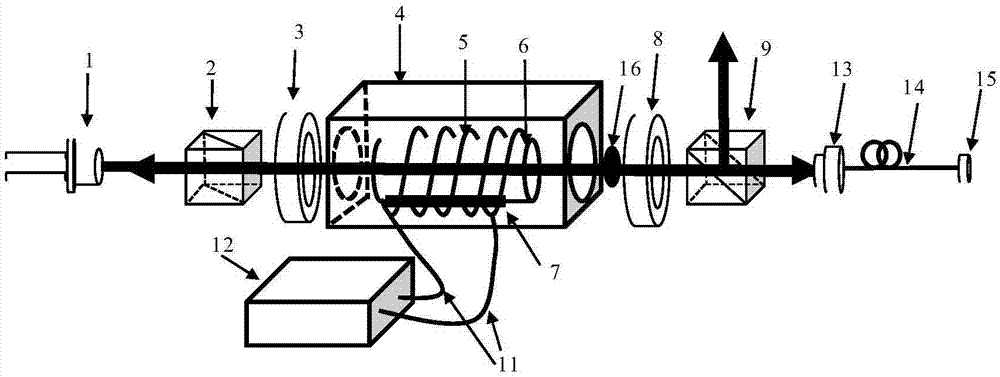

ActiveCN107370016AEnsure long-term stabilityGuaranteed accuracyLaser detailsSemiconductor amplifier structureMicrometerLasing wavelength

The invention provides a communication waveband 1.5 micrometer laser wavelength standard generating method which comprises the steps of (1), making laser which is transmitted from a laser diode with a reflection reducing coating penetrate through an RF excited rubidium atom 5P-4D excitation state 1529nm optical filter, thereby performing selection on the frequency of the laser; (2), performing feedback of the laser after selection to the laser diode; and (3), outputting a laser wavelength standard which forms laser at a 5P-4D transition wavelength that corresponds with rubidium atom filtering. According to the method of the invention, the laser diode with the reflection reducing coating, the RF excited rubidium atom 5P-4D excitation state 1529nm optical filter and a laser chamber mirror are used for performing feedback, and a communication waveband 1.5 micrometer laser wavelength standard is realized. The communication waveband 1.5 micrometer laser wavelength standard has long-term stability and high accuracy and is a novel long-term stable 1.5 micrometer laser wavelength standard in the optical communication field.

Owner:PEKING UNIV

Liquid Human Fibrinogen Composition

InactiveUS20200093896A1Avoiding increasing osmolalityMinimize side effectsOrganic active ingredientsPeptide/protein ingredientsArginineHuman fibrinogen

The invention relates to a pharmaceutical composition comprising between 10 and 30 g / l of fibrinogen, between 10 and 300 mM of arginine and between 10 and 300 mM of glutamate. In addition, the pH of the composition is between 6 and 8.

Owner:LABE FR DU FRACTIONNEMENT & DES BIOTECH SA

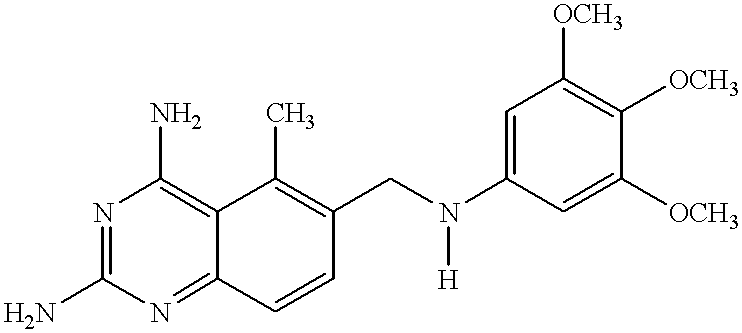

Compositions comprising trimetrexate

InactiveUS6576635B2Improved chemical and physical characteristicLittle color changeBiocidePowder deliveryDiseaseMalaria

This invention is directed to the novel composition of matter trimetrexate ascorbate, to compositions comprising trimetrexate ascorbate, and to compositions comprising trimetrexate and ascorbic acid. These compositions are useful in the treatment of diseases in mammals such as, but not limited to, cancer, bacterial and protozoal infections, malaria, psoriasis, and rheumatoid arthritis. The invention is further related to methods of stabilizing trimetrexate to degradation caused by heat, light, oxygen, or water.

Owner:MEDIMMUNE ONCOLOGY

Chemical mechanical polishing aqueous dispersion preparation set, method of preparing chemical mechanical polishing aqueous dispersion, chemical mechanical polishing aqueous dispersion, and chemical mechanical polishing method

InactiveUS8470195B2Excellent long-term storage stabilityReduce surface defectsOther chemical processesNanoinformaticsOrganic acidColloidal silica

A chemical mechanical polishing aqueous dispersion preparation set including: a first composition which includes colloidal silica having an average primary particle diameter of 15 to 40 nm and a basic compound and has a pH of 8.0 to 11.0; and a second composition which includes poly(meth)acrylic acid and an organic acid having two or more carbonyl groups other than the poly(meth)acrylic acid and has a pH of 1.0 to 5.0.

Owner:JSR CORPORATIOON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com