Mode-locked multi-mode fiber laser pulse source

a fiber laser and multi-mode technology, applied in the direction of laser details, active medium shape and construction, electrical equipment, etc., can solve the problems of modal dispersion, the most detrimental effect of diffraction-limited coherent light generation, and the early work on fiber lasers that did not attract considerable attention, etc., to increase the energy storage potential of optical fiber amplifiers, increase fiber cross section, and reduce spontaneous emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

FIG. 12 illustrates an amplifier system according to the present invention. In the example shown in FIG. 12, a femtosecond single-mode (SM) fiber oscillator 1010, such as an erbium fiber oscillator, is coupled into a multi-mode (MM) fiber amplifier 1012, such as an erbium / ytterbium fiber amplifier. Other examples of suitable MM fiber amplifiers include those doped with Er, Yb, Nd, Tm, Pr or Ho ions. Oscillators suitable for use in this system are described in the above-mentioned U.S. patent application Ser. No. 08 / 789,995 to Fermann et al.

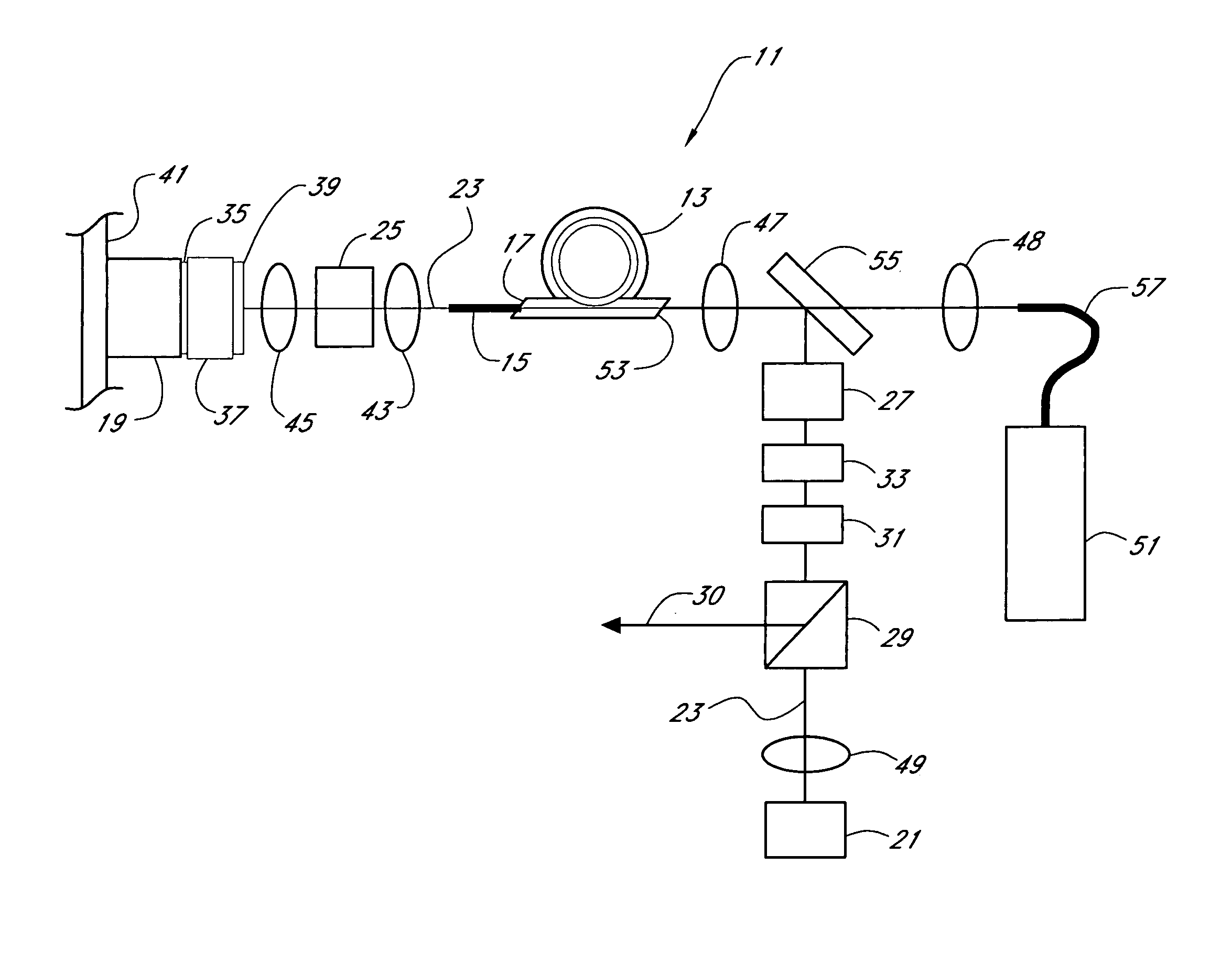

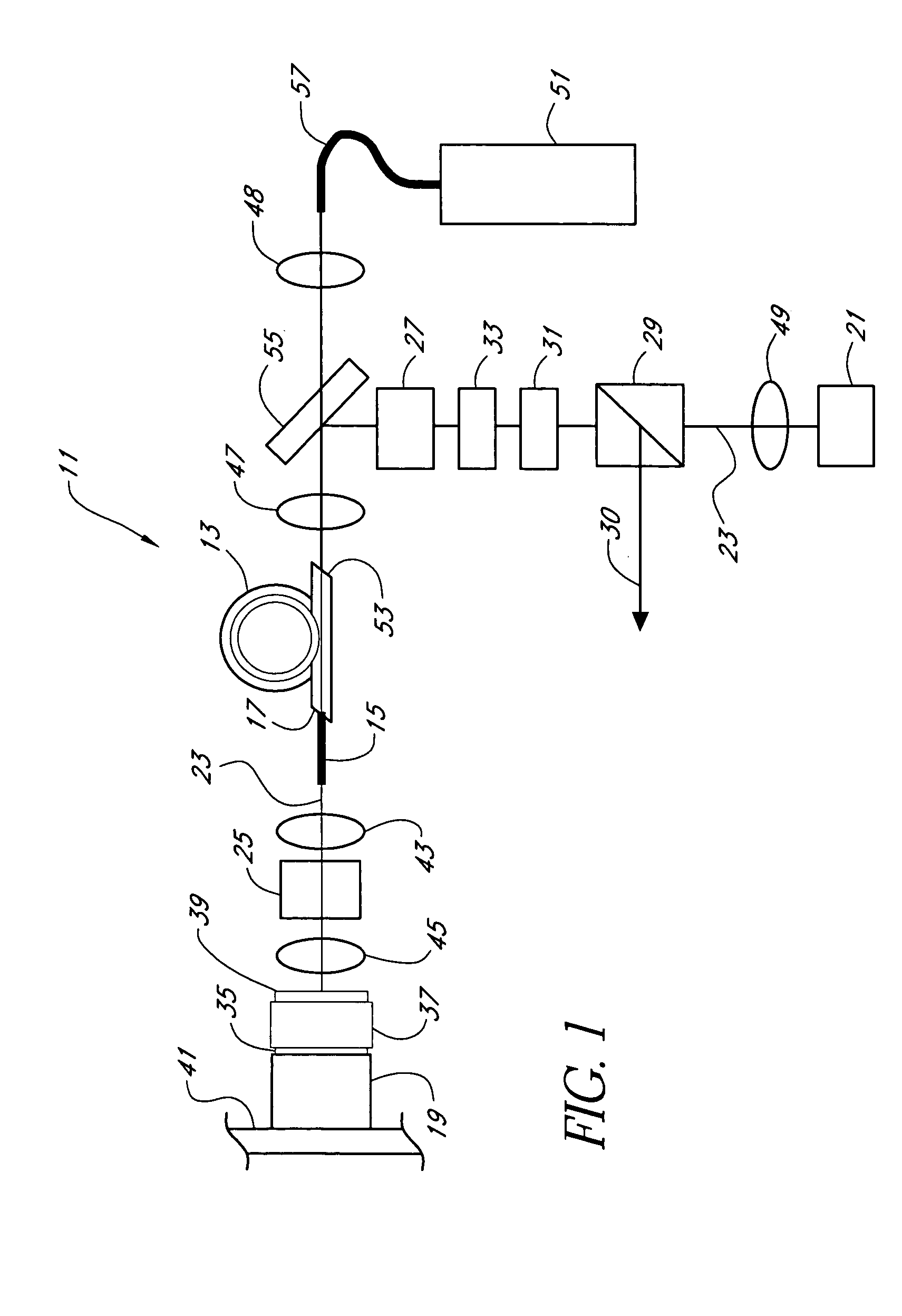

A two-lens telescope 14 (L1 and L2) is used to match the mode from the oscillator 1010 to the fundamental mode of the MM amplifier 1012. In addition, the output of the pumped MM fiber 1012 is imaged into a second SM fiber (mode-filter (MF) fiber 1016 in FIG. 12) using lenses L3 and L4. Lenses L3 and L5 and beamsplitter 1018 are used to couple the pump light from pump source 1020 into the amplifier fiber, as described below.

In one example of the ...

second embodiment

FIG. 16 is a block diagram of a multi-mode fiber amplifier system according to the present invention. The system includes a near-diffraction limited input beam, a mode-converter 1050 and a MM fiber amplifier 1052. The near-diffraction limited input beam can be generated from any laser system, which need not be a fiber laser. The near-diffraction limited input beam can contain cw or pulsed radiation. The mode-converter 1050 can consist of any type of optical imaging system capable of matching the mode of the MM amplifier 1052. For example, a lens system may be employed. Alternatively, a section of tapered fiber may be employed, such that the output mode at the end of the tapered fiber is matched to the mode of the MM amplifier fiber 1052. In this case, the mode-converter can be spliced directly to the MM fiber 1052 producing a very compact set-up. Any pumping configuration could be employed for the MM amplifier fiber, such as contra- or co-directional pumping with respect to the sign...

fourth embodiment

FIG. 18 is a diagrammatic view of a system according to the present invention. As shown in FIG. 18, a mode-filter 1070 is inserted in front of one of the cavity mirrors M1 and M2 to ensure a diffraction-limited output of the system. The mode filter 1070 can consist of a standard SM fiber in conjunction with appropriate mode-matching optics. Alternatively, a tapered fiber can be used (as discussed above) to provide for mode-matching. For optimum mode-coupling the efficiency of the laser will be nearly as high as for an all-SM laser. However, the use of MM amplifier 1076 allows for increased design flexibility. Thus, double-clad erbium / ytterbium fibers with different core-cladding ratios can be employed wherever appropriate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com