Five-axis high-speed precision-machining numerical control machine tool

A precision machining and CNC machine tool technology, which is applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problem of unreasonable design of the guide rail structure of CNC machine tools, affecting work efficiency and enterprise economic benefits, and the processing accuracy of parts cannot be reached. Requirements and other issues to achieve the effect of ensuring long-term stable operation, wide processing range, improving machining efficiency and dimensional accuracy of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

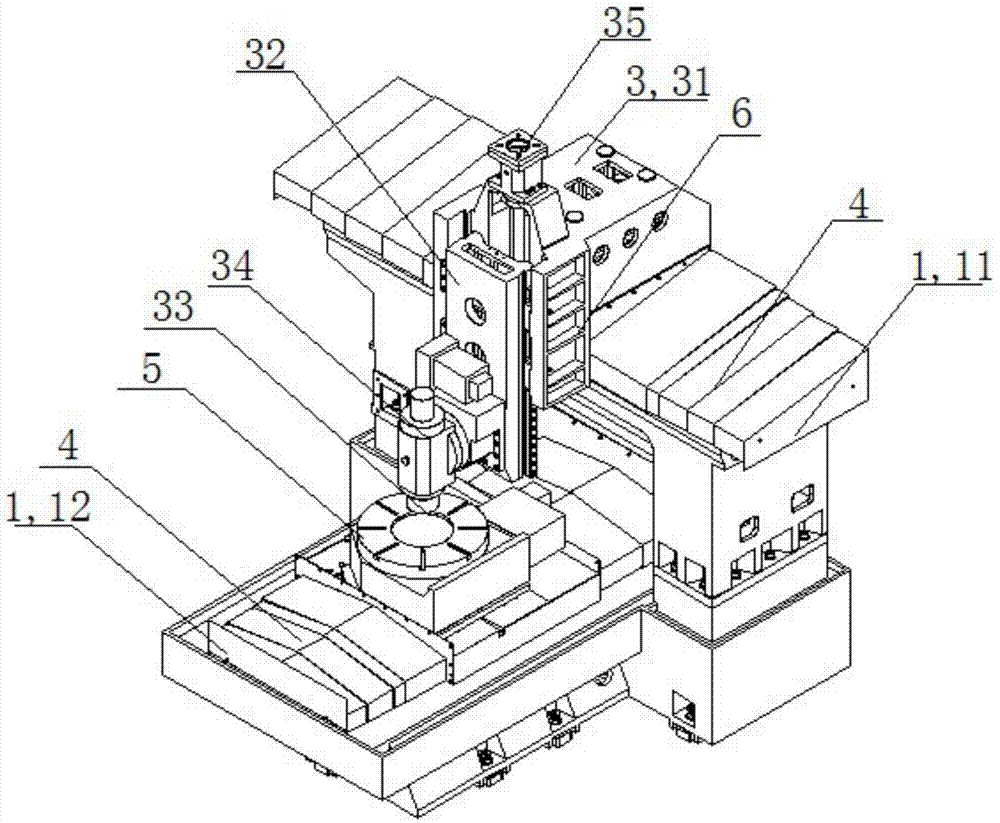

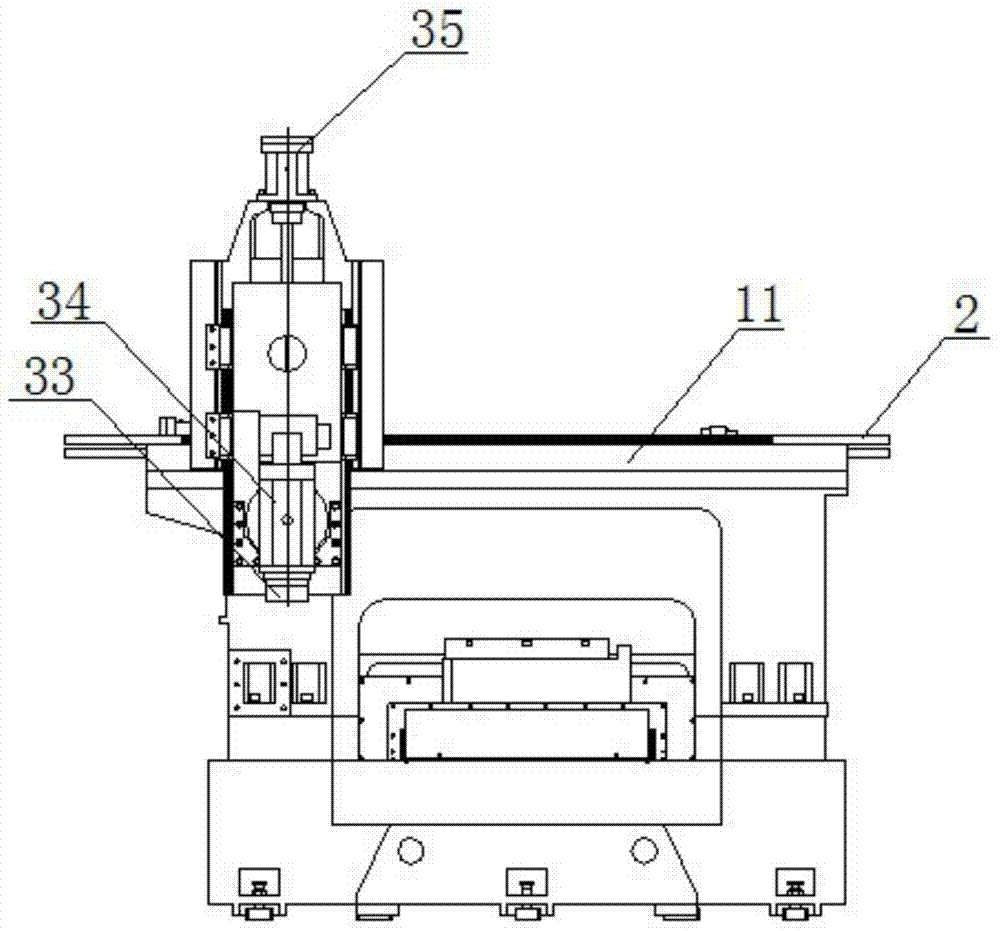

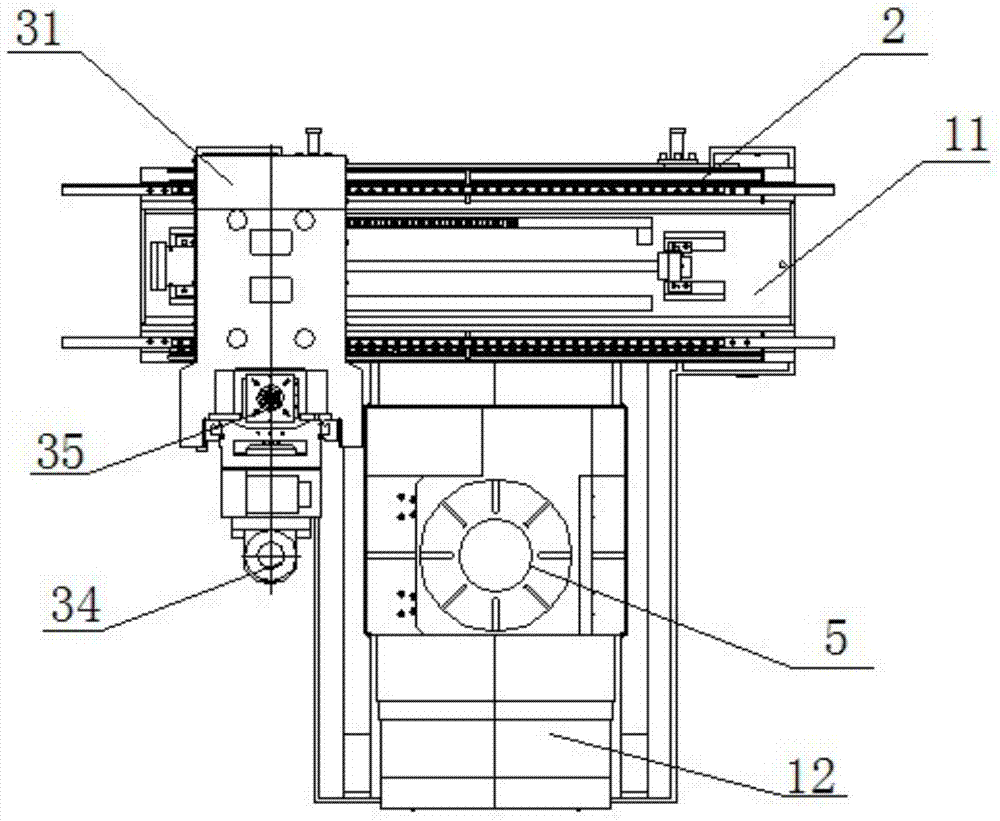

[0025] See Figure 1 to Figure 4 , a five-axis high-speed precision machining CNC machine tool of the present invention, comprising a machine bed 1, the machine bed 1 is "T" shaped, including a horizontal bed 11 in the X-axis direction and a vertical bed 12 in the Y-axis direction; Both the bed 11 and the vertical bed 12 are provided with sliding guide rails, and the sliding guide rails are high-precision roller linear guide rails 2 . There are two high-precision roller linear guide rails 2 on the horizontal bed 11 and the vertical bed 12, respectively located on both sides of the horizontal bed 11 and the vertical bed 12 in the length direction.

[0026] Preferably, the upper part of the transverse bed 11 and the vertical bed 12 is provided with a tensile shield 4, which can prevent dust from entering the linear guide rail, maintain the cleanliness of the guide rail surface, and provide a guarantee for improving the machining accuracy of the machine tool.

[0027] The horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com