Leather-like sheet

a technology of leather-like sheets and sheets, applied in the field of leather-like sheets, can solve problems such as fuzz generation, and achieve the effects of excellent supple feeling, excellent surface quality, and excellent bending resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

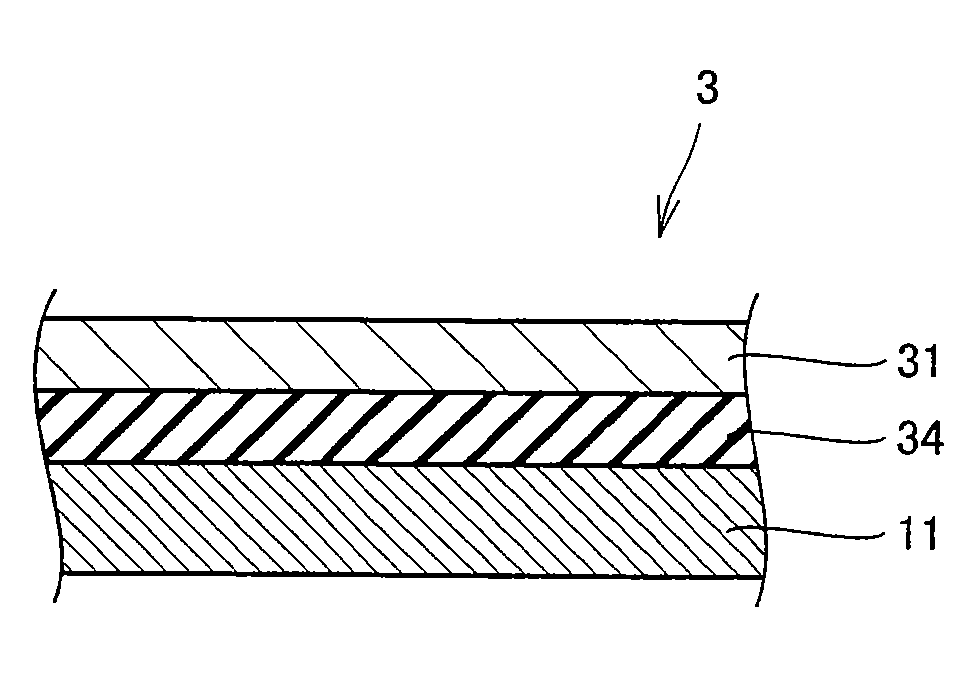

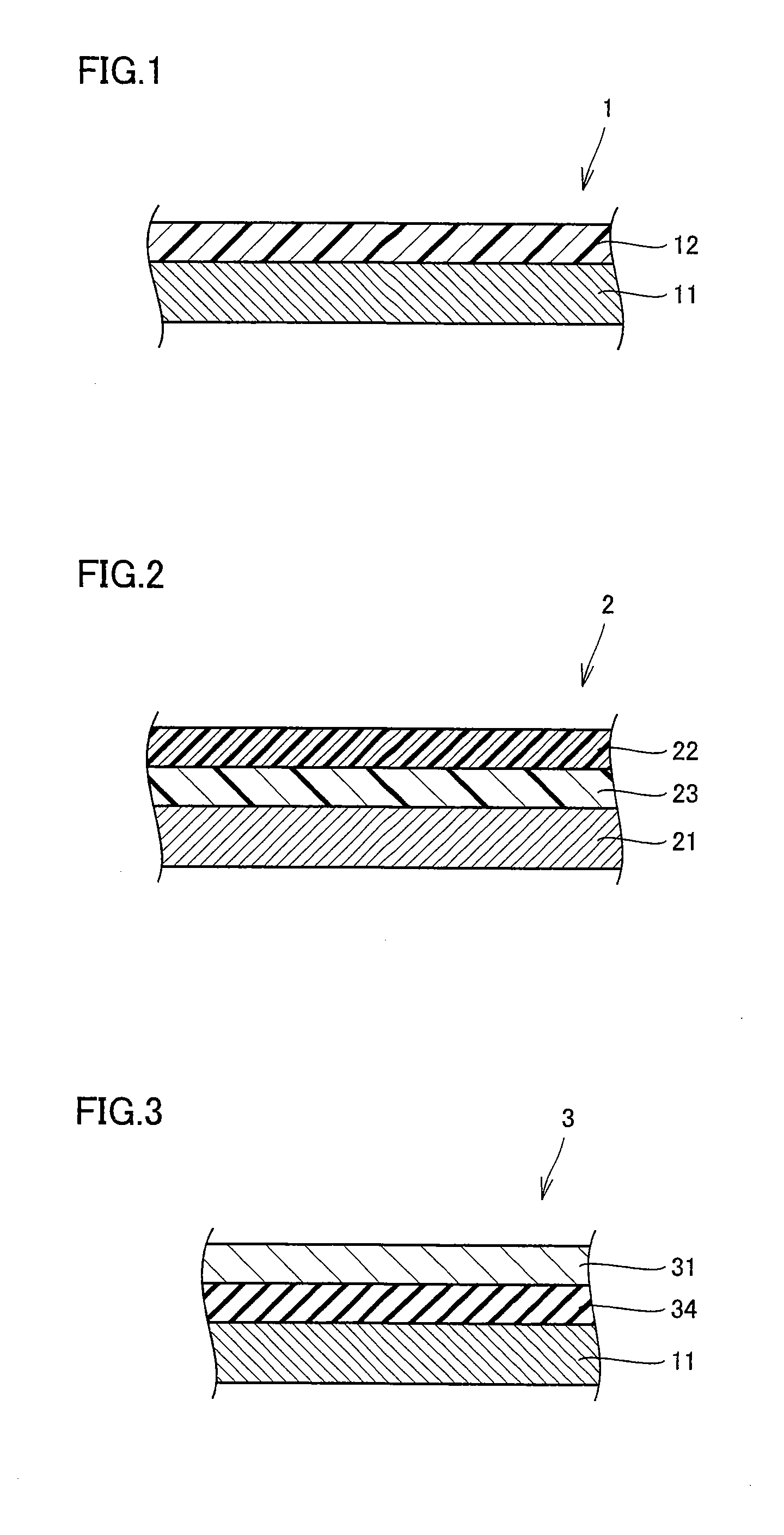

Image

Examples

synthesis example 1

[0162]An alkylene oxide adduct of bisphenol A that was obtained by adding 6 mol of propylene oxide into 1 mol of bisphenol A was reacted with sebacic acid and isophthalic acid, and a polyester polyol (I) having a number average molecular weight of 2000 was obtained.

[0163]50 parts by mass of polytetramethylene glycol having a number average molecular weight of 2000 and 50 parts by mass of the polyester polyol (I) that was synthesized above were heated to 120° C. at a reduced pressure in a four-neck flask having a capacity of 1 liter, and it was dehydrated until the moisture ratio became 0.05% by mass.

[0164]Then, 20 parts by mass of 4,4′-diphenylmethanediisocyanate was added into a mixture of the polytetramethylene glycol and the polyester polyol (I) that was cooled to 60° C., 0.01 parts by mass of di-n-butyltindilaurate was further added thereto as a catalyst, and then the temperature was increased to 110° C., the reaction was performed for 5 hours until the content of the isocyanate...

synthesis example 2

[0165]A urethane prepolymer (2) was obtained by adding 0.68 parts by mass of 2-hydroxyethylacrylate and 0.01 parts by mass of tin octylate into 100 parts by mass of the urethane prepolymer (1) that was heated to 110° C. The ratio of the number of the isocyanate groups with which the hydroxyl groups of 2-hydroxyethylacrylate were reacted based on the entire number of the isocyanate groups in the urethane prepolymer (1) ((HEA / NCO)×100) was 10%.

[0166]Here, ((HEA / NCO)×100) of the urethane prepolymer (2) was obtained by the following method. Excessive dibutylamine was added into urethane prepolymer (2), and the isocyanate groups that remained in urethane prepolymer (2) were reacted with dibutylamine. Then, the amount of the isocyanate groups in the urethane prepolymer was calculated by obtaining the amount of the remaining dibutylamine with a back titration method using hydrochloric acid, and ((HEA / NCO)×100) of the urethane prepolymer (2) was calculated. The ((HEA / NCO)×100) of urethane p...

synthesis example 3

[0167]A urethane prepolymer (3) was obtained with the same method as in Synthesis Example 2 except that the amount of 2-hydroxyethylacrylate used was changed to 1.36 parts by mass. The ((HEA / NCO)×100) of the urethane prepolymers (3) was 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com