Heat-conductive gap interface material and preparation method thereof

A technology of interface materials and gaps, applied in the direction of chemical instruments and methods, other chemical processes, etc., to achieve the effect of improving thermal conductivity and reducing material thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

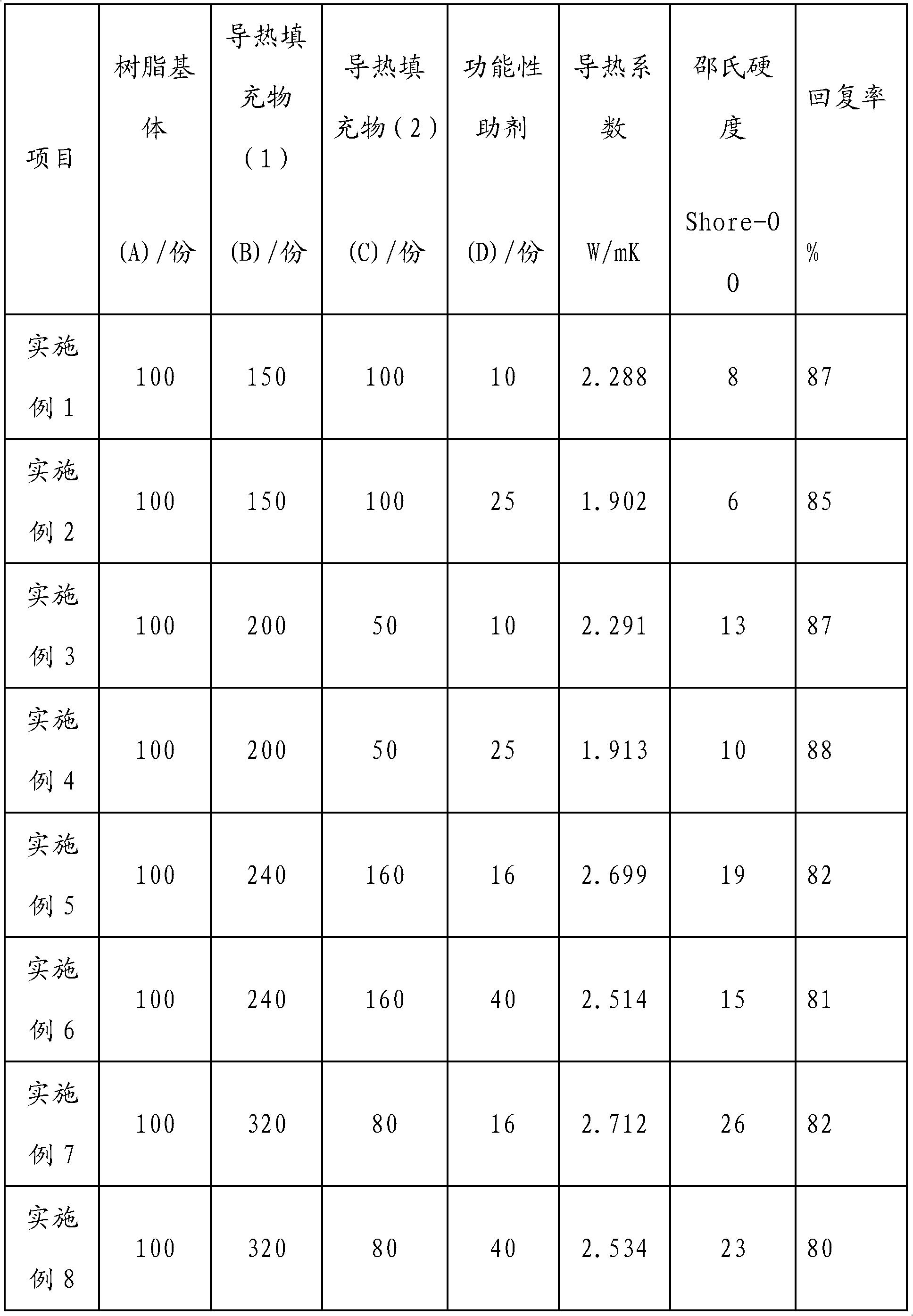

Examples

Embodiment 1

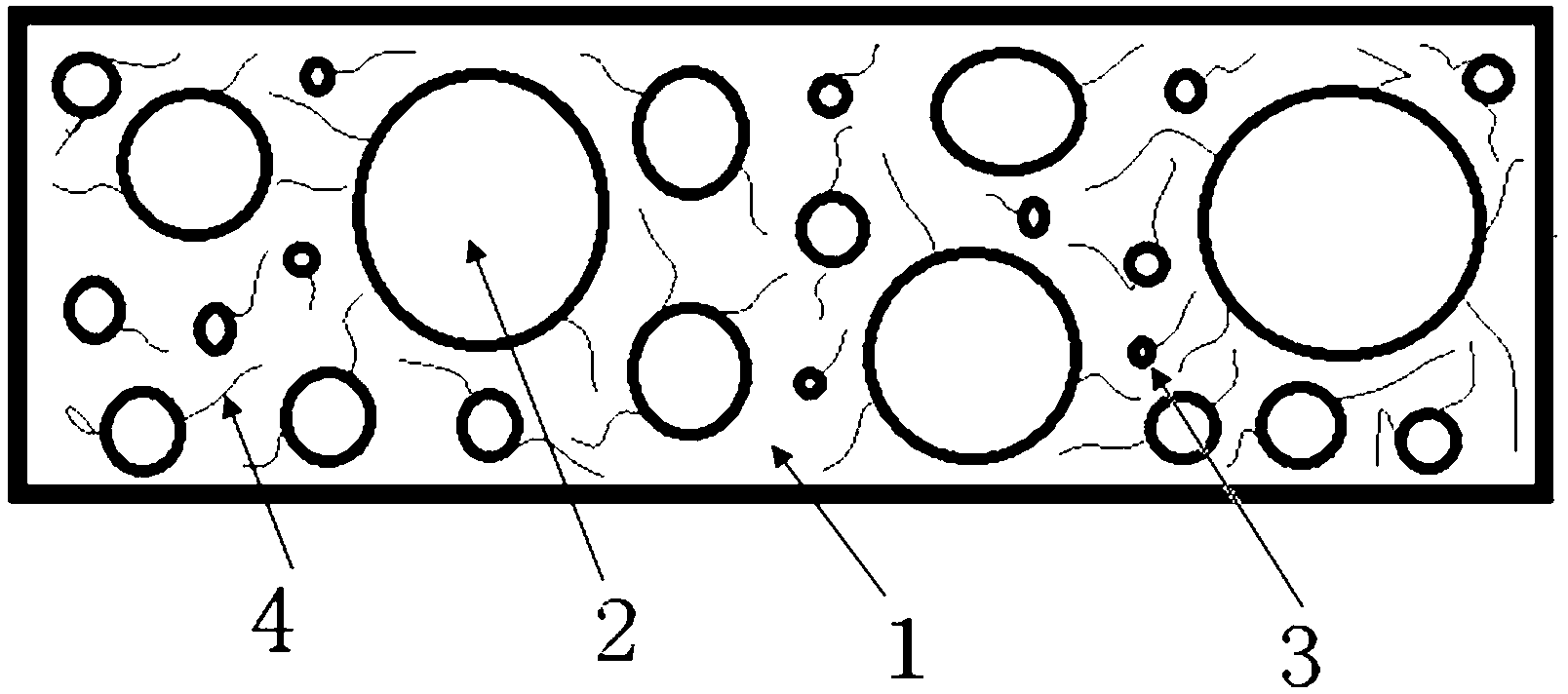

[0035] Such as figure 1 As shown, accurately weigh 1100 parts of the resin matrix, and add 10 parts of functional additive 4, add it into the mixing mixer, and stir for 20 minutes at a vacuum of -0.1MPa. After the stirring is completed, add it to the above mixture Add 100 parts of thermally conductive filler (2) 3, stir for 7 minutes at a vacuum of -0.1MPa, add 150 parts of thermally conductive filler (1) 2, and stir for 10 minutes at a vacuum of -0.1MPa to produce The mixture was molded into a 5 mm sheet, and cured at 130° C. for 30 minutes to obtain the interface material for thermally conductive gaps.

[0036] Wherein, the parts are all parts by weight. The thermally conductive filler (1) is aluminum oxide, and the thermally conductive filler (2) is zinc oxide.

Embodiment 2

[0038] Accurately weigh 100 parts of the resin matrix, add 25 parts of functional additives, add it into the mixing mixer, and stir for 40 minutes under a vacuum of -0.1MPa. After the stirring is completed, add 100 parts of the above mixture Stir the thermally conductive filler (2) for 5 minutes at a vacuum of -0.1MPa, add 150 parts of the thermally conductive filler (1), stir for 30 minutes at a vacuum of -0.1MPa, and then discharge the mixture into 5mm sheet, cured at 130°C for 20 minutes, the thermal gap interface material was obtained.

[0039] Wherein, the parts are all parts by weight. The thermally conductive filler (1) is aluminum hydroxide, and the thermally conductive filler (2) is boron nitride.

Embodiment 3

[0041] Accurately weigh 100 parts of the resin matrix, add 10 parts of functional additives, add it into the mixing mixer, and stir for 30 minutes at a vacuum of -0.1MPa. After the stirring is completed, add 50 parts of Stir the thermally conductive filler (2) for 10 minutes at a vacuum of -0.1MPa, add 200 parts of the thermally conductive filler (1), stir for 30 minutes at a vacuum of -0.1MPa, and then discharge the mixture into 5mm sheet, after curing for 40 minutes at 130°C, the thermal gap interface material was obtained.

[0042] Wherein, the parts are all parts by weight. The thermally conductive filler (1) is aluminum hydroxide, and the thermally conductive filler (2) is aluminum oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com