Making method of additive-free cubilose gelled food

The technology of a gel food and a production method, which is applied in the field of food processing, can solve problems such as beautiful appearance, and achieve the effects of beautiful appearance, good elasticity and chewability, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

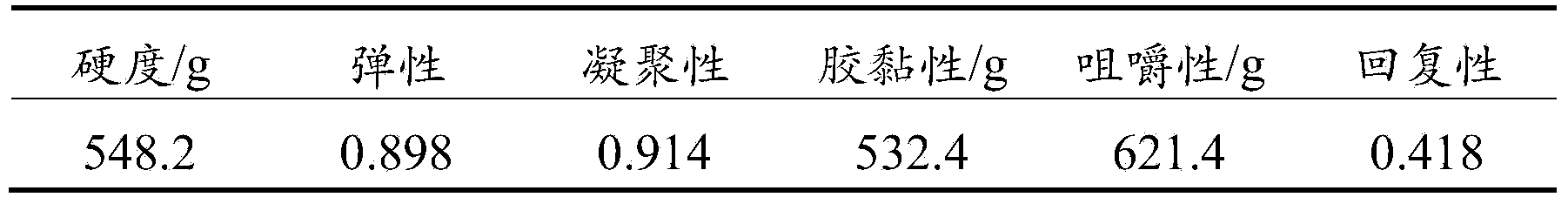

Embodiment 1

[0017] (1) Soak 100g of bird’s nest in 1kg of deionized water at room temperature for 5 hours, remove impurities such as bird hair during soaking, and filter and wash with pure water for 6 times;

[0018] (2) Take the soaked bird’s nest, add deionized water whose mass is 30 times the dry weight of the bird’s nest, and stew in a stew pot for 60 minutes;

[0019] (3) Place the stewed bird's nest in a reaction device, and heat at 115°C for 60 minutes to obtain a bird's nest solution;

[0020] (4) centrifuge the heated bird's nest solution at 5000rpm / min for 10min, and get the supernatant;

[0021] (5) Spray-drying the supernatant liquid at an air inlet temperature of 160°C and an outlet temperature of 90°C to obtain bird's nest powder;

[0022] (6) The bird's nest powder obtained by spray drying is extruded under a pressure of 10KN;

[0023] (7) Add deionized water with 8 times the dry weight to the bird's nest product obtained by extrusion, and obtain bird's nest gel food afte...

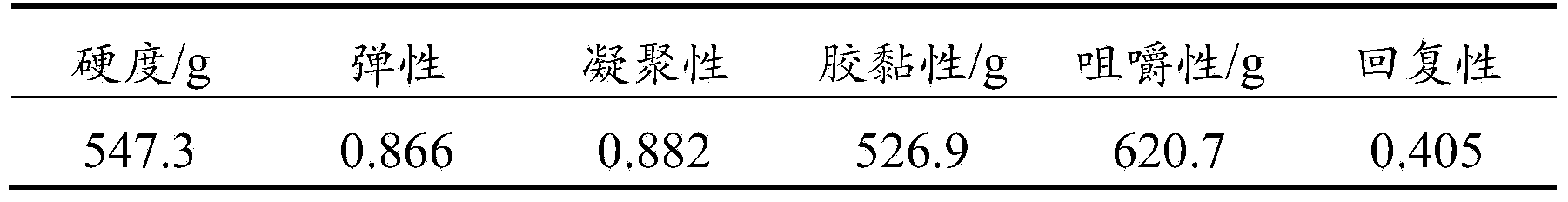

Embodiment 2

[0027] (1) Soak 100g of bird’s nest in 1kg of deionized water at room temperature for 6 hours, and remove impurities such as bird’s hair during the soaking process, filter and wash with pure water for 4 times;

[0028] (2) Take the soaked bird’s nest, add deionized water whose mass is 50 times the dry weight of the bird’s nest, and simmer for 30 minutes in an electromagnetic oven;

[0029] (3) Place the stewed bird's nest in a reaction device, and heat at 130°C for 30 minutes to obtain a bird's nest solution;

[0030] (4) The heated bird's nest solution is centrifuged at 4500rpm / min for 30min, and the supernatant is taken;

[0031] (5) Freeze-dry the supernatant at -60°C and 5Pa for 40 hours to obtain bird's nest powder;

[0032] (6) The bird's nest powder obtained by spray drying is extruded under 80KN pressure;

[0033] (7) Add deionized water with 10 times the dry weight to the bird's nest product obtained by extrusion, and obtain bird's nest gel food after absorption bal...

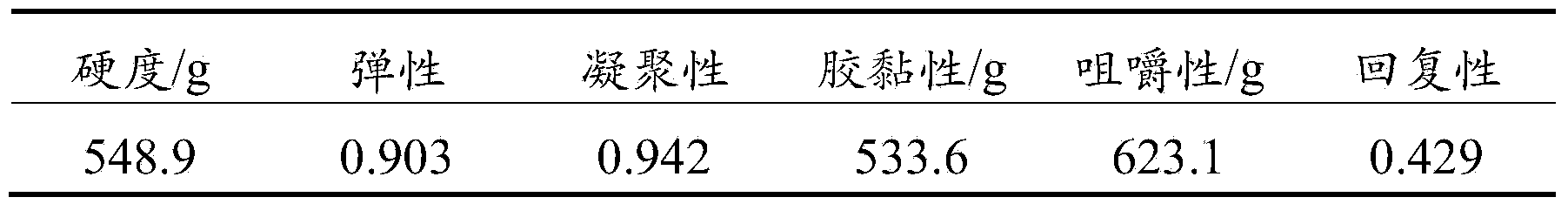

Embodiment 3

[0037] (1) Soak 100g of bird’s nest in 1kg of deionized water at room temperature for 8 hours, and remove impurities such as bird hair during the soaking process, and filter and wash it with pure water for 5 times;

[0038] (2) Take the soaked bird’s nest, add deionized water whose mass is 60 times the dry weight of the bird’s nest, and stew for 40 minutes in a stew pot;

[0039] (3) Place the stewed bird's nest in a reaction device, and heat at 120°C for 50 minutes to obtain a bird's nest solution;

[0040] (4) centrifuge the heated bird's nest solution at 5000rpm / min for 20min, and get the supernatant;

[0041] (5) Spray-dry the supernatant liquid at an inlet temperature of 180° C. and an outlet temperature of 80° C. to obtain bird’s nest powder;

[0042] (6) The bird's nest powder obtained by spray drying is extruded under 60KN pressure;

[0043] (7) Add deionized water with 6 times the dry weight to the bird's nest product obtained by extrusion, and obtain bird's nest ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com