Fatigue life prediction method for friction stir welded component based on small crack propagation

A fatigue life prediction and friction stir welding technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of different small crack propagation laws and difficult life prediction, and achieve the effect of simple calculation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0086] Example 1: Fatigue Life Prediction of 7075 Aluminum Alloy Friction Stir Welded Joint Based on Small Crack Growth

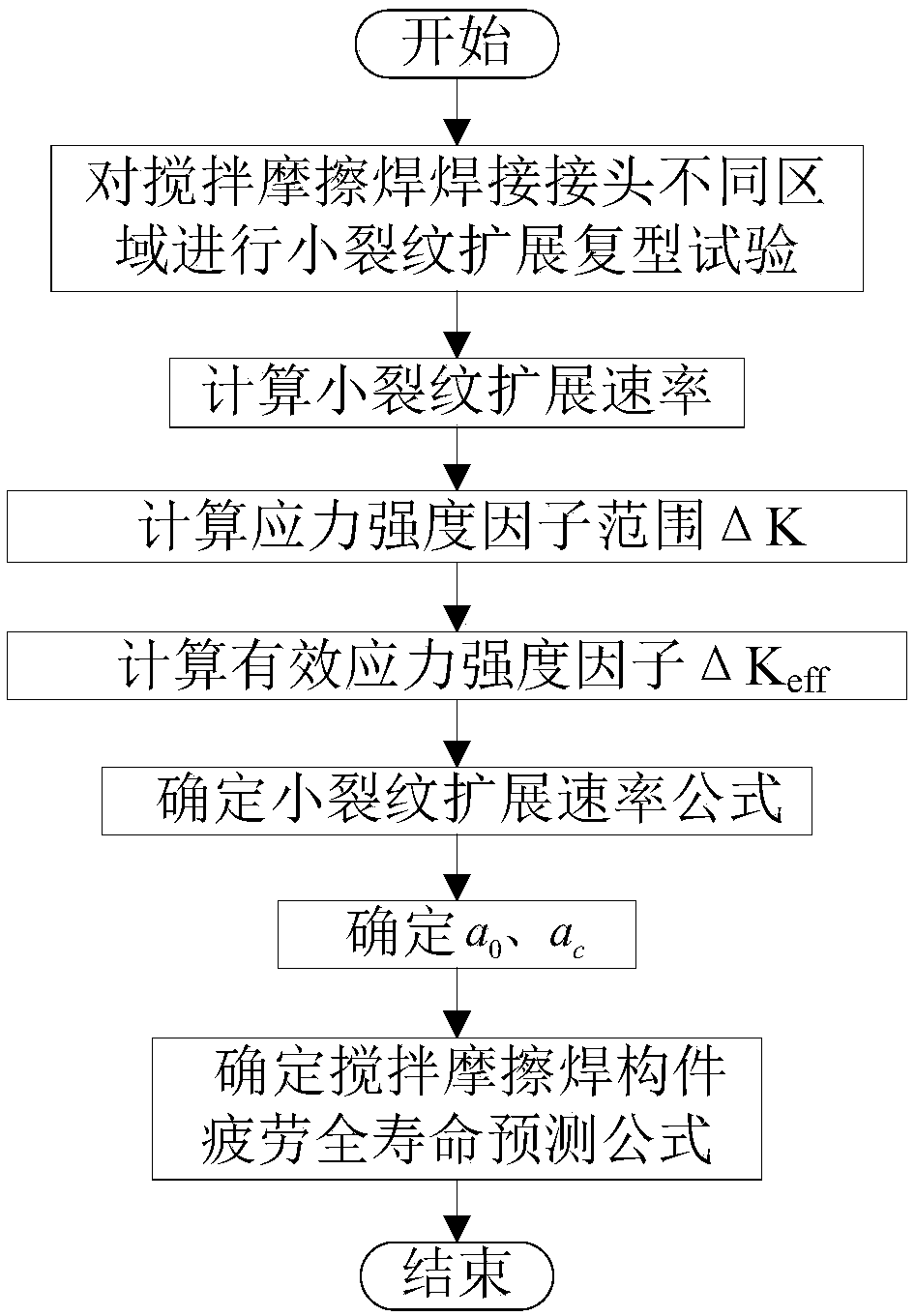

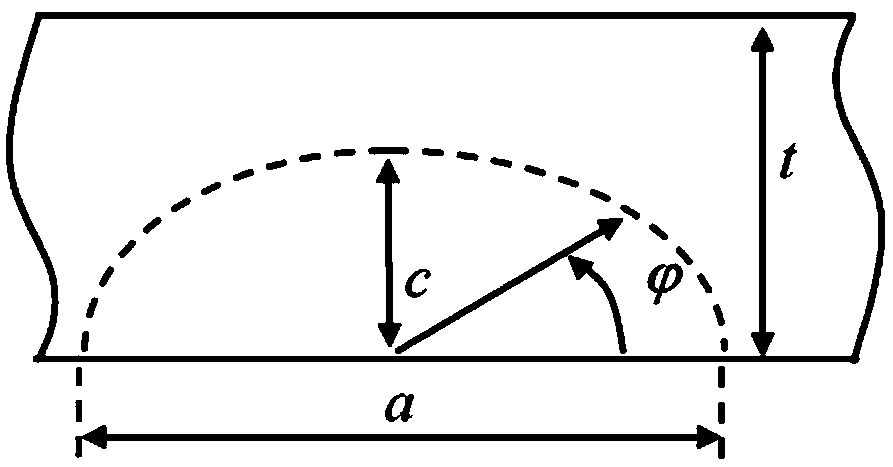

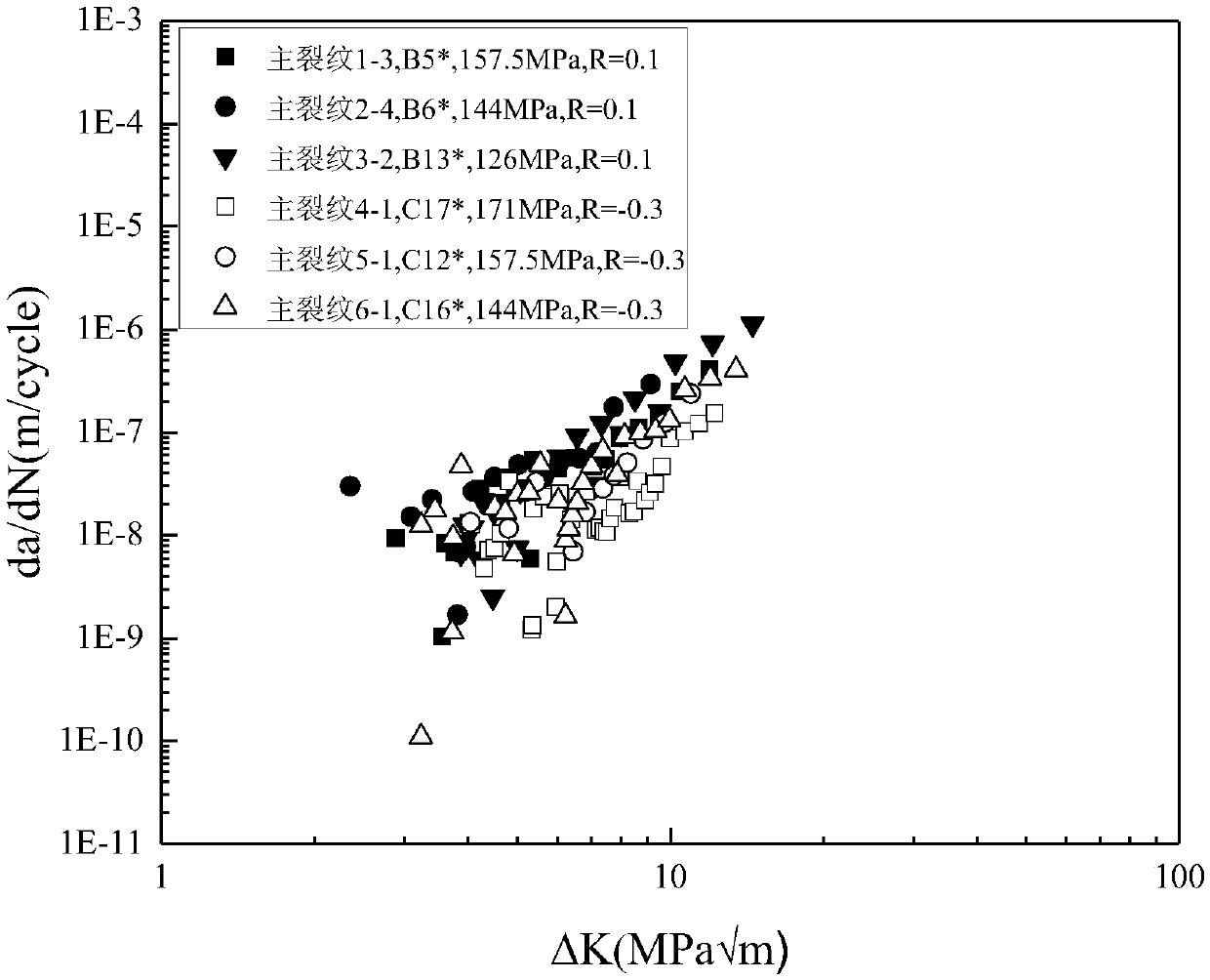

[0087] (1) Prepare 7075 aluminum alloy friction stir welding fatigue samples, carry out fatigue small crack growth replica tests with different stress loading and stress ratios of 0.1 and -0.3 in different areas of the joint, and use the secant method to calculate the small crack growth rate; (2) Use the New-Raju model to calculate the range of stress intensity factors for small cracks in welded joints; (3) Measure the c value in the depth direction and the a / 2 value in the width direction of the semi-arc-shaped fatigue crack propagation zone in the fracture morphology of different regions of the welded joint , the calculated average value of the crack depth-length ratio 2c / a is about 0.9; (4) Draw the curves of crack growth rate changing with the range of stress intensity factor under different stress ratios and different stress levels, as shown in image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com