Sponge and cloth cleaning device

a cleaning device and cloth technology, applied in the direction of carpet cleaners, cleaning processes and utensils, printing, etc., can solve the problems of cloths not generally holding liquids as readily, sponges tend to be easily damaged when used on surfaces with edges and corners, and are too abrasiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

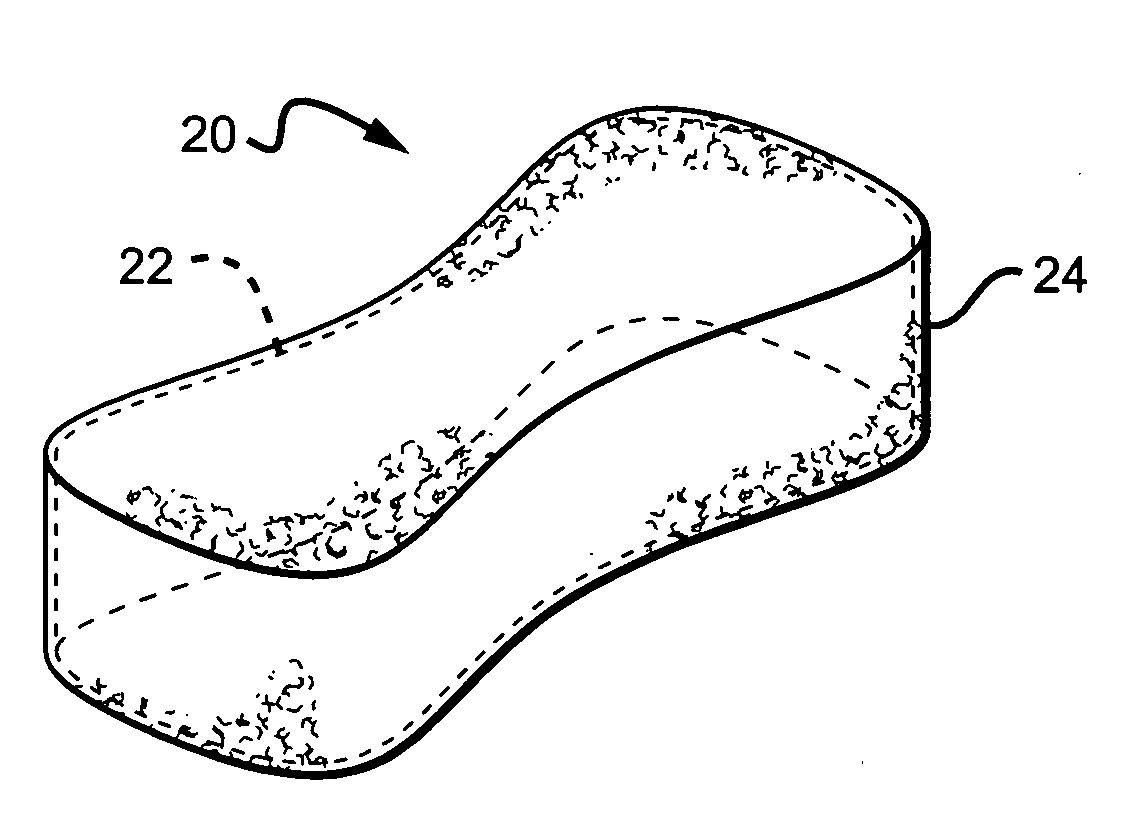

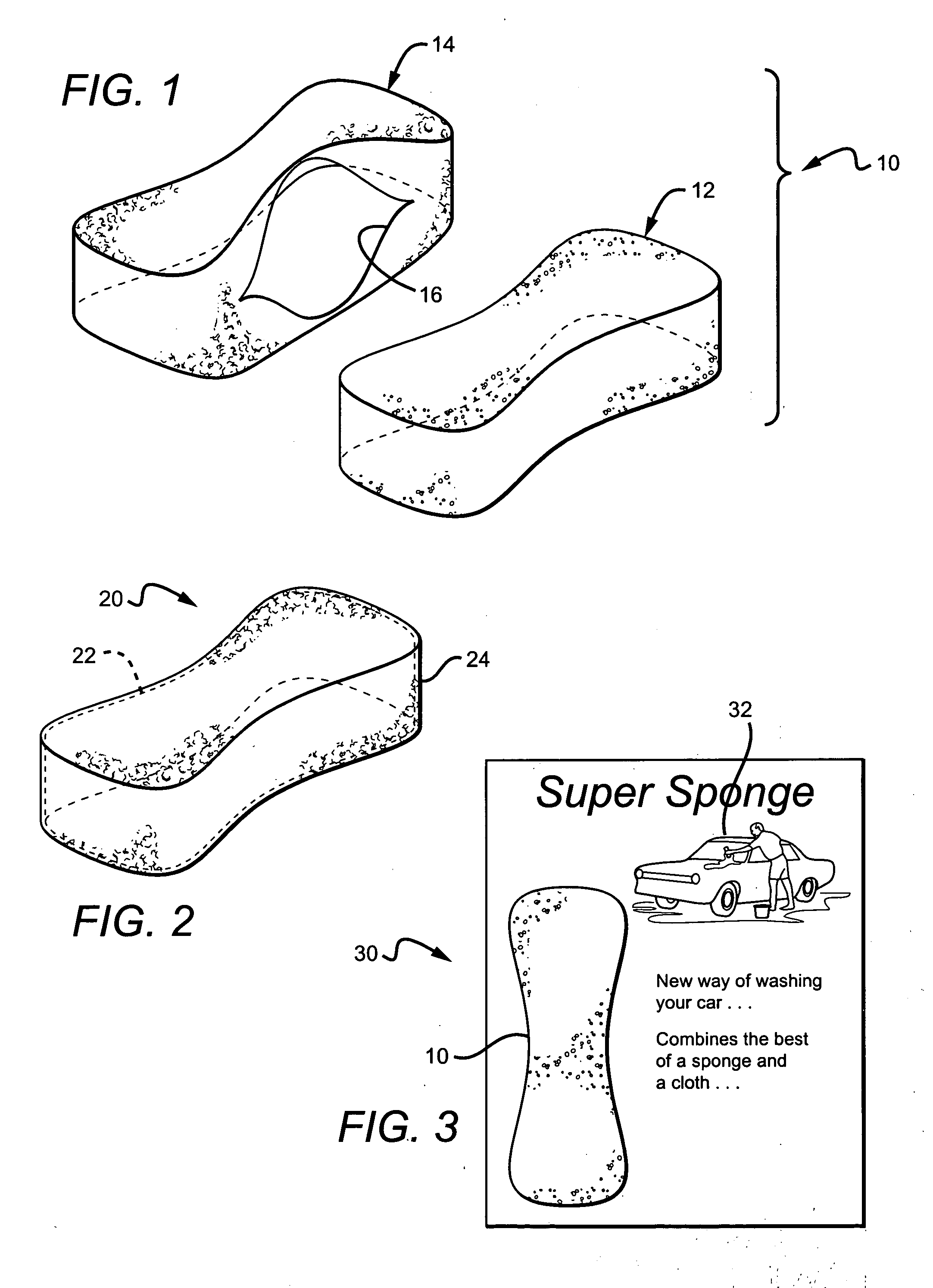

[0014] In FIG. 1 an article of manufacture 10 includes a sponge 12 and a cloth 14.

[0015] The sponge 12 can comprise any suitable material, including natural sponges, but more preferably comprises a closed cell Ensolite™ urethane, rubber, latex, or other synthetic material for improved durability and liquid absorption.

[0016] Sponge 12 can also have any suitable size and shape. For automotive use larger sponges are preferred, especially those large enough that they extend out both sides of a person's palm when the sponge is grasped arounds its mid-section. Such sponges are therefore at least 10 cm long, more preferably at least 15 cm long, and most preferably at least 18 cm long. The thickness should be at least 2 cm, but is advantageously much thicker, such as at least 4 cm, 6 cm, or even 8 cm. Preferred width is at least 6 cm, and more preferably at least 8 cm or 10 cm.

[0017] In FIG. 1 the sponge 12 is dog bone shaped, with a narrowed mid section and bulbous ends. Other shapes ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com