Microwave nondestructive testing device of metal surface defects and testing method thereof

A metal surface, non-destructive testing technology, applied in the use of microwave flaw detection and other directions, can solve the problems of inability to real-time online monitoring, low detection rate of metal surface defects, inability to record, analyze, process and archive inspection results, and achieve automation. The effect of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

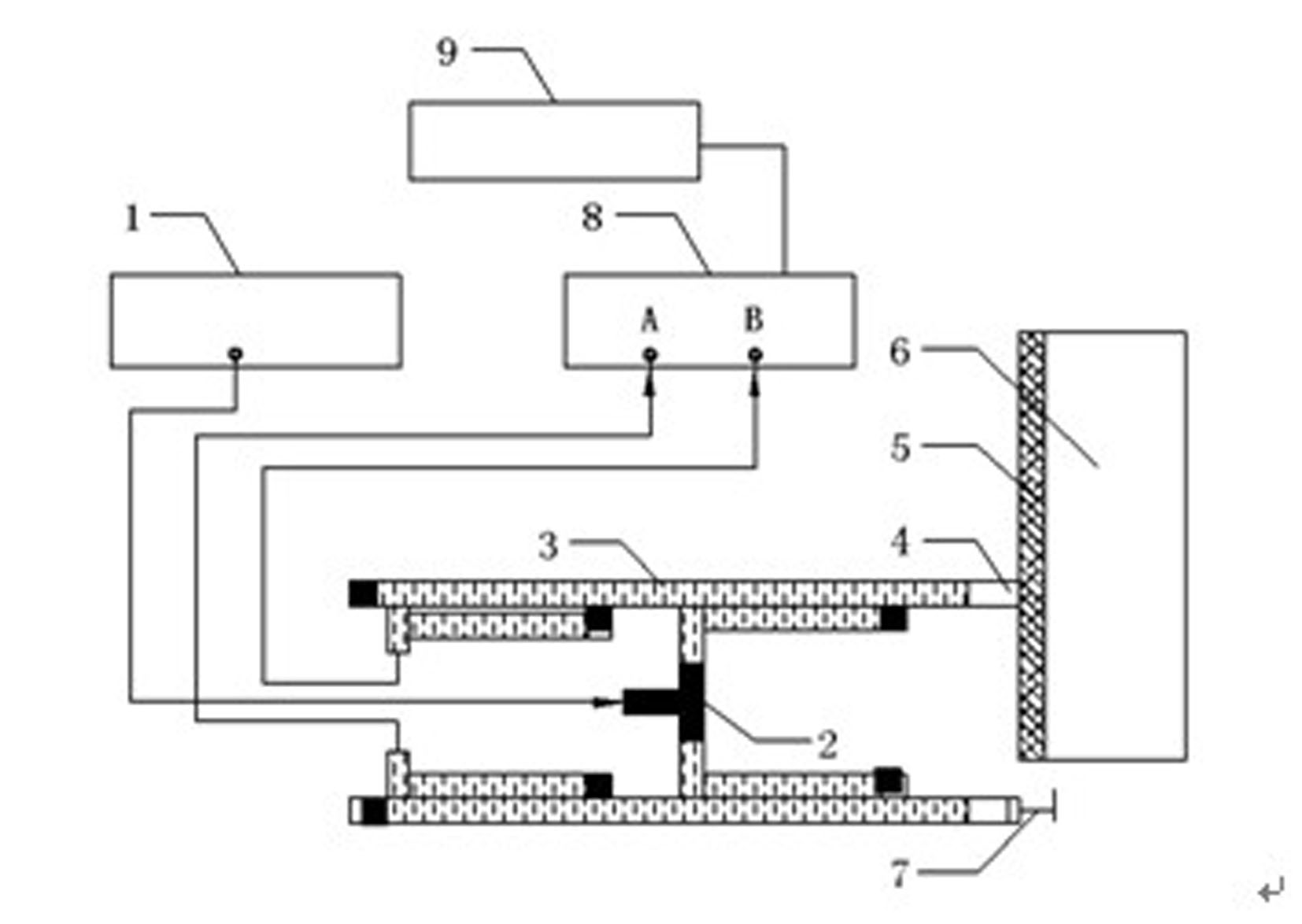

[0019] Implementing a microwave non-destructive detection device for metal surface defects described in the present invention includes setting a "T"-shaped tube 2 through a waveguide-coaxial converter and a coaxial line connected to a microwave frequency scanner 1, wherein:

[0020] The structure of the "T"-shaped pipe 2 includes a long arm and a cross arm, and the middle part of the cross arm is vertically integrated with the long arm and communicates with the long arm. In the present invention, the "T" type tube 2 is a "T" type microwave channel tube structure in which the main waveguide is perpendicular to the first waveguide and the second waveguide, and the first waveguide and the second waveguide are respectively coupled with the directional The corresponding input signal of the device 3 is transmitted. When the main waveguide receives the signal, the two arms of the first waveguide and the second waveguide excite microwave signals of equal amplitude and phase.

[0021] ...

specific Embodiment approach 2

[0024] Implement the detection method of a kind of metal surface defect microwave nondestructive detection device described in the present invention:

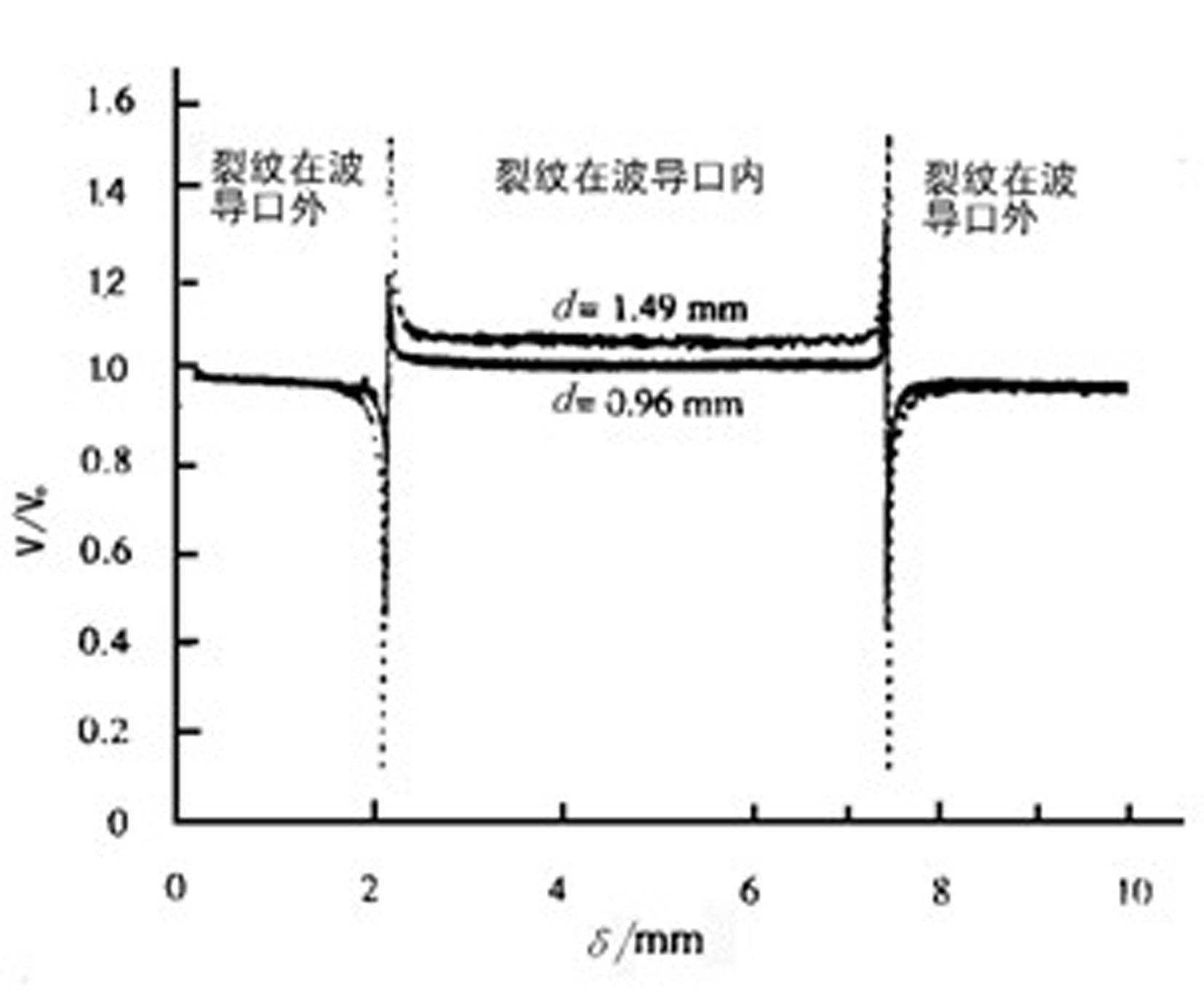

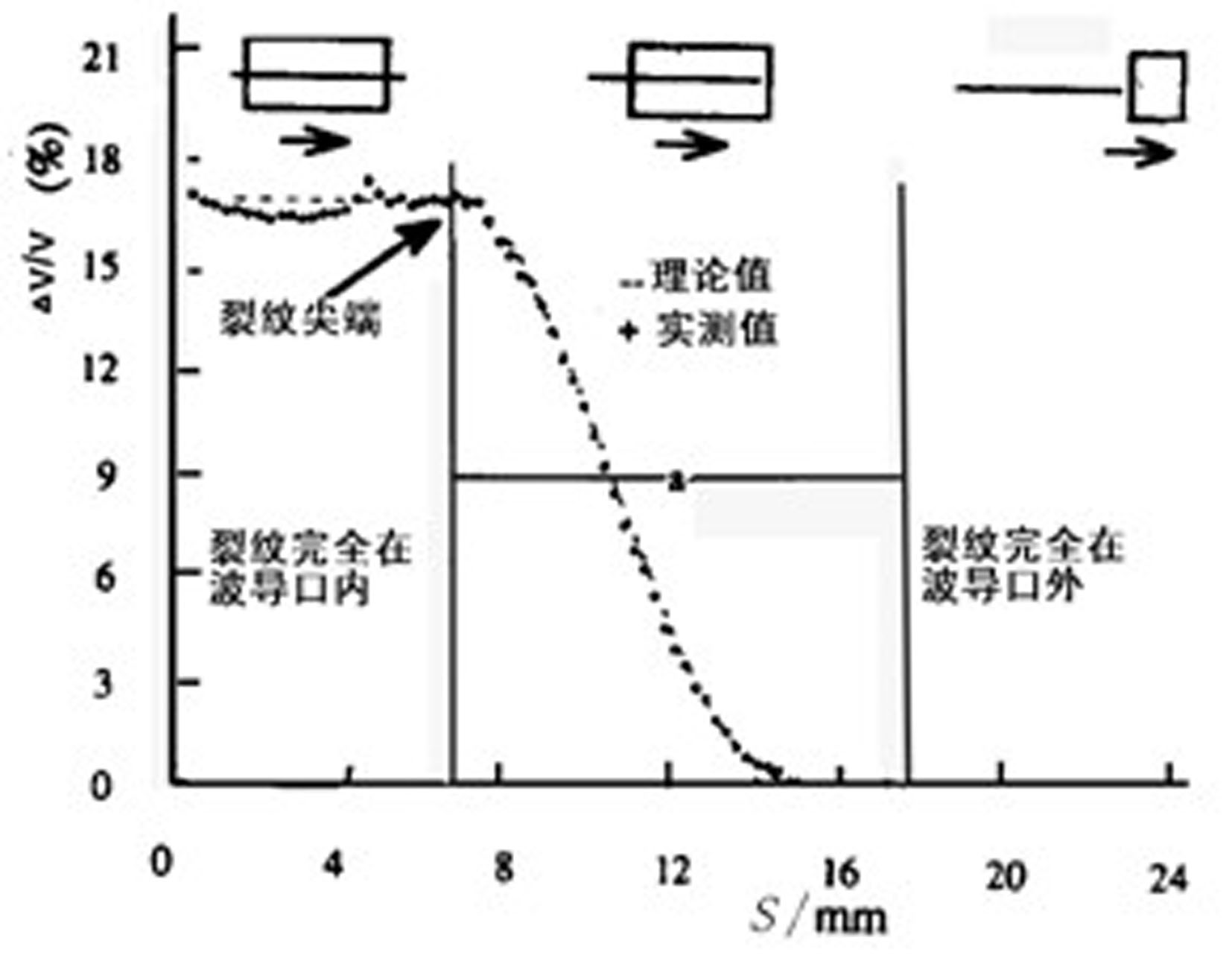

[0025] Such as figure 1 , a detection method for the metal surface defect microwave non-destructive detection device according to the present invention, the detection method is to feed the frequency-sweeping microwave signal generated by the microwave frequency sweeper 1 into a "T"-shaped tube, "T" The microwave input signal is then divided into the first signal and the second signal with the same size and phase by the type tube, which are respectively fed to the corresponding input ends of the directional coupler 3. When the main waveguide receives the signal, the two arms of the first waveguide and the second waveguide A microwave signal of equal amplitude and phase is excited; wherein, the first waveguide signal is fed to the rectangular waveguide with the first terminal opening, and the waveguide terminal opening is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com