Blind hole method residual stress automatic drilling testing device

A residual stress and testing device technology, applied in the direction of boring/drilling, feeding device, positioning device, etc., can solve the problems of inconvenient adjustment of drilling height, slow development of testing equipment, inconvenient measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

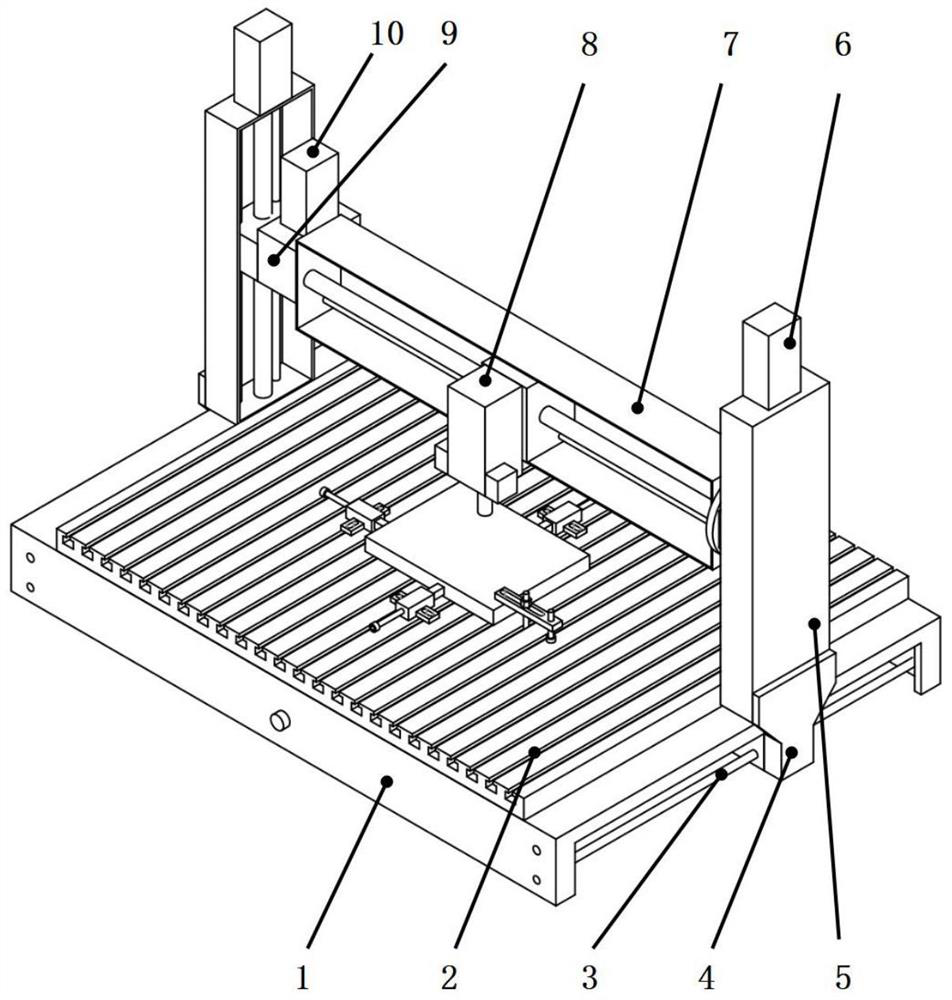

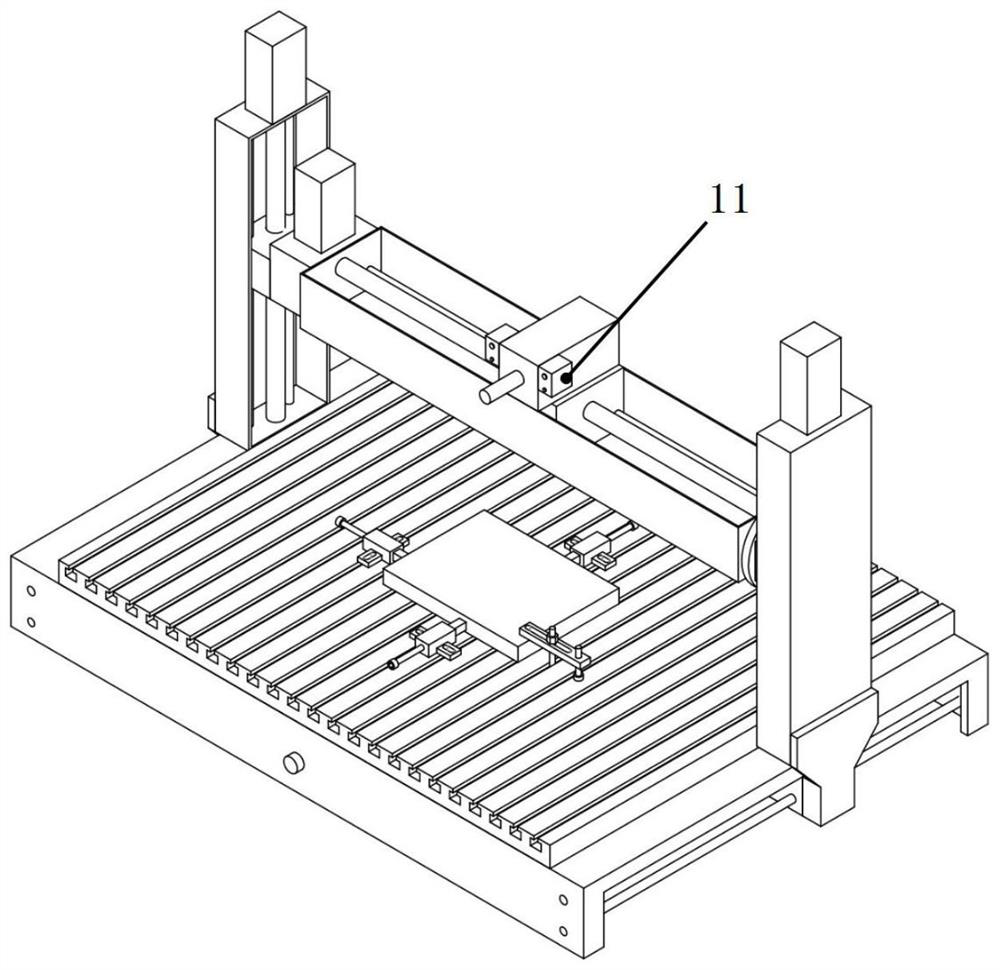

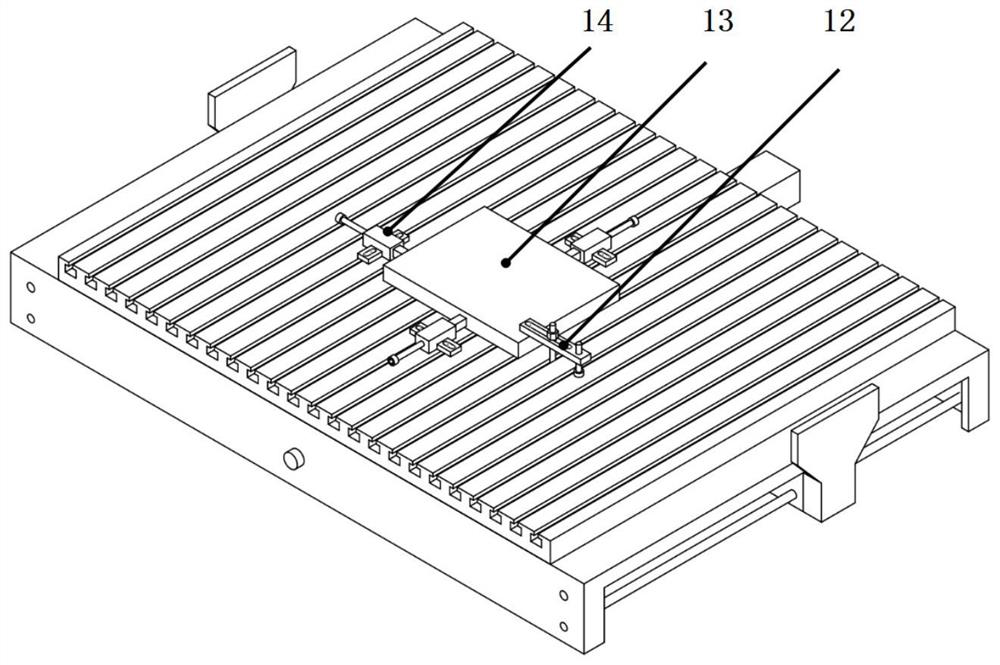

[0018] The invention designs an automatic drilling test device for blind hole method residual stress, which includes a drilling system, a clamping system, a positioning system and an automatic testing system. The drilling system includes X-axis slide rail, Y-axis slide rail, Z-axis slide rail, A-axis motor, drilling spindle and tools. The A-axis motor can control the X-axis slide rail to rotate ±180° around the X-axis. The drill The hole system can be used to drill holes on any plane of the test sample; the clamping system is composed of a T-slot table, a clamping fixture, a clamping fixture and a sample. Reduce the stress introduced by the clamping to a certain extent, and reduce the measurement error; the positioning system includes a binocular camera and image recognition software, which can automatically identify the position of the strain gauge, calculate the coordinates of the drilling position, and measure the aperture after the drilling is completed; automatically The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com