Capacitance measuring sensor device in absolute position

A sensor device and a technology for measuring sensors, which are applied in the direction of using electric/magnetic devices to transmit sensing components, etc., can solve the problems of inability to reduce costs, increase production costs, and difficult implementation of sensors, so as to reduce energy consumption and improve measurement accuracy , Improve the effect of anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

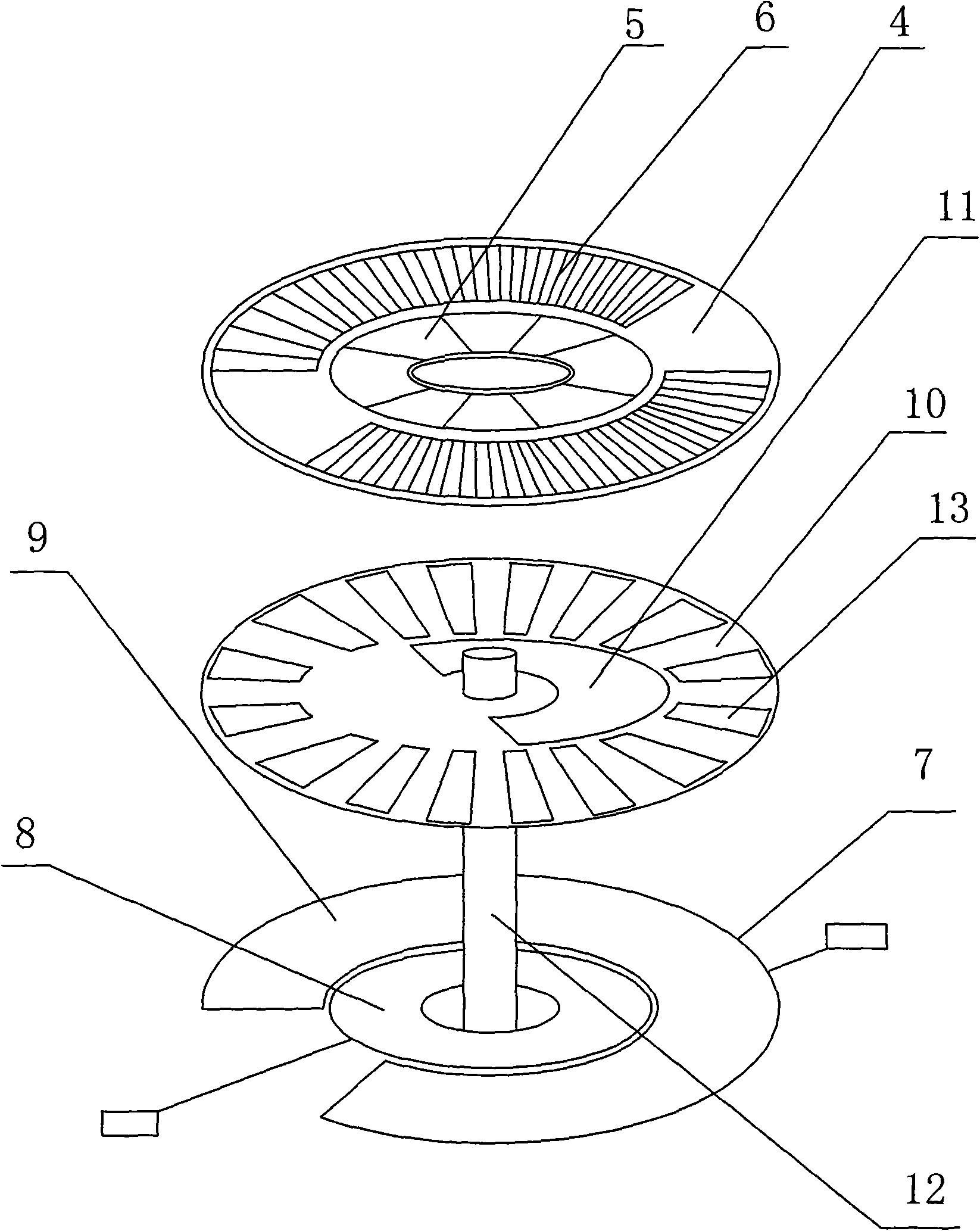

[0048] The capacitive measuring sensor device for absolute position of the present invention includes a capacitive sensor, a measurement signal processor, a data processor and a display. The capacitive sensor is mainly a circular capacitive sensor 1, and includes a calibration sensor with a 360-degree circle as a pitch. And a measurement sensor with a pitch value greater than 1, the circular capacitance sensor 1 has a three-piece transmissive structure as the best form:

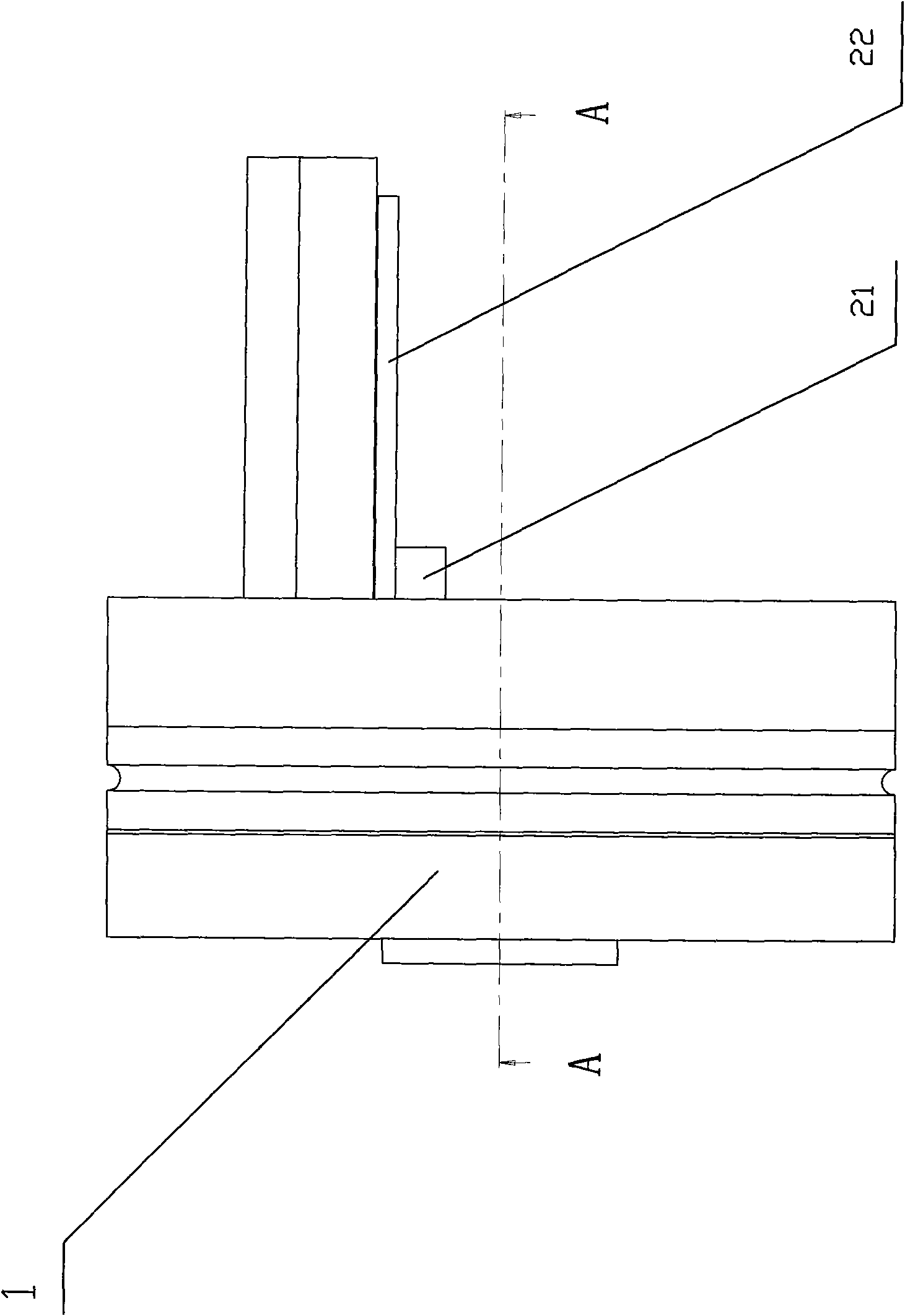

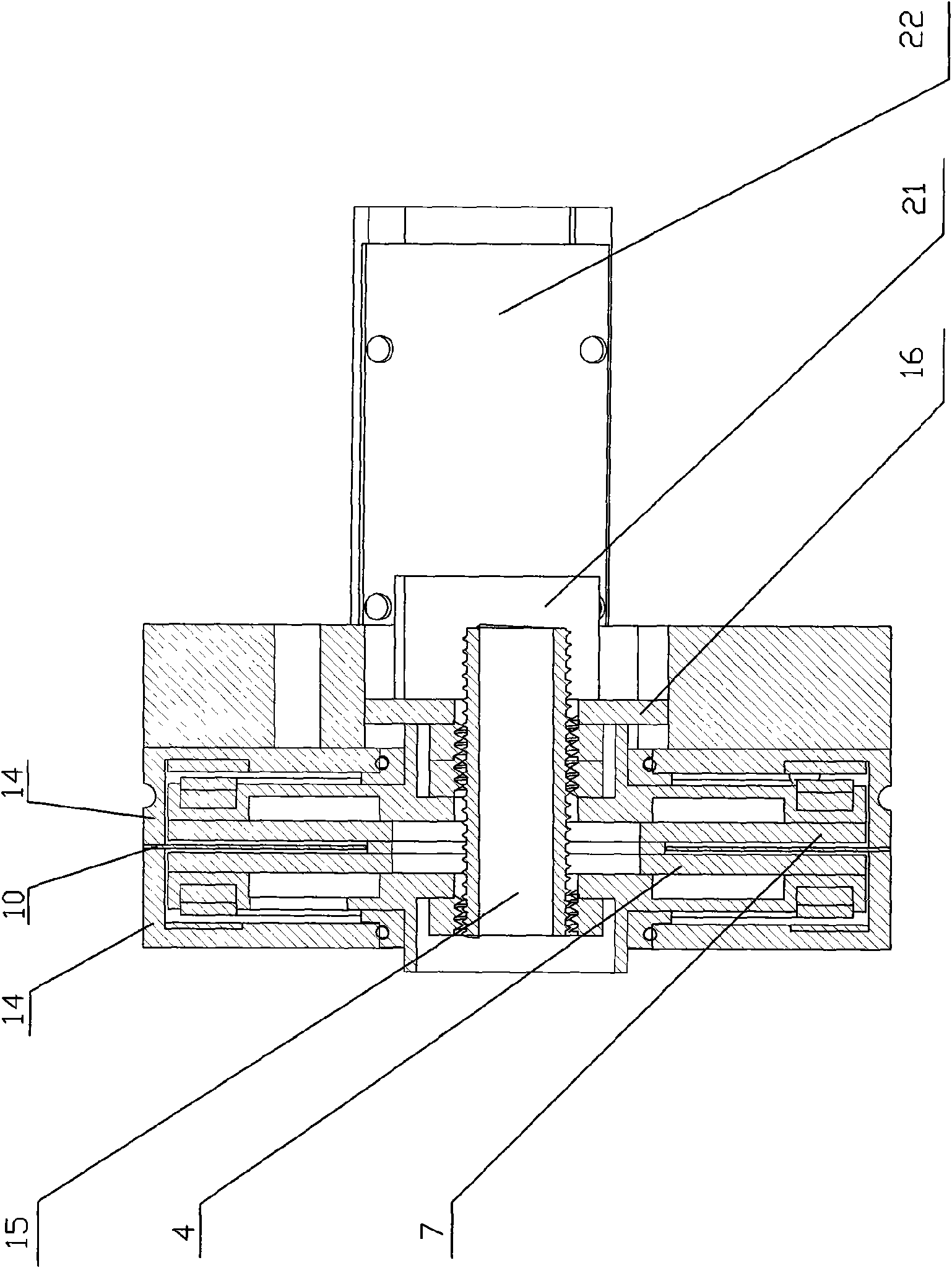

[0049] Such as figure 1 As shown, the circular capacitance grid sensor 1 is composed of a parallel and coaxial circular emitter 4, a circular receiver 7 and a circular screen baffle 10, the emitter 4 and the receiver 7 are fixedly arranged, and the screen baffle 10 Between the emitter 4 and the receiver 7, it is driven to rotate by the central axis 12. The emitter 4 is concentrically provided with two kinds of emission grids, the calibration sensor emission grid 5 in the central area and the measurement senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com