Cylinder part outer contour geometric tolerance measuring instrument

A form and position tolerance and measuring instrument technology, applied in the field of measuring instruments, can solve the problems of non-coincidence of measuring reference and design reference, low measurement accuracy, inconvenient movement, etc., achieve flexible and variable positioning methods, solve complex structures, and facilitate measurement management effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

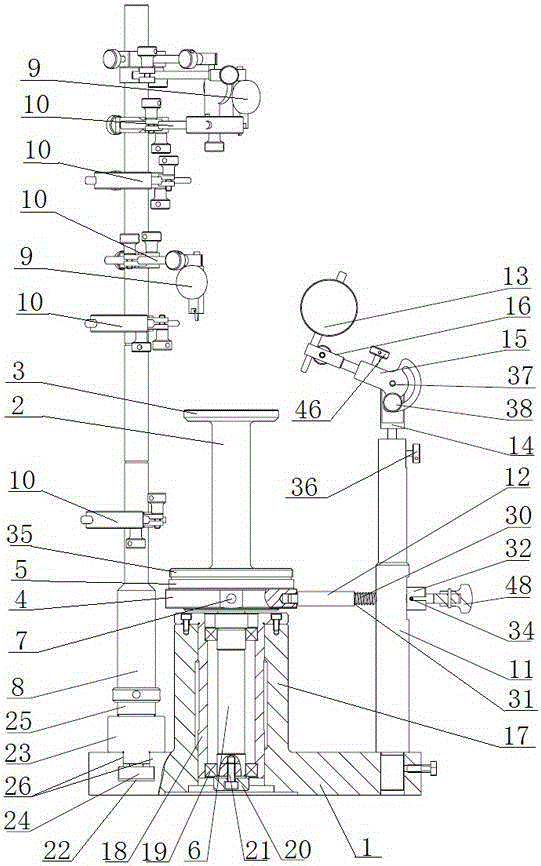

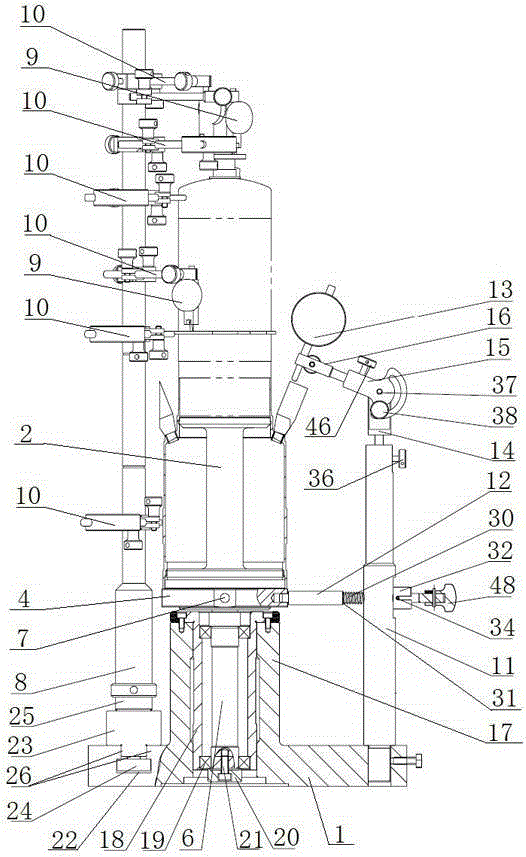

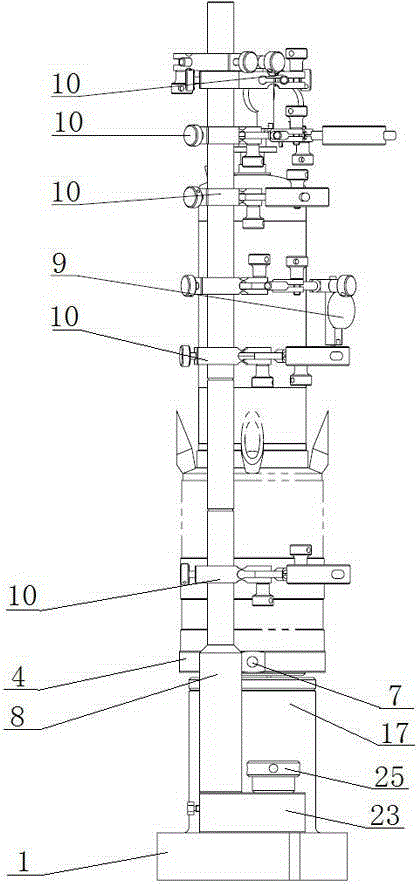

[0062] Such as Figure 1 to Figure 12 As shown, an embodiment of the present invention includes a positioning device, a first measuring device, a second measuring device and a base 1, and the positioning device includes a positioning mandrel 2, and the upper section of the positioning mandrel 2 is provided with a second part in contact with the inner hole of the part. The first outer circular surface 3 in contact with a positioning surface, the lower section is provided with a positioning end surface 4 and a second outer circular surface 5 in contact with the second positioning surface of the inner hole of the part, and the bottom end of the positioning mandrel 2 is a cylindrical section 6 , the positioning end face 4 is located below the second outer circular surface 5, and the diameter of the positioning end face 4 is larger than the diameter of the second outer circular surface 5, and the positioning end face 4 is evenly distributed with indexing holes 7; the first measuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com