Connection part between a panel and a support

A technology for connecting parts and supports, applied in the direction of thin plate connection, connecting components, other connecting parts, etc., can solve the problems of damaged panels, unfavorable panels and body connections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

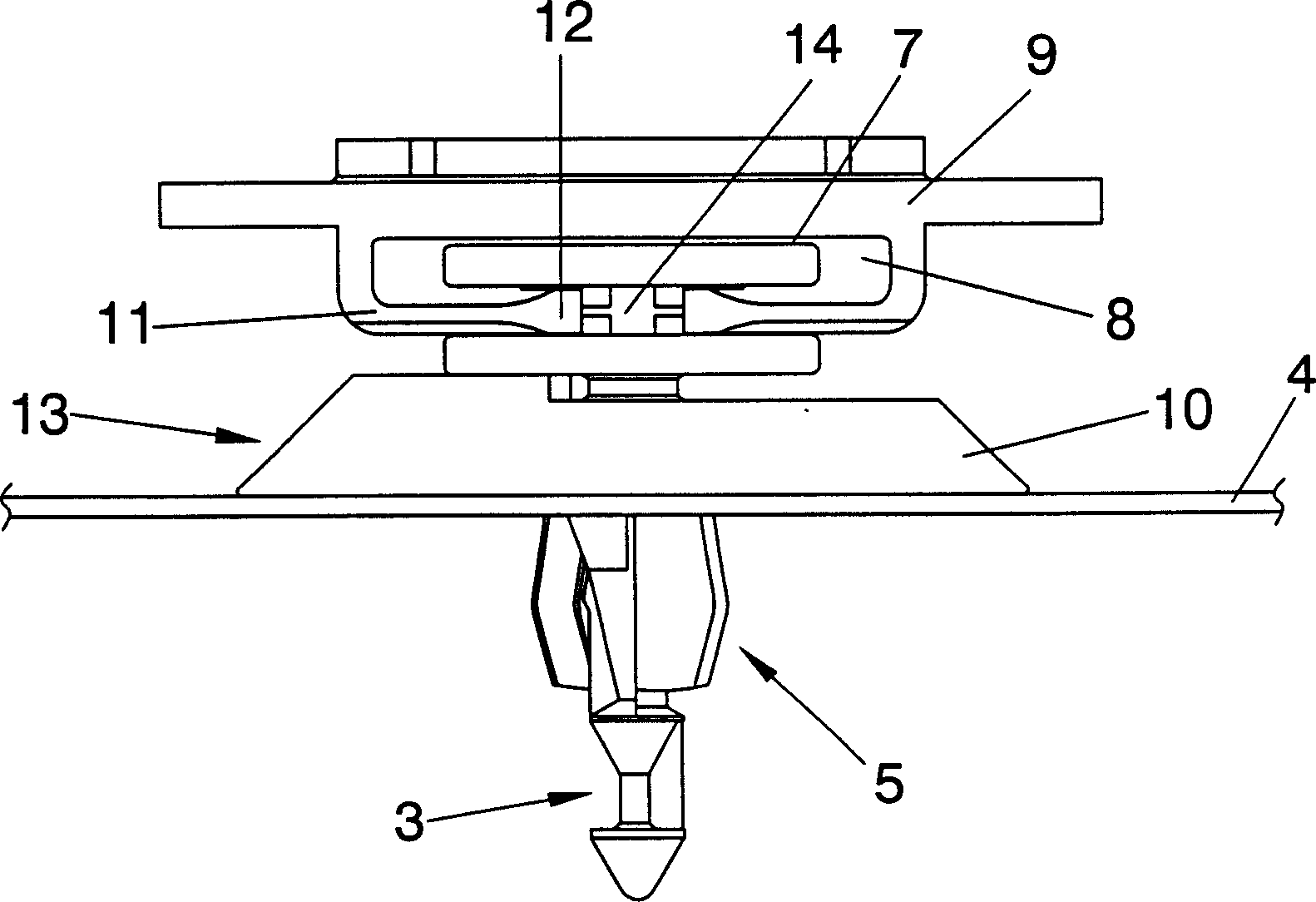

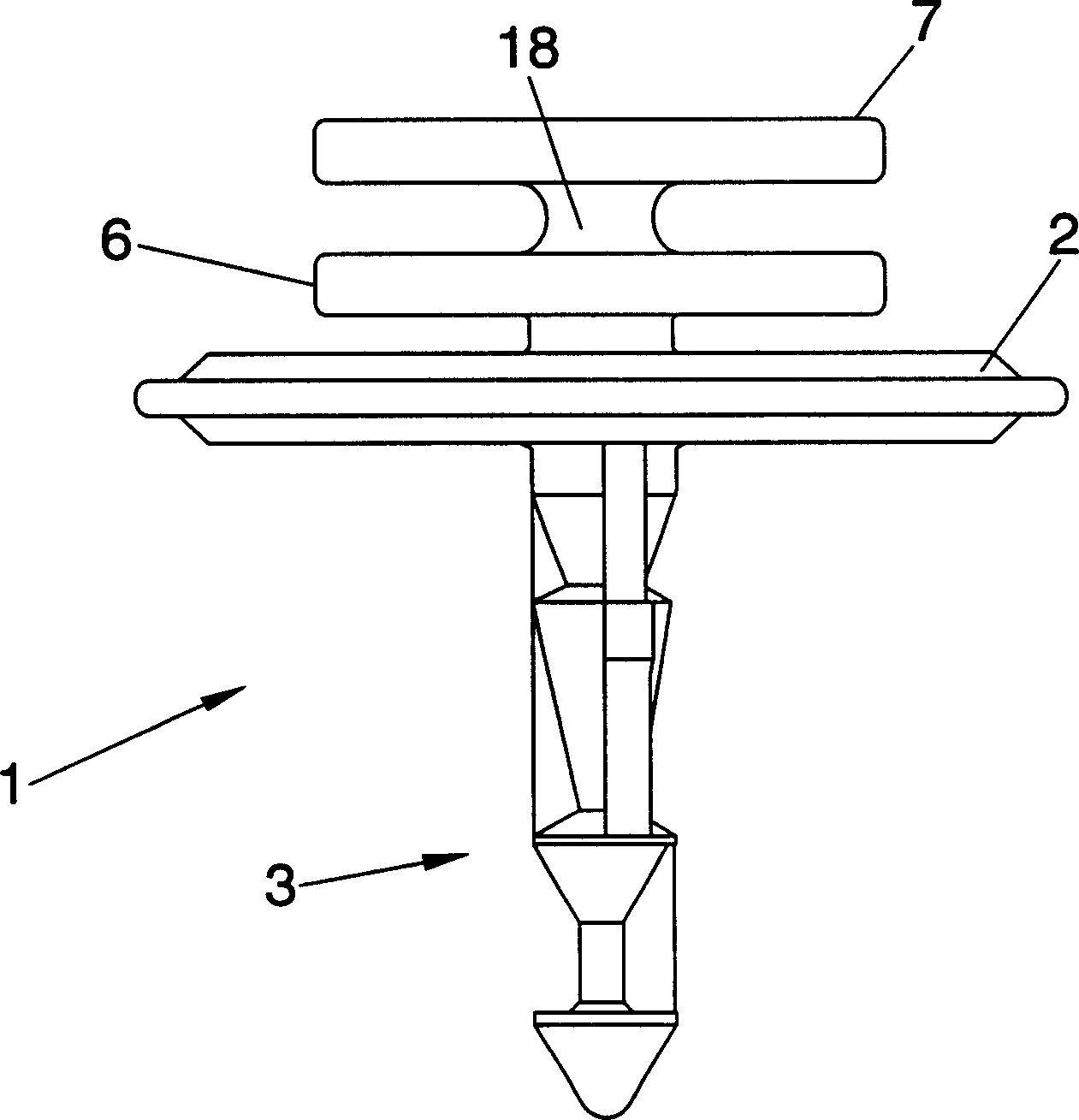

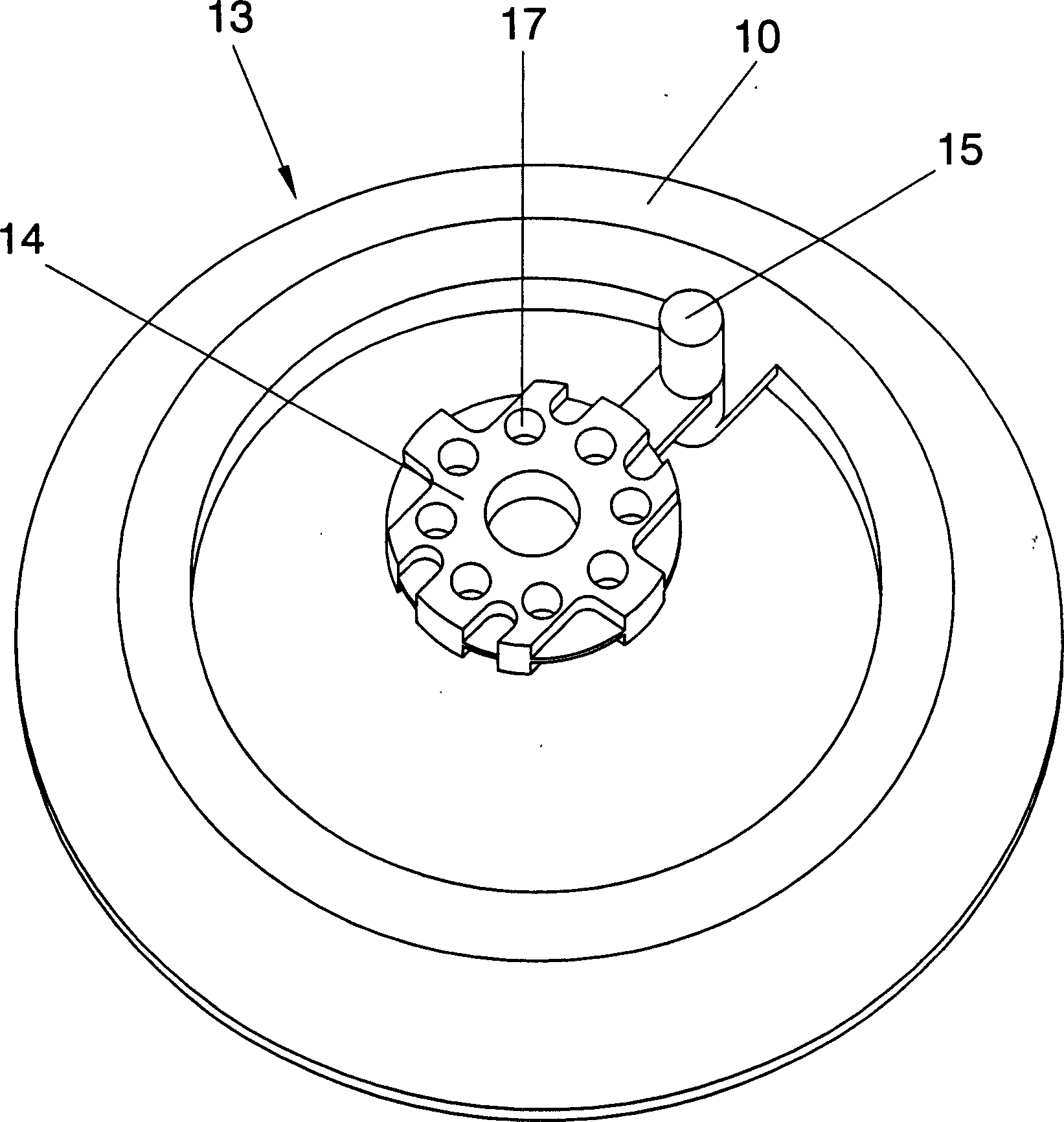

[0024] Object of the invention, the connecting part between the panel and the support comprises a body (1) formed by a disc-shaped base (2), from which an elongated section (3) extends downwards and through what may be a vehicle body Part of the hole in the support (4) and inserted into the retaining bushing (5), at the top of the disc base (2) there is the middle disc segment (6) and the upper disc segment (7), connected to the panel The cutout (8) of the retainer (9) (not shown) is locked on the upper disc-like segment (7), this cutout (8) being delimited at its bottom by the plate (11). The plate (11) has a neck (12) for connecting the body (1).

[0025] From this basic structure, the main feature of the connecting part of the present invention is that it combines a casting part (13) made of soft and compressible material on the body (1), and the body (1) is provided with a surrounding body (1 ) of the segment (18) of the absorber ring (14), the segment (18) is between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com