Patents

Literature

32results about "Other connections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

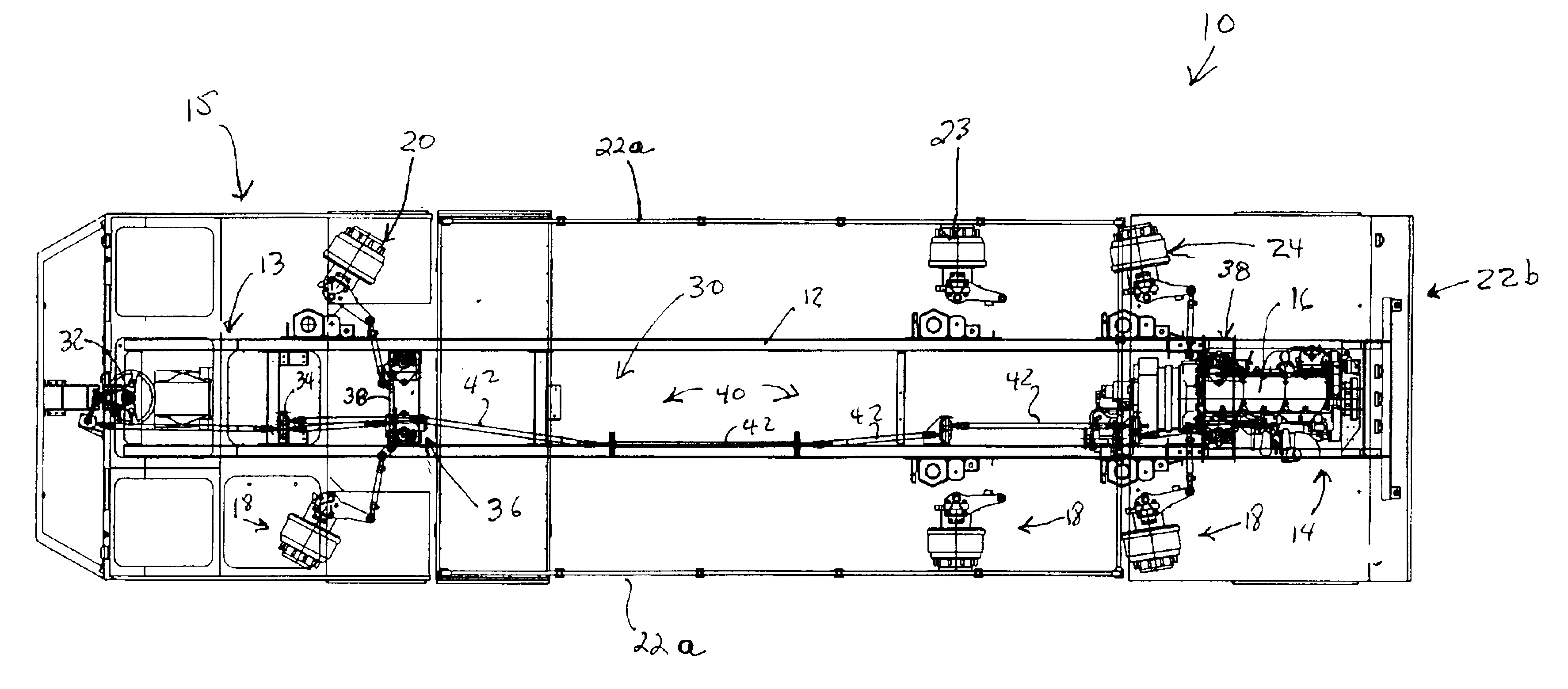

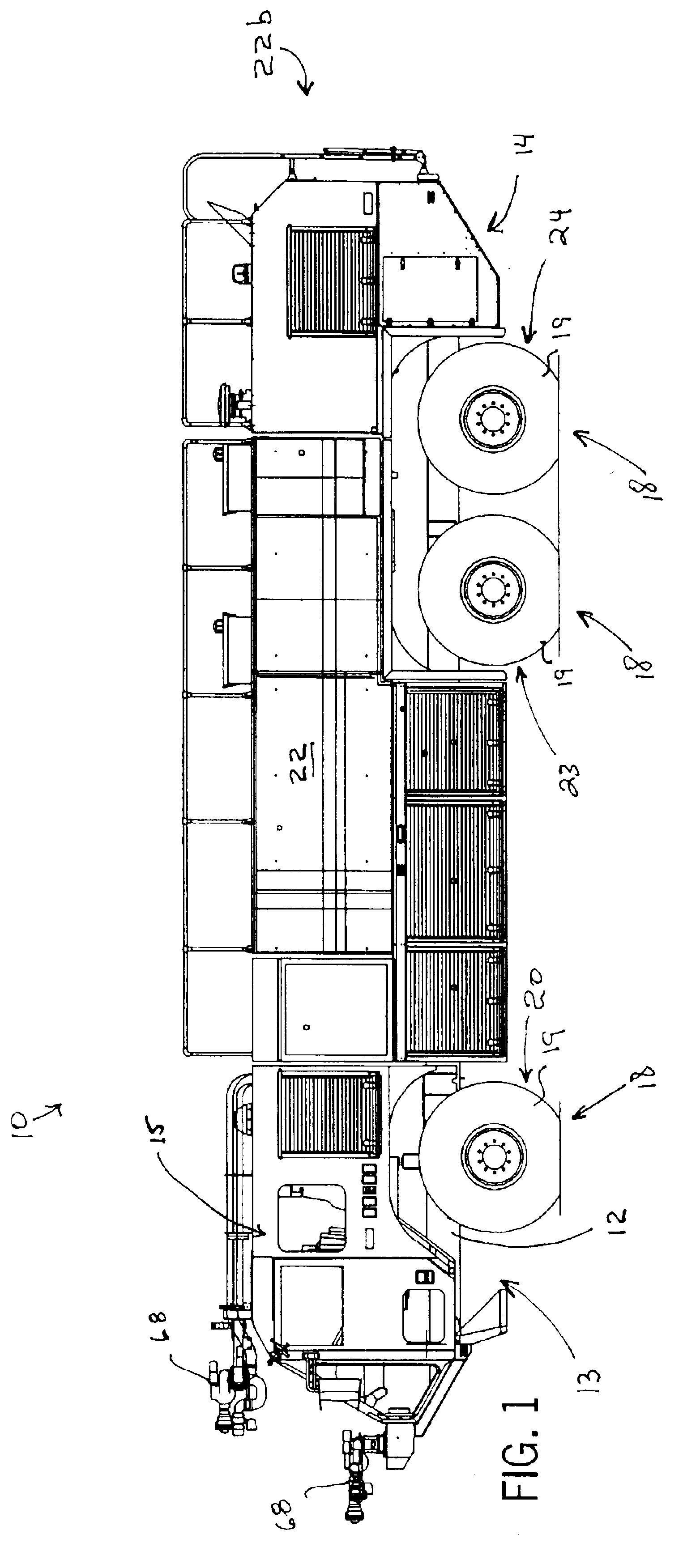

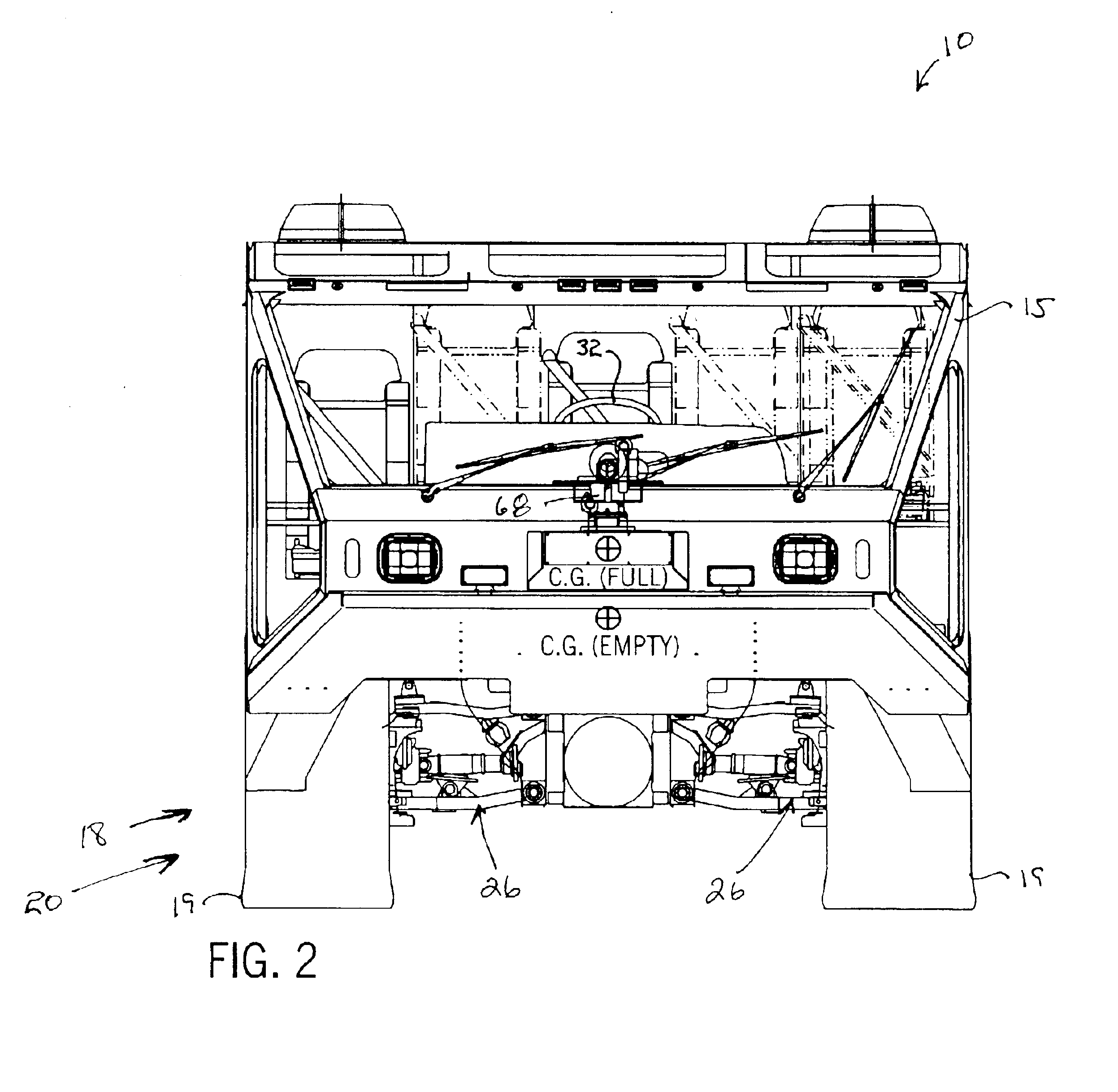

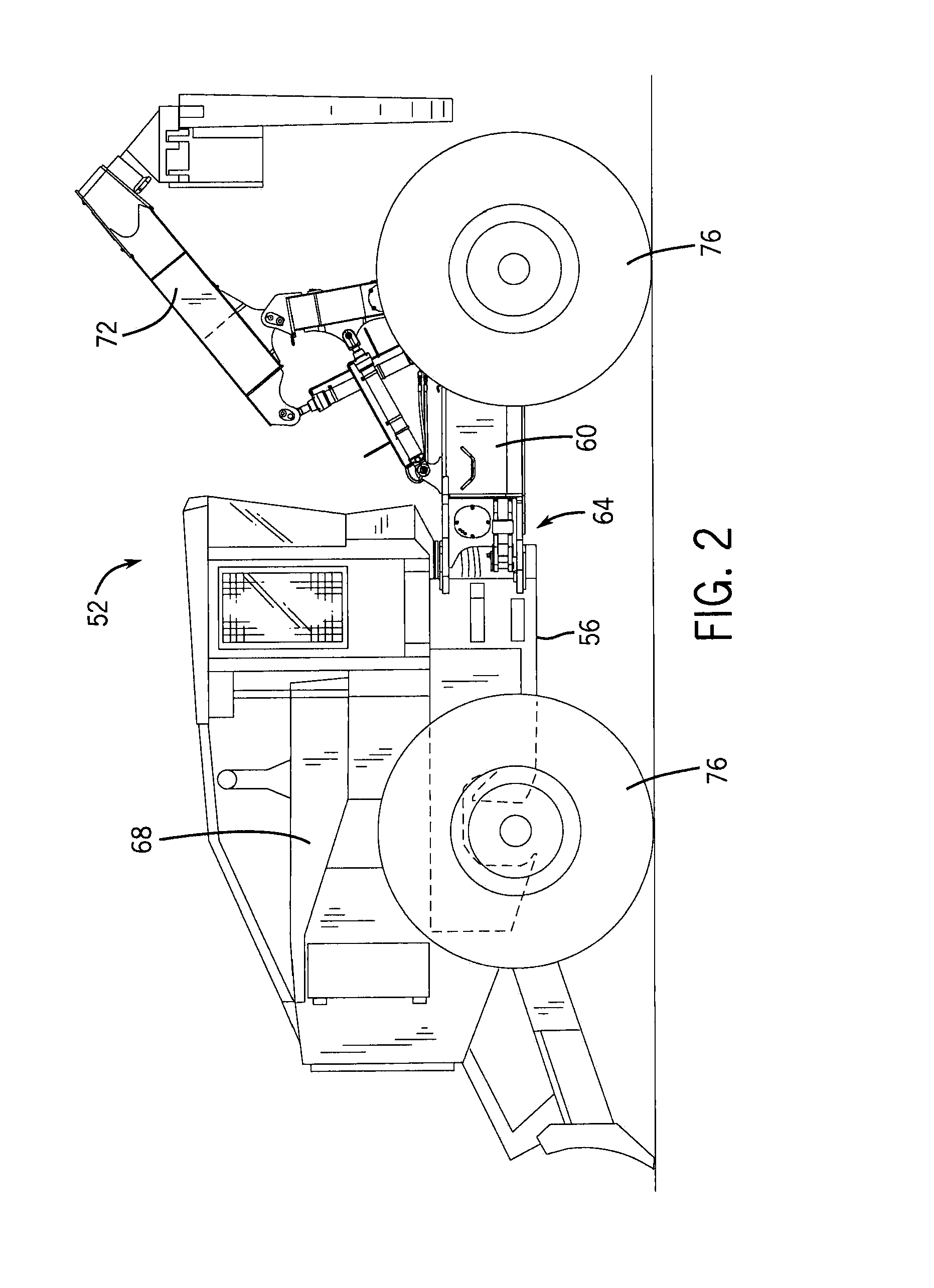

Fire-fighting vehicle

An airport rescue fire-fighting vehicle comprising a support structure coupled to at least two wheel sets. The support structure has a front end and a back end with one wheel set coupled to the front end of the support structure and one wheel set coupled to the back end of the support structure. A power source is mounted on the support structure and coupled to at least one wheel set. Each wheel of the vehicle is coupled to a modular independent suspension. A mechanical steering apparatus is coupled to the front wheel set and at least one rear wheel set.

Owner:OSHKOSH CORPORATION

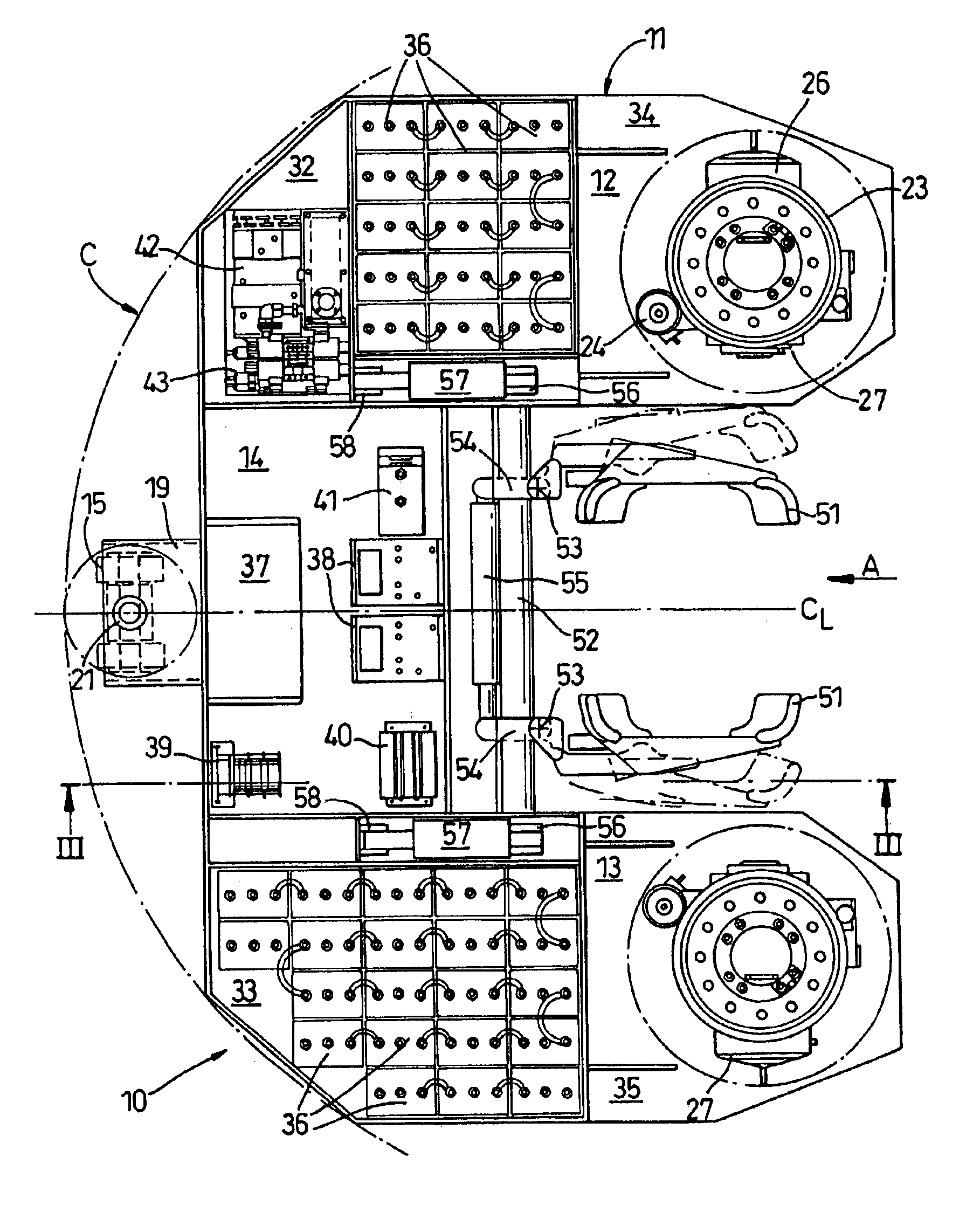

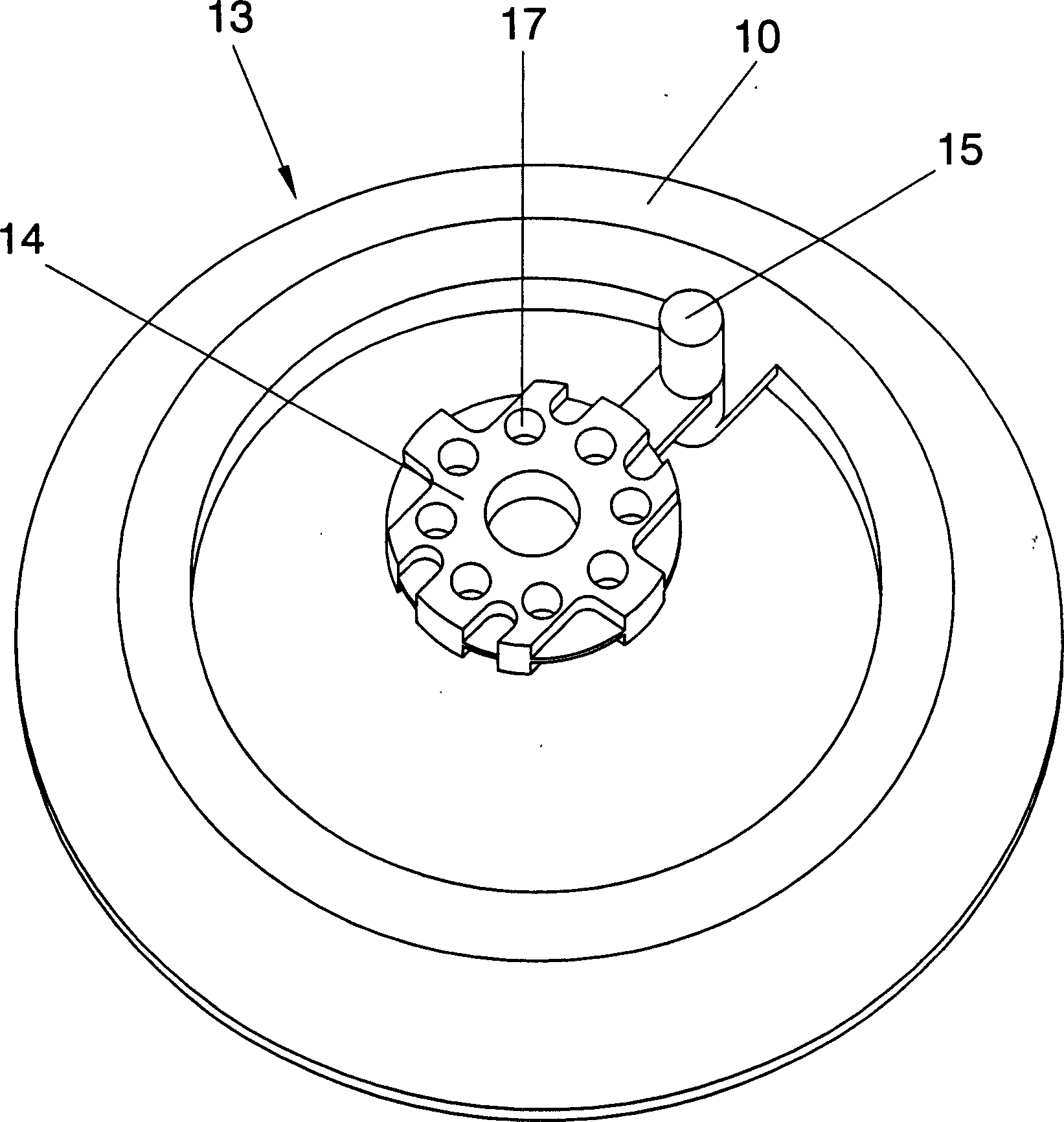

Aircraft handler

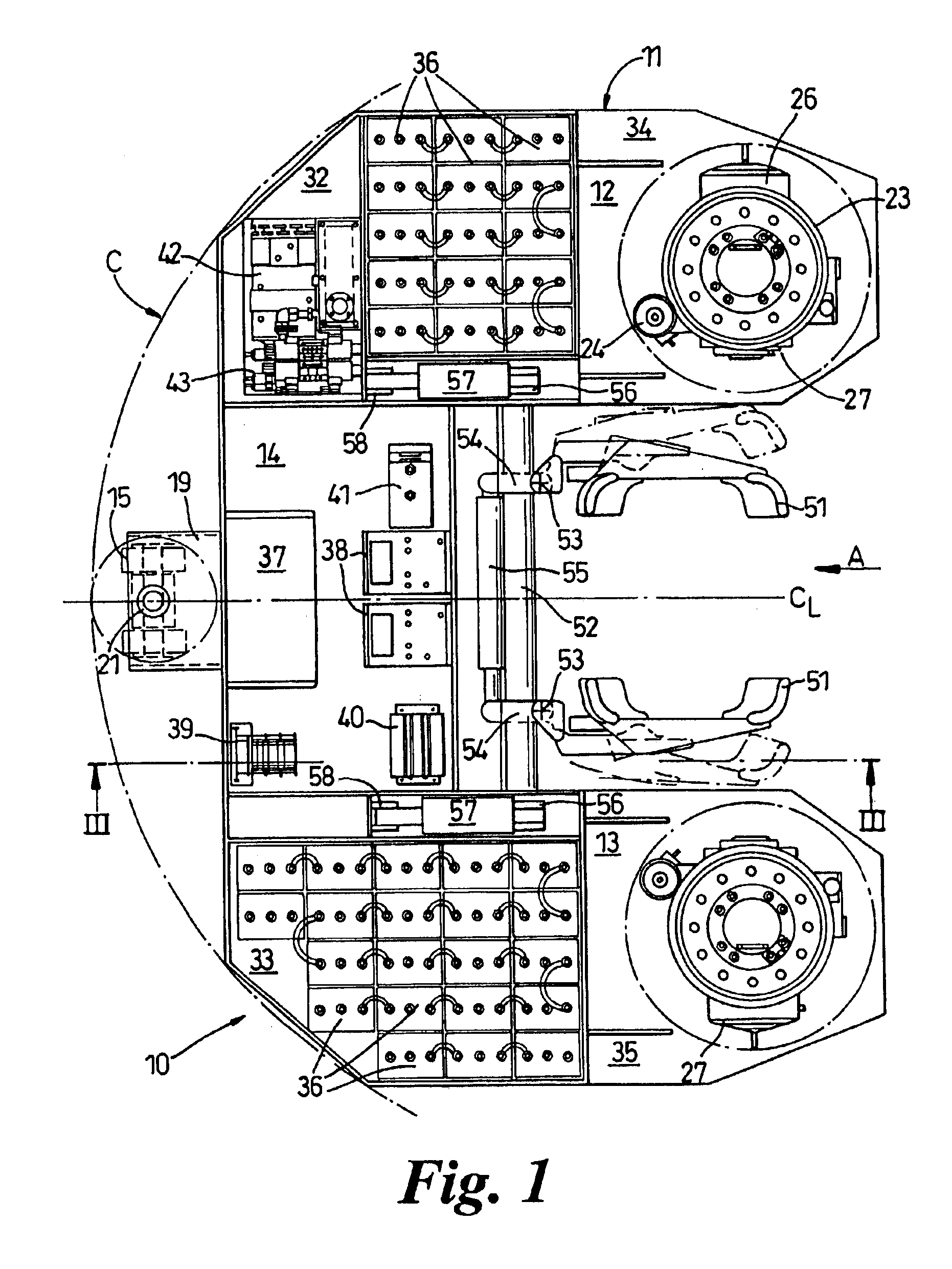

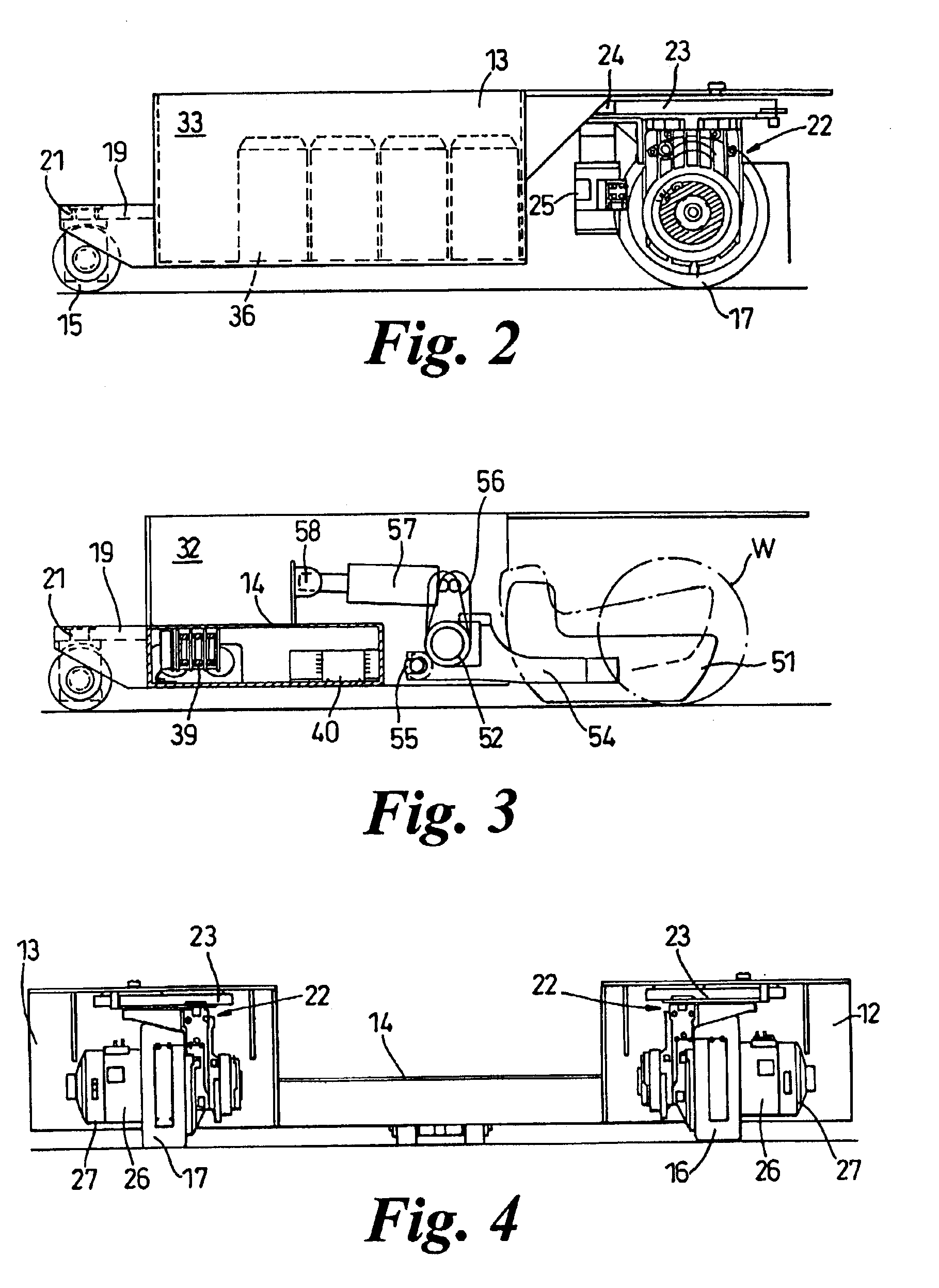

An aircraft handler (10) for use with an undercarriage of an aircraft, the handler being self-propelled and comprising a generally “U” shaped body (11) having arms (12 &13) linked by a bridge (14) at one end thereof with a pair of drive wheels (16 &17) located one at the free end of each arm, with at least one wheel(15) located adjacent the bridge(14). A pair of clamping jaws (51) are mounted on the body (11) between the drive wheels (16 &17) and the bridge (14)and jaws (51) have a lower profile than the arms (12 &17). The drive wheel (16 &17) are driven by DC electric motors powered by batteries stored in the arms.

Owner:DOUGLAS EQUIPMENT +1

Mobile advertising frame

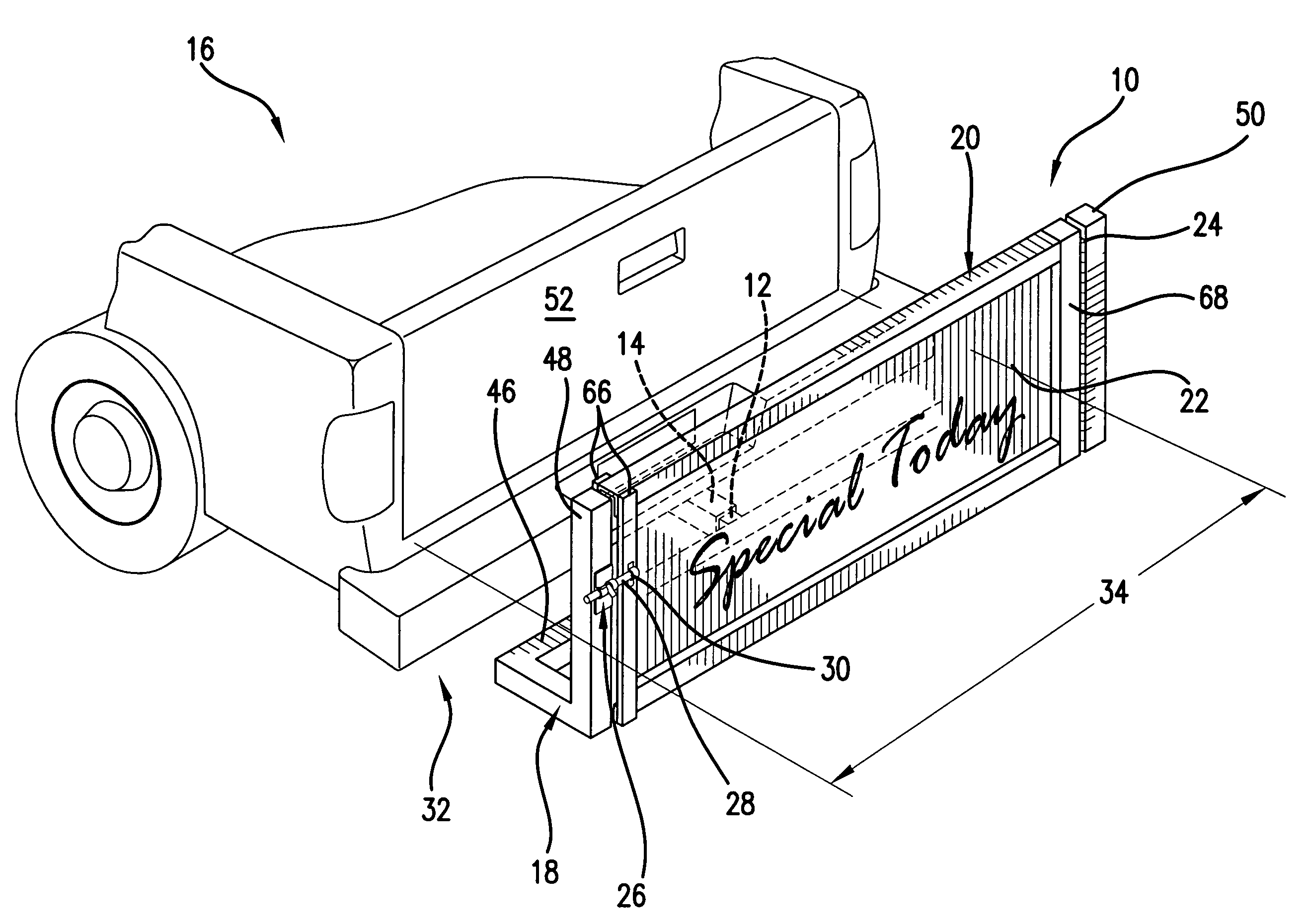

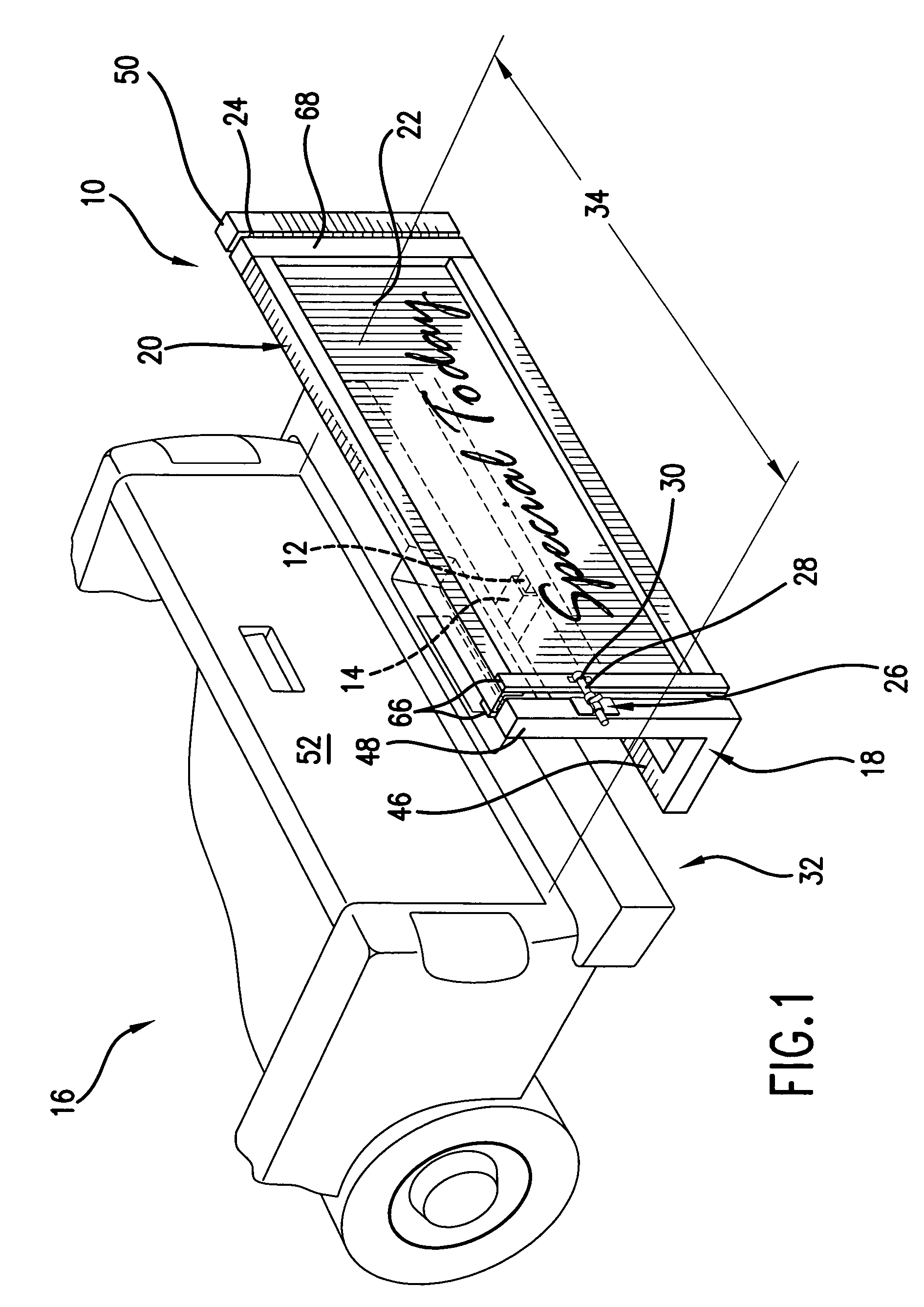

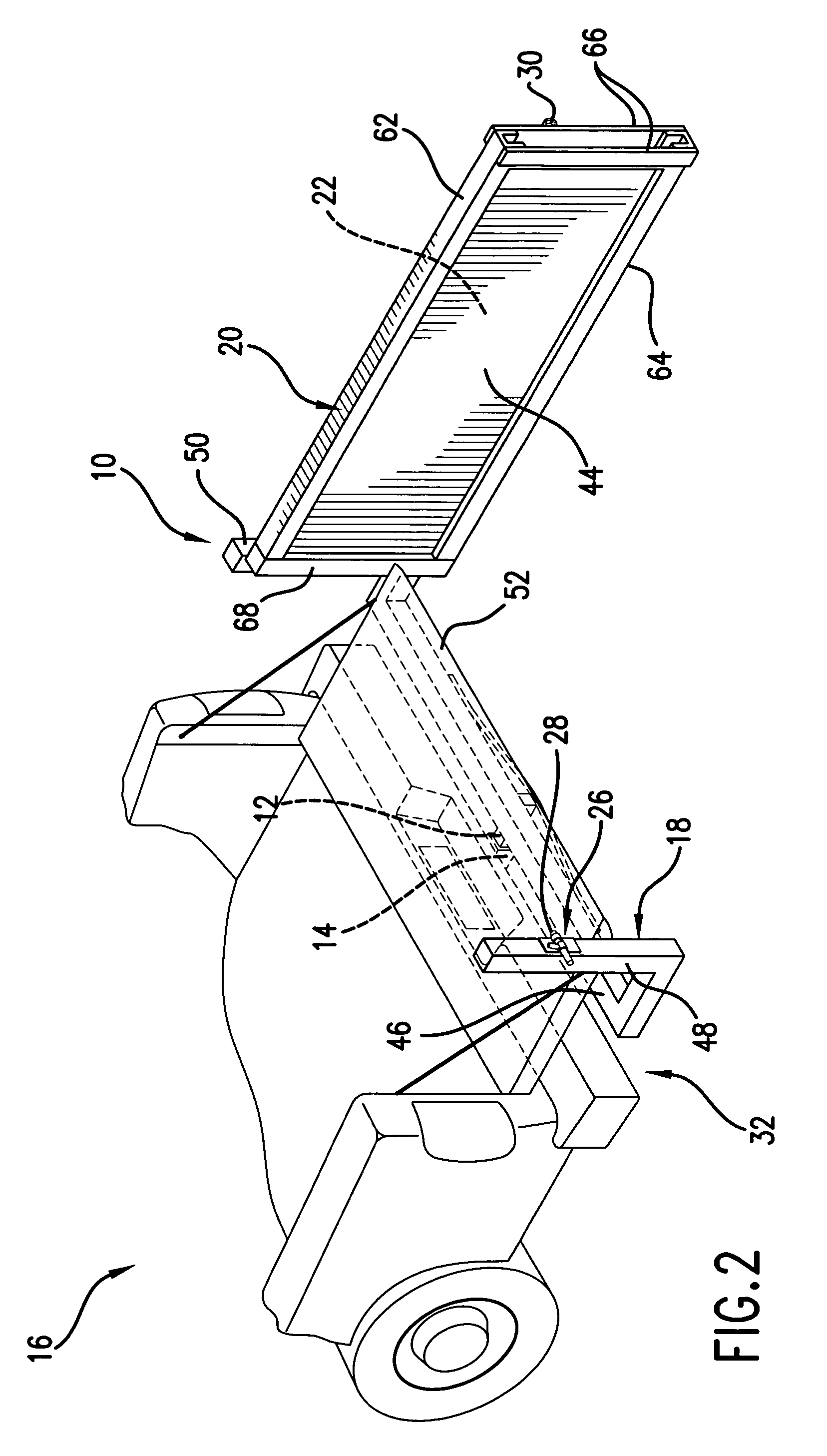

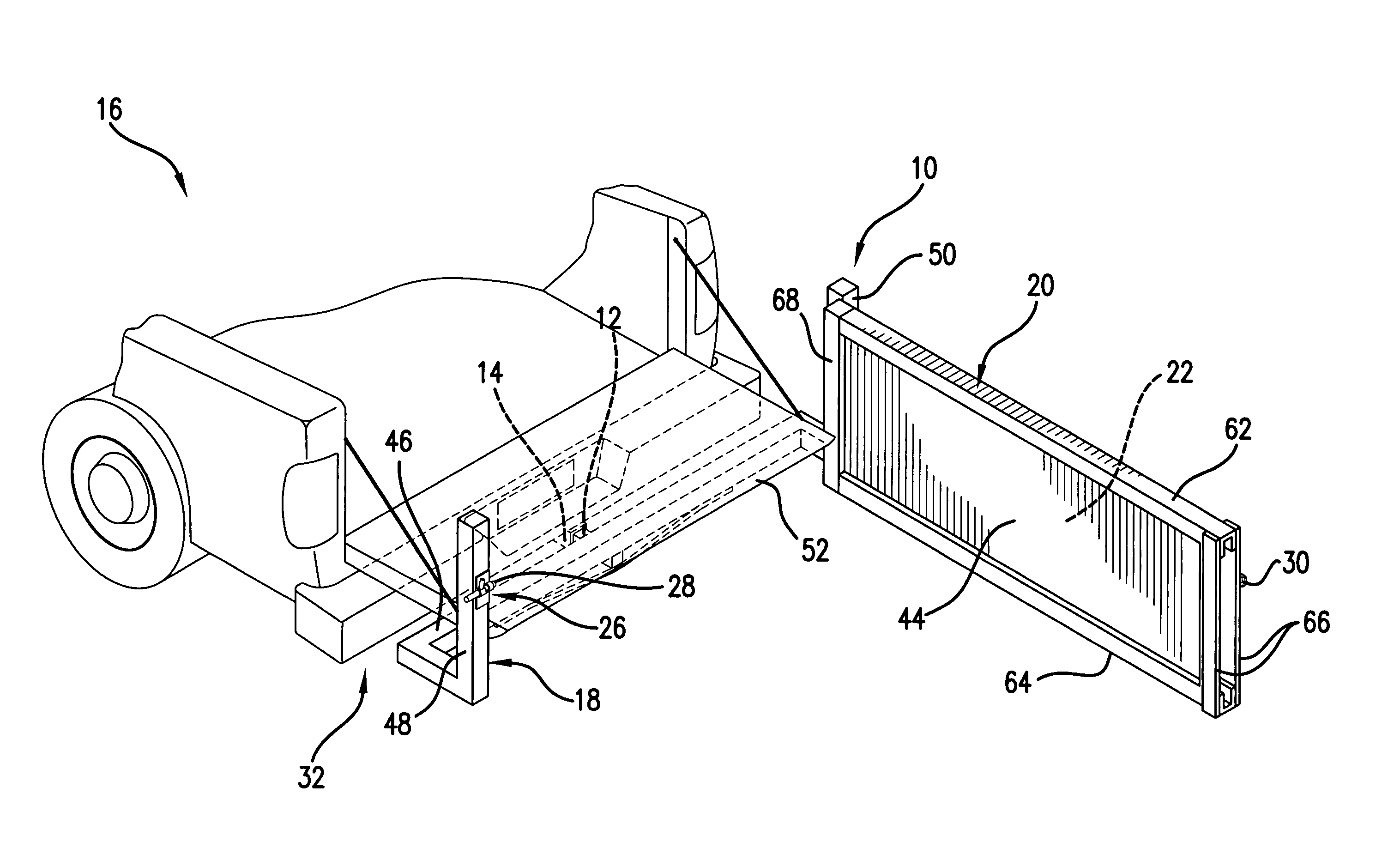

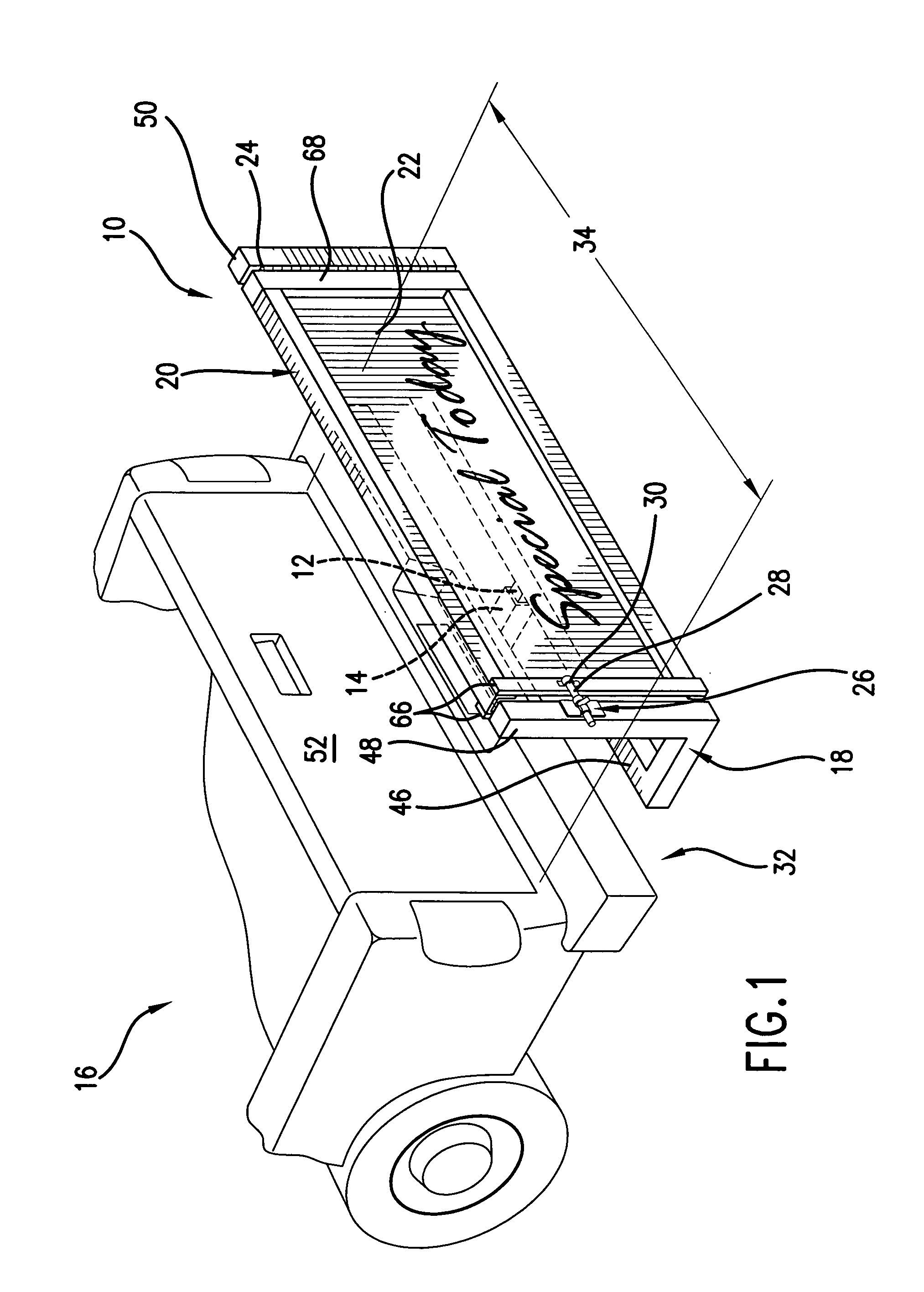

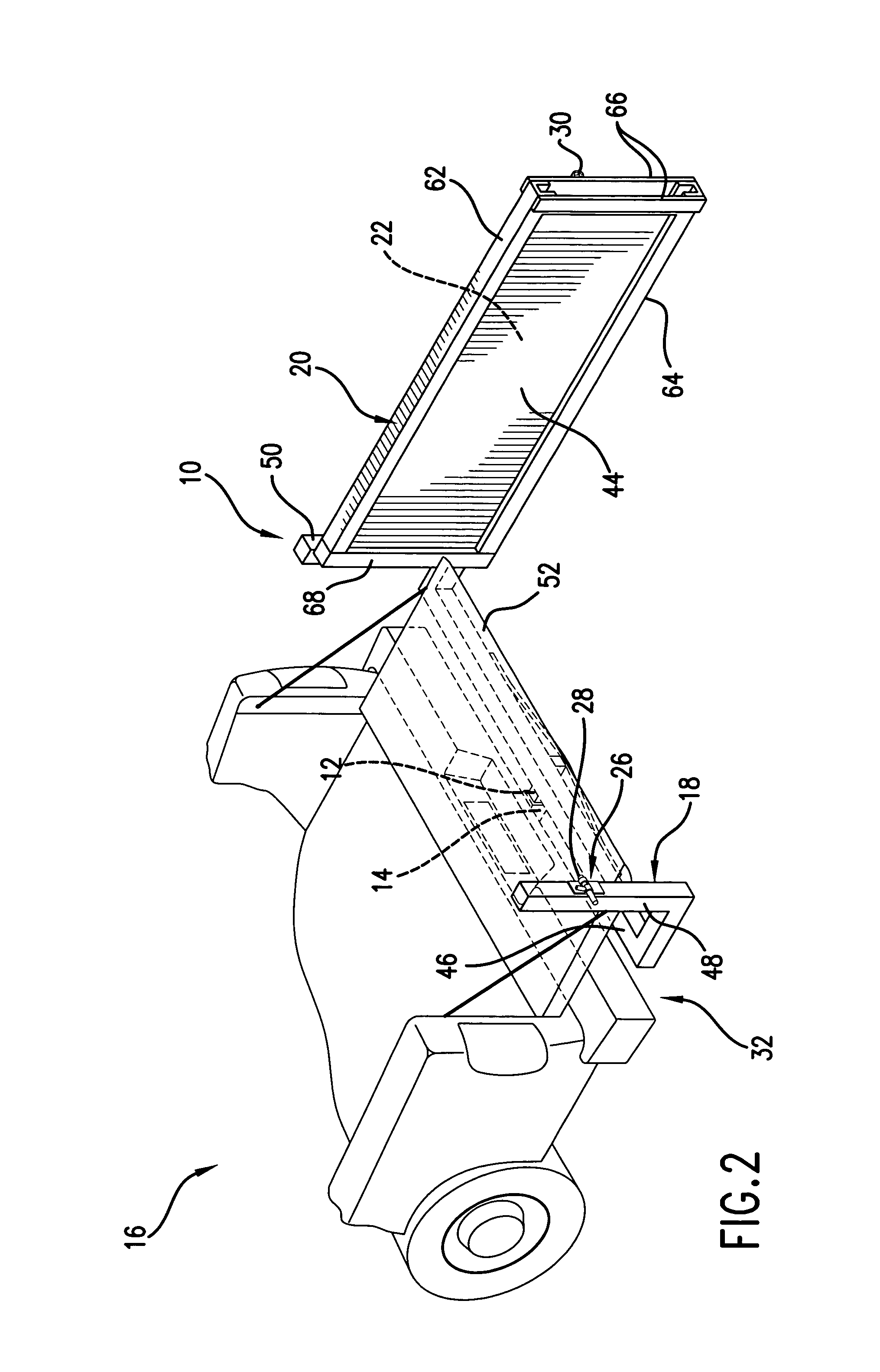

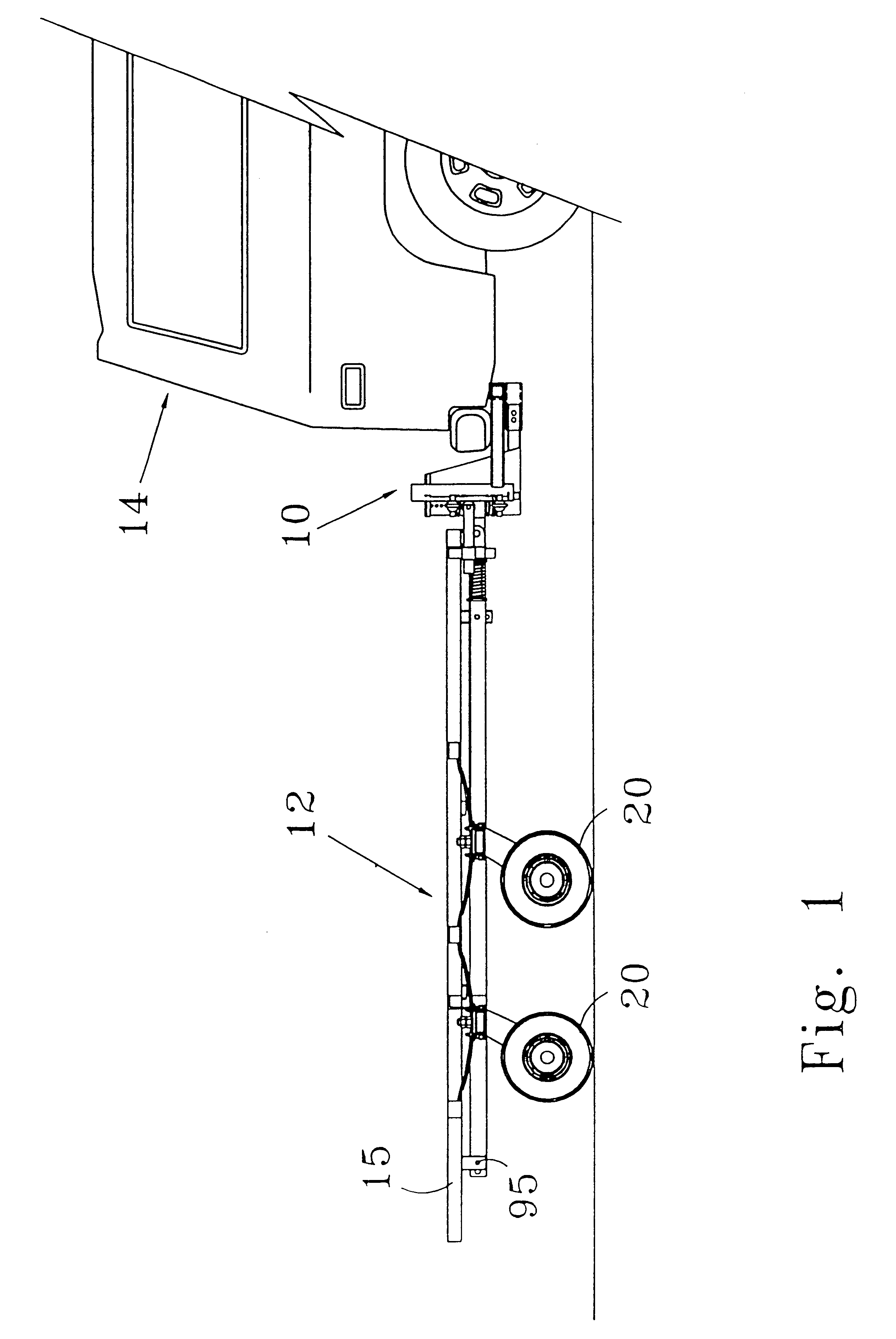

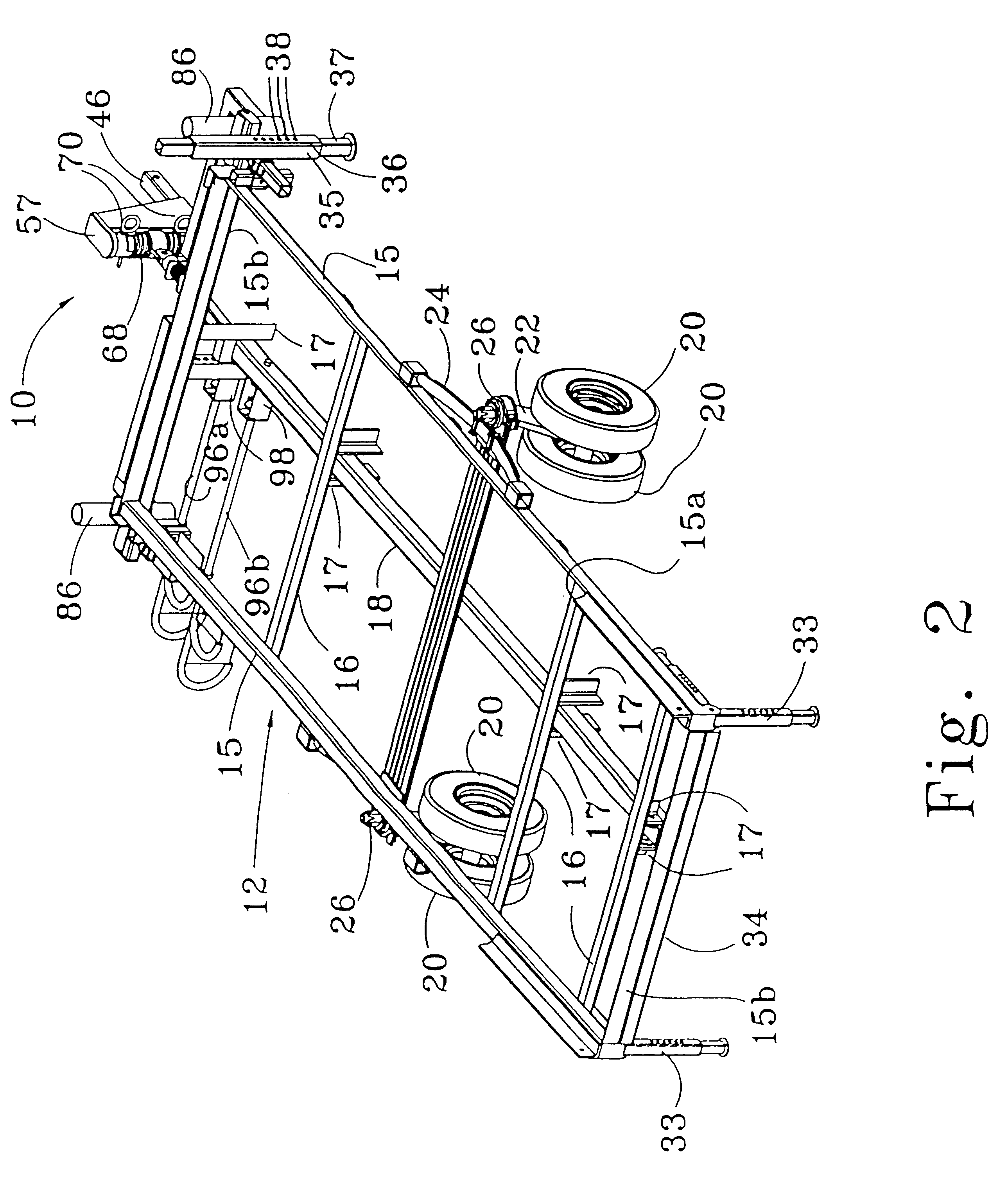

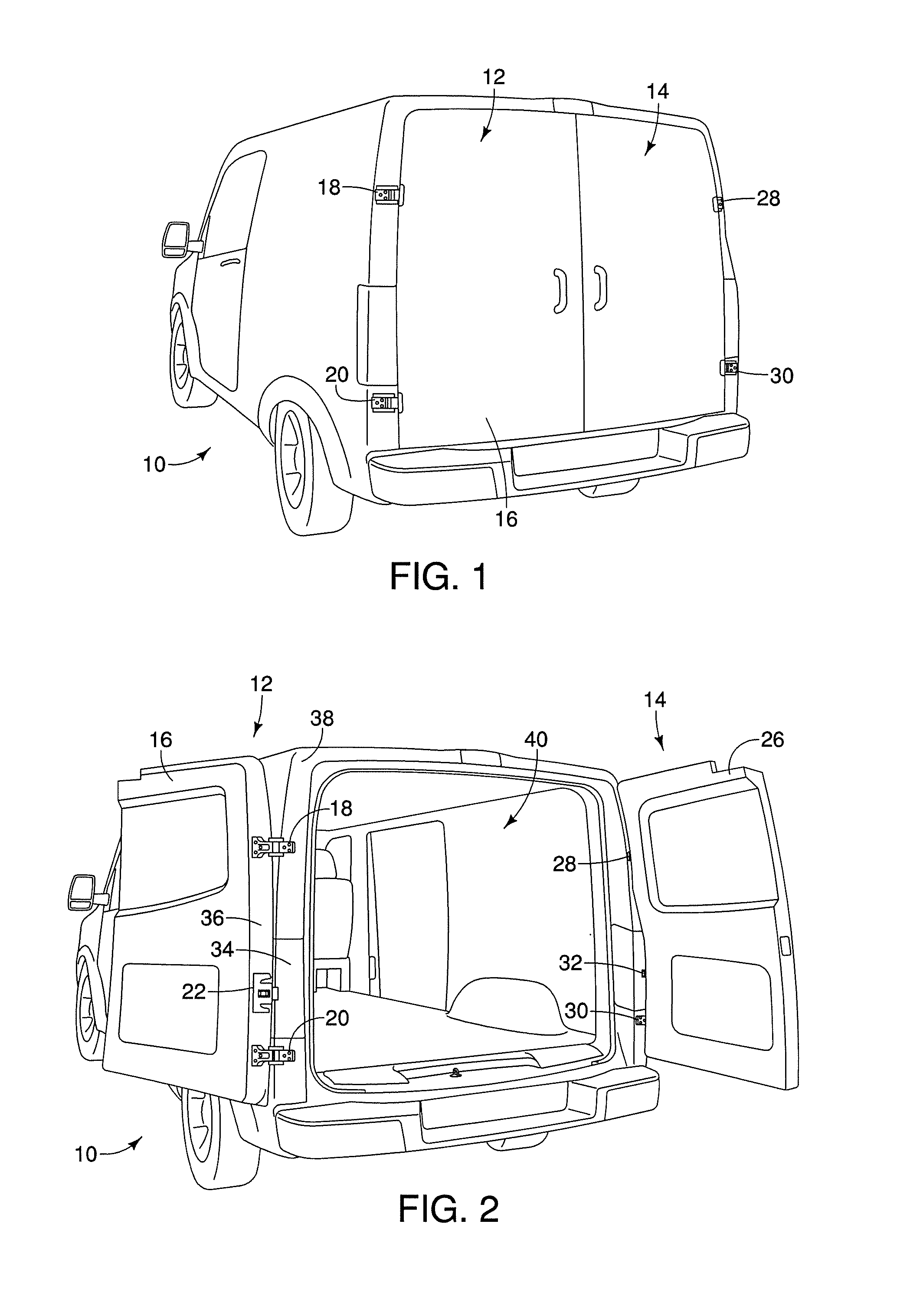

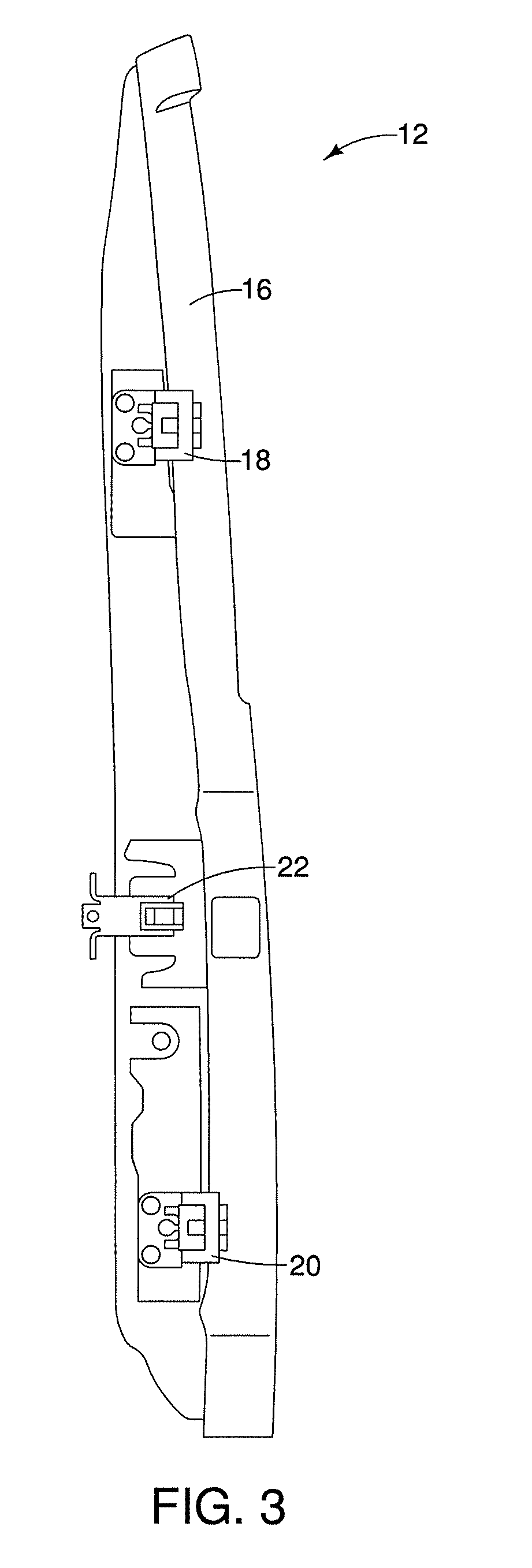

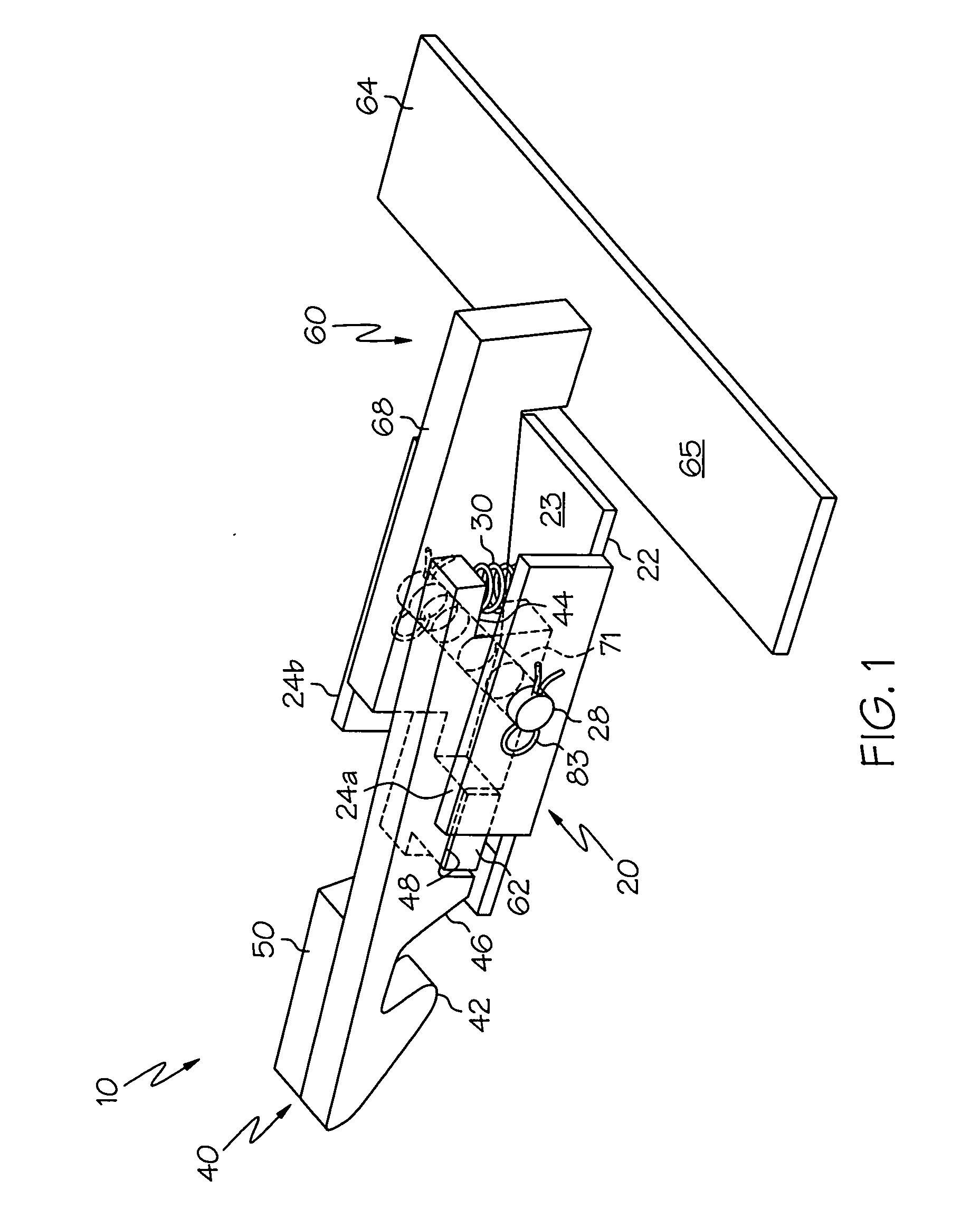

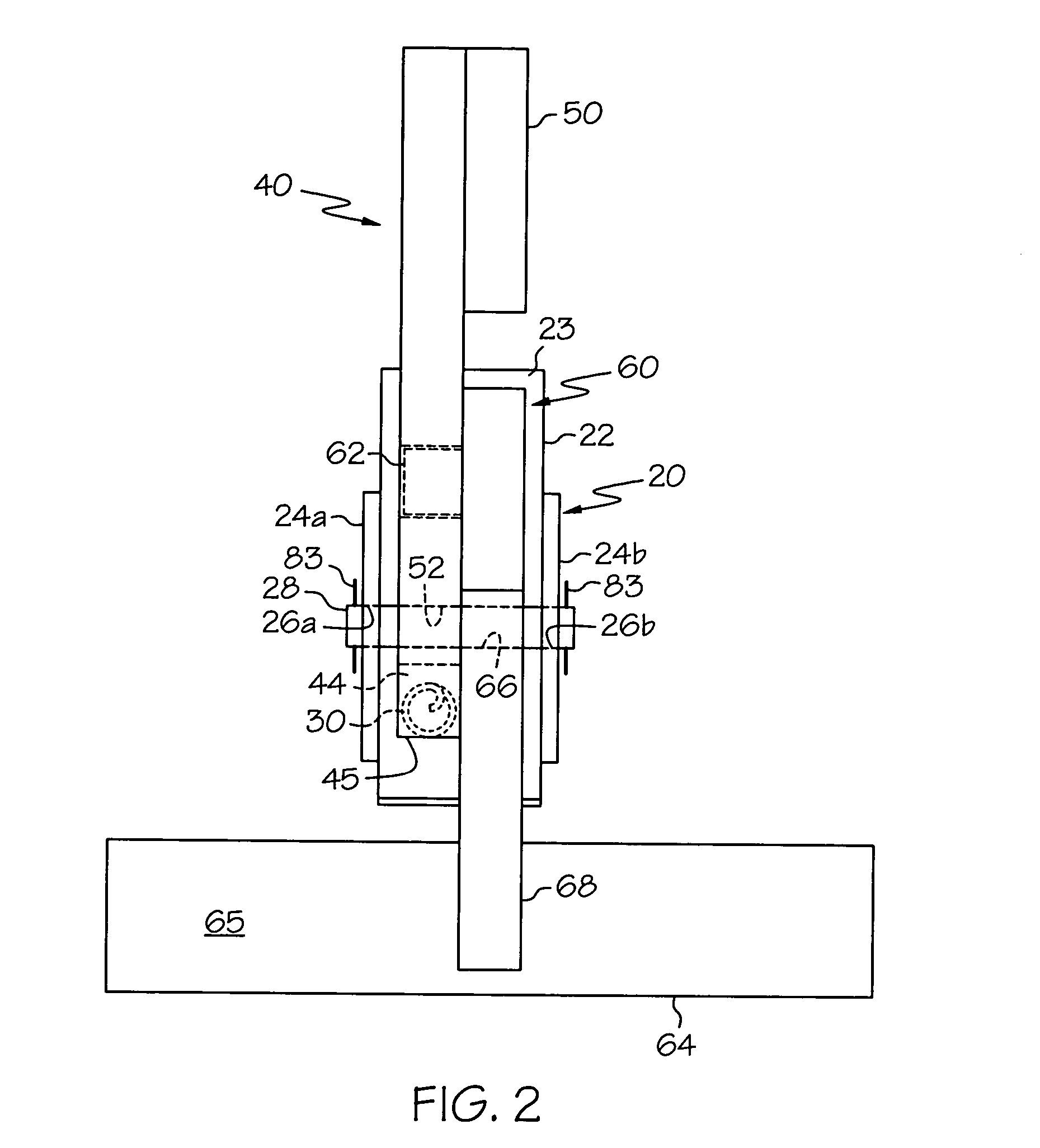

An advertising frame for use with a vehicle so as to render the advertising frame mobile is provided. The advertising frame includes a vehicle engagement that is configured for engaging a vehicle. A signage member is included and is configured for carrying advertising signage. The signage member is pivotable with respect to the vehicle engagement member so as to be configured for providing access to the rear of a vehicle. A tailgate, hatch, trunk, spare tire or other component or portion of the rear of the vehicle may be accessed by pivoting the signage member out of the way.

Owner:FROG MARKETING

Mobile advertising frame

An advertising frame for use with a vehicle so as to render the advertising frame mobile is provided. The advertising frame includes a vehicle engagement that is configured for engaging a vehicle. A signage member is included and is configured for carrying advertising signage. The signage member is pivotable with respect to the vehicle engagement member so as to be configured for providing access to the rear of a vehicle. A tailgate, hatch, trunk, spare tire or other component or portion of the rear of the vehicle may be accessed by pivoting the signage member out of the way.

Owner:FROG MARKETING

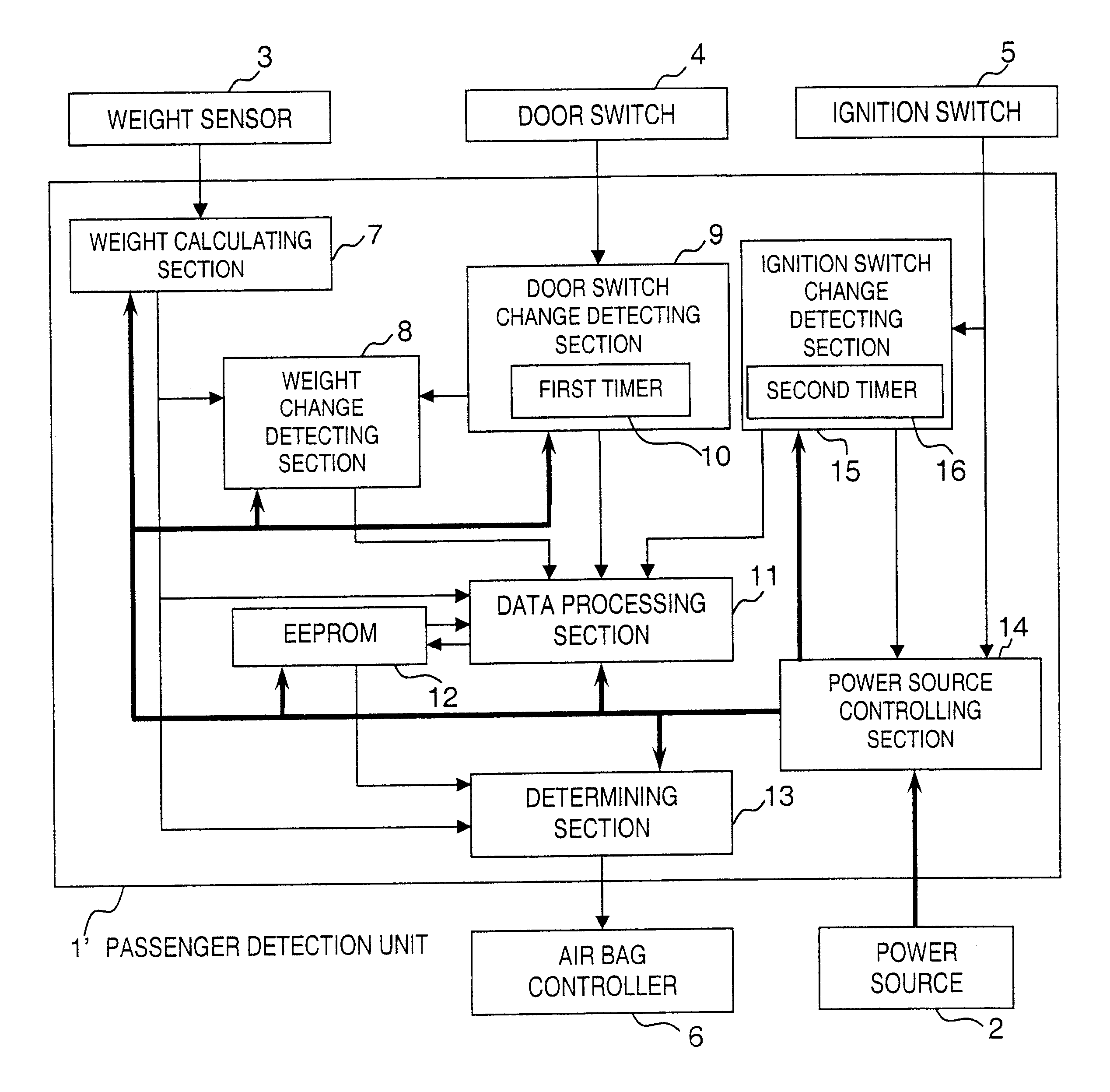

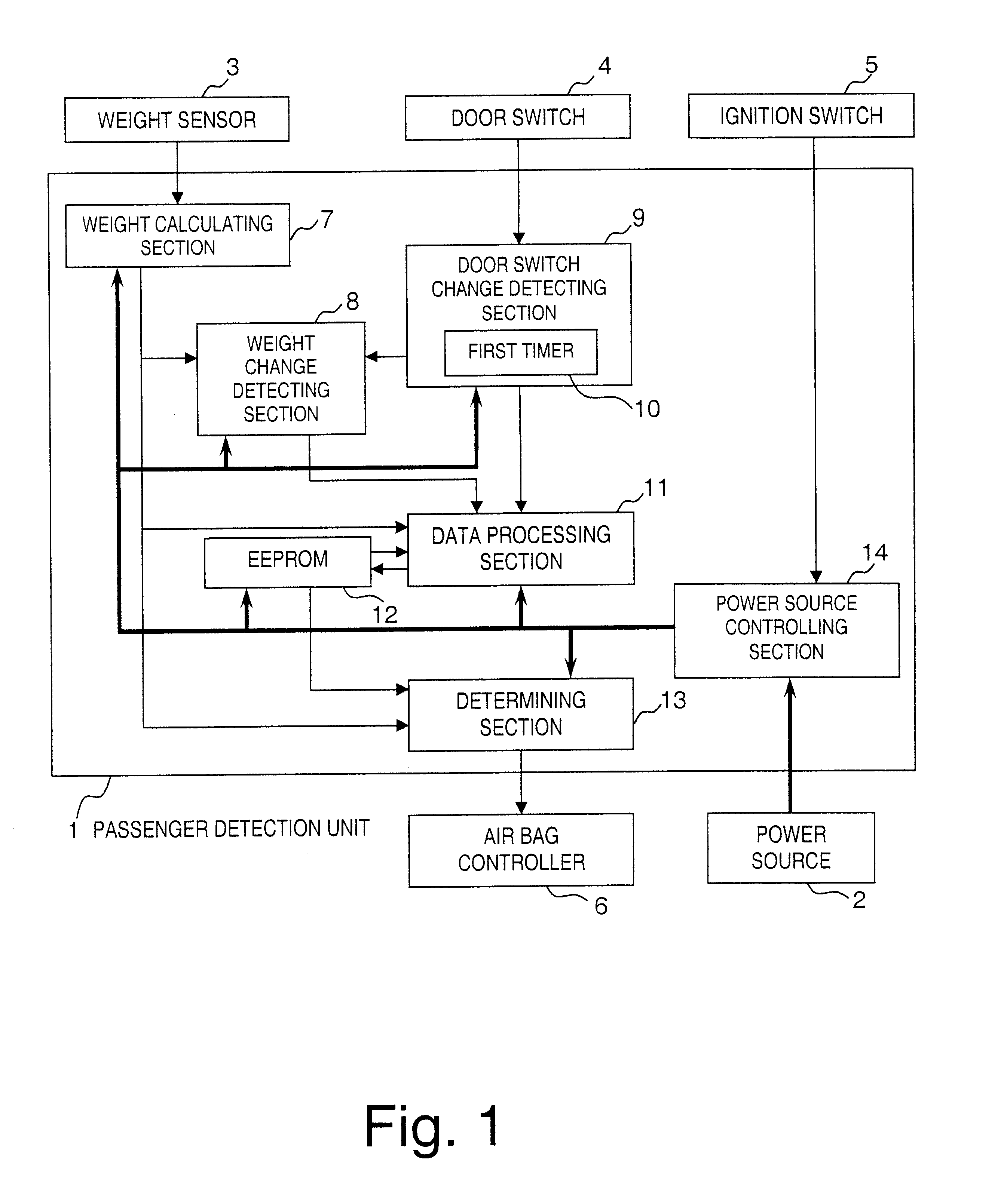

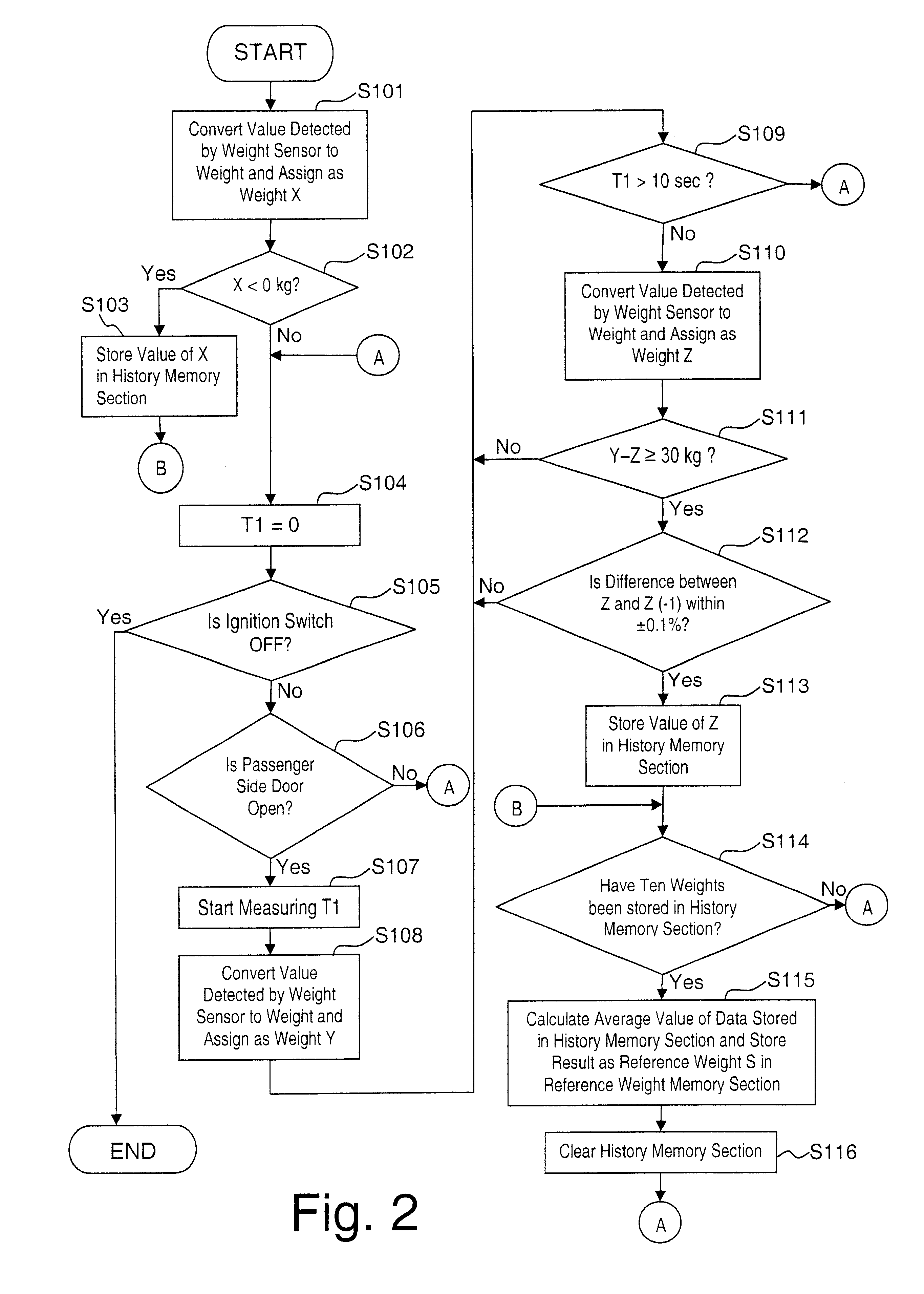

Passenger detection system

InactiveUS6727823B2Accurate measurementSimple configurationVehicle seatsDigital data processing detailsEngineeringClosed state

A passenger detection system is provided to determine if a passenger is present or not because the weight value corresponding to when the seat is empty has shifted. The passenger detection system detects when the door has changed from the closed state to the open state based on a signal from a door switch. The passenger detection system then senses the decrease in weight that occurs thereafter and stores the weight value obtained after the decrease as the empty seat value.

Owner:NISSAN MOTOR CO LTD

Hitch and trailer assembly

InactiveUS6357778B1Easy wheel repairEasy to useMechanical machines/dredgersTractor-trailer combinationsMobile vehicleEngineering

A hitch and trailer assembly includes a trailer having a mounting member and a hitch receiver mountable to a motor vehicle for receiving the mounting member. The hitch and trailer assembly also include a plurality of rollers for connection to one of the trailer and the motor vehicle and a plurality of bumpers for connection to the other one of the trailer and the motor vehicle to allow the rollers and the bumpers abut each other when the mounting member is disposed in the hitch receiver.

Owner:ROSS LOUIS J

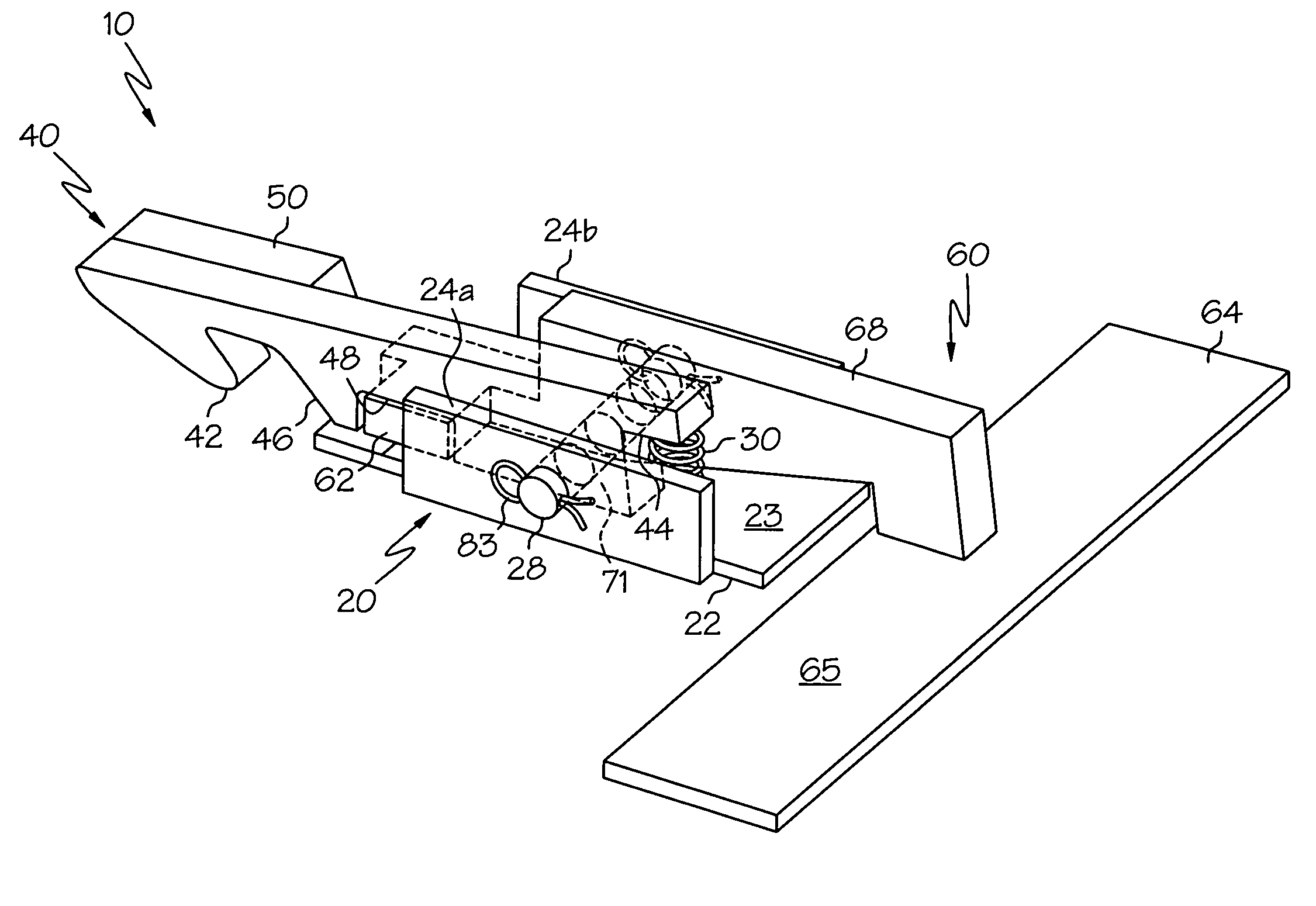

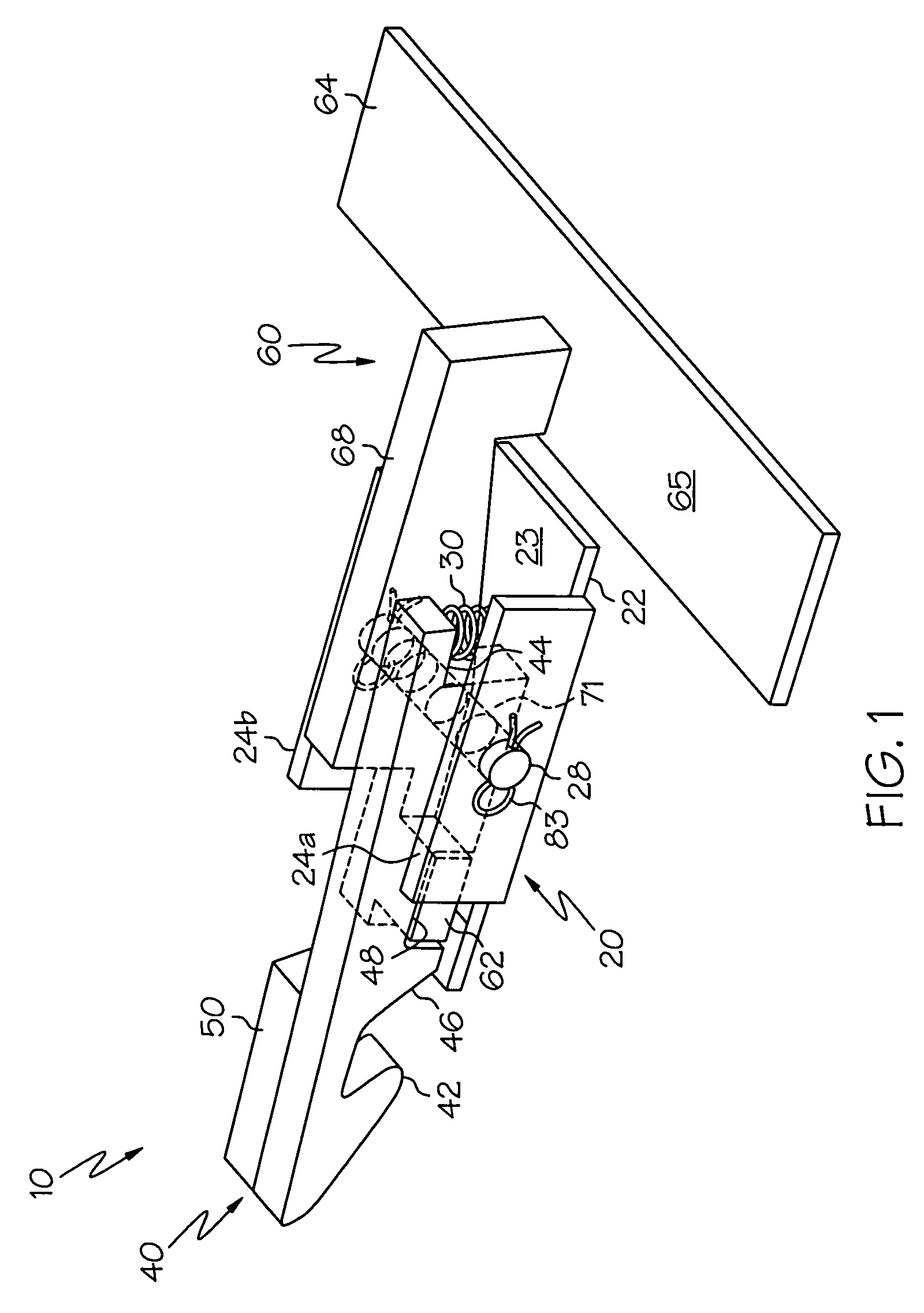

Automatic hitch assembly

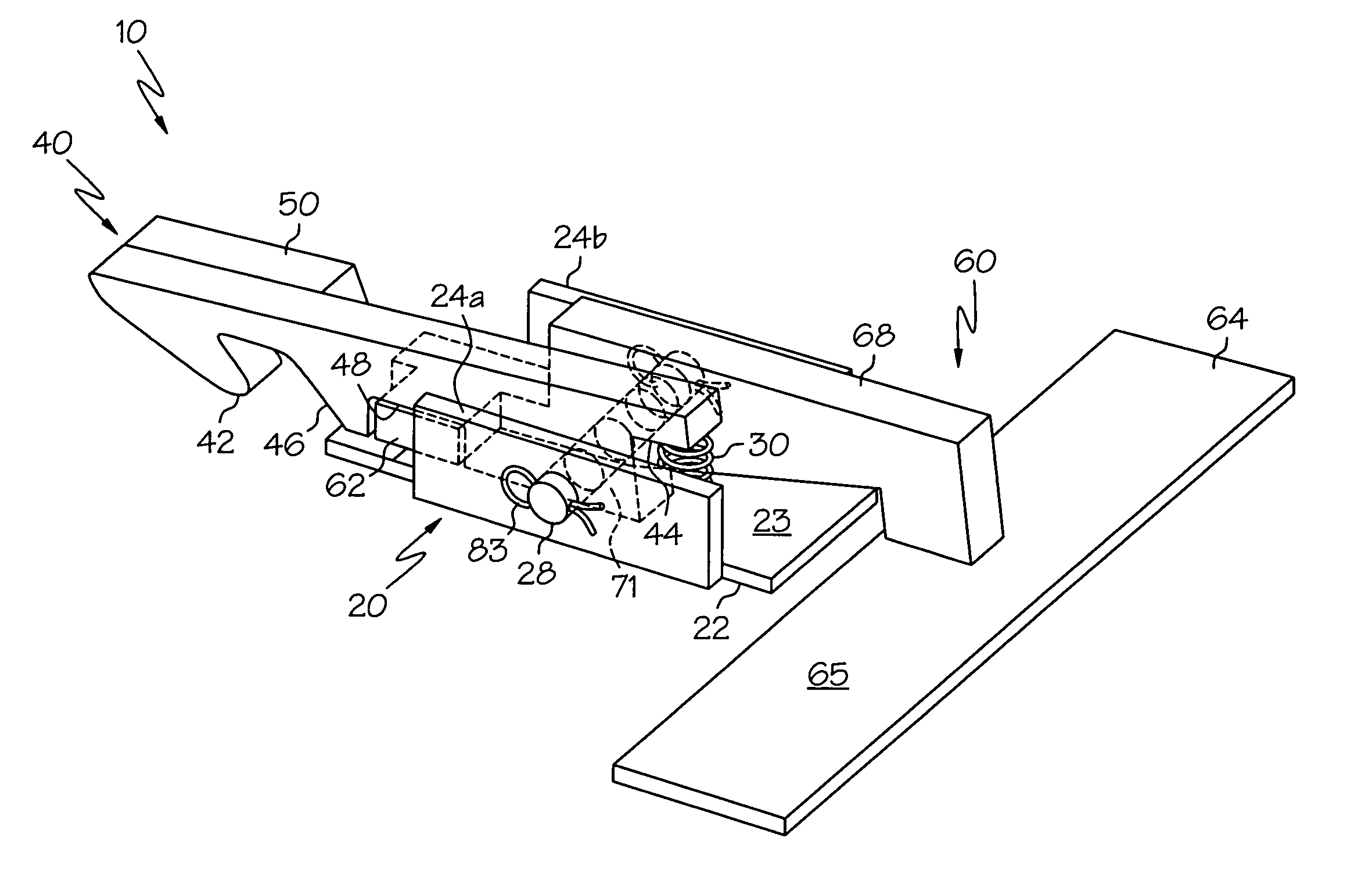

An automatic hitch may include a base, a support surface, a jaw assembly connected to the base and having engaged and disengaged positions and a biasing member associated with the jaw assembly. The biasing member may be configured to normally bias the jaw assembly toward the support surface. The automatic hitch may also include a release mechanism configured to apply upward force to the jaw assembly upon downward actuation of the release mechanism to move the jaw assembly into the disengaged position.

Owner:TOYOTA MOTOR ENGINEERING & MANUFACTURING NORTH AMERICA

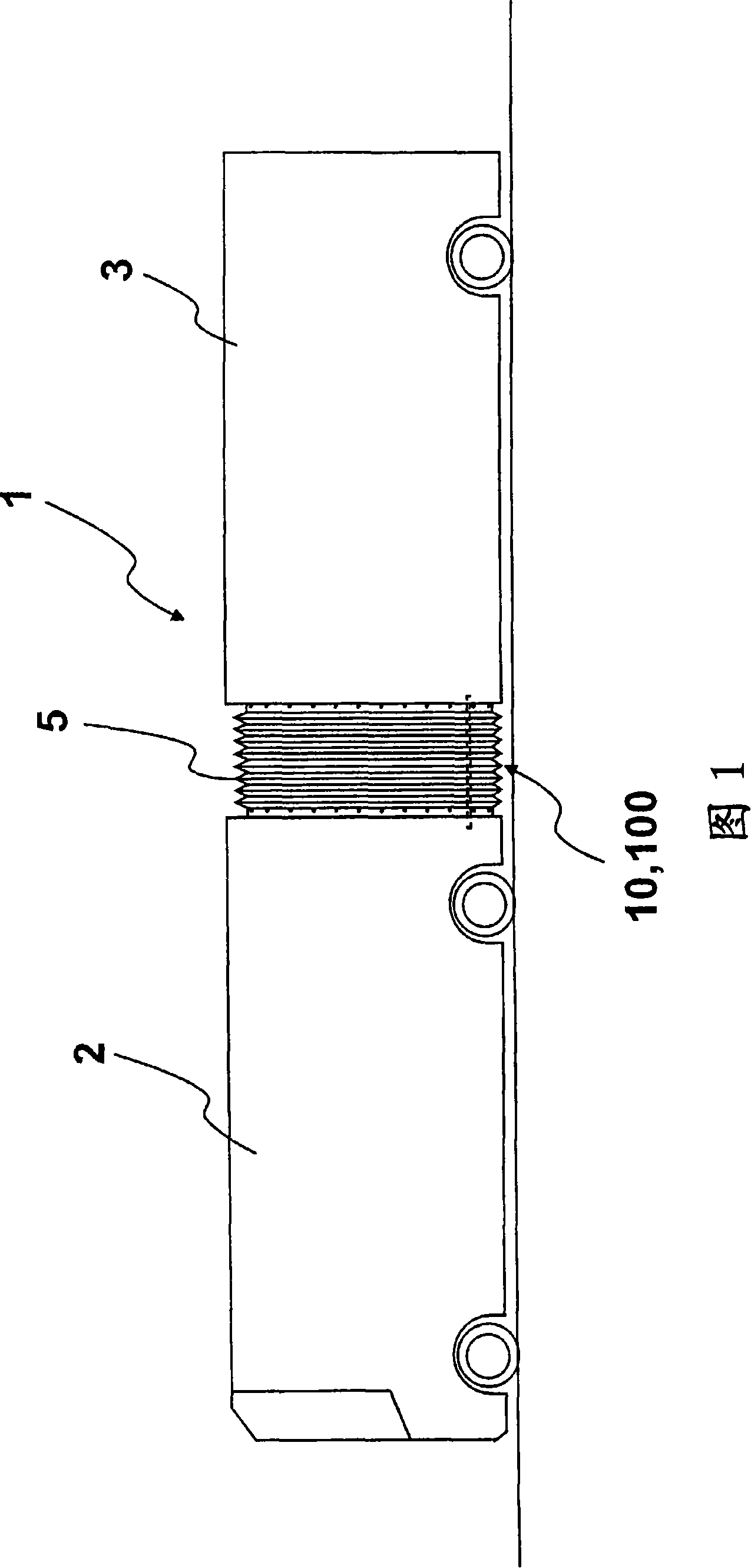

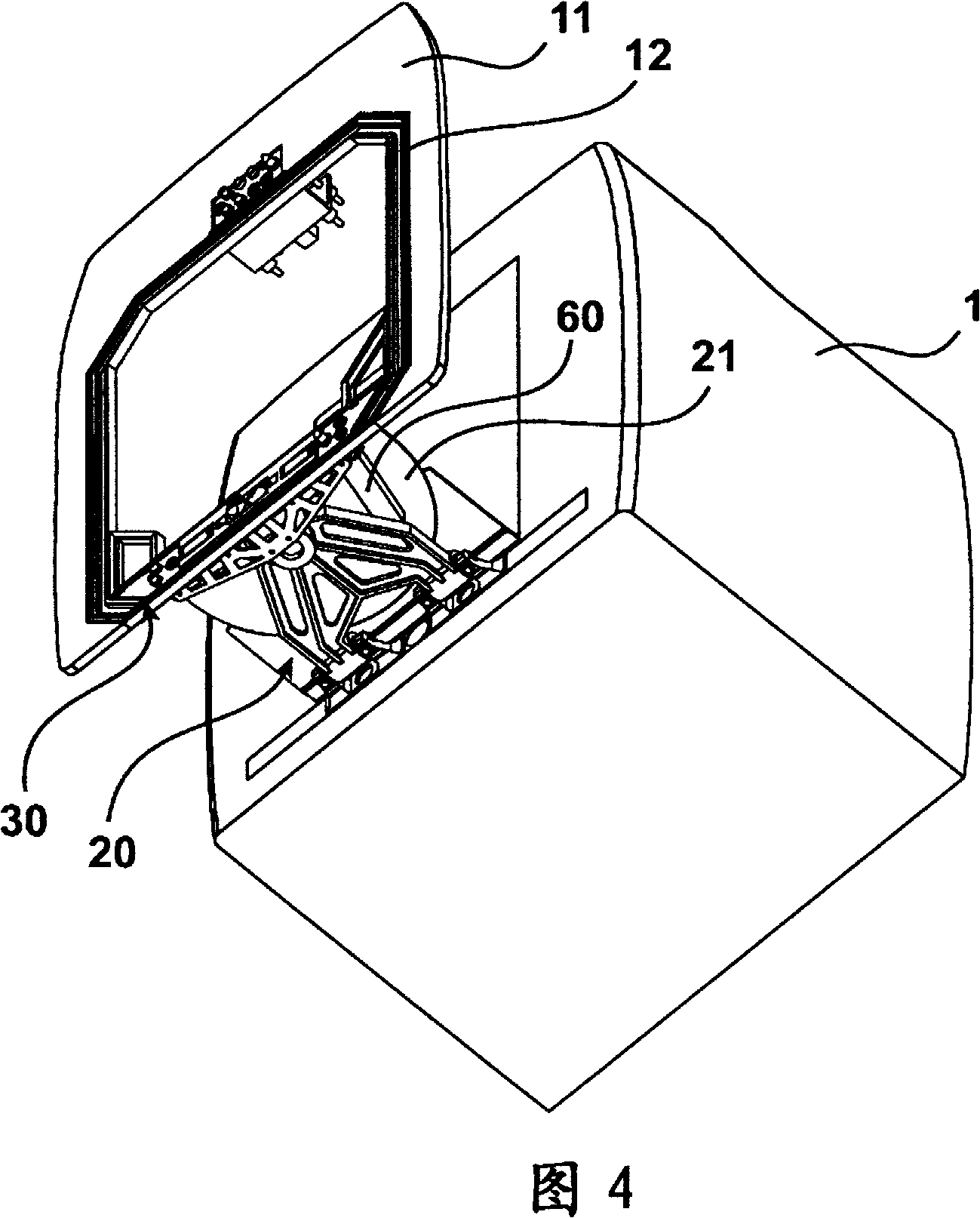

Coupling between two articulated vehicle parts, e.g. for an articulated vehicle

InactiveCN101168345ABending motion attenuationFast preparationTractor-trailer combinationsOther connectionsCouplingArticulated vehicle

The invention relates to a coupling portion (10, 100) between two articulated vehicle parts (2, 3), e.g. for an articulated vehicle, which comprises a curved hinge connecting with a vehicle part (2, 3) by a articulating device (50, 120, 220, 320) transmitting pitching and cycloidal motion.

Owner:HUBNER GMBH

Vehicle door check link mechanism

Owner:NISSAN MOTOR CO LTD

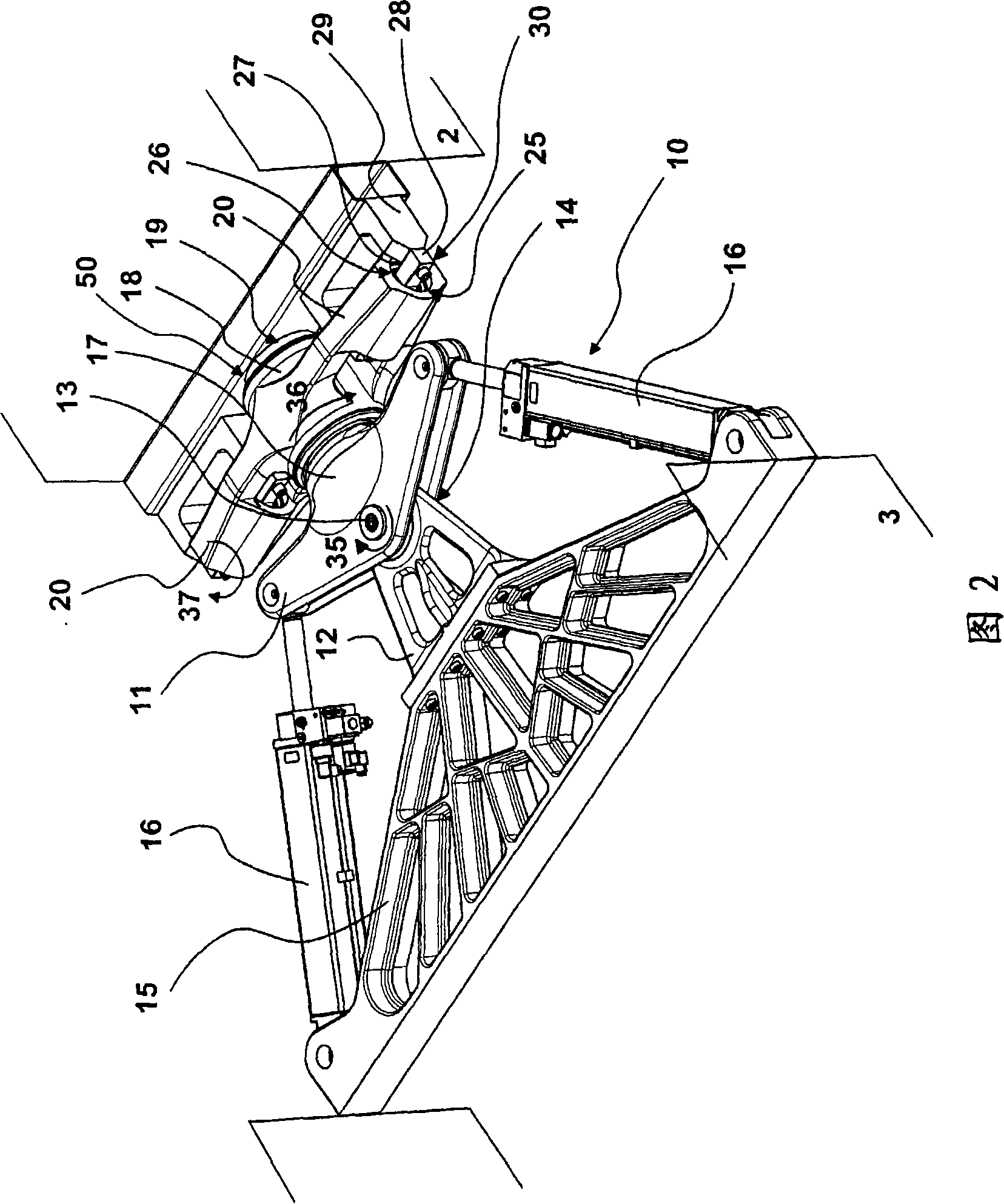

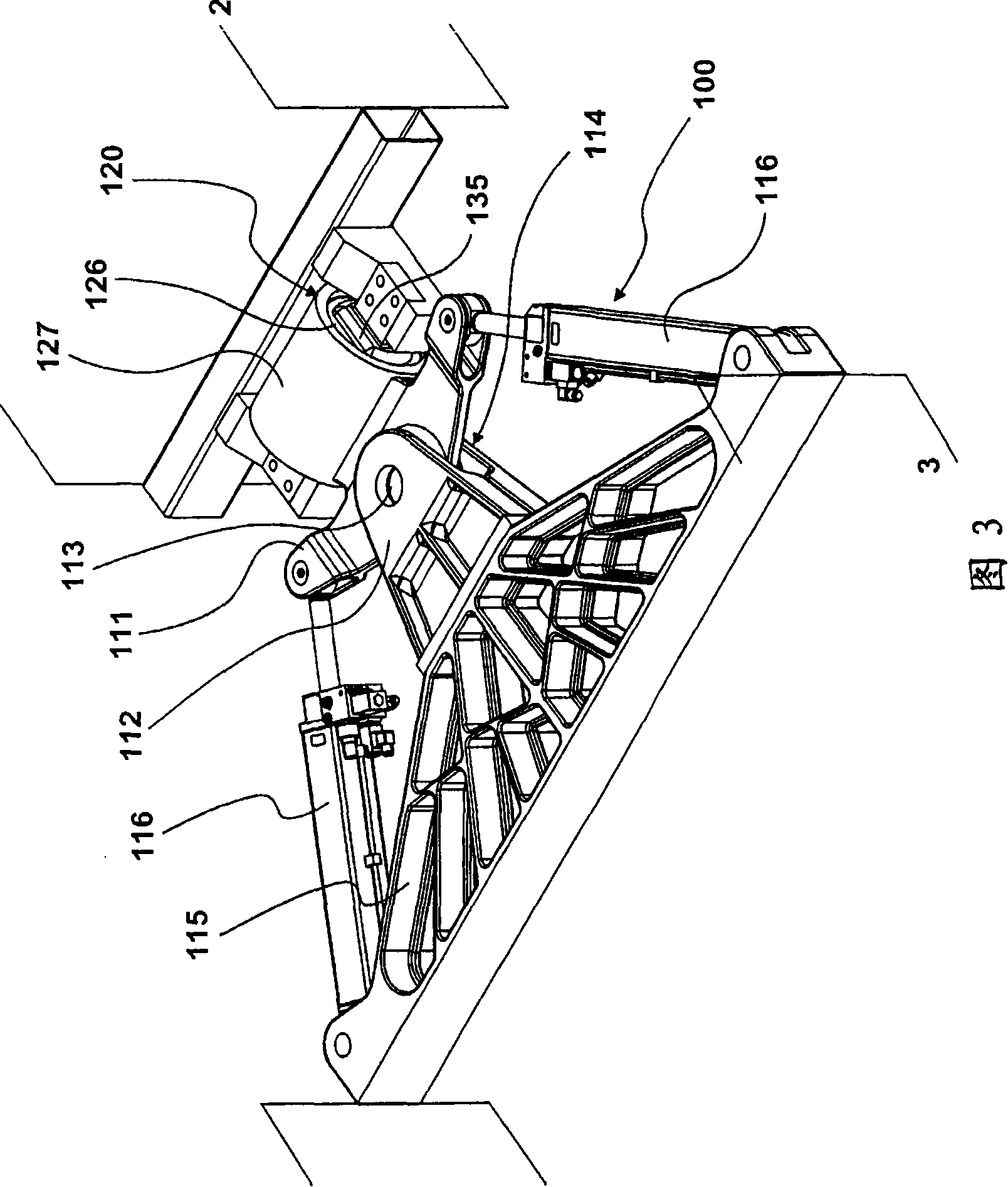

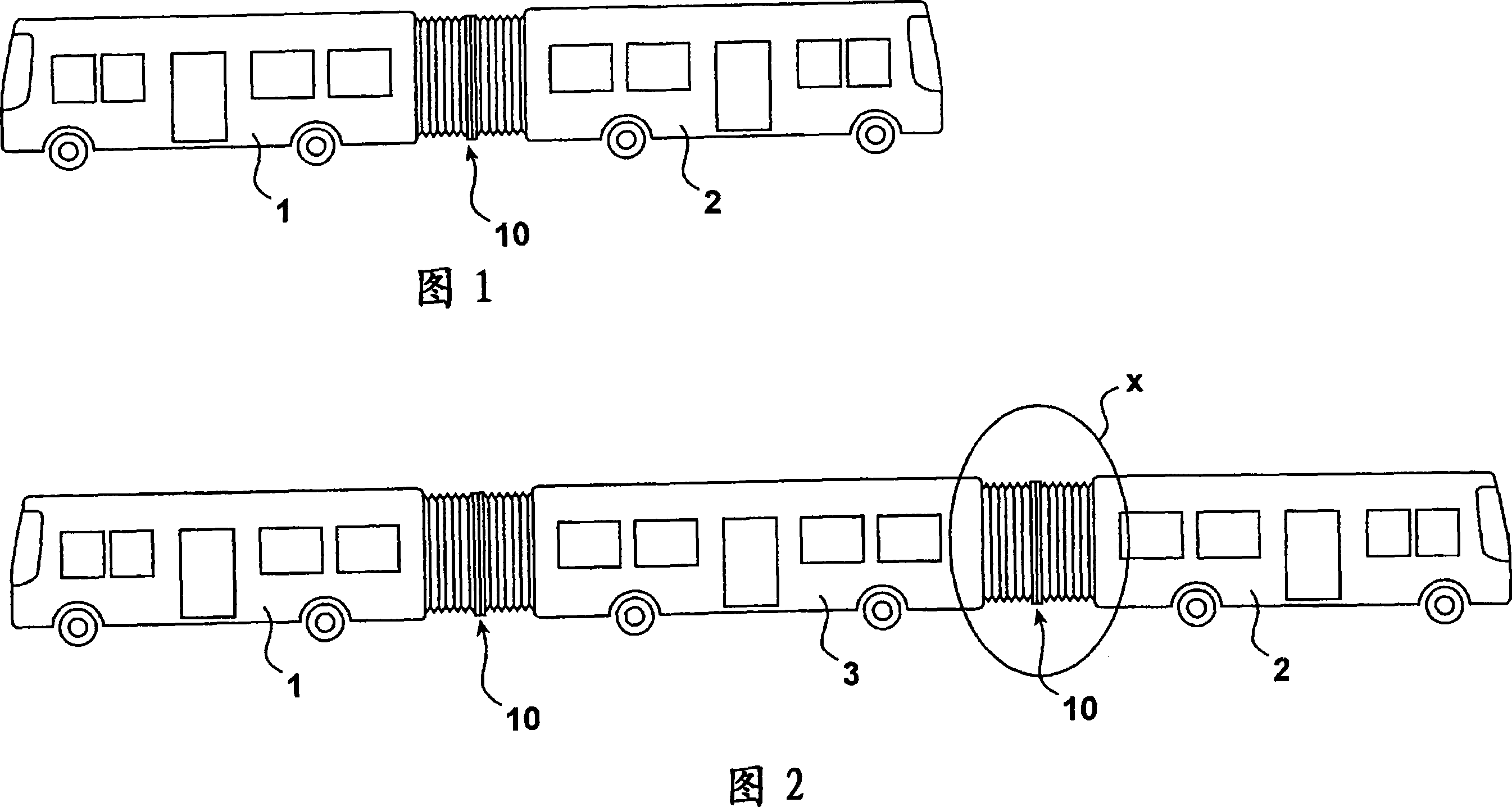

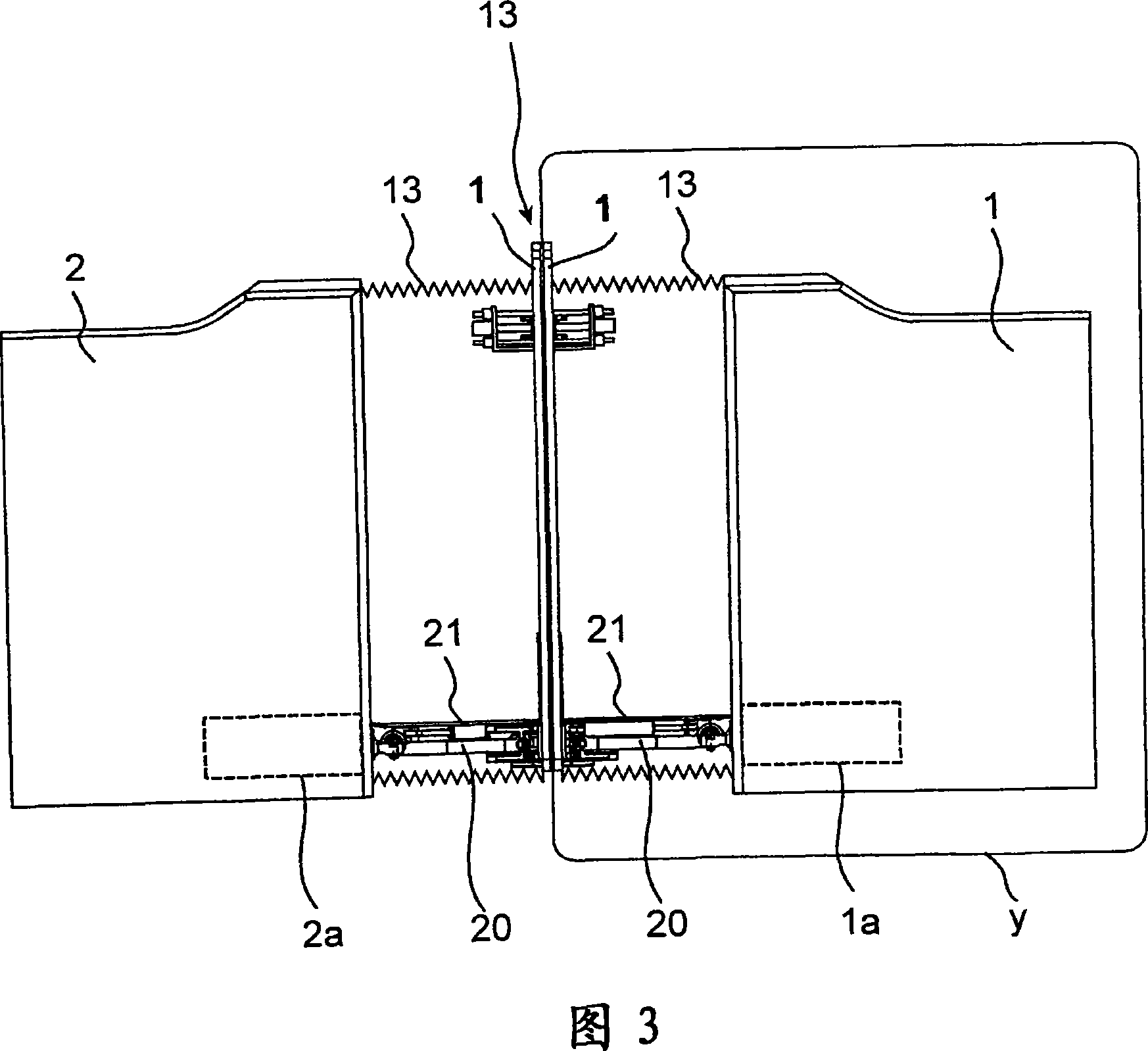

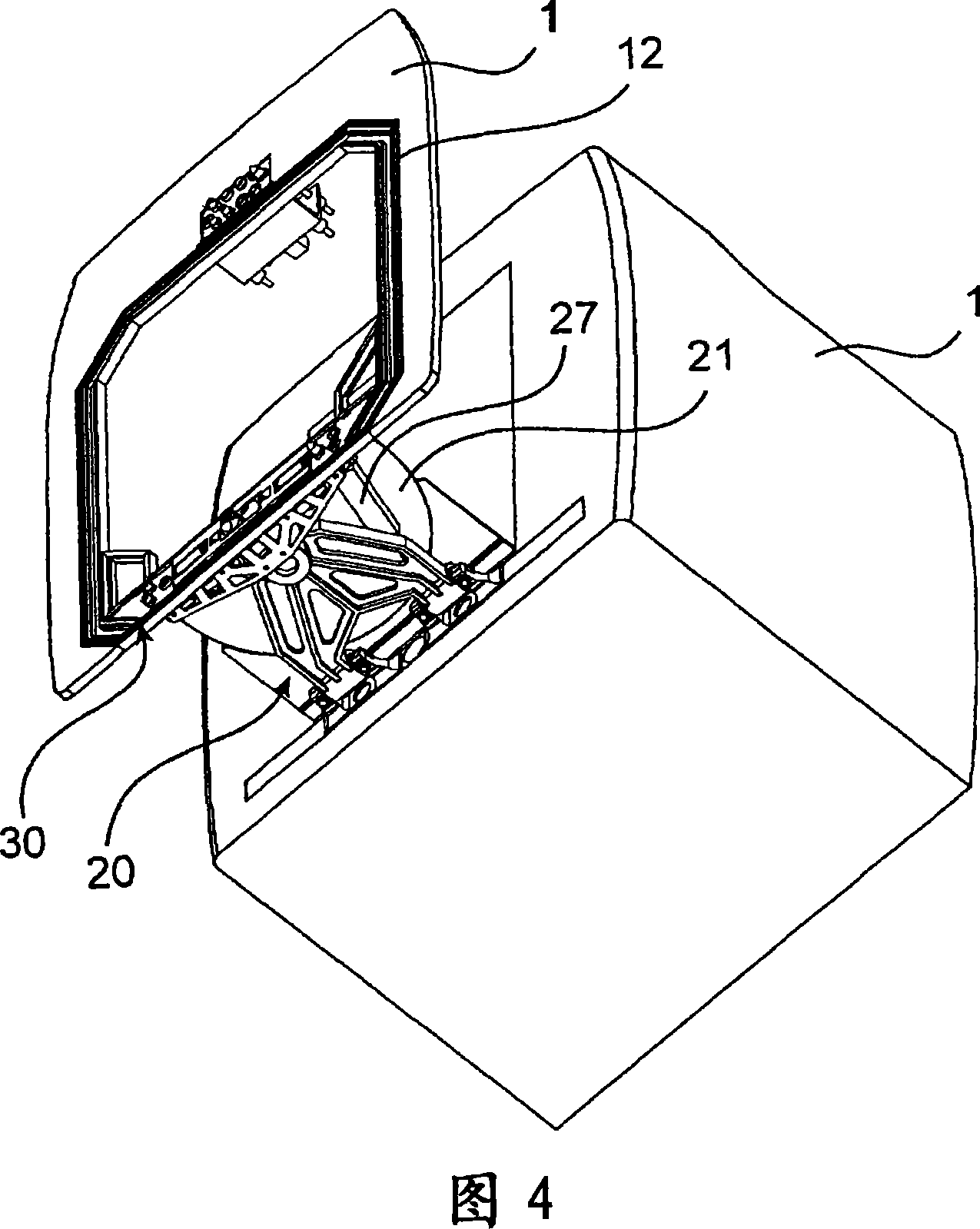

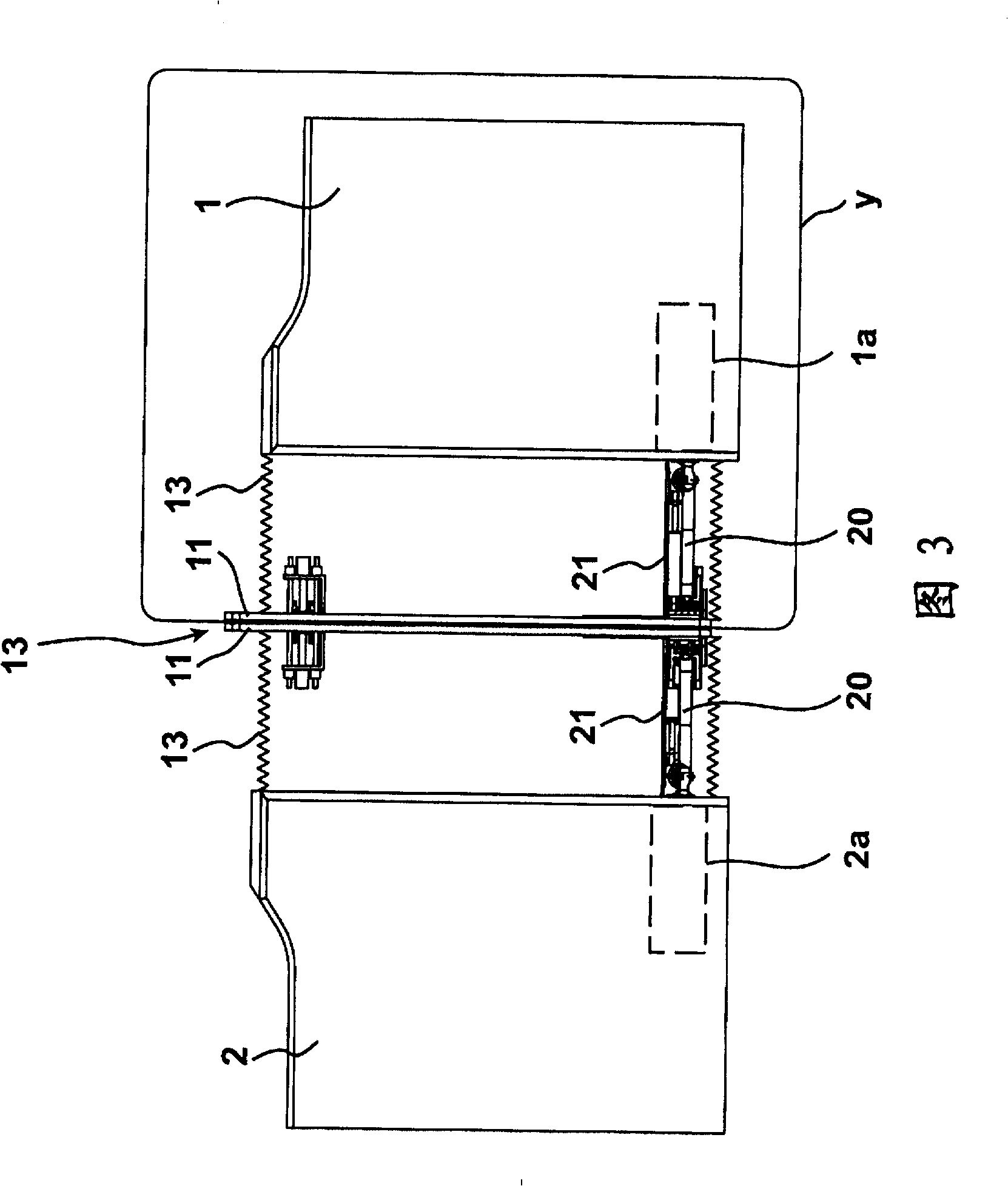

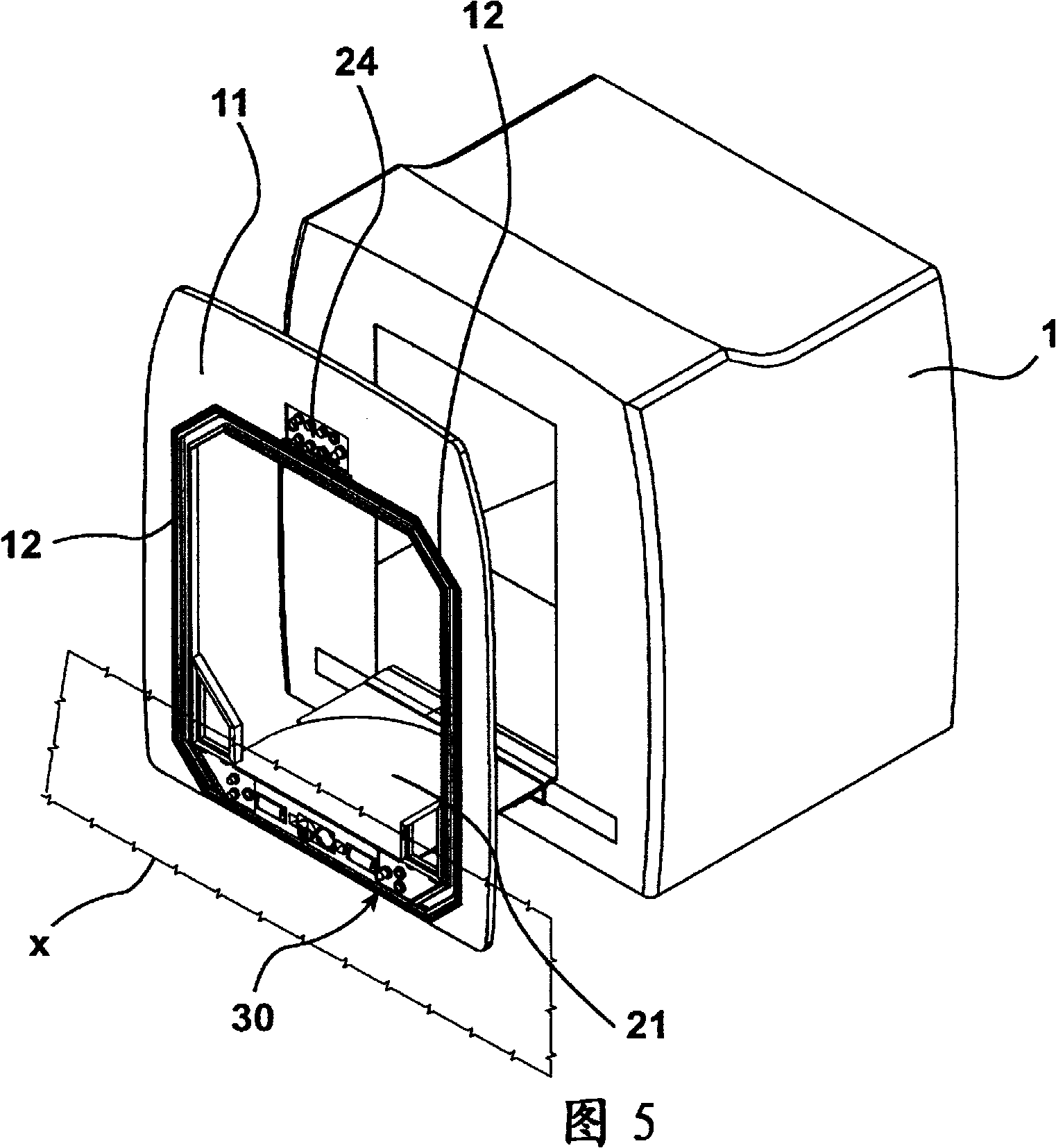

Articulated vehicle composed of several coupled vehicle sections

InactiveCN101085593ARealize unloadingDamage cannot be avoidedOther connectionsAxle-box lubricationCouplingEngineering

The invention relates to an articulated car by coupling many car parts (1,2), wherein each car part (1,2) with at least two car axles and a coupling frame (12) and the said coupling frame is connected with the car parts (1,2) by fold shed (13), wherein articulated devices (20,31) is respectively set between the said car parts (1,2) and coupling frame (12), wherein the articulated device is with bracket (30) of coupling part which is approximately in the plane (12) of the said coupling frame, wherein the said bracket (30) of coupling part at least comprises a coupling structure (25) connected with articulated device (20,31) ot the other car parts (1,2).

Owner:HUBNER GMBH

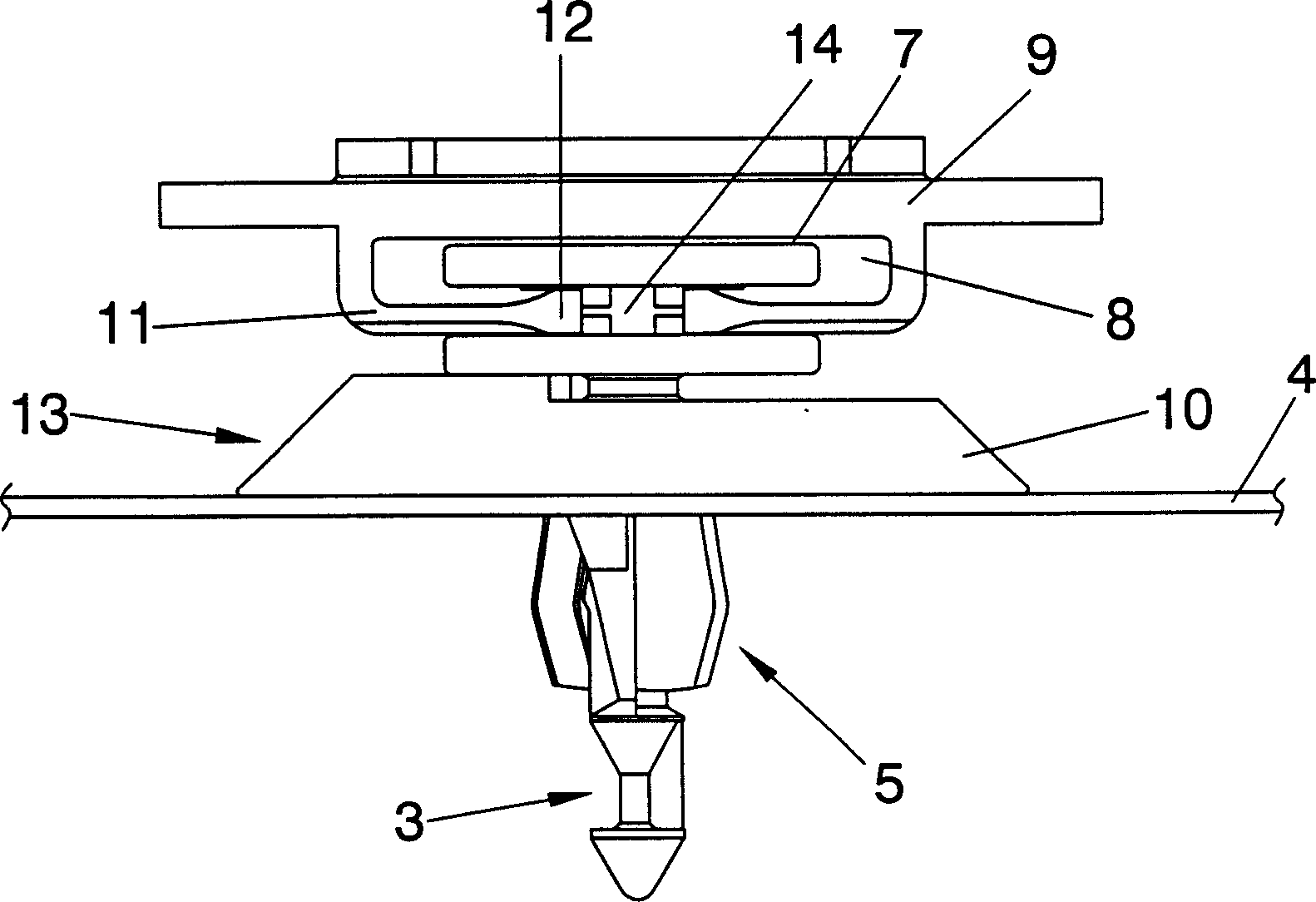

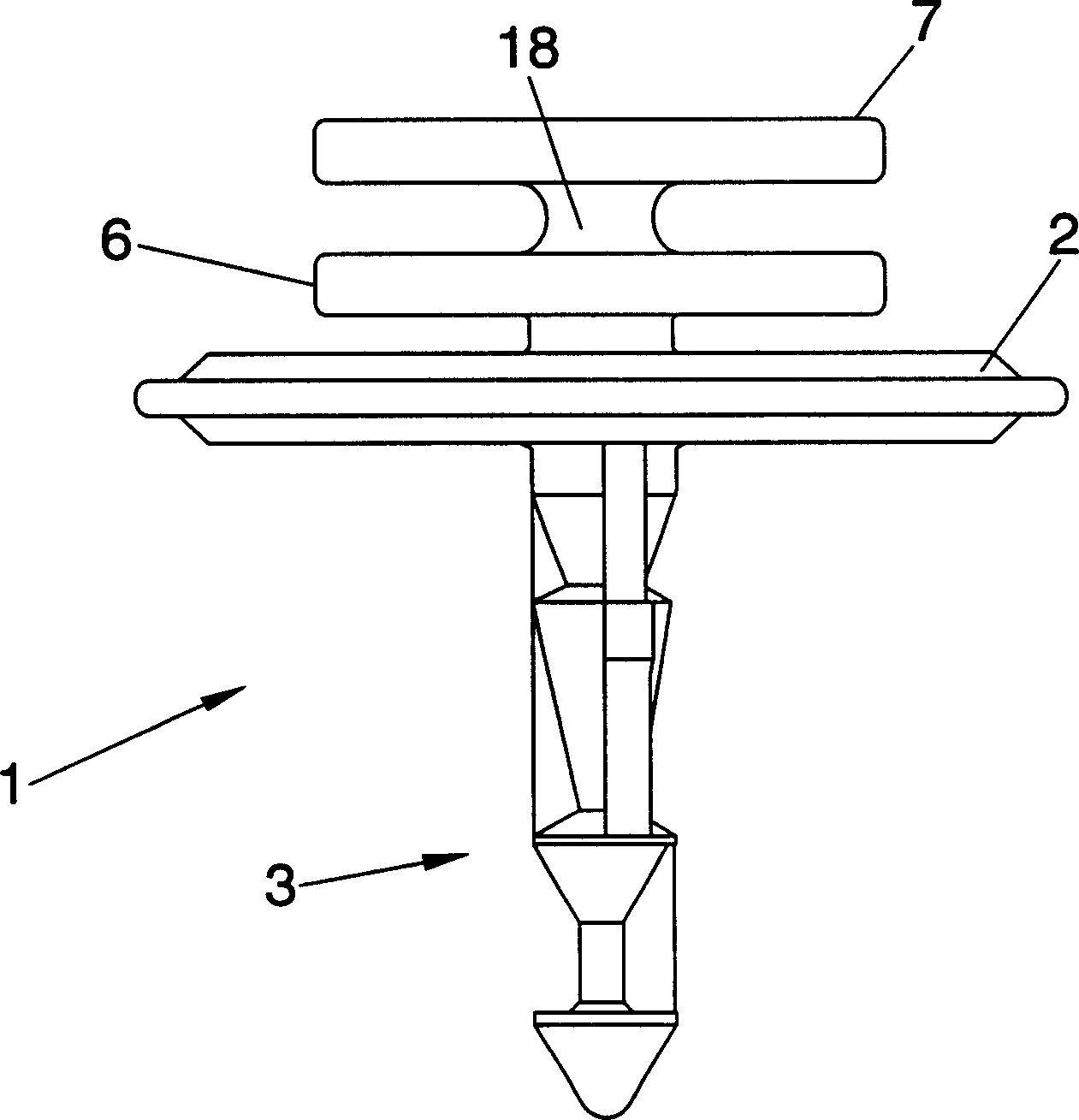

Connection part between a panel and a support

Owner:I T W ESPANA

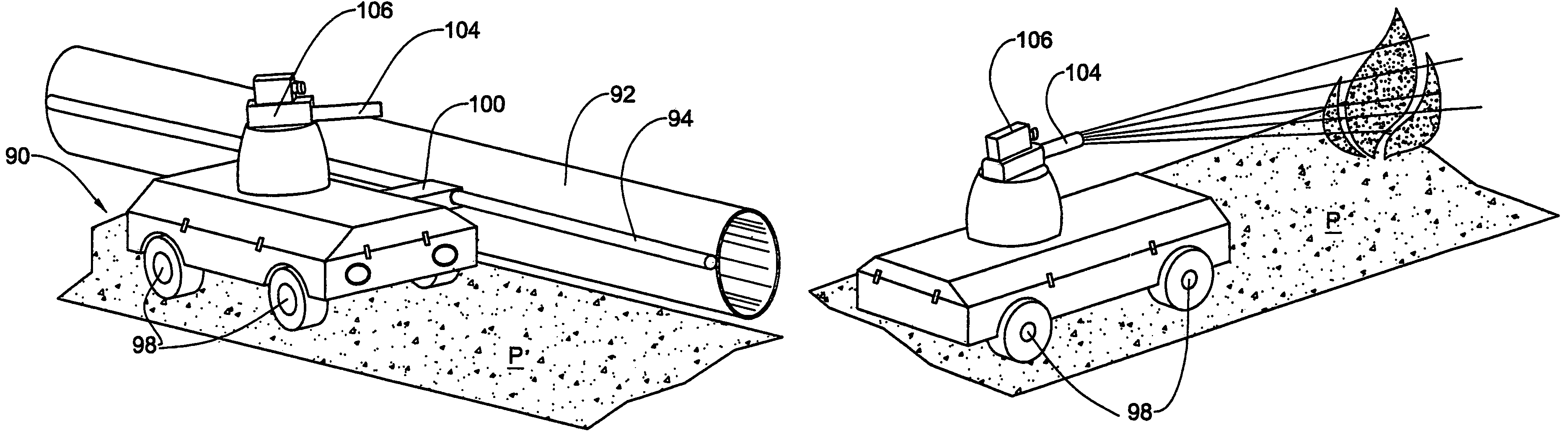

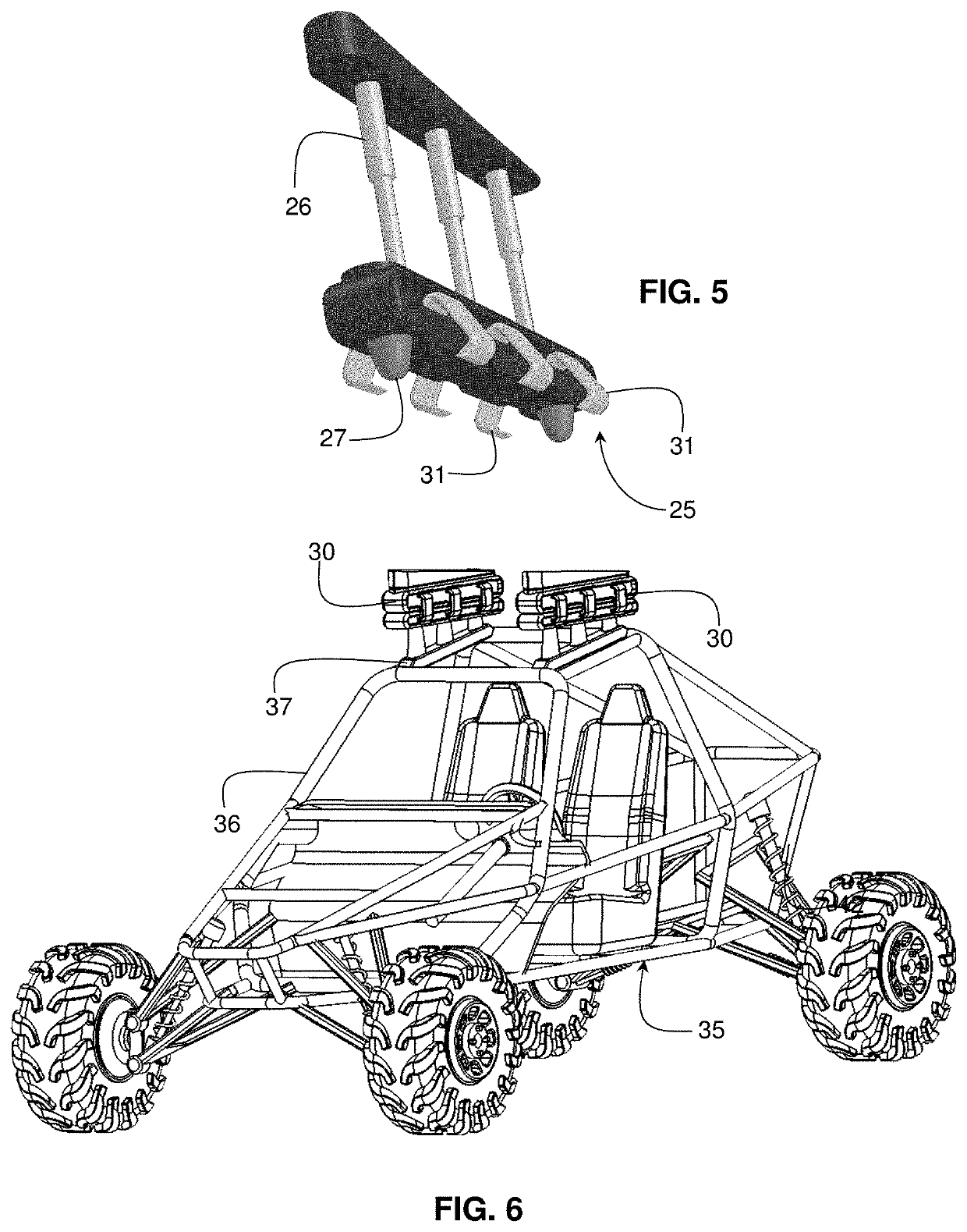

Unmanned tactical platform

Owner:ISRAEL AEROSPACE IND

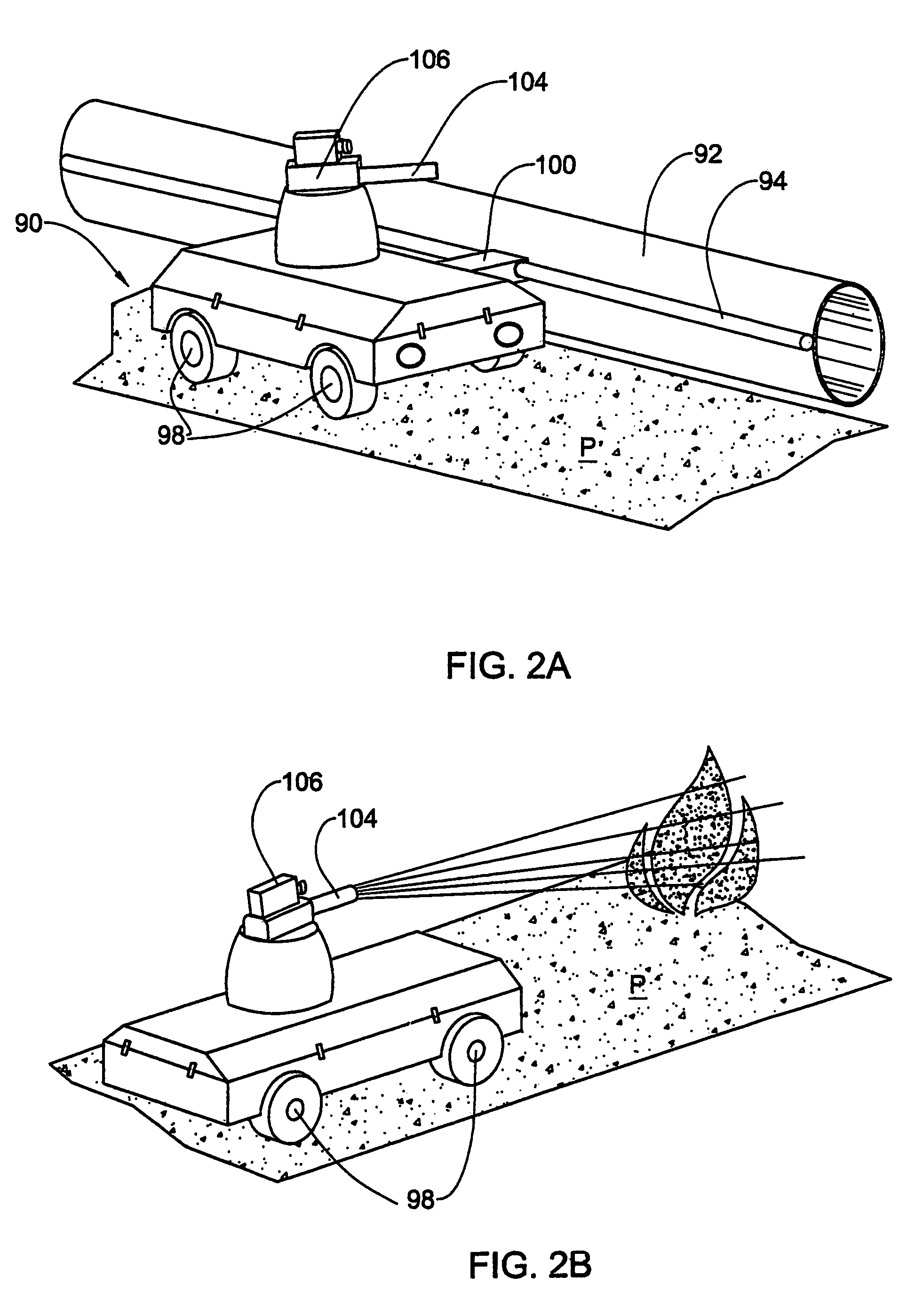

Vehicle capture and restraint device

InactiveUS20100156080A1Safely apprehendSafely restrain fleeing vehicleDeflectorsOther connectionsEngineeringMechanical engineering

A device designed to be used on a police pursuit vehicle to hook and restrain another fleeing vehicle. The device is carried within or attached to the front bumper of the pursuit vehicle. The attachment mechanism can be spring powered, pneumatically or hydraulically or electrically operated to deploy the hook. A hook device can be mounted on either the left side or right side of the front bumper of the pursuit vehicle or mounted to both sides of the bumper. The hook is deployed in a telescoping fashion from the end of the bumper so that it hooks into the sheet metal and at least one frame member behind the rear fender well of the fleeing vehicle. Once the device deploys and cuts in to the sheet metal and underlying structure of the fleeing vehicle, the brakes are applied on the pursuit vehicle, and the fleeing vehicle is brought to a stop and remains securely restrained by the pursuit vehicle.

Owner:NAPIER KENNETH L

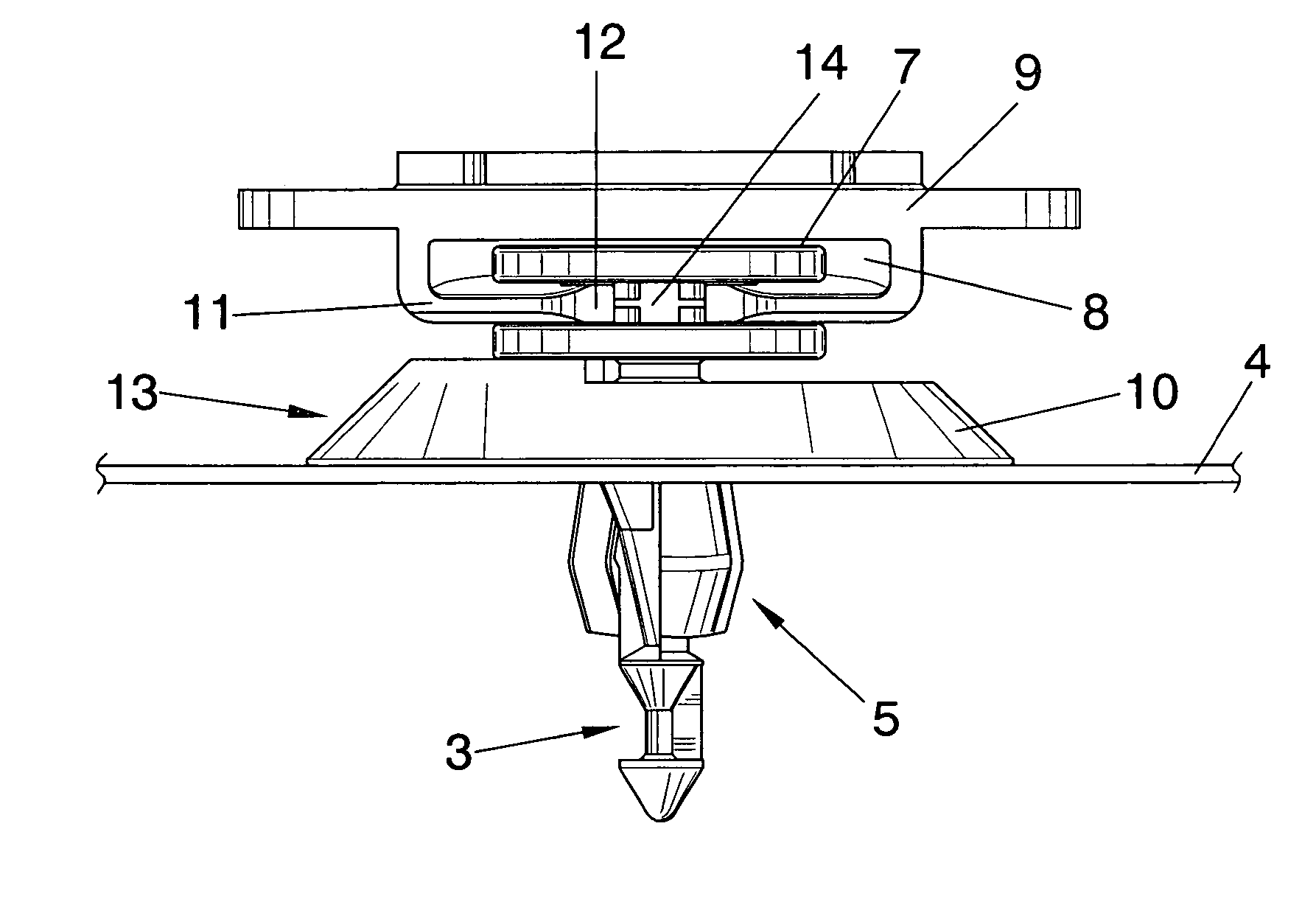

Connection part between a panel and a support

Comprises a body provided with an elongated segment that crosses an orifice made in the support, which may be a sector of a vehicle body, on the body locking a recess belonging to a retainer joined to a panel. It incorporates an overinjected part made of a soft and compressible material on the body, which is provided with an absorption ring that envelopes a segment of the body and is in contact with a neck of the retainer absorbing the lateral compressions resulting from positional misalignments due to manufacturing errors and expansions of the support and the panel.

Owner:ITW ESPANA

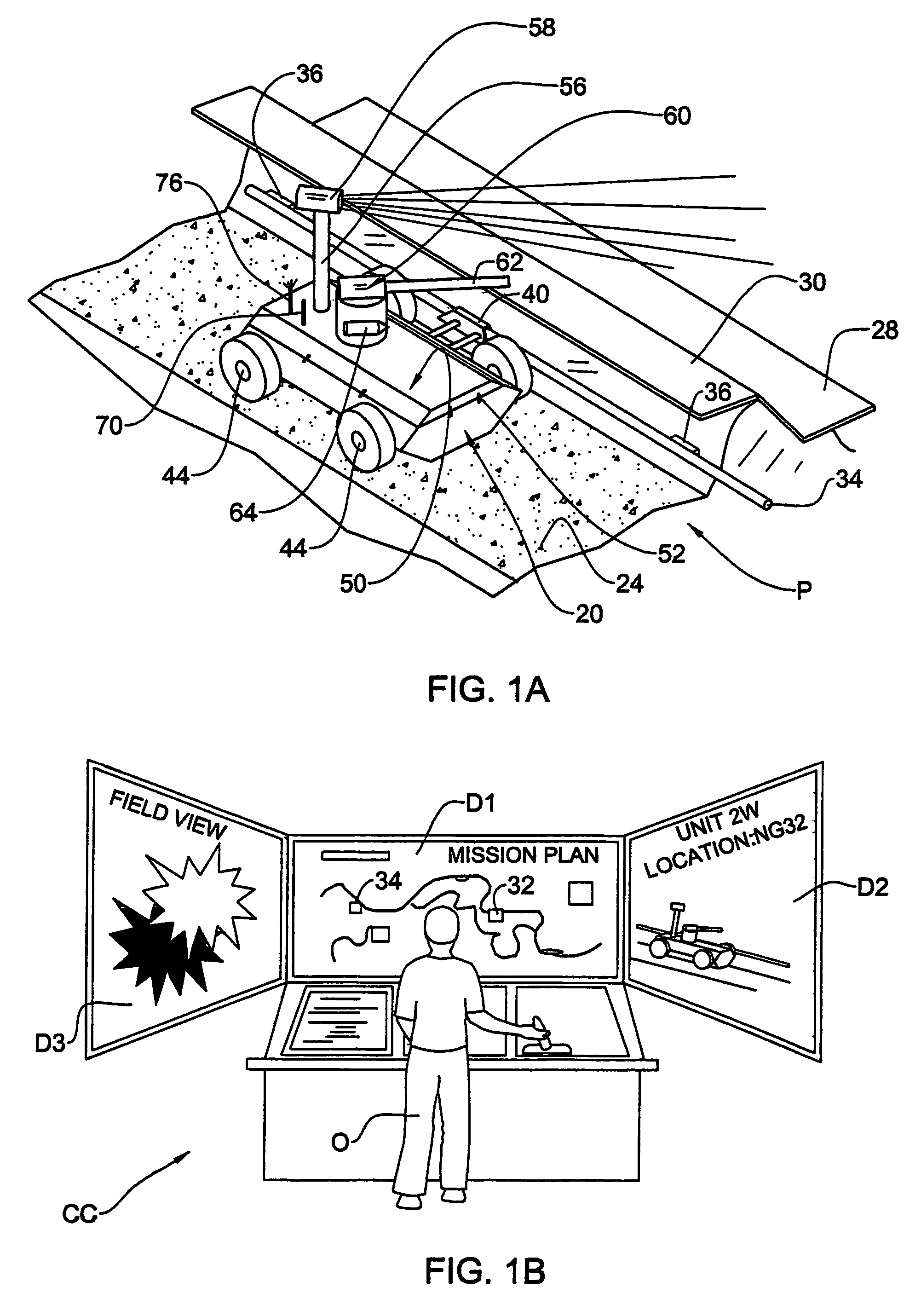

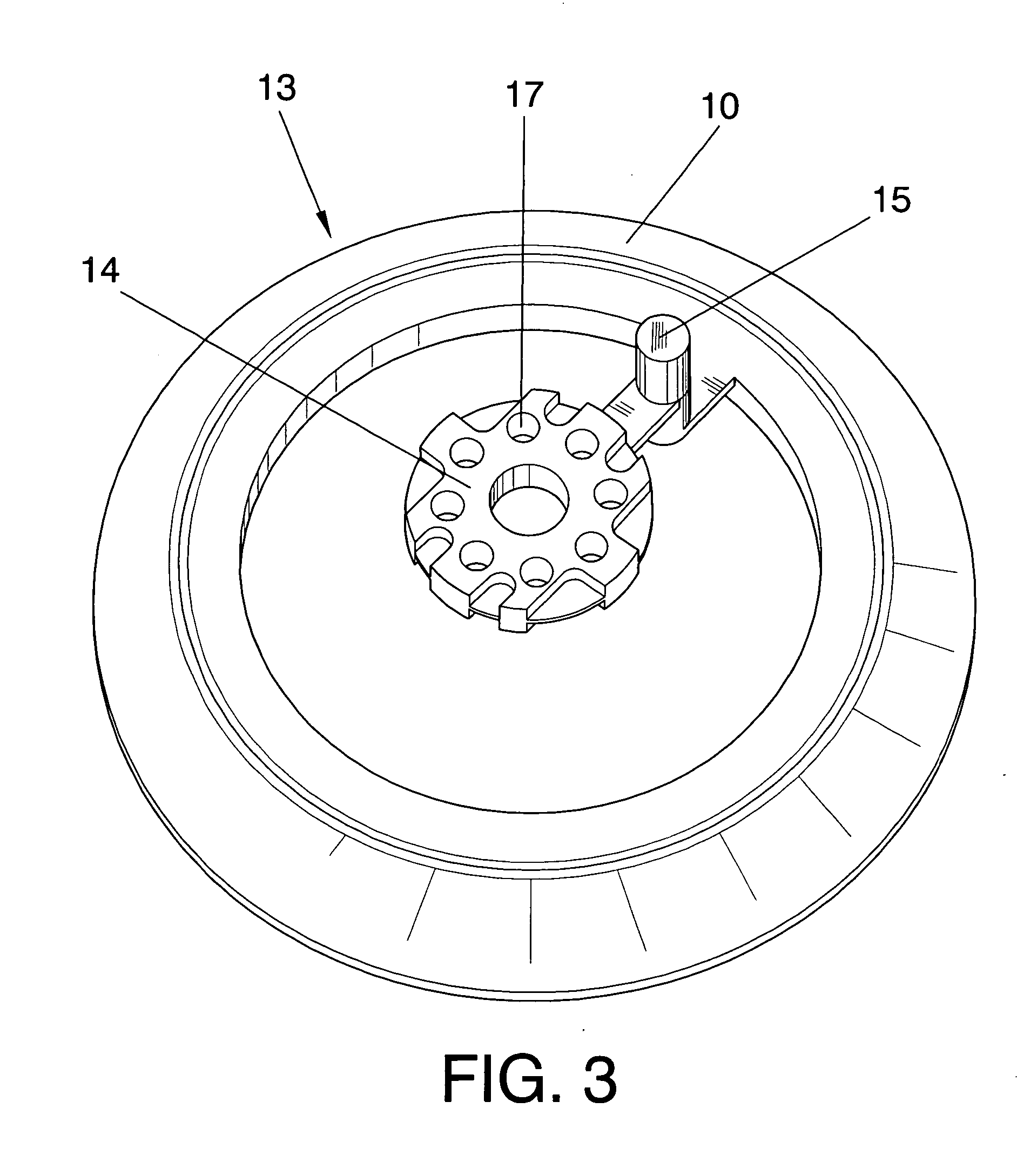

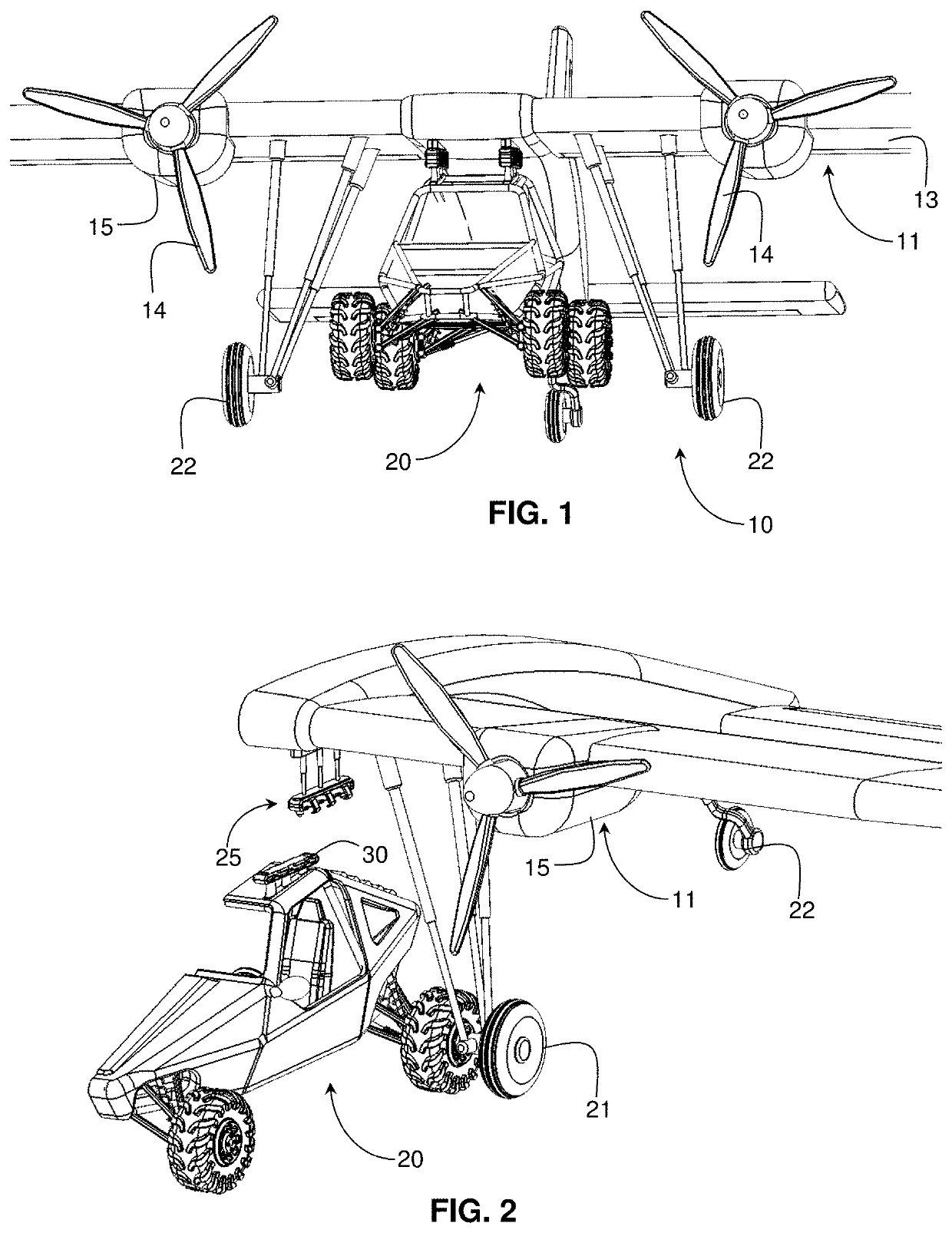

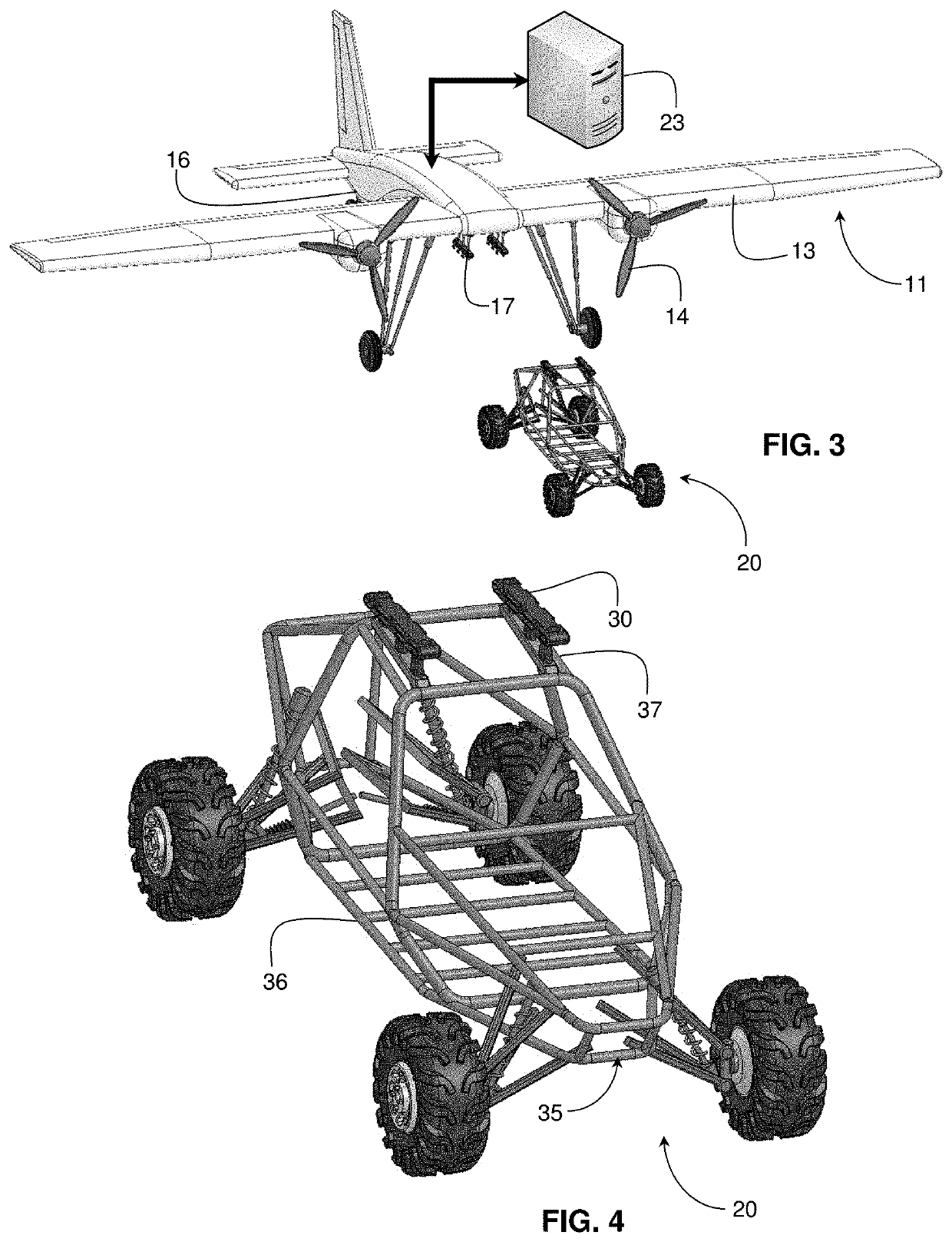

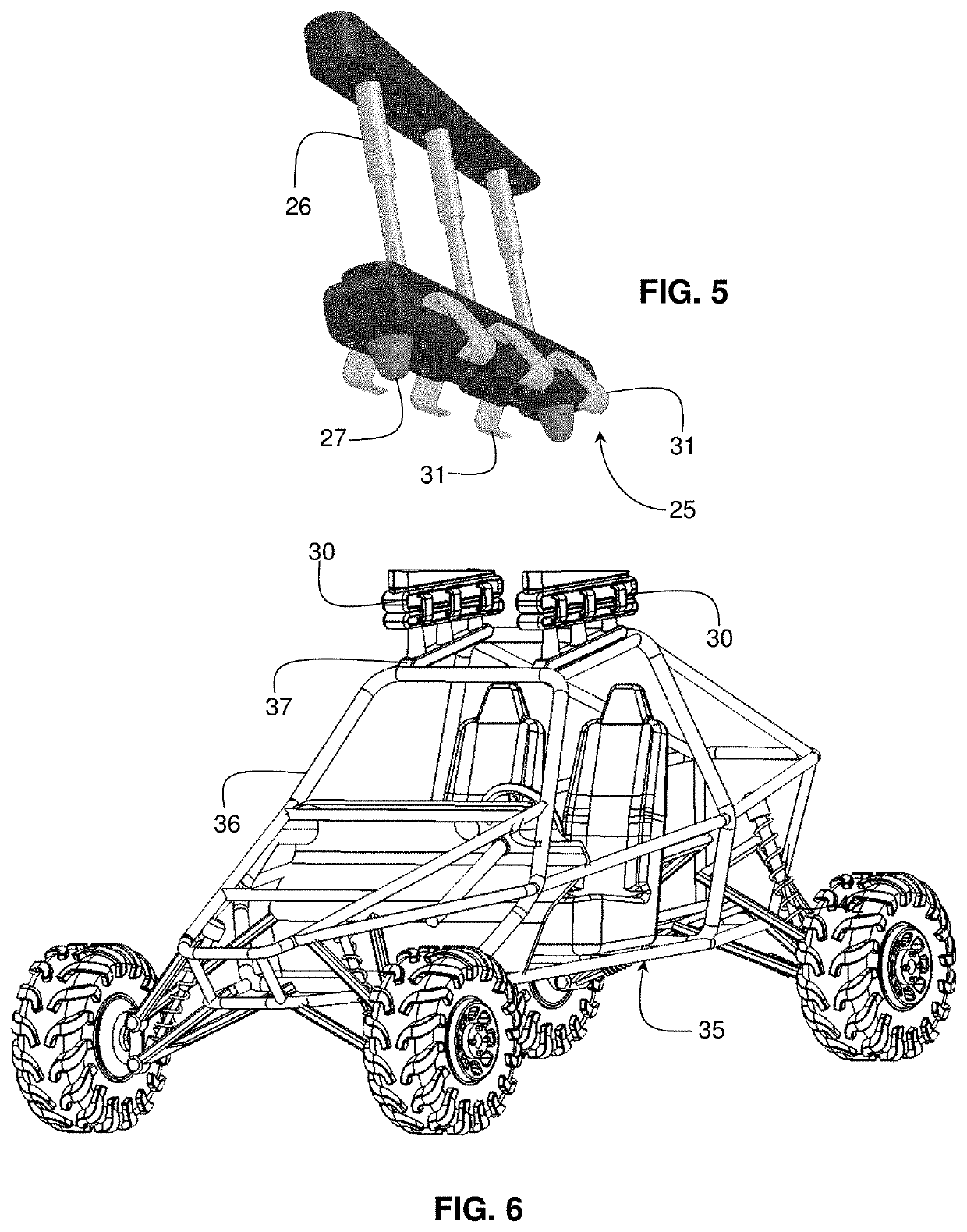

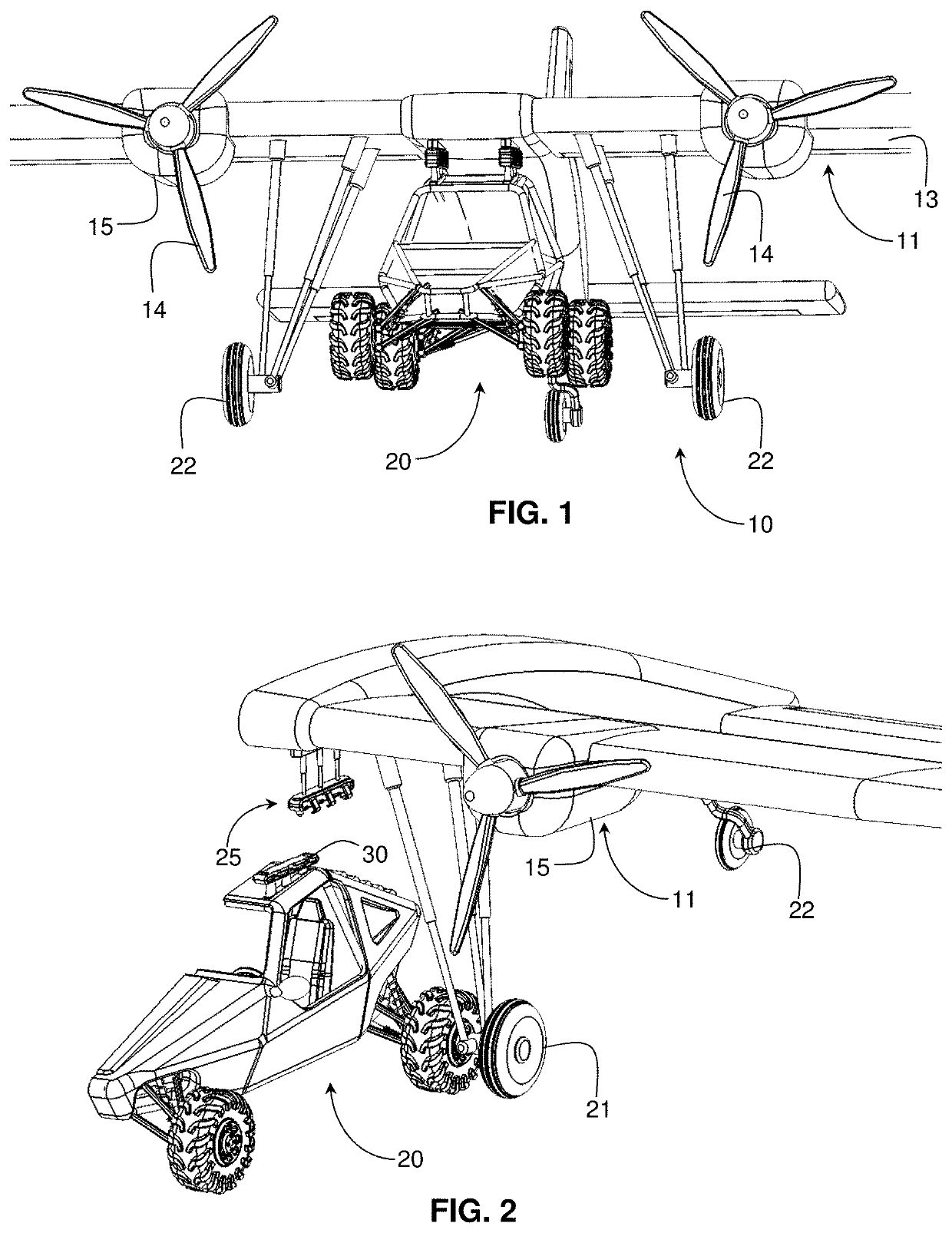

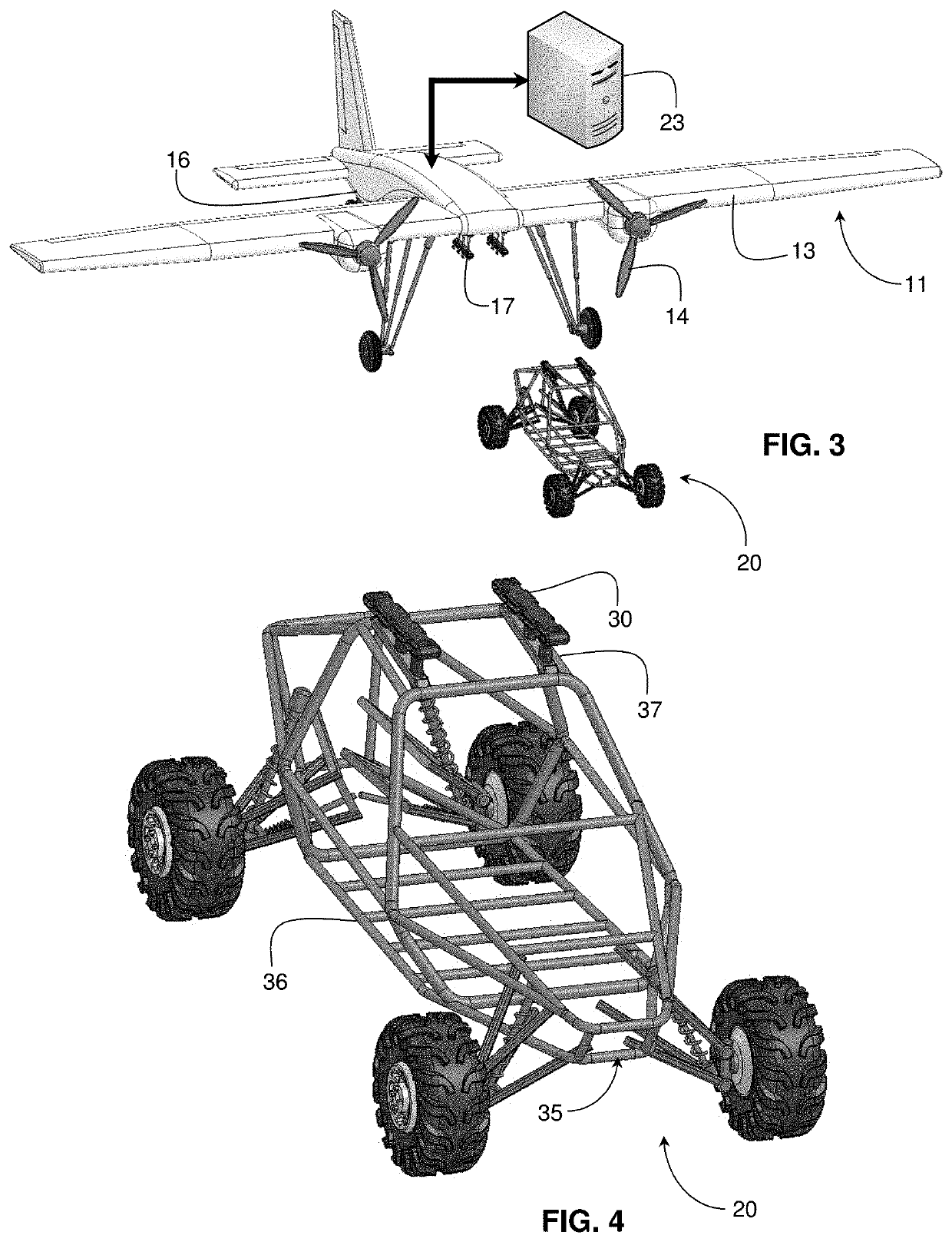

Universal flying terrain vehicle

ActiveUS20200140081A1Low costConvertible aircraftsWithout power ampliicationFly controlFlight vehicle

A universal aerial platform (11, 41) supports lift elements (13, 14), thrusters (15), landing gear (21, 22) and a fuel supply (16) and has a coupling mechanism (17) external to the aerial platform for coupling to a terrain vehicle (20) so as to convert any suitably adapted terrain vehicle to a flying vehicle (10, 40). The terrain vehicle forms the cockpit of the flying vehicle. The terrain vehicle (20) includes flight controls that are automatically coupled to the airplane structure either wirelessly or by wires when the terrain vehicle is coupled thereto.

Owner:LEVY & CIE

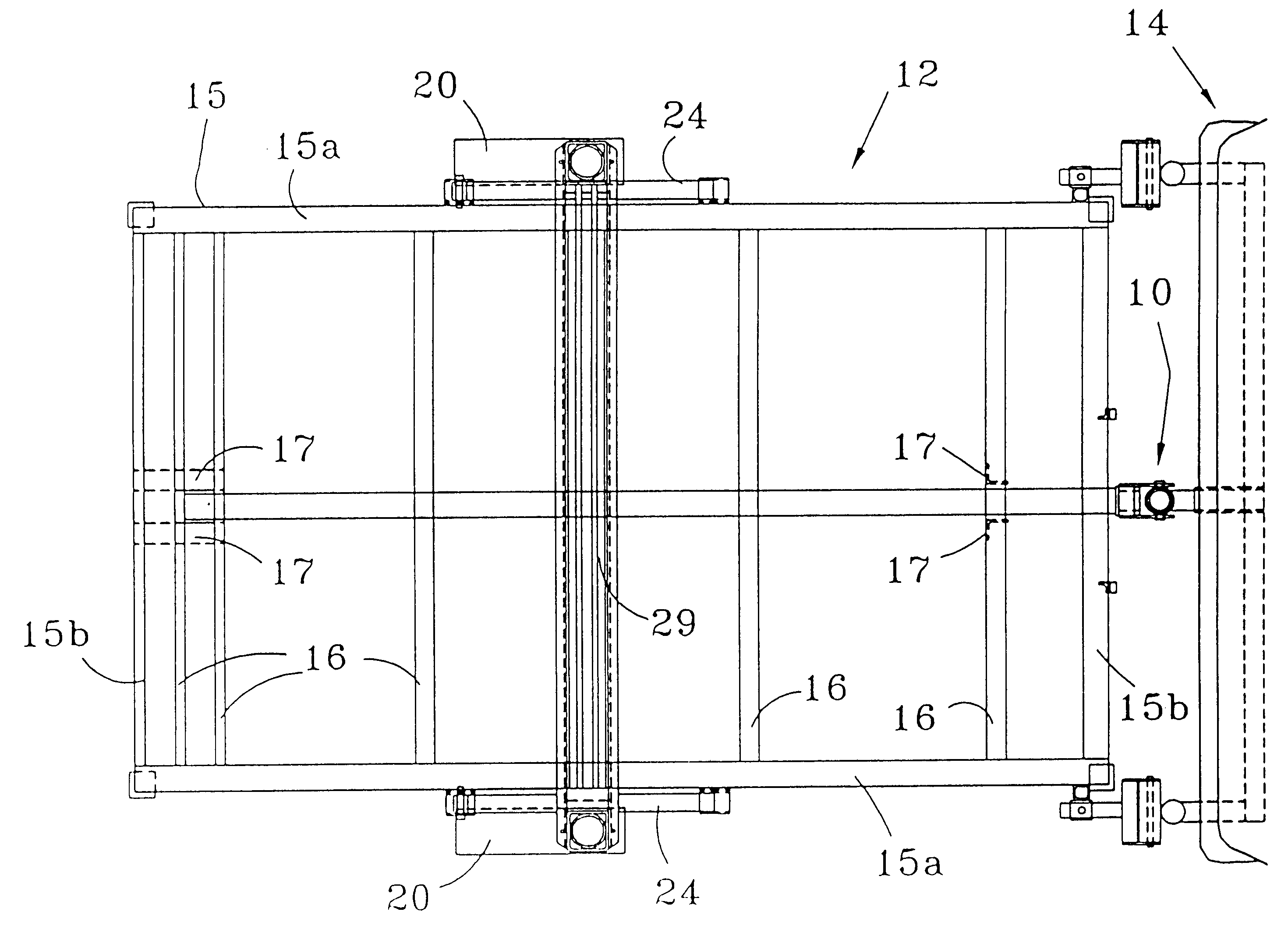

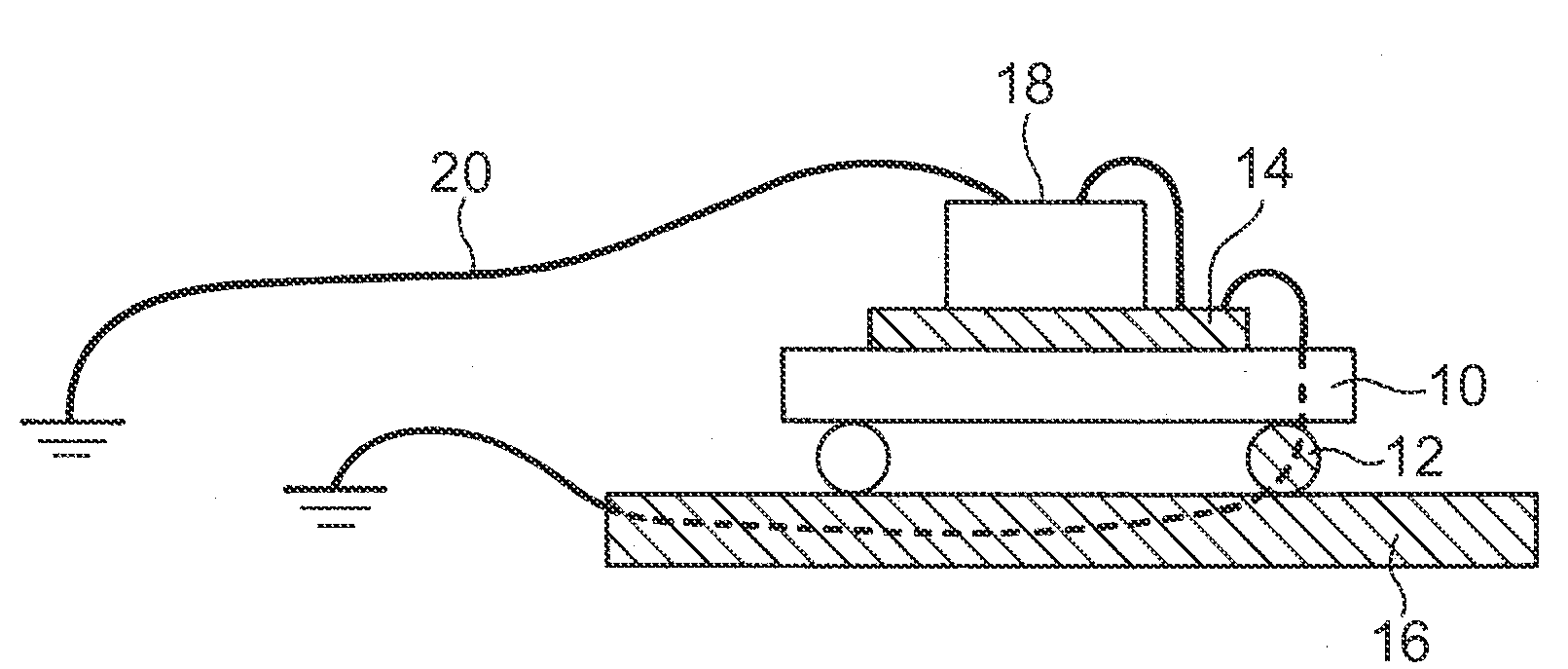

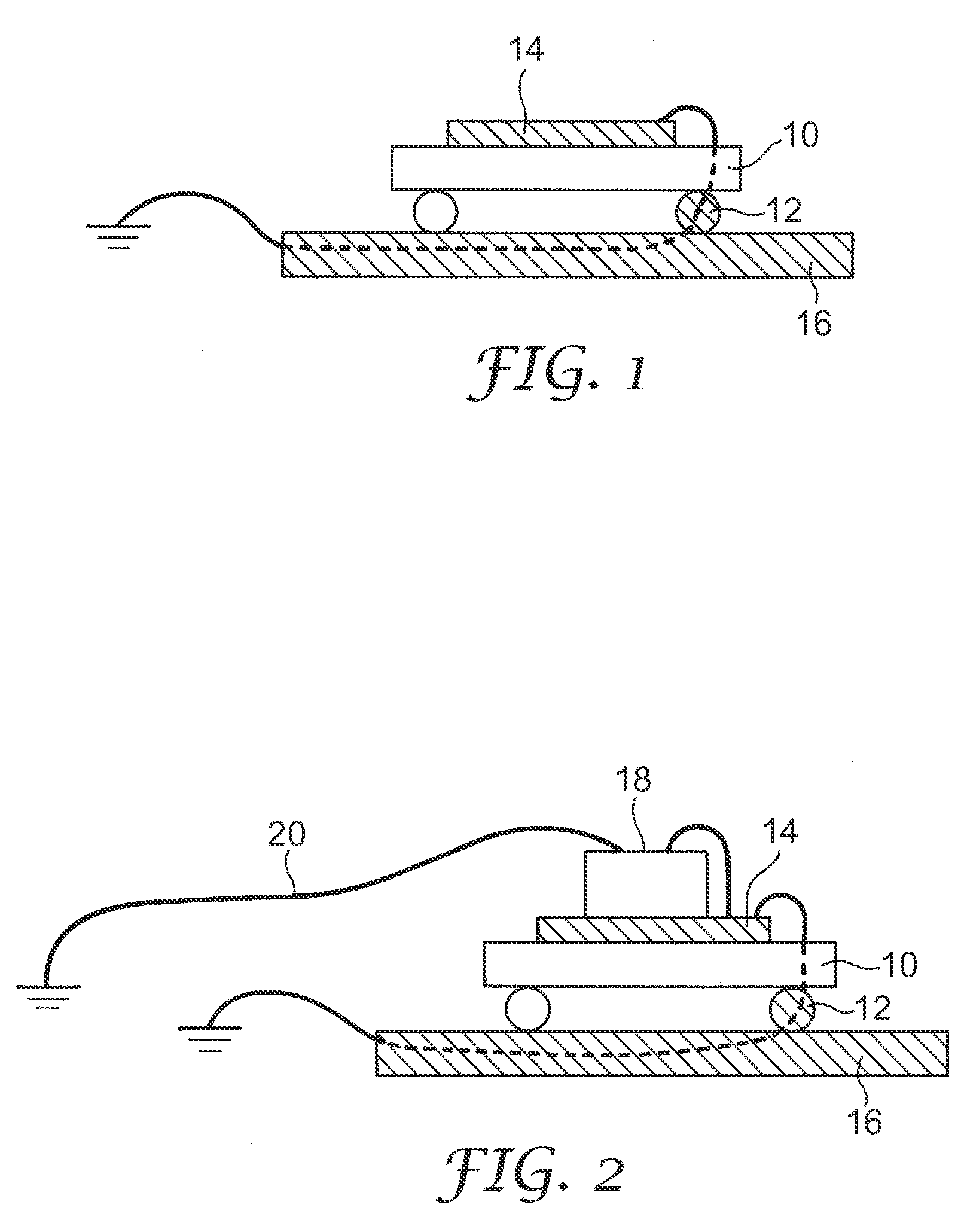

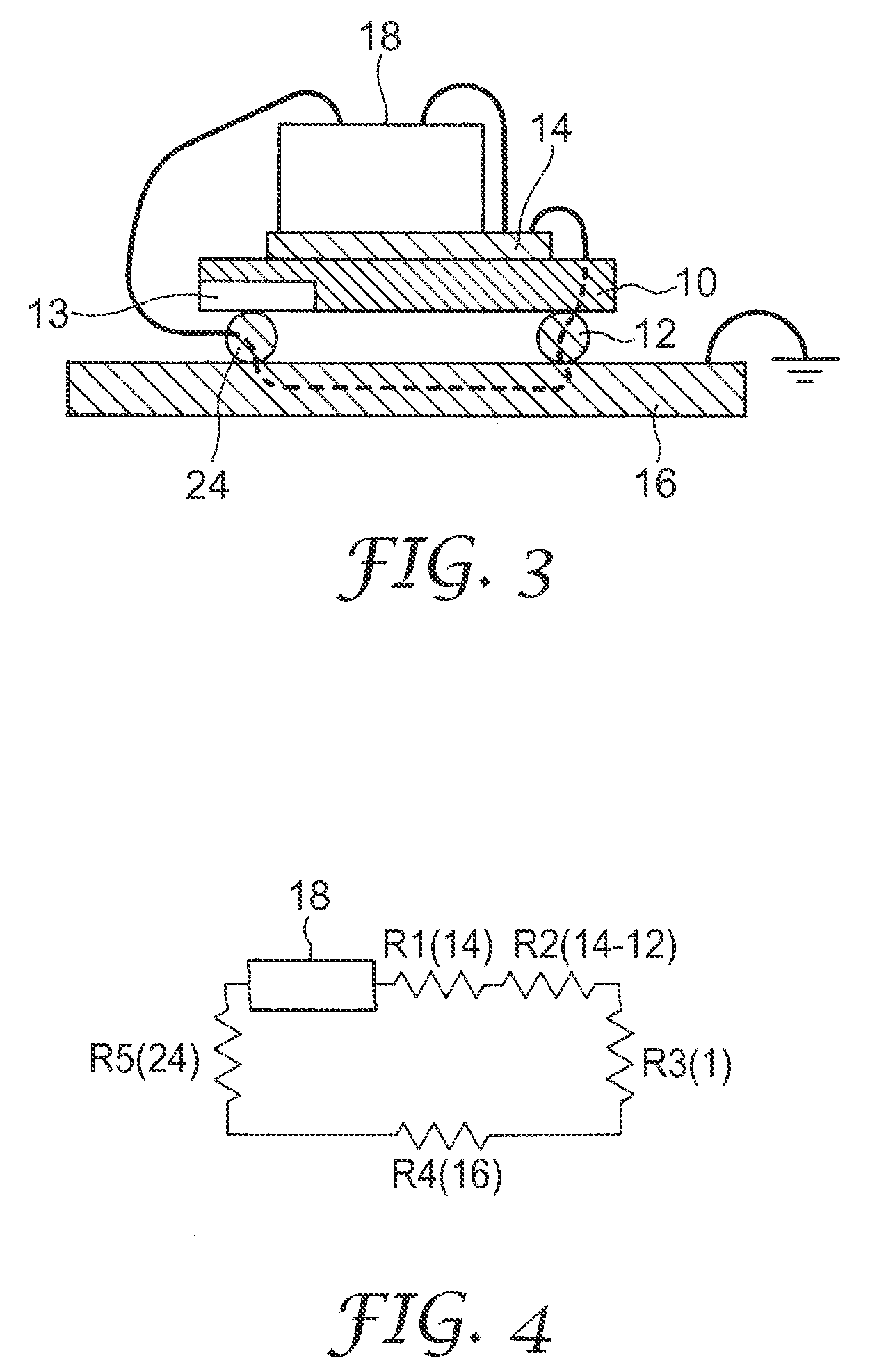

Wheeled moving body and grounding condition monitoring apparatus for the same

InactiveUS20090020969A1Vehicle seatsEmergency protective arrangement detailsEngineeringCondition monitoring

To provide a wheeled moving body incorporating electrostatic protection measures and capable of constantly monitoring its grounding condition, and a grounding condition monitoring system for the same. An electrostatic conductive mat 14 on a cart 10 is connected to an electrostatic conductive wheel 12 for grounding, and one end of an ohm meter (or volt meter) 18 mounted on the cart 10 is connected to the electrostatic conductive mat 14, while the other end is grounded by connecting it to a conductive wheel 24 insulated from the cart 10 by an insulating plate 13.

Owner:3M INNOVATIVE PROPERTIES CO

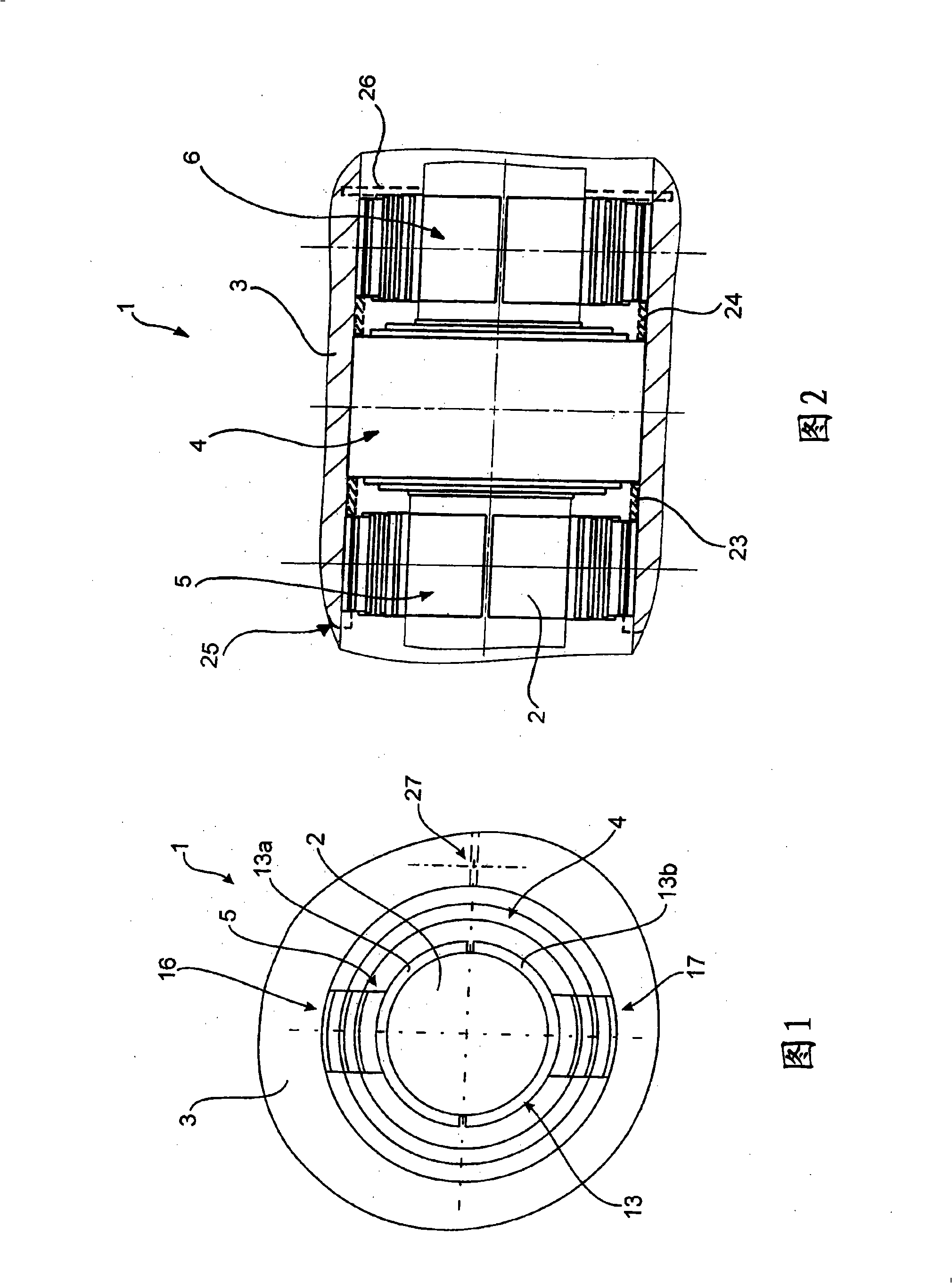

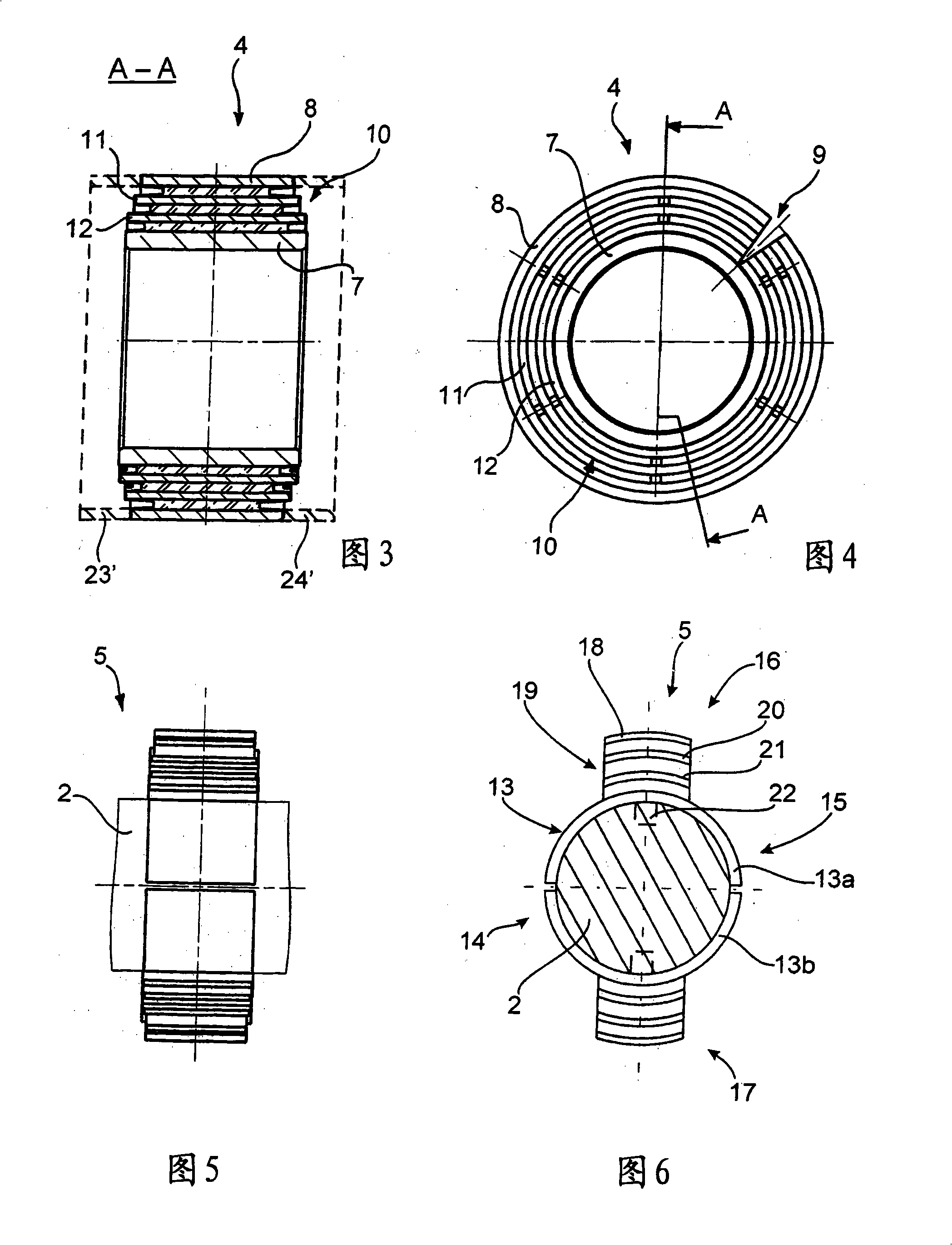

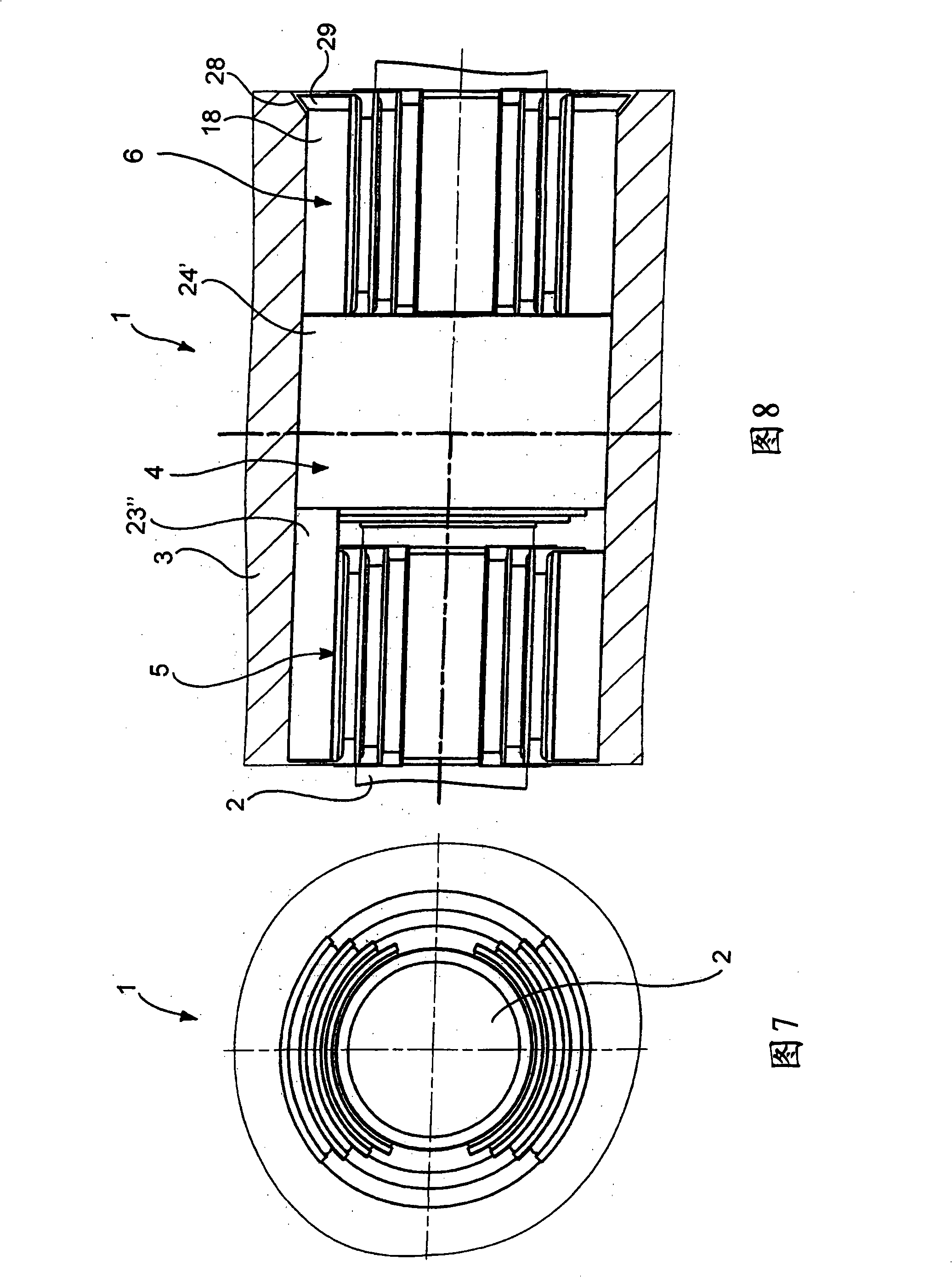

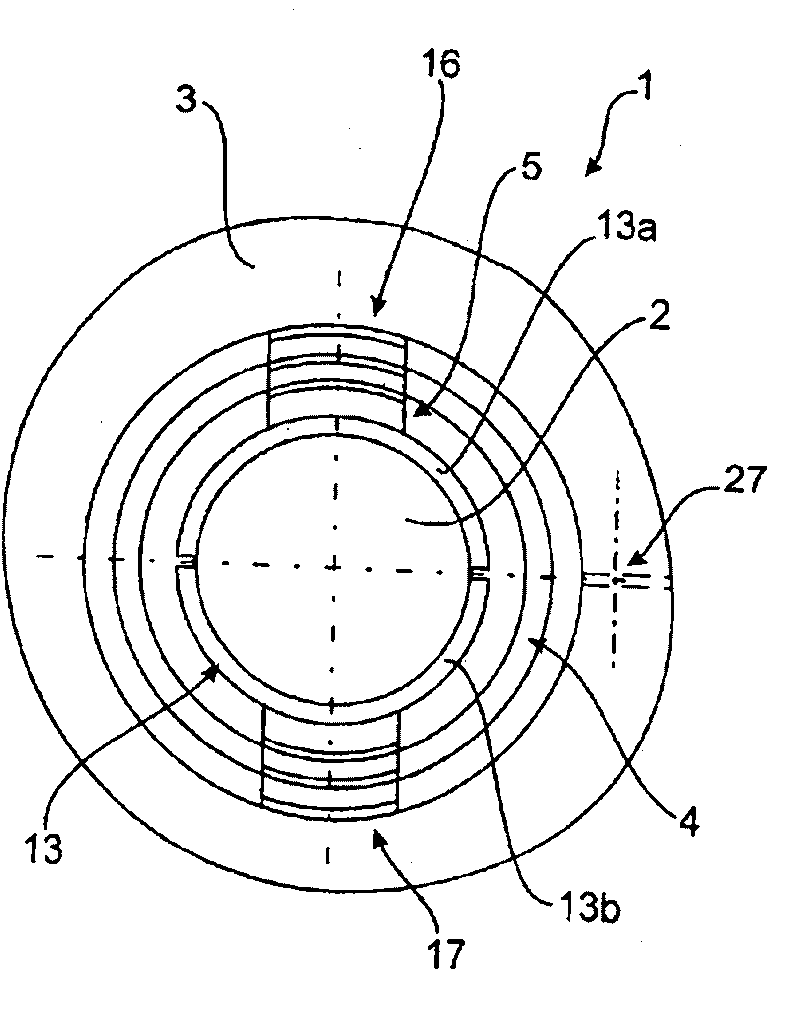

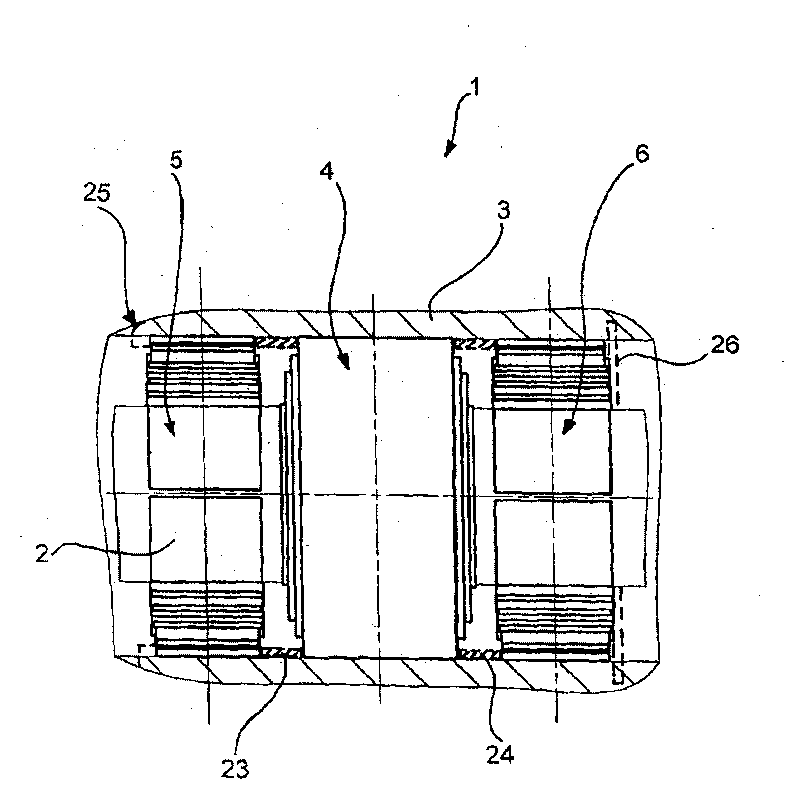

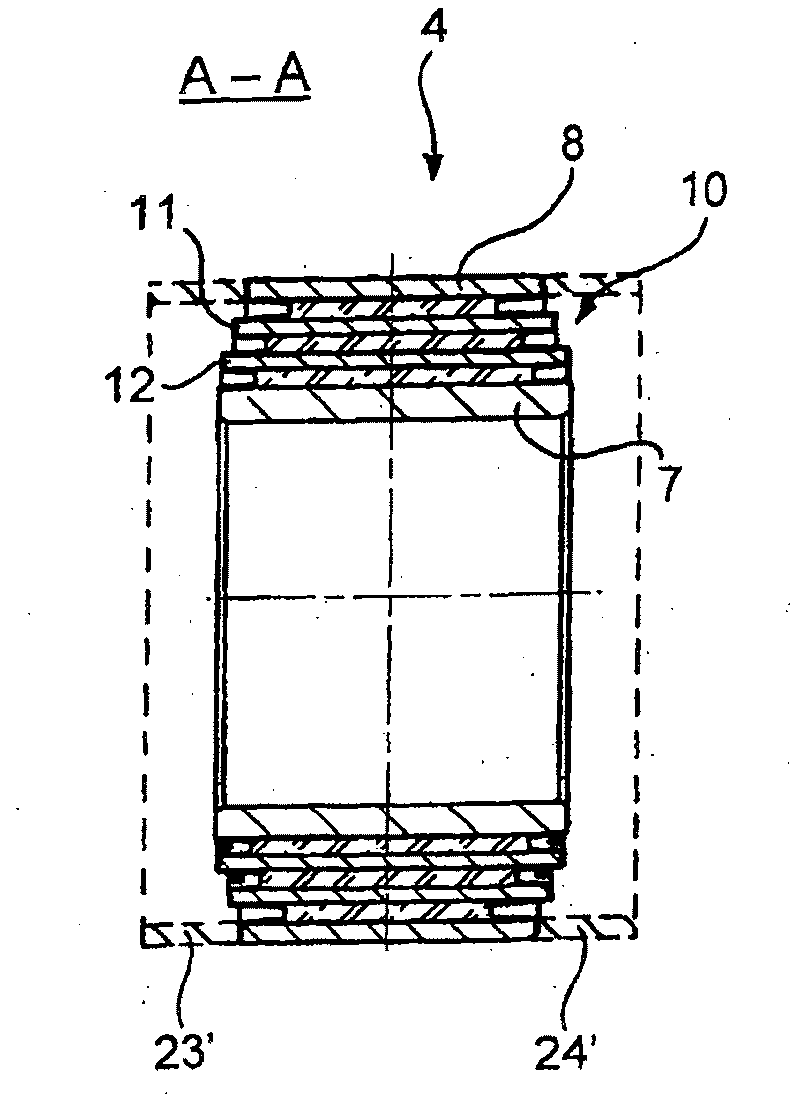

Pivot bearing, in particular on a swivel joint between a front wheel and a rear wheel of an articulated bus

InactiveCN101280816AReduce rigidityEvenly distributedMultiple spring combinationsOther connectionsElastomerLongitudinal plane

The present invention relates to a pivot bearing, in particular on a swivel joint between a front wheel and a rear wheel of an articulated bus, which includes a cylindrical articulated bus (4) composed of a inner pipe (7), a outer pipe (8), a composition rubber layer (10) between them and a contain cover (3), the inner pipe mounted on the a bearing pin (2) with anti-torsion function, the outer pipe provided with a longitudinal seam (9).The pre-tightening articulated bus (4) inserts in the contain cover (3).According to the invention, an elastomer metal bushings (5, 6) are arranged at both end of the pre-tightening articulated bus (4) and are spaced slightly from it.The elastomer metal bushings includes a inner pipe (13) which has a interrupted elastomer layer case (16, 17) clinging and crossing the free-space (14, 15) at individual radial direction relative place, and inserting into the contain cover (3) with pre-tightening inside of the elastomer layer case (16, 17) under assembling condition, wherein the inner pipe (13) is mounted on the a bearing pin (2) with anti-torsion function, and the elastomer layer shells lies in a common longitudinal plane.

Owner:JORN +1

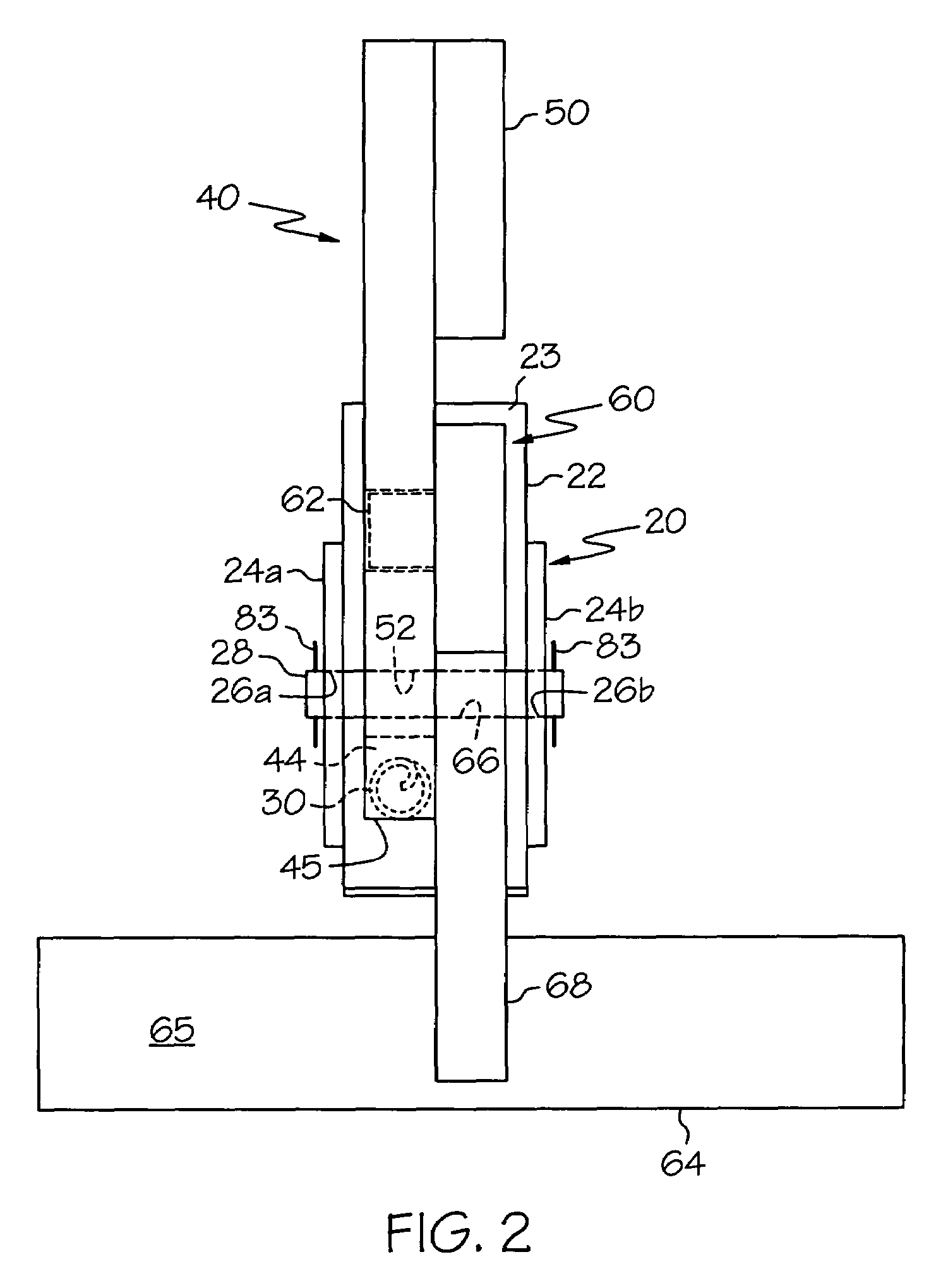

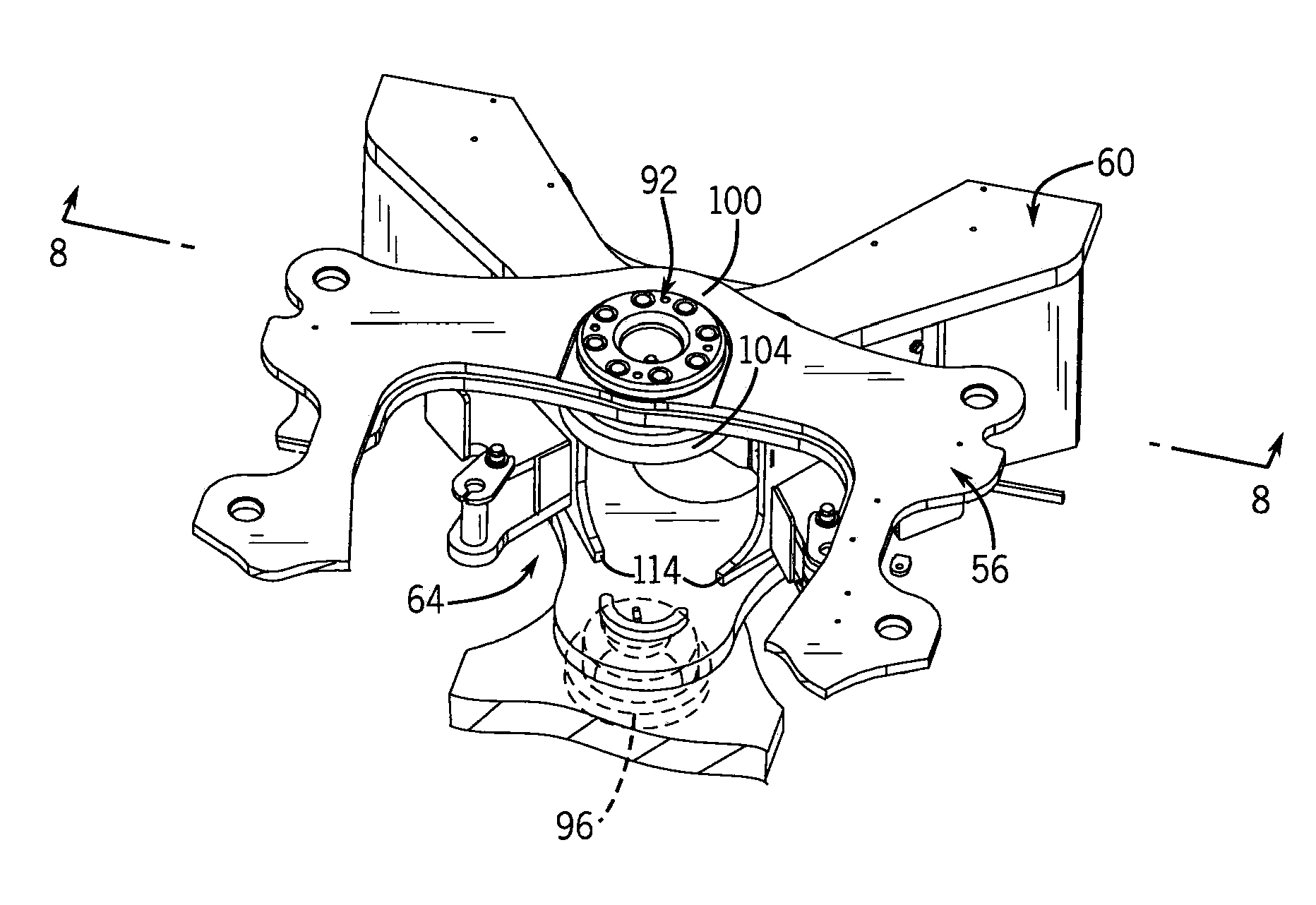

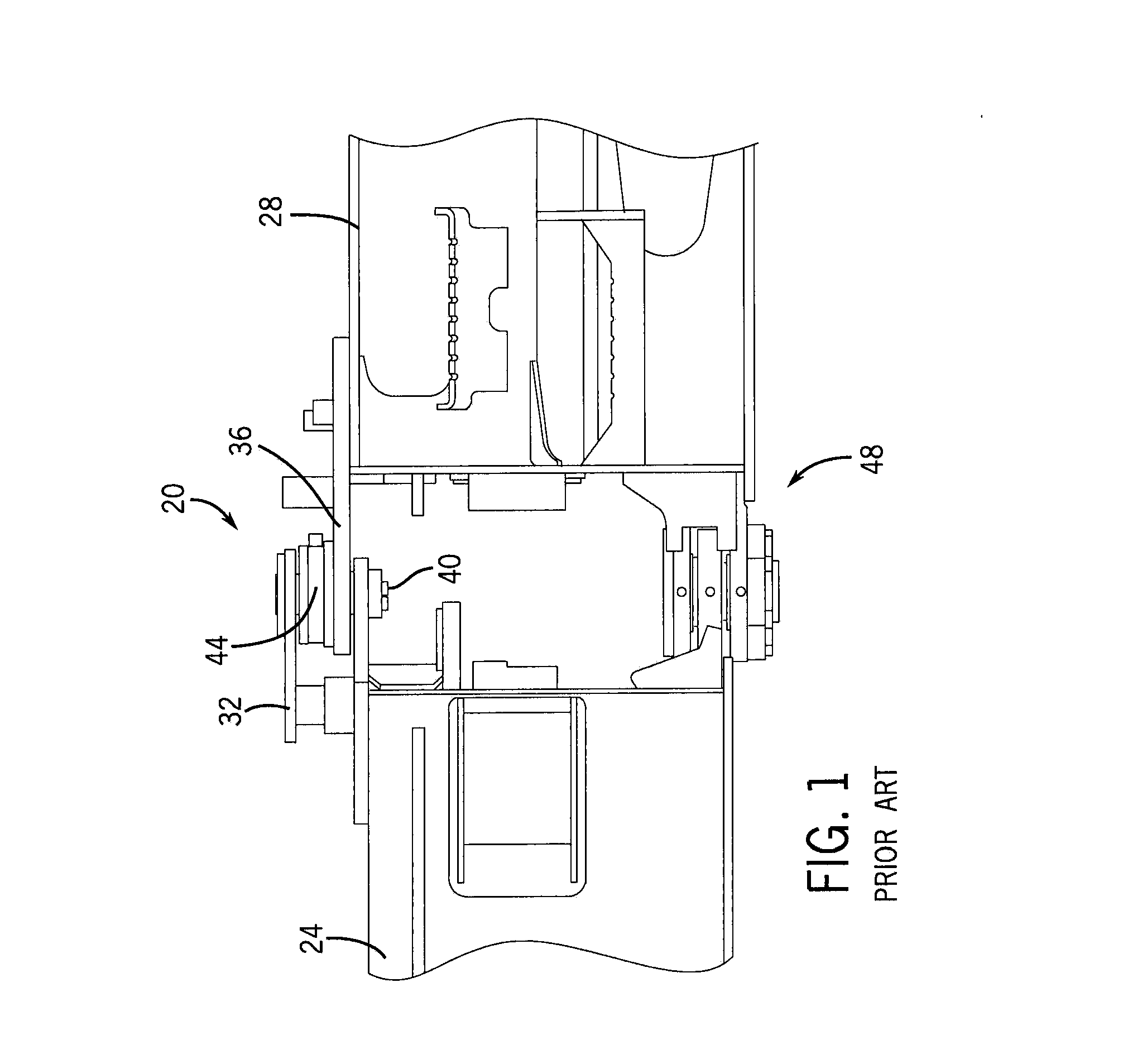

Work vehicle chassis articulation joint

InactiveUS20150084309A1Reducing and avoiding clevis-connectionsAvailable spaceTractor-trailer combinationsOther connectionsEngineeringRolling chassis

An articulated chassis work vehicle has an articulation joint rotatably coupling separate engine and equipment frames of the vehicle chassis. The articulation joint can have upper and lower joint assemblies. One or both of the upper and lower joint assemblies are constructed and arranged so that a corresponding bearing assembly is located between a single tab-like lug of each frame. In one arrangement, the articulation joint does away with clevis connections at both the upper and lower joint assemblies such that the available space within the articulation joint defined between the innermost upper and lower lugs is not reduced by additional lug and bearing components of either joint assembly.

Owner:DEERE & CO

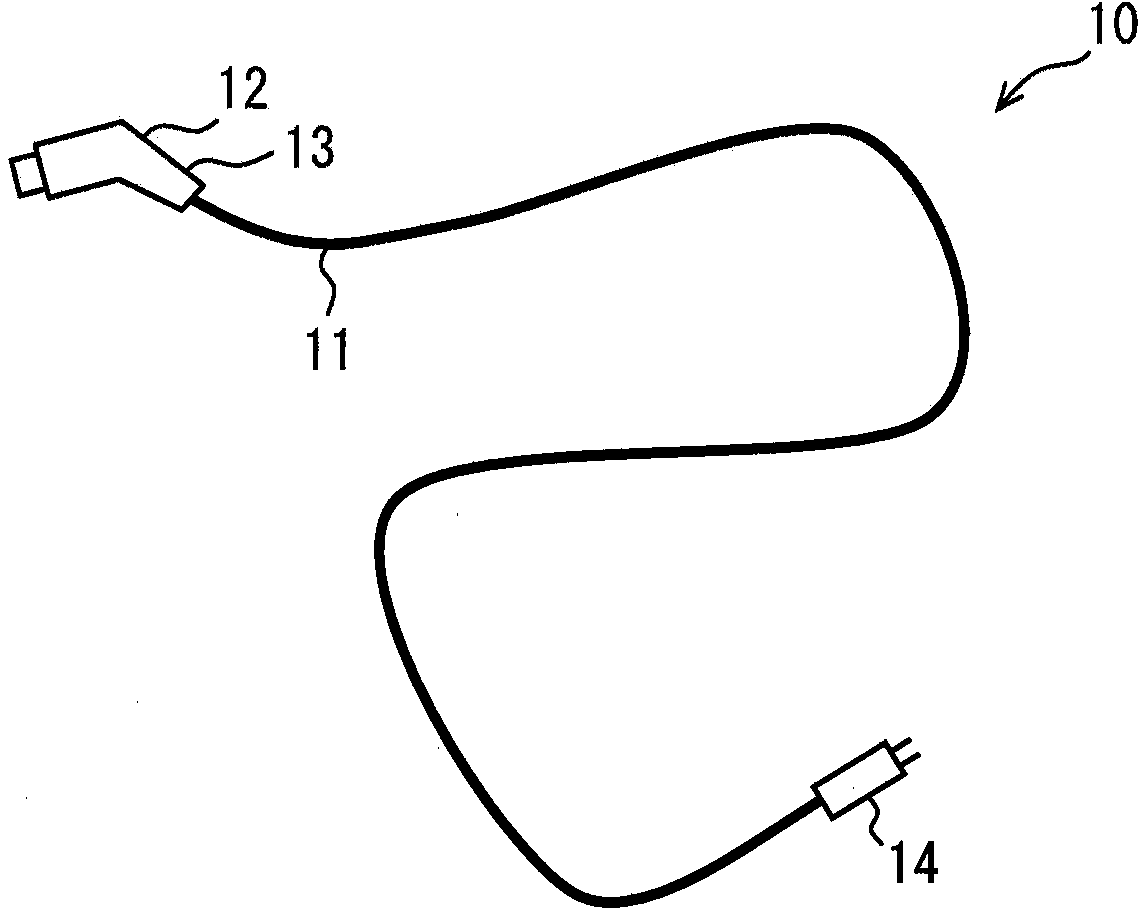

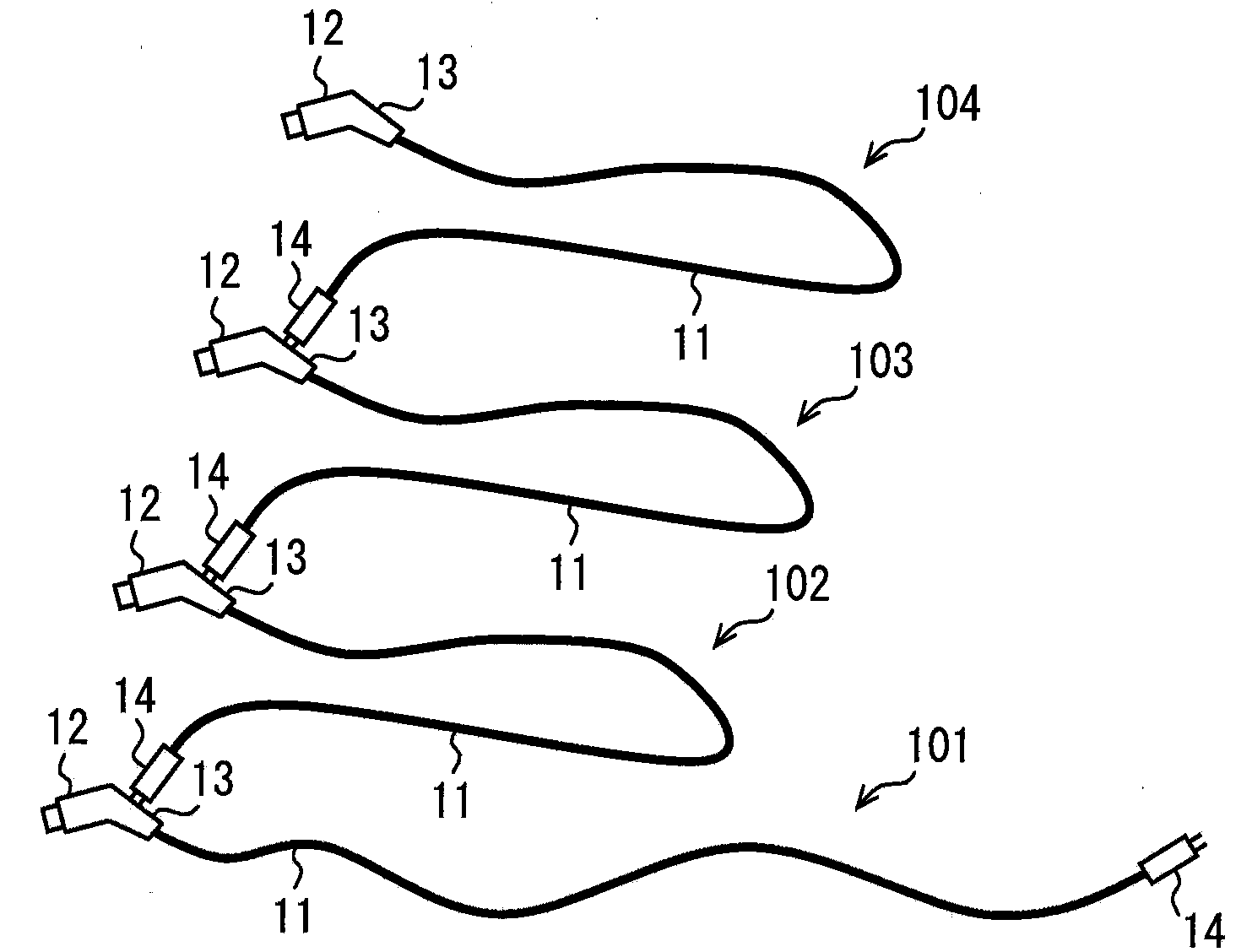

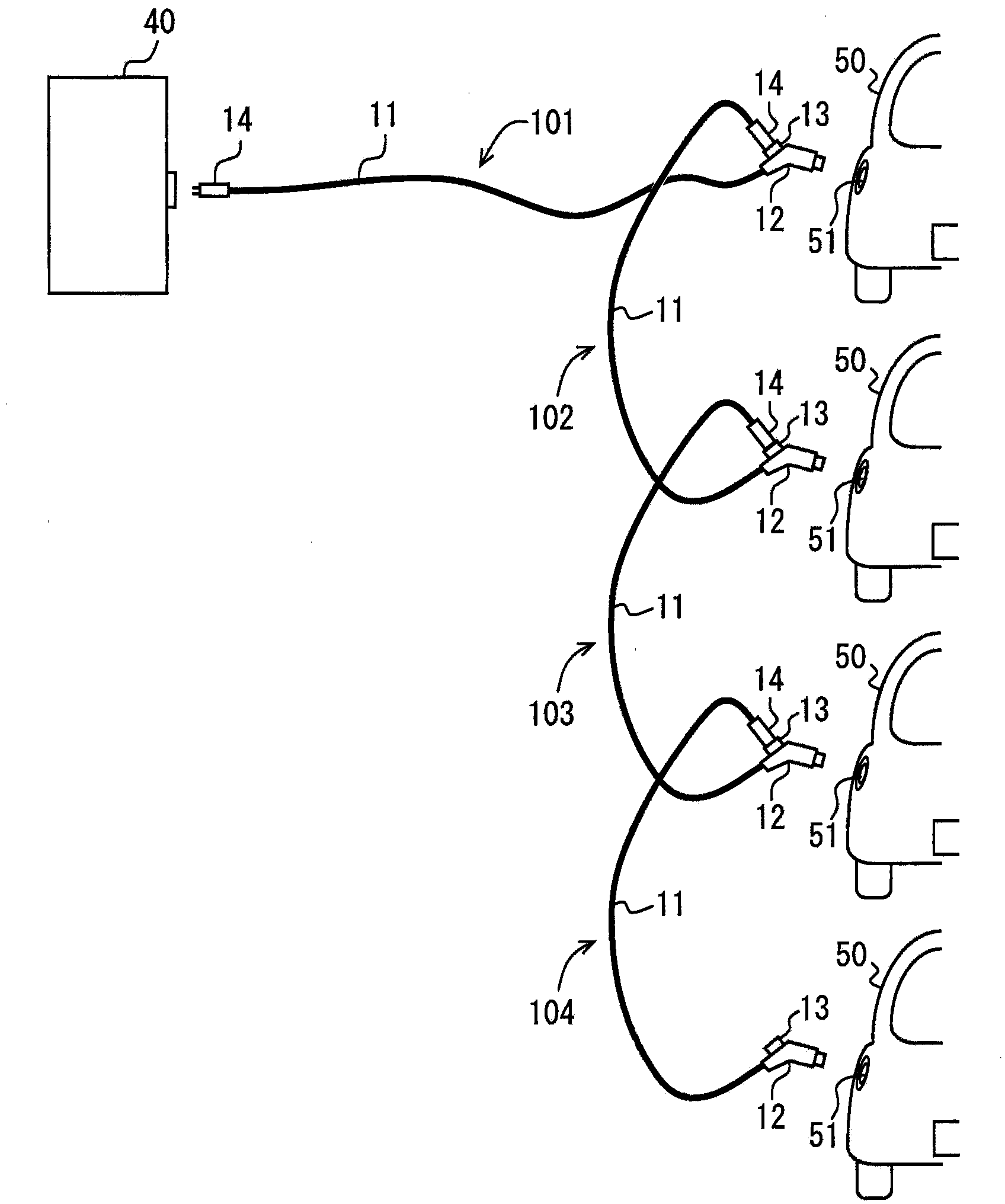

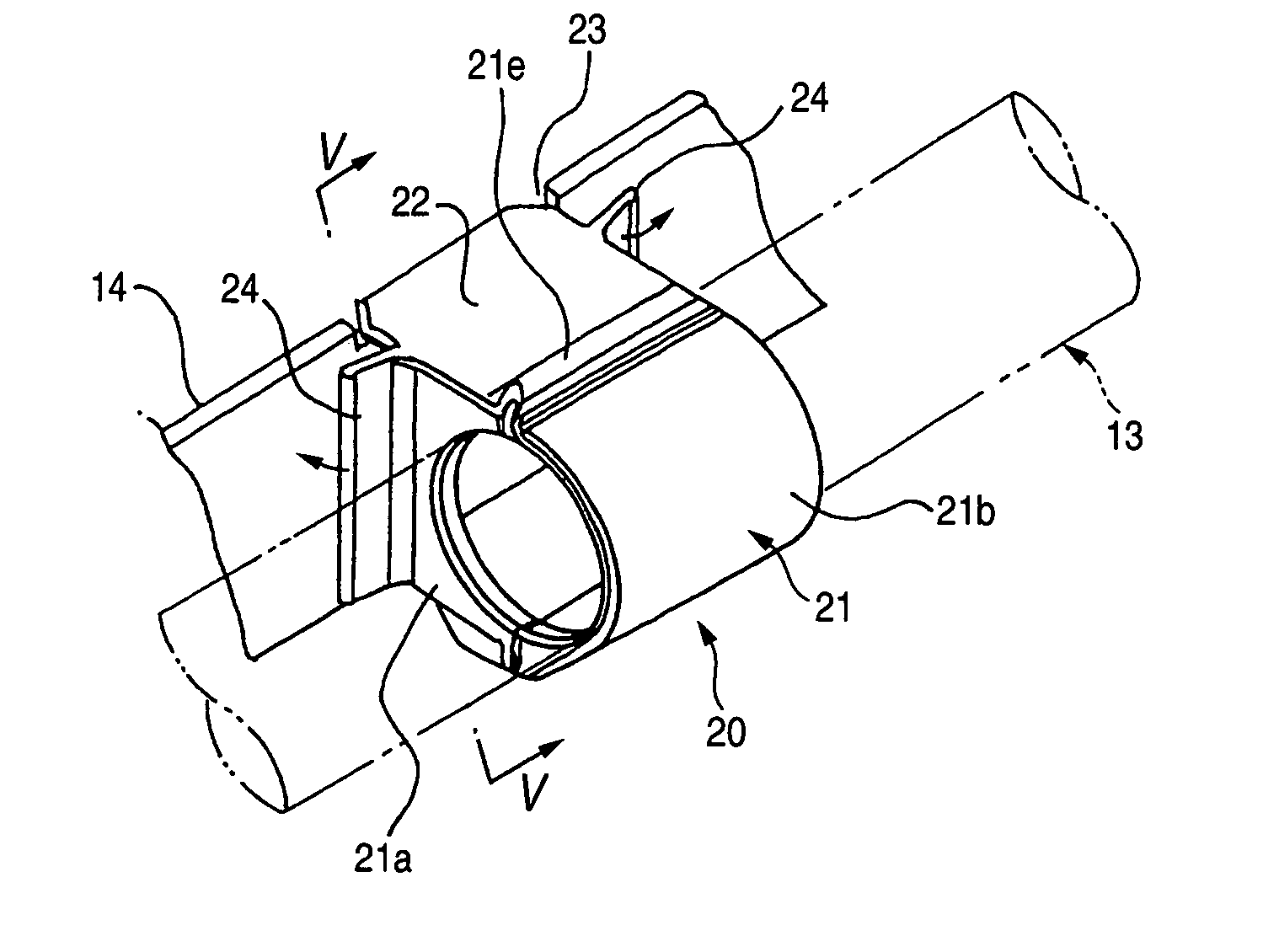

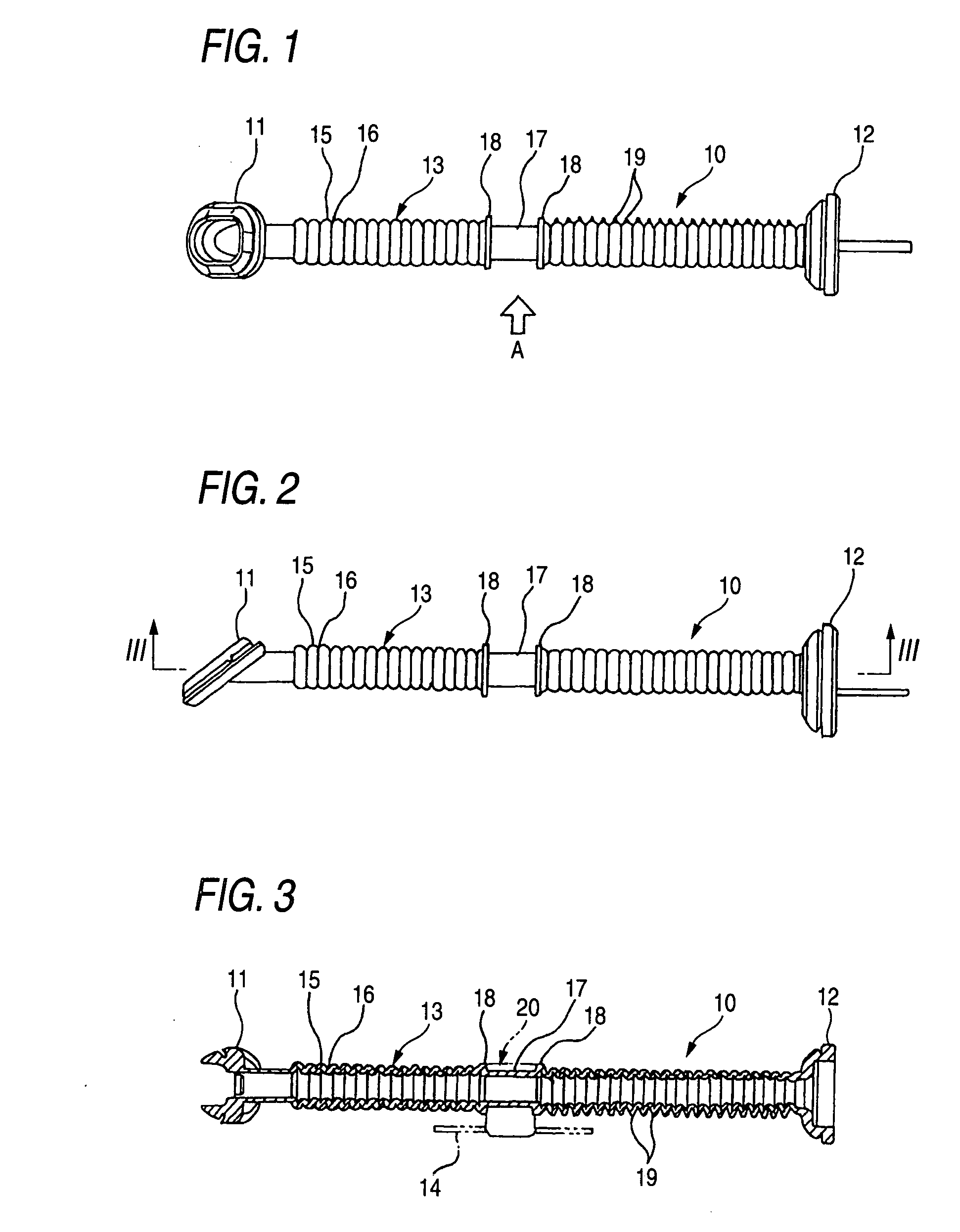

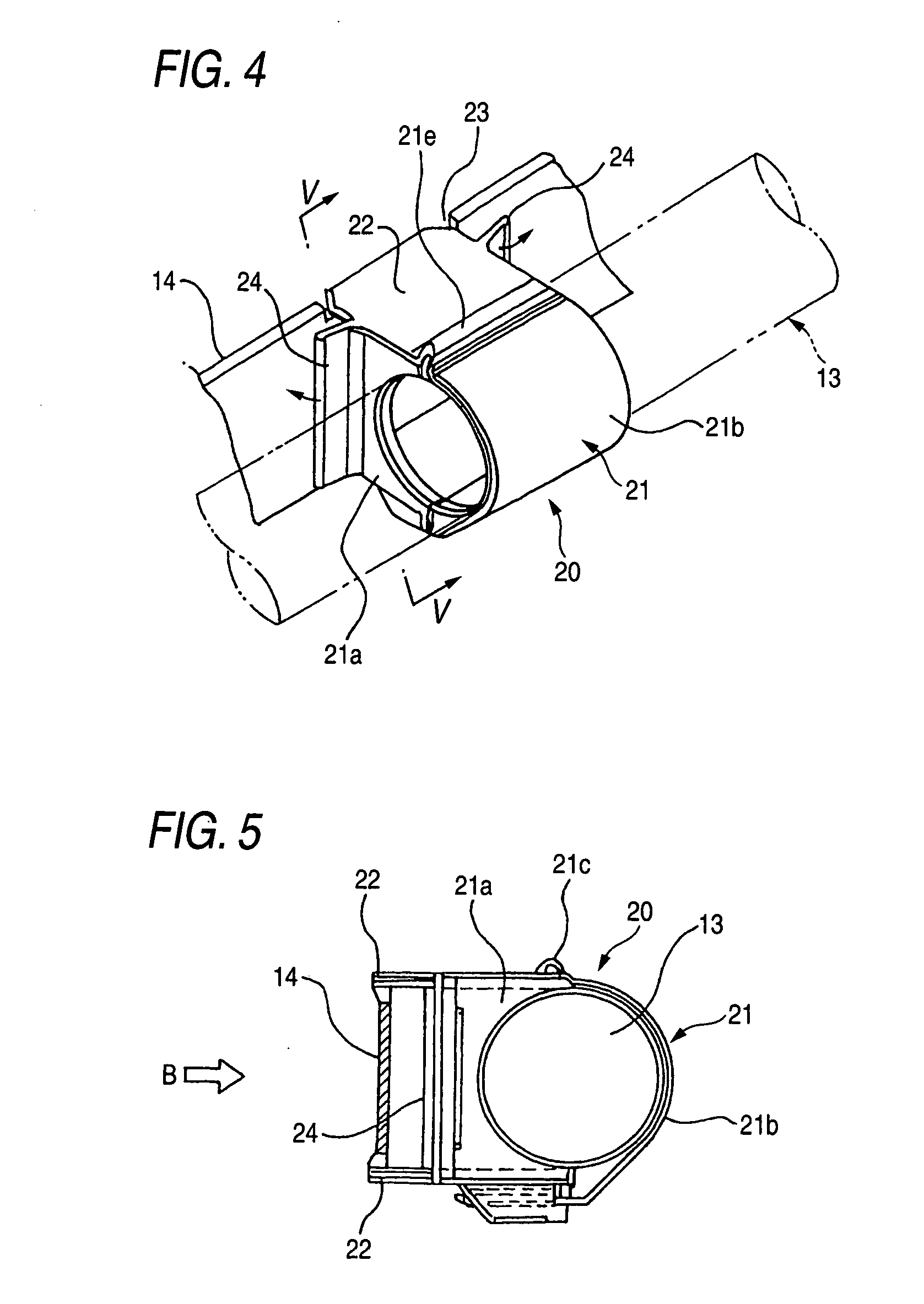

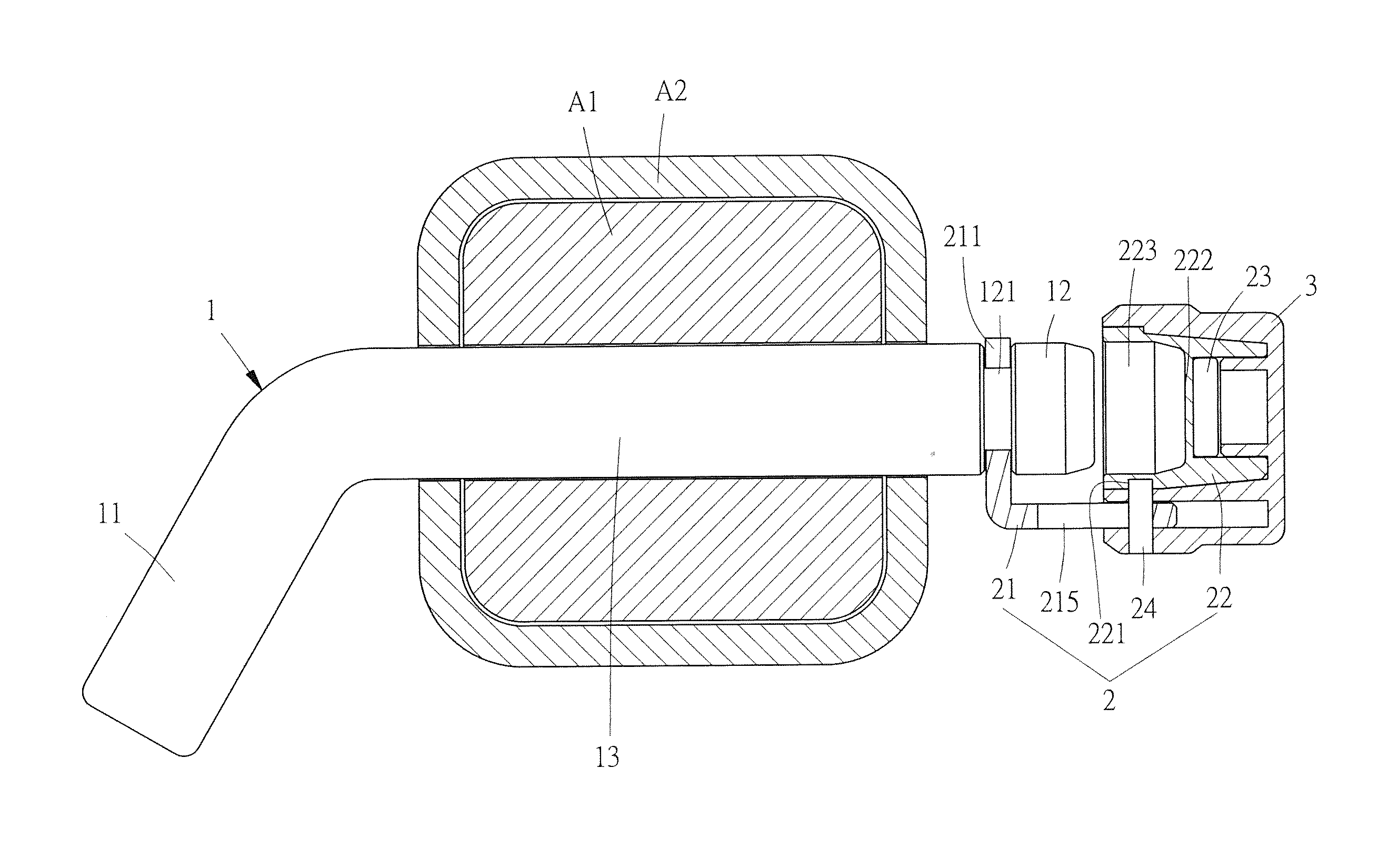

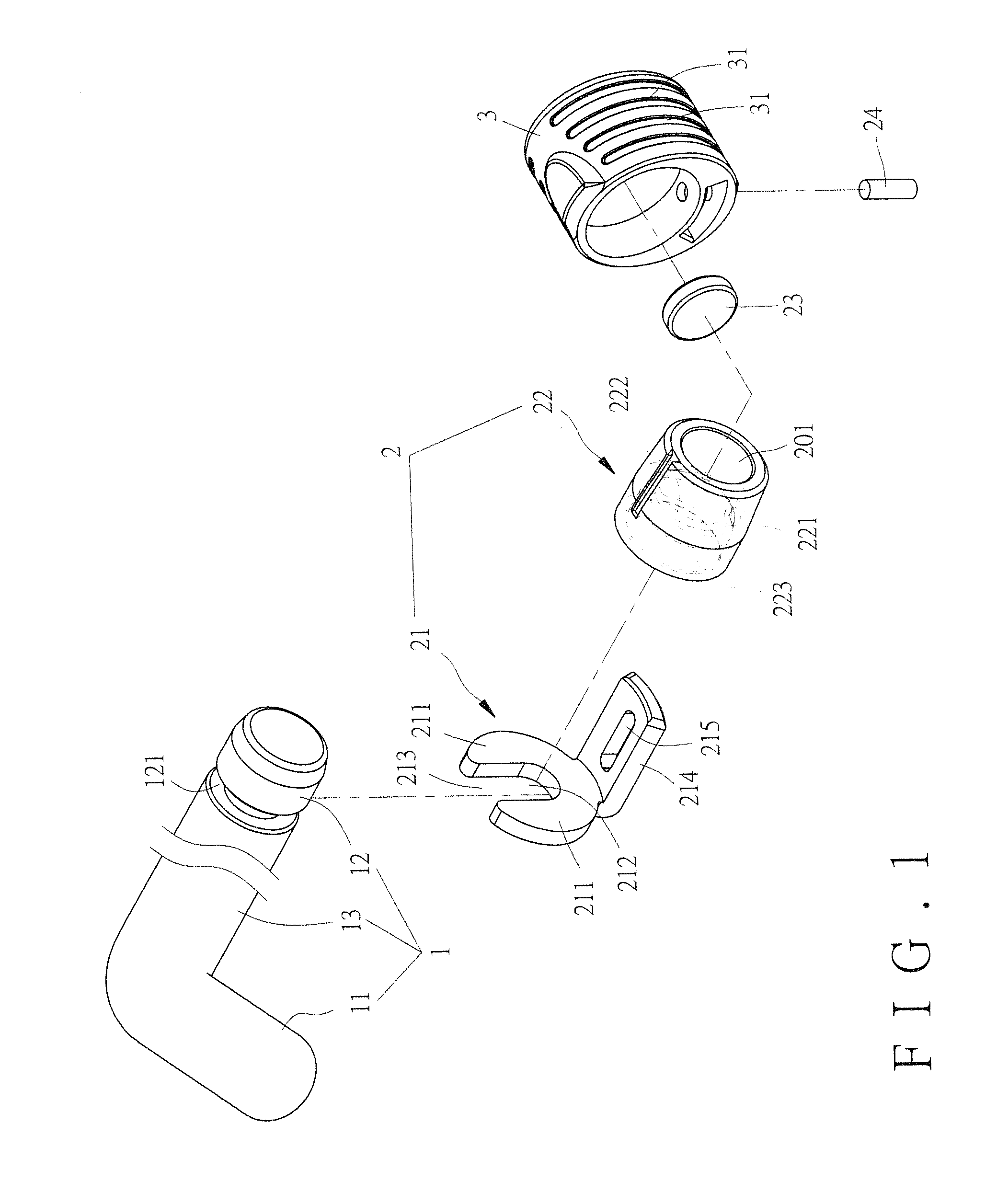

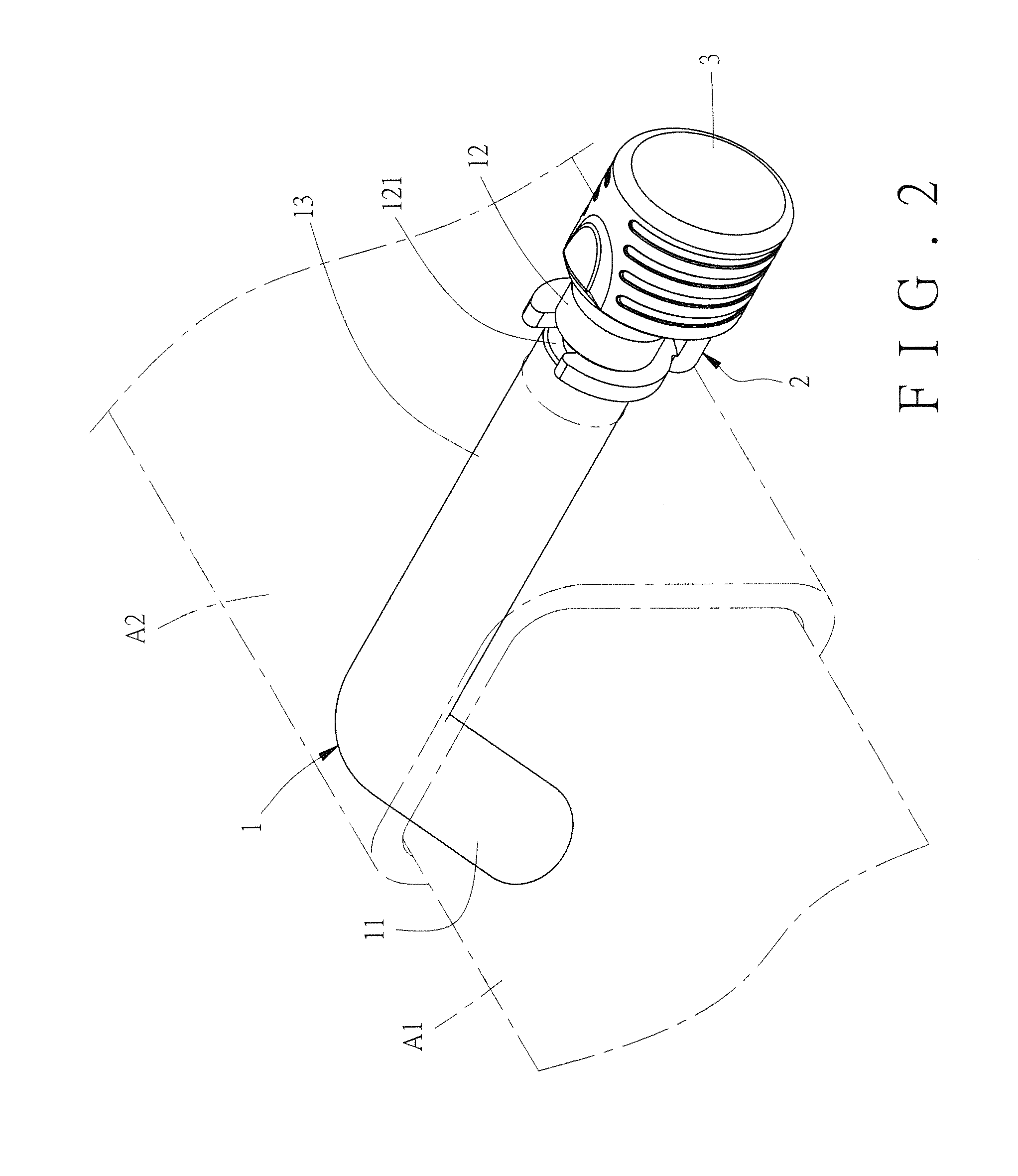

Charge Cable Device

InactiveCN103887675ATotal length minimizedImprove acceleration performanceCharging stationsCoupling device detailsElectricityElectric power system

The present invention discloses a charge cable device. The charge cable device includes: a cable (11) having one end detachable from a power source (40) or another charge cable device and an electric power line (21) for supplying electricity to a vehicle from the electric power source or another charge cable device; a charge connector (12) on the other end of the cable (11) detachable from a charge inlet (51) of the vehicle; a cable connector (13) detachable from further another charge cable device to connect between further another charge cable device and the electric power line (21); and a controller (25). When the cable connector (13) is not attached to further another charge cable device, the controller (25) controls to supply electricity from the one end of the cable (11) to the charge connector (12). When the cable connector (13) is attached to further another charge cable device, the controller (25) controls an electric power supply amount of electricity to the charge connector (12) and to further another charge cable device.

Owner:DENSO CORP

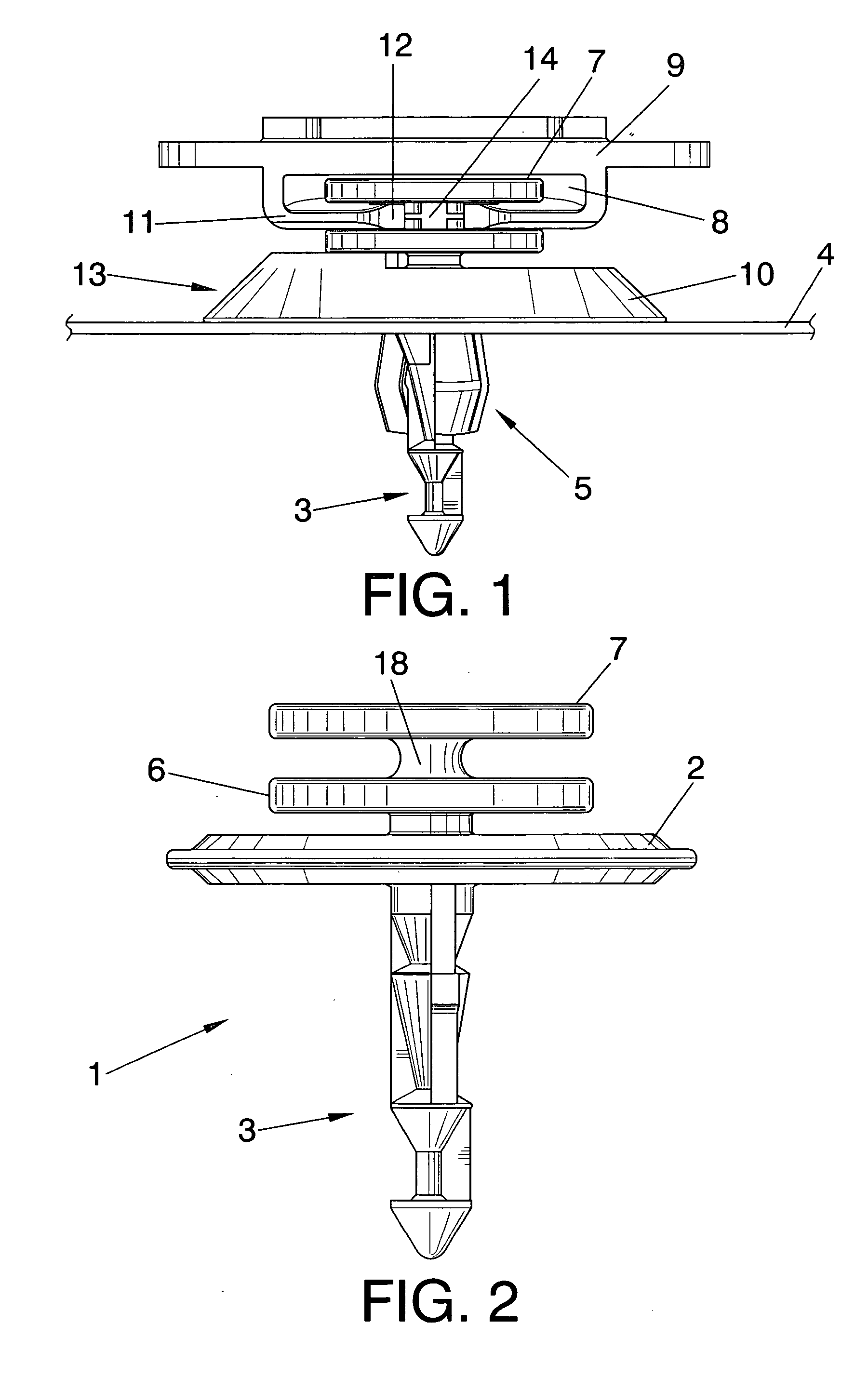

Grommet-mounting structure and grommet

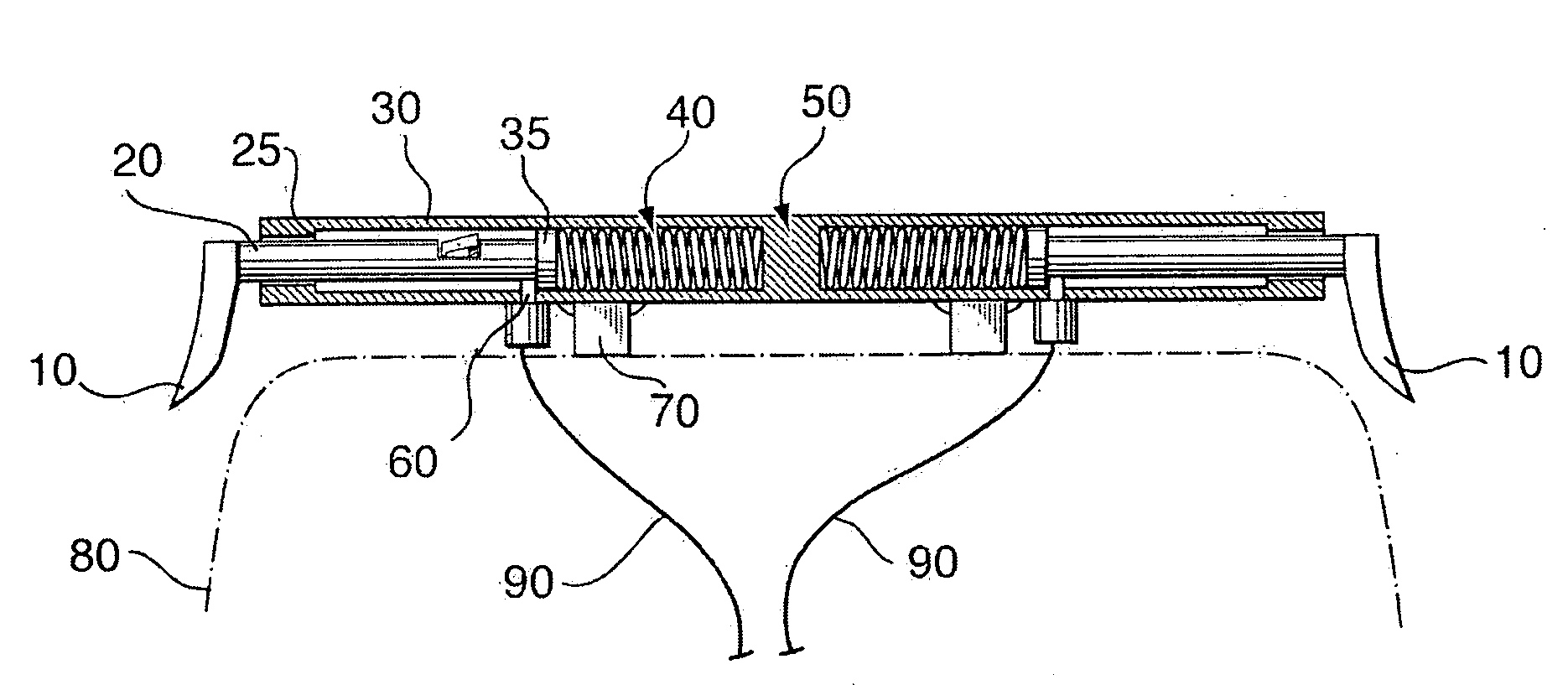

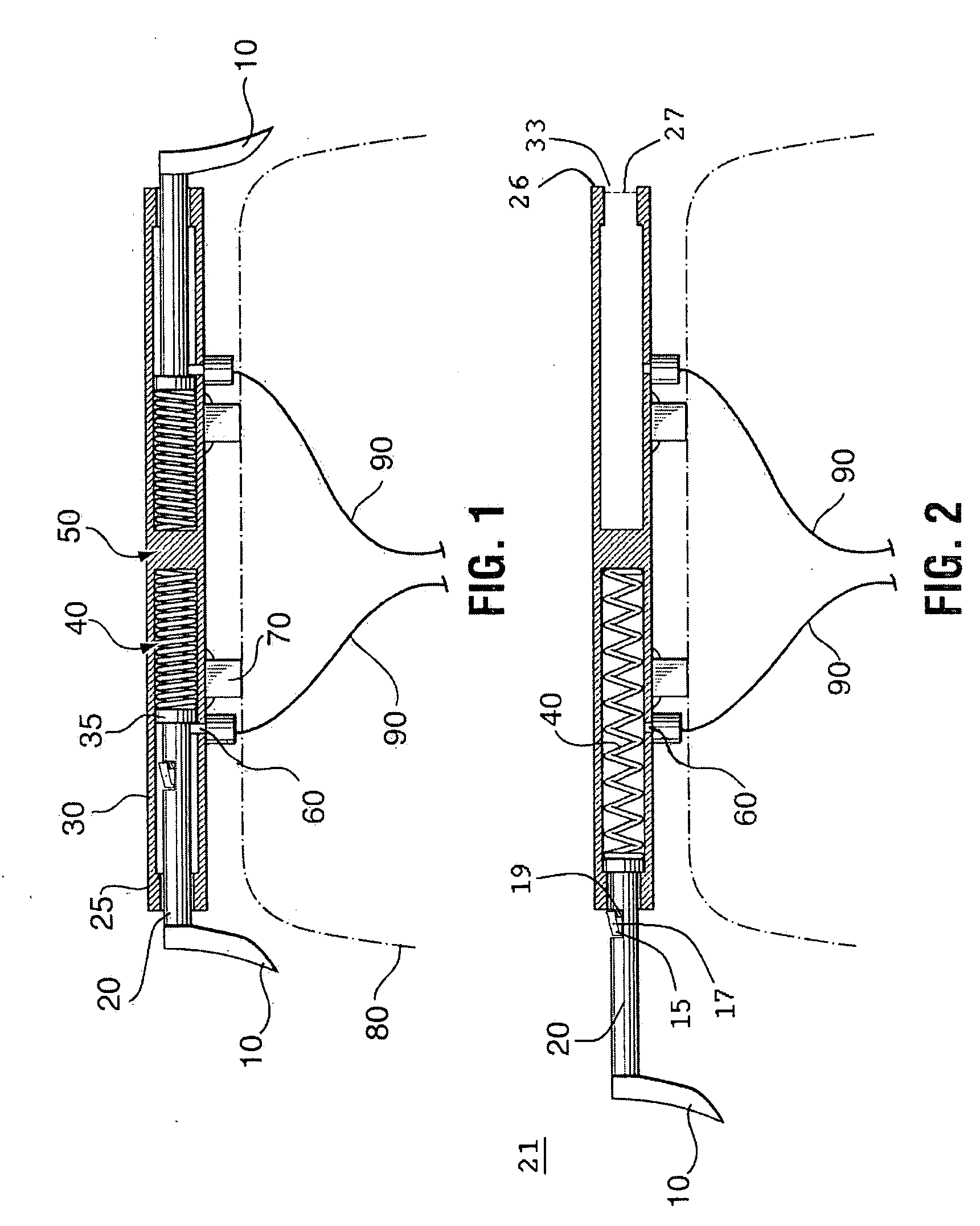

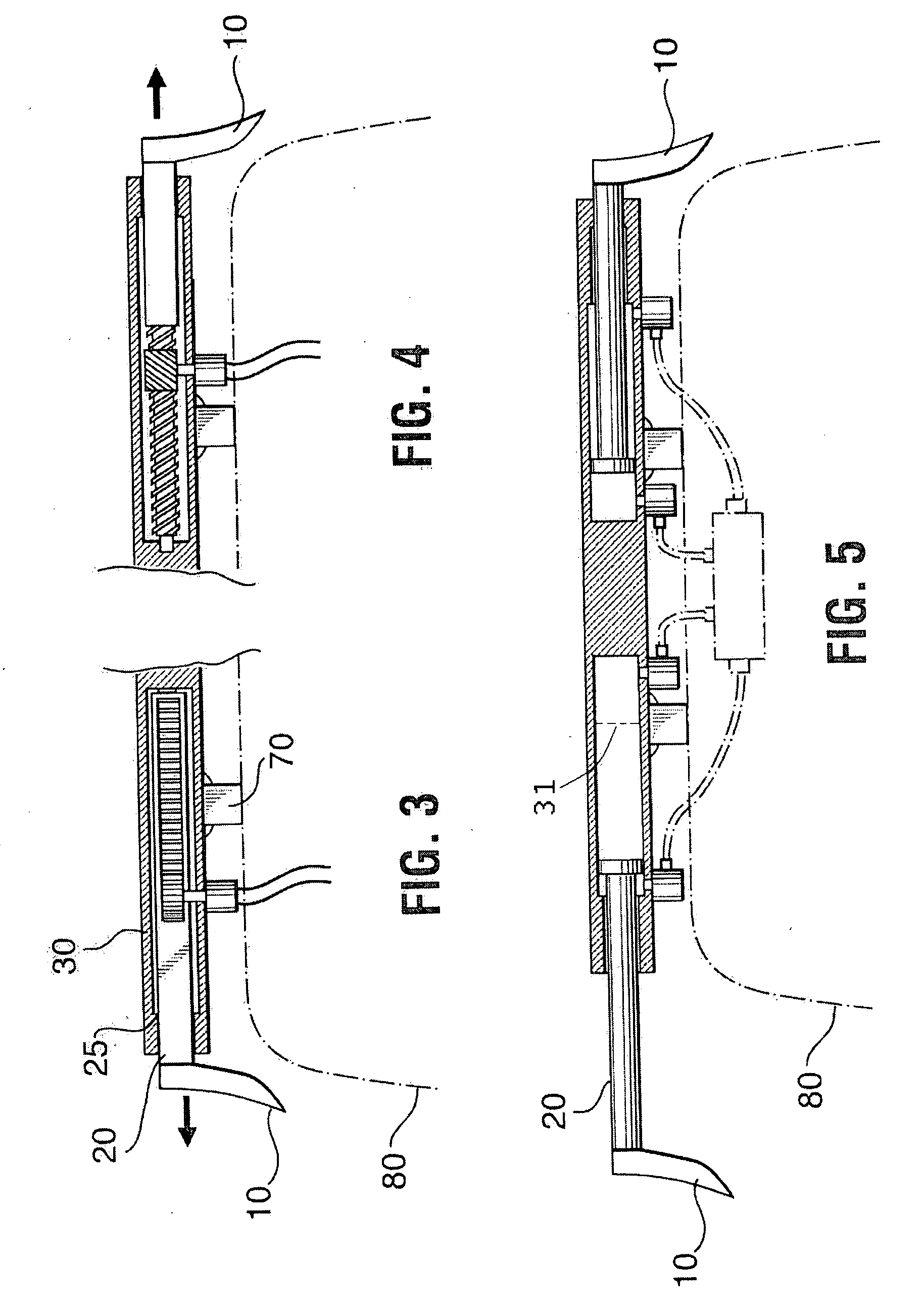

InactiveUS20050047859A1Avoid displacementPrevented from being bitingly heldScaffold connectionsOther connectionsGrommet

A structure of mounting a grommet, includes a first member, a second member, a link mechanism which connects the first member and the second member so that the first member and the second member are movable toward and away from each other, a grommet which is arranged between the first member and the second member. The grommet includes a first fixing portion fixed to the first member, a second fixing portion fixed to the second member, a flexible tubular portion extending between the first fixing portion and the second fixing portion, and an attaching portion provided on the tubular portion. A grip member grips the attaching portion. The tubular portion is fixed to at least one of the link mechanism, the first member and the second member through the grip member.

Owner:YAZAKI CORP

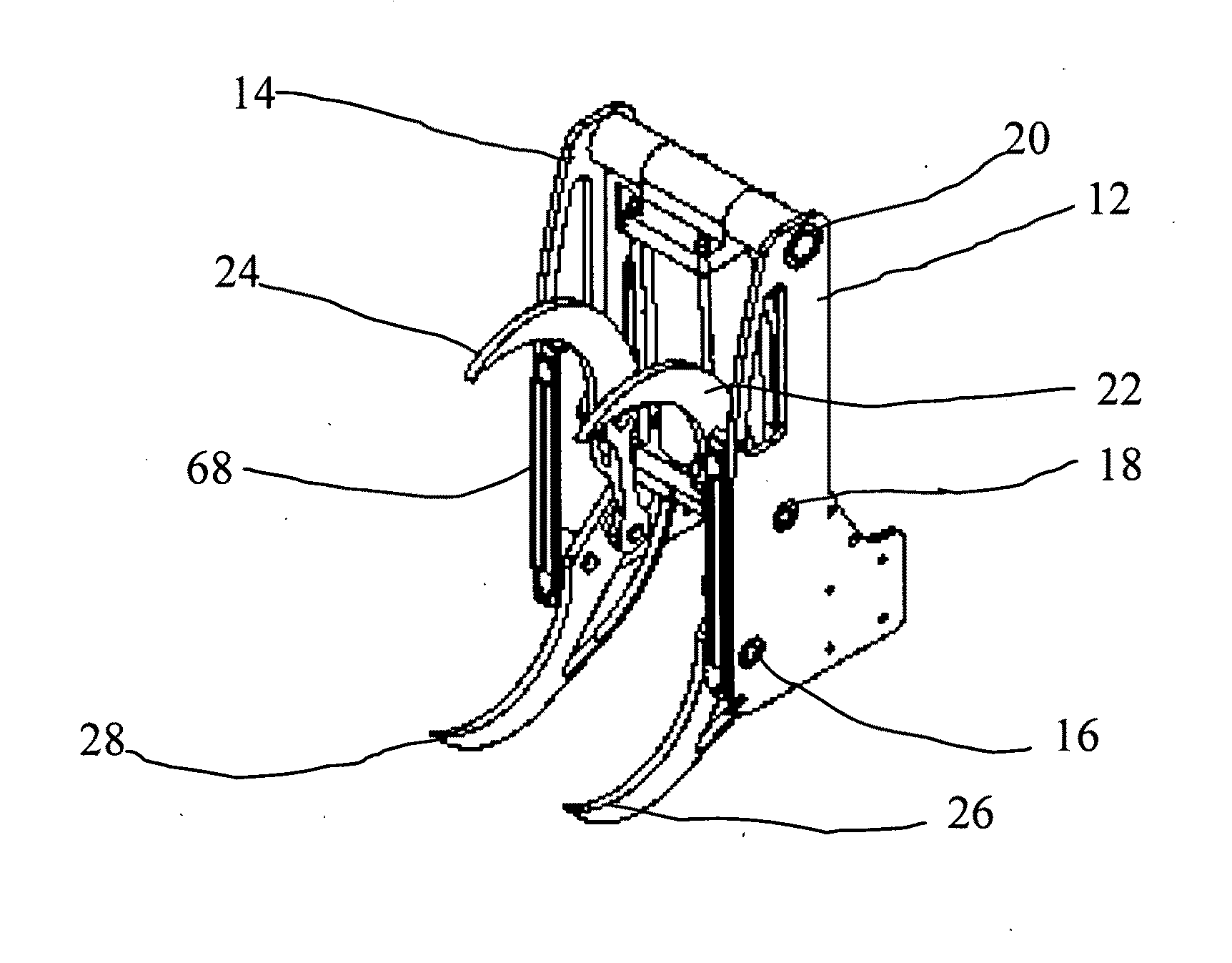

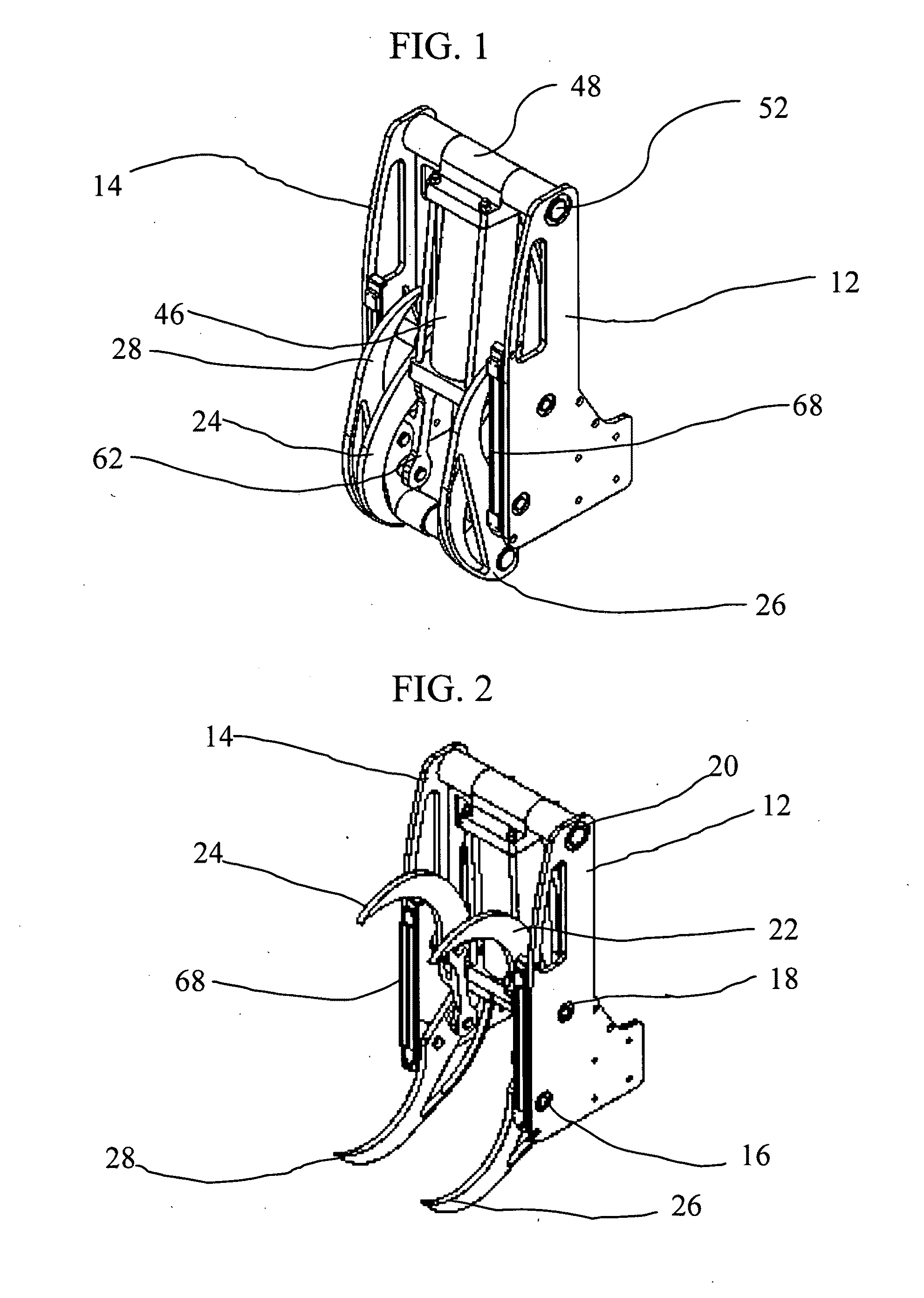

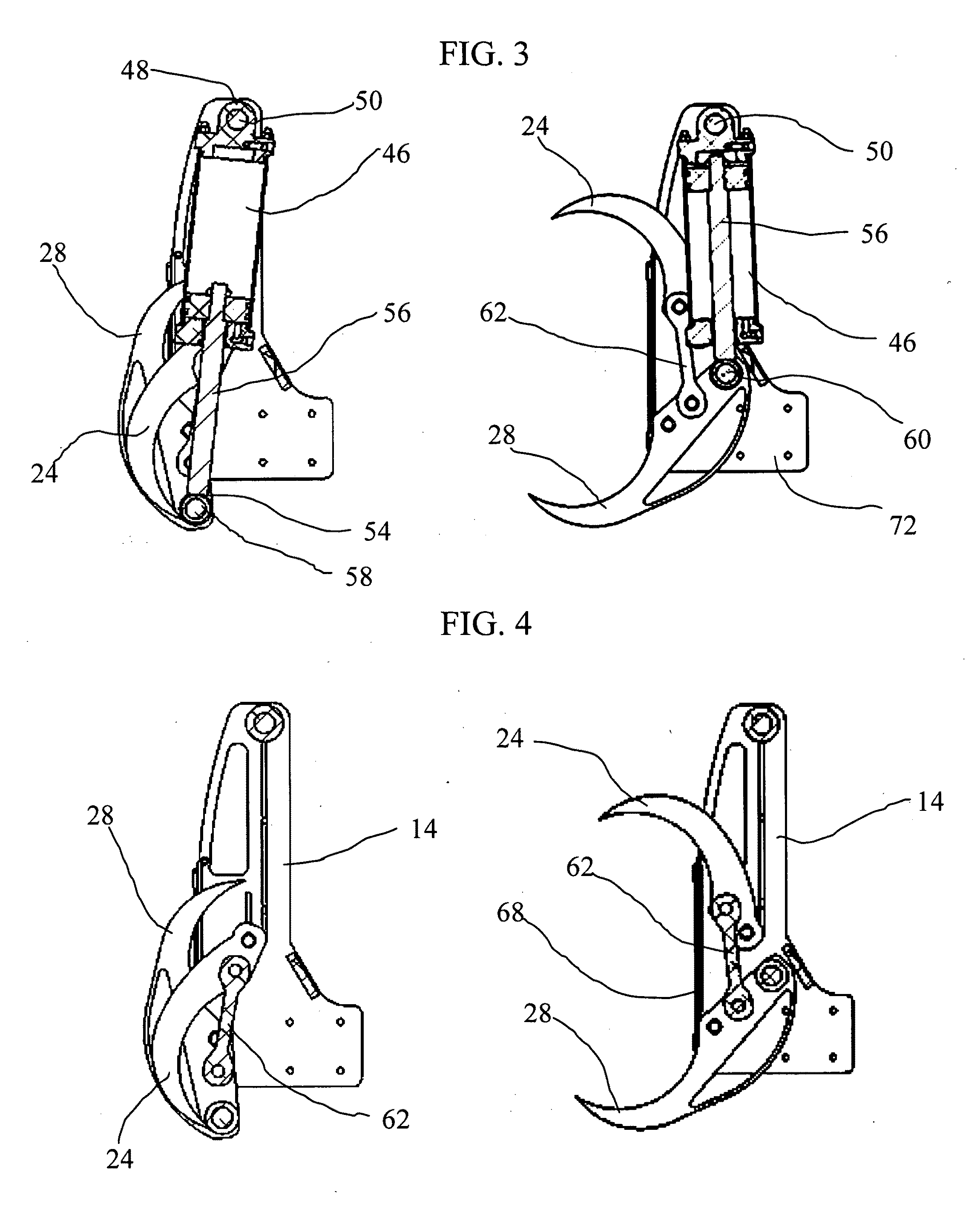

System for capturing a vehicle

The system for capturing a vehicle is a device, which is mounted on the front of a first vehicle for deploying a grasping hook for grasping the rear bumper of a second vehicle. In operation, the system begins in a locked configuration, with a hook member being positioned rearward with respect to a lower shaft. When the first vehicle brings an actuating arm in contact with the rear bumper of the second vehicle, pressure on the actuating arm generates rotation in the upper shaft. This rotation of the upper shaft causes disengagement of the lower end of an engaging member from a recess formed in a disc mounted on the lower shaft, causing the resiliently biased lower shaft to rotate. Rotation of the lower shaft rotates an elongated hook support and the hook member into the deployed configuration, with the hook member grasping the rear bumper of the second vehicle.

Owner:POHLER HARVEY L

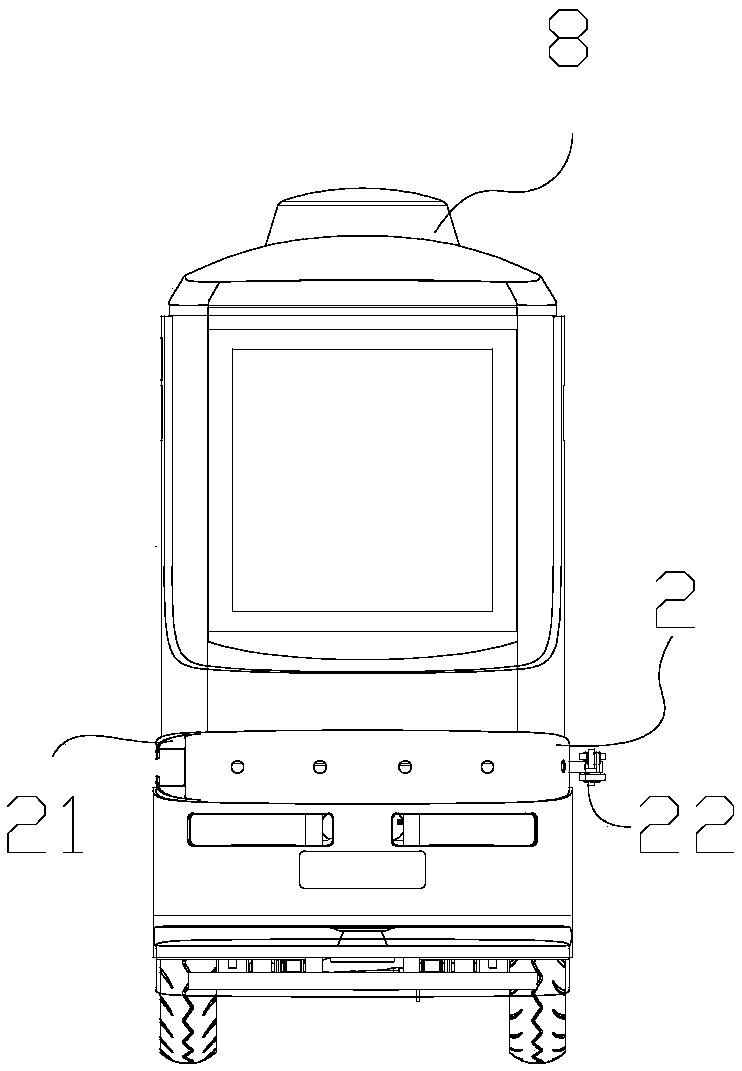

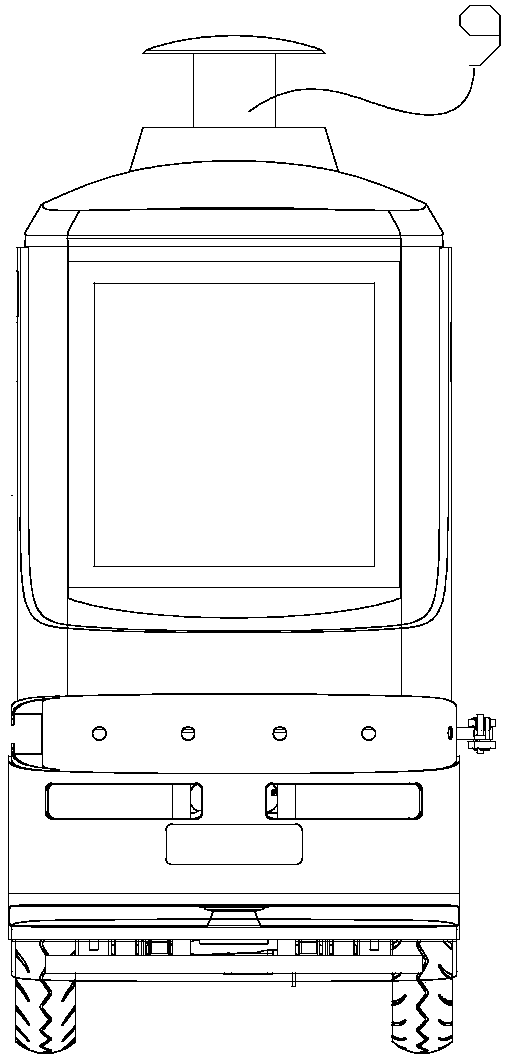

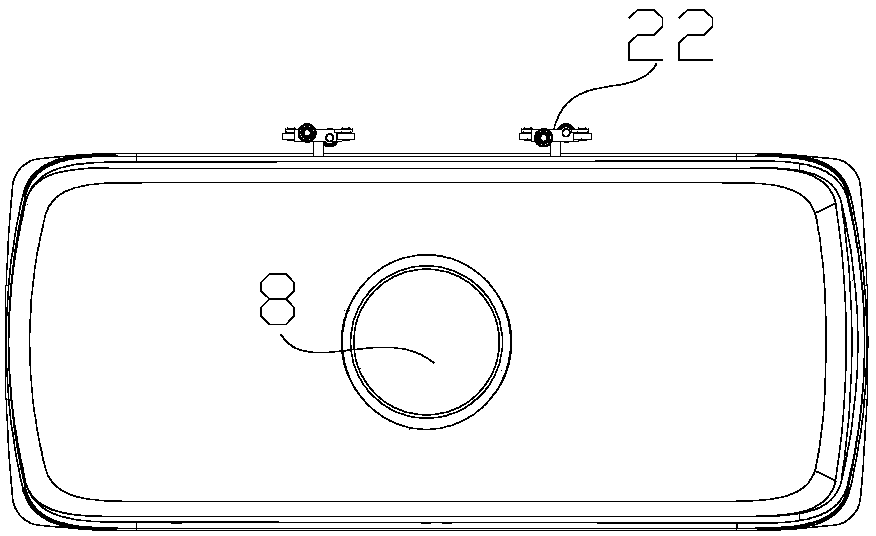

Smart delivery vehicle

PendingCN109987016ARealize unmannedEasy to transportLoad securingOther connectionsDelivery vehicleDelivery efficiency

The invention discloses a smart delivery vehicle. The smart delivery vehicle comprises a vehicle body, a compartment used for placing cargos is arranged on the vehicle body, the front face is in the running direction of the vehicle body, and a vehicle body combined part is arranged on the lateral sides of the vehicle body. The vehicle body combined part comprises one or more guide rail mechanism and one or more guide wheel mechanisms, the guide rail mechanisms are located on one lateral side of the vehicle body, and the guide wheel mechanisms are located on the other lateral side of the vehicle body; the guide wheel mechanisms are matched with the guide wheel mechanisms on an adjacent vehicle body, and the guide wheel mechanisms are clamped into the guide rail mechanisms to complete assembly and combination of the adjacent vehicle bodies. The smart delivery vehicle can load assembly type movable self-pickup cabinets, can make the cabinet bodies transferred between two adjacent vehiclesand can achieve unmanned delivery of express items. The problems can be solved that in the existing express industry, manpower cost of express item delivery is high, the delivery efficiency is low and the express items are disorderly stored and taken.

Owner:CHANGSHA XINGSHEN INTELLIGENT TECH CO LTD

Universal flying terrain vehicle

A universal aerial platform (11, 41) supports lift elements (13, 14), thrusters (15), landing gear (21, 22) and a fuel supply (16) and has a coupling mechanism (17) external to the aerial platform for coupling to a terrain vehicle (20) so as to convert any suitably adapted terrain vehicle to a flying vehicle (10, 40). The terrain vehicle forms the cockpit of the flying vehicle. The terrain vehicle (20) includes flight controls that are automatically coupled to the airplane structure either wirelessly or by wires when the terrain vehicle is coupled thereto.

Owner:LEVY & CIE

Fastening device for fastening trailer connectors

InactiveUS20160082795A1Eliminate useImprove applicabilityPadlocksOther connectionsEngineeringMechanical engineering

Owner:SU WEN CHUN +1

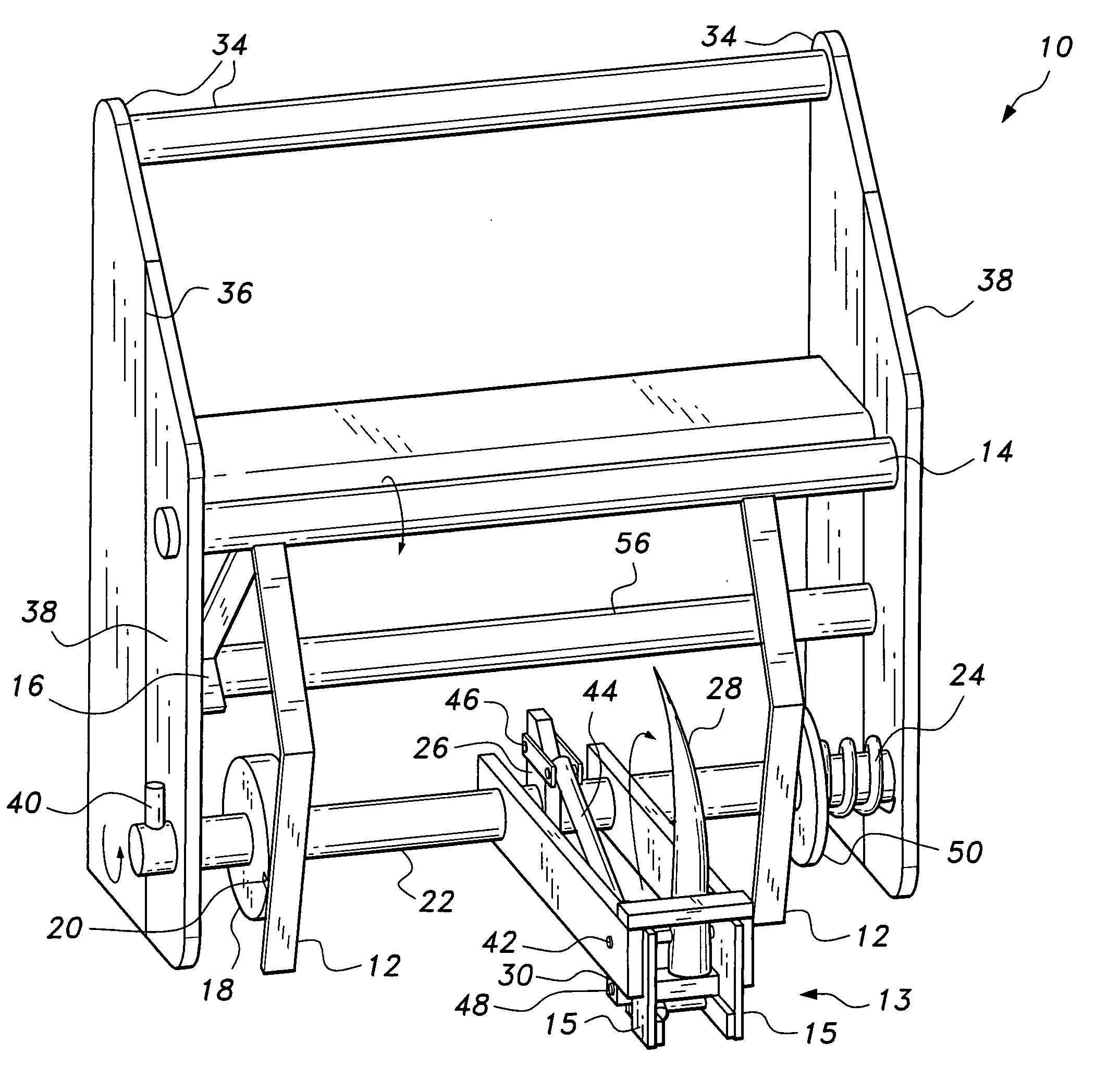

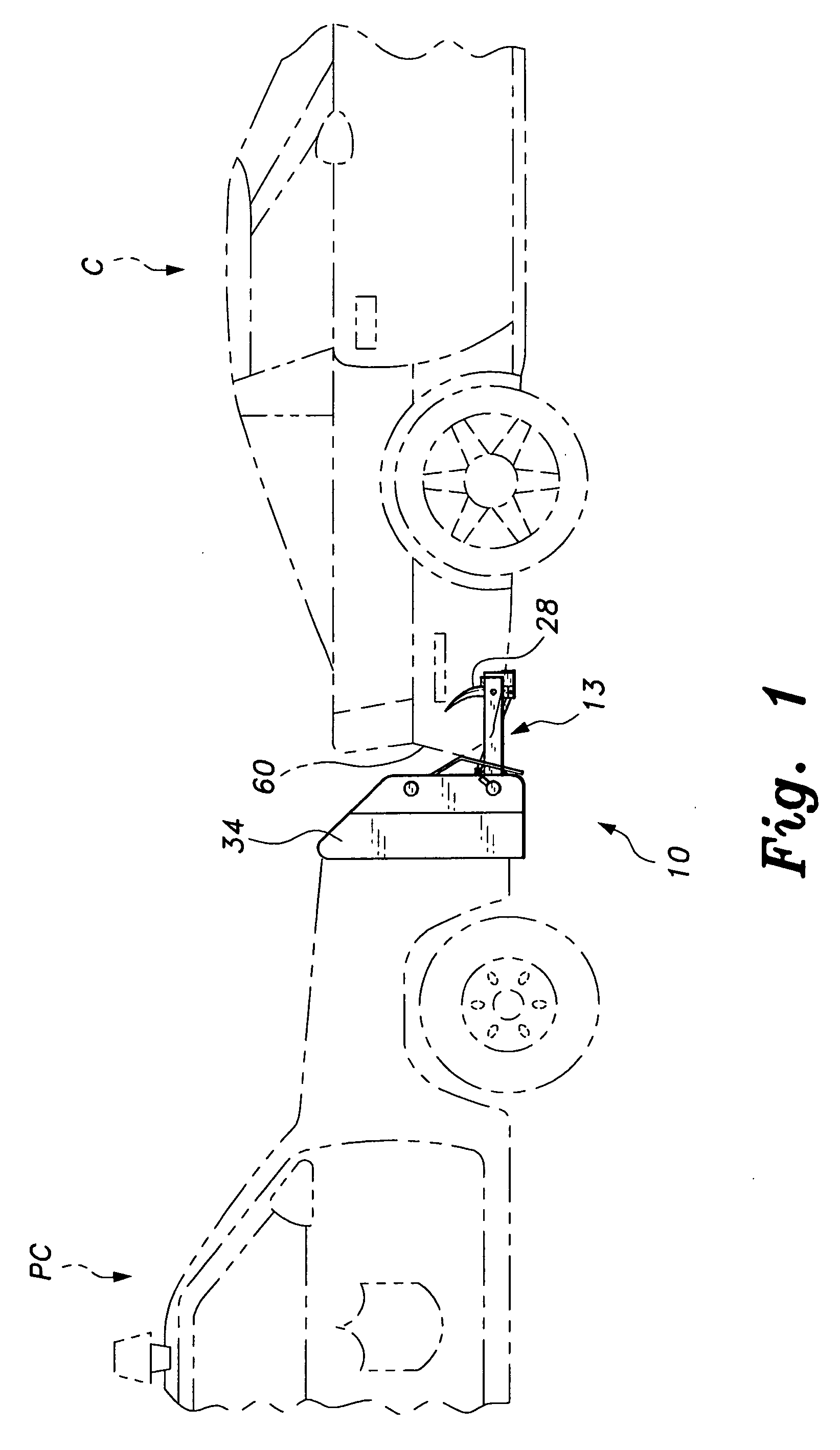

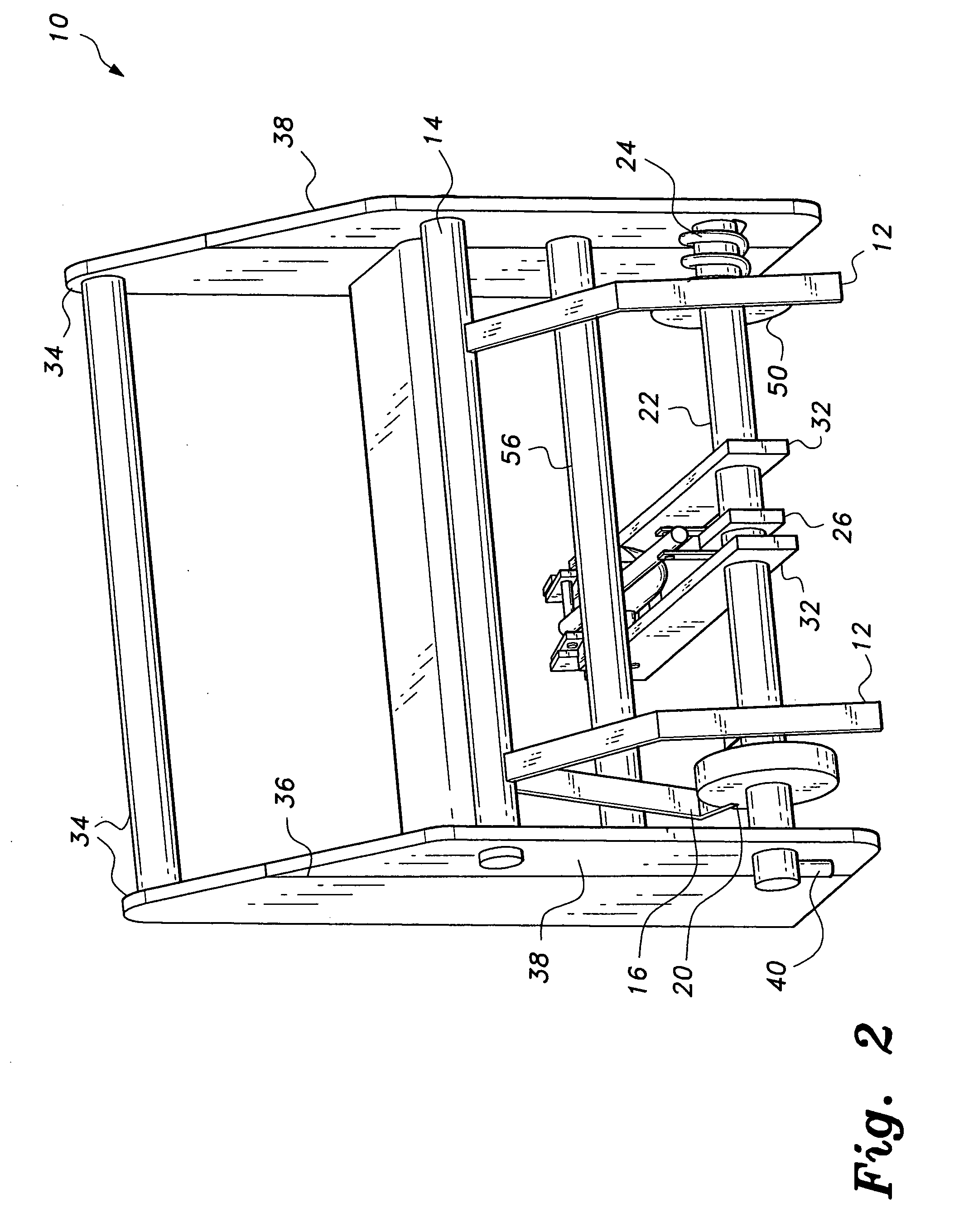

Vehicle grasping apparatus

InactiveUS20110272957A1Quickly and safely graspingEasy to installAnti-theft devicesOther connectionsMobile vehicleEngineering

A vehicle-to-vehicle grasping apparatus which utilizes a pair of top and bottom clamp fingers to grasp the back end of a fleeing vehicle. The clamp fingers are opened and closed through the use of a pneumatic cylinder and rod. The grasping apparatus is connected to the front bumper of a motor vehicle. When not in use, the clamp fingers of the grasping apparatus are maintained in a closed position. When a fleeing vehicle is to be stopped, the chase vehicle operator would cause the pneumatic cylinder of the grasping apparatus to be pressurized so that the clamp fingers are in an open position. Once the impact or proximity triggers of the grasping apparatus come into contact with the fleeing vehicle, the clamp fingers instantly close upon the fleeing vehicle's rear bumper or trunk. By applying the chase vehicle's brakes, the fleeing vehicle will be sufficiently slowed or stopped.

Owner:FETCH RENE H

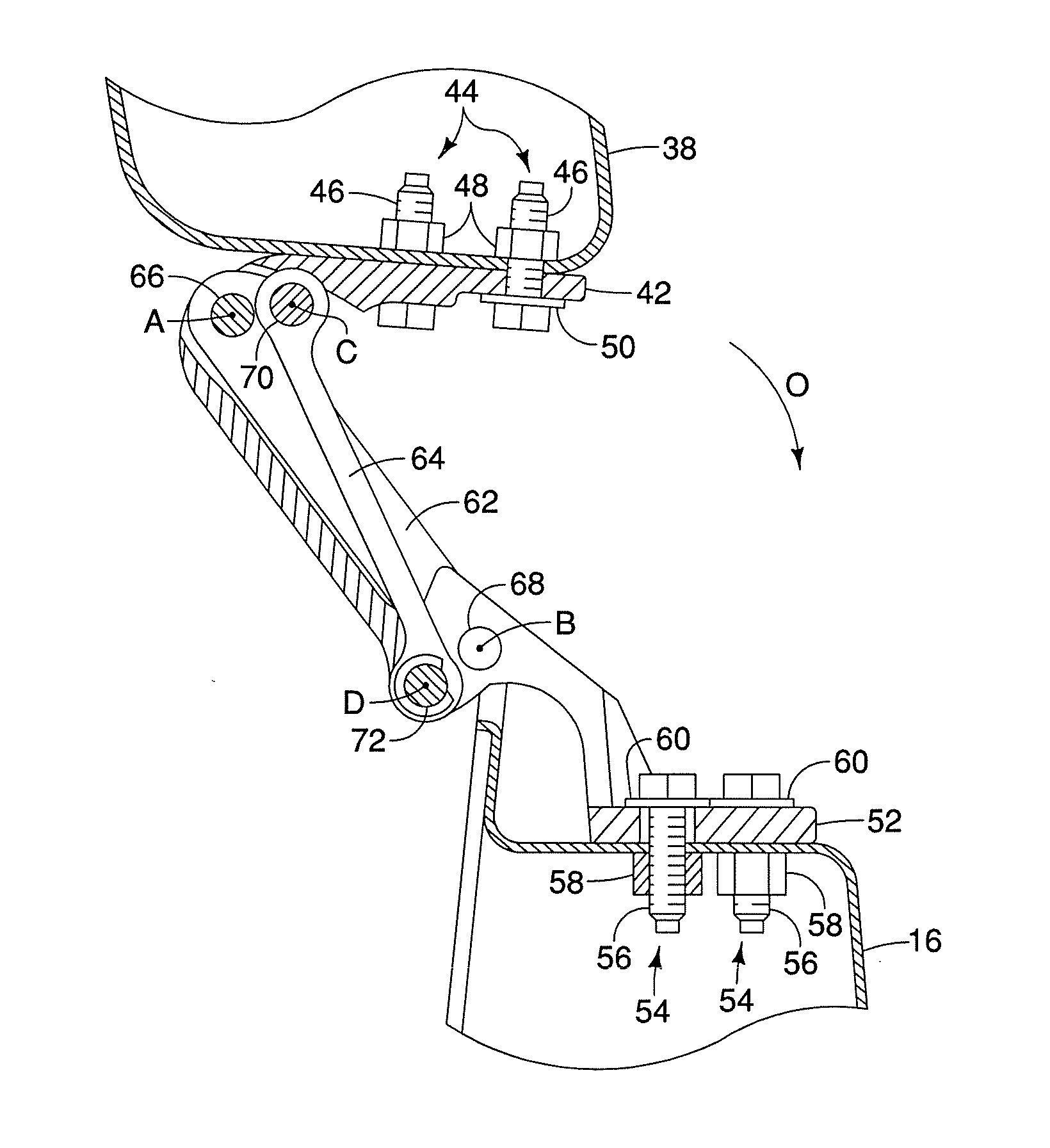

Automatic hitch assembly

An automatic hitch may include a base, a support surface, a jaw assembly connected to the base and having engaged and disengaged positions and a biasing member associated with the jaw assembly. The biasing member may be configured to normally bias the jaw assembly toward the support surface. The automatic hitch may also include a release mechanism configured to apply upward force to the jaw assembly upon downward actuation of the release mechanism to move the jaw assembly into the disengaged position.

Owner:TOYOTA MOTOR ENGINEERING & MANUFACTURING NORTH AMERICA

Articulated vehicle composed of several coupled vehicle sections

Owner:HUBNER GMBH

Pivot bearing and an articulated bus

InactiveCN101280816BReduce rigiditySuitable for connectionMultiple spring combinationsOther connectionsElastomerClassical mechanics

The present invention relates to a pivot bearing, in particular on a swivel joint between a front wheel and a rear wheel of an articulated bus, which includes a cylindrical articulated bus (4) composed of a inner pipe (7), a outer pipe (8), a composition rubber layer (10) between them and a contain cover (3), the inner pipe mounted on the a bearing pin (2) with anti-torsion function, the outer pipe provided with a longitudinal seam (9).The pre-tightening articulated bus (4) inserts in the contain cover (3).According to the invention, an elastomer metal bushings (5, 6) are arranged at both endof the pre-tightening articulated bus (4) and are spaced slightly from it.The elastomer metal bushings includes a inner pipe (13) which has a interrupted elastomer layer case (16, 17) clinging and crossing the free-space (14, 15) at individual radial direction relative place, and inserting into the contain cover (3) with pre-tightening inside of the elastomer layer case (16, 17) under assembling condition, wherein the inner pipe (13) is mounted on the a bearing pin (2) with anti-torsion function, and the elastomer layer shells lies in a common longitudinal plane.

Owner:JORN +1

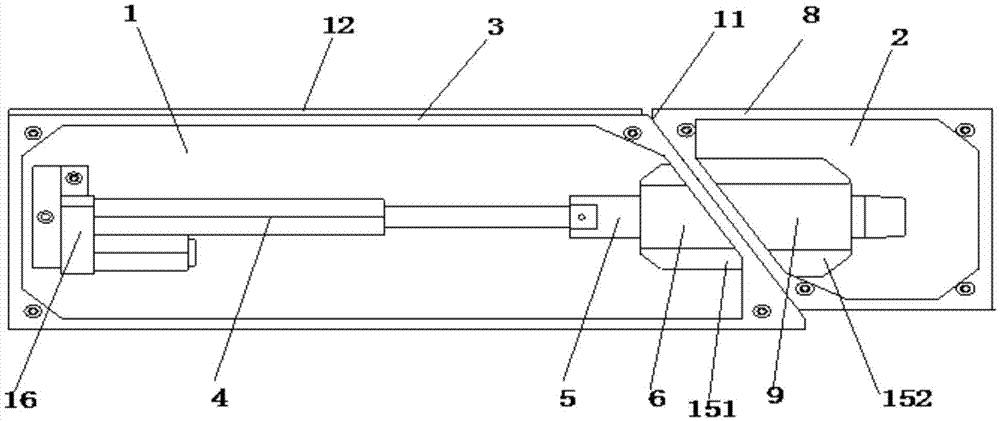

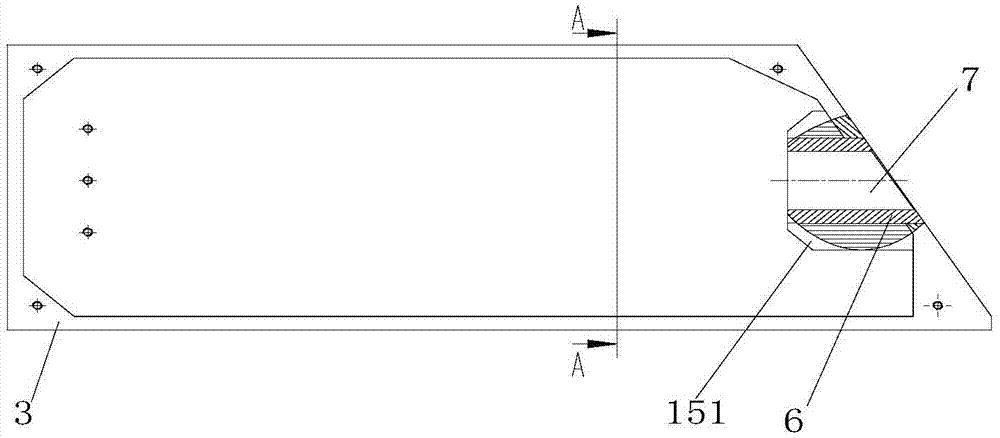

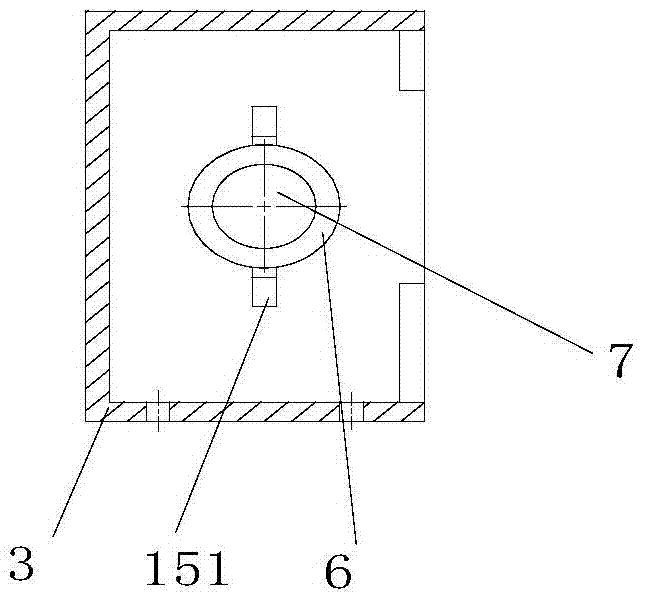

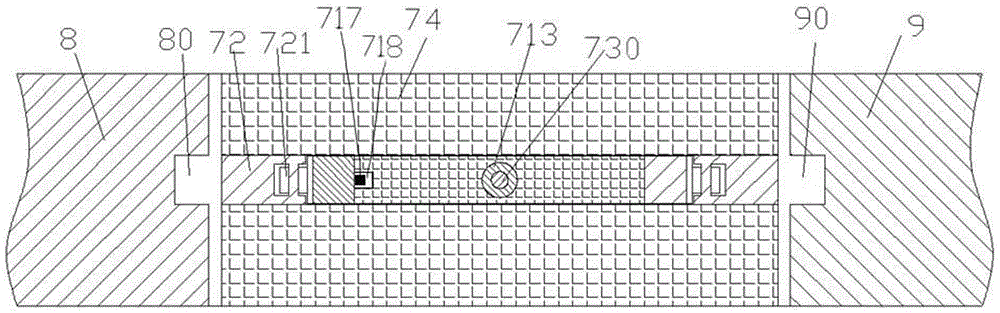

Automatic splicing mechanism

The invention provides an automatic splicing mechanism which comprises an active splicing part and a passive splicing part, wherein the active splicing part is provided with an active splicing part box body, an electric push rod, a splicing pin shaft and an active splicing part guide cylinder, wherein a through hole is formed in the active splicing part guide cylinder, one end of the splicing pin shaft is connected with the electric push rod, and the other end of the splicing pin shaft is movably inserted into the through hole of the active splicing part guide cylinder; the passive splicing part is provided with a passive splicing part box body and a passive splicing part guide cylinder, wherein a containing hole is formed in the passive splicing part guide cylinder; and the splicing pin shaft can pass through the through hole in the active splicing part guide cylinder to extend into the containing hole in the passive splicing part guide cylinder under the drive of the electric push rod. The automatic splicing mechanism is simple in structure, convenient to install and simple in operation; and the splicing operation is mainly realized by pushing the splicing pin shaft by virtue of the electric push rod, thereby reducing the working difficulty of the splicing operation, reducing the workload of the splicing operation and saving time and labor.

Owner:BEIJING XINGDA TECH DEV

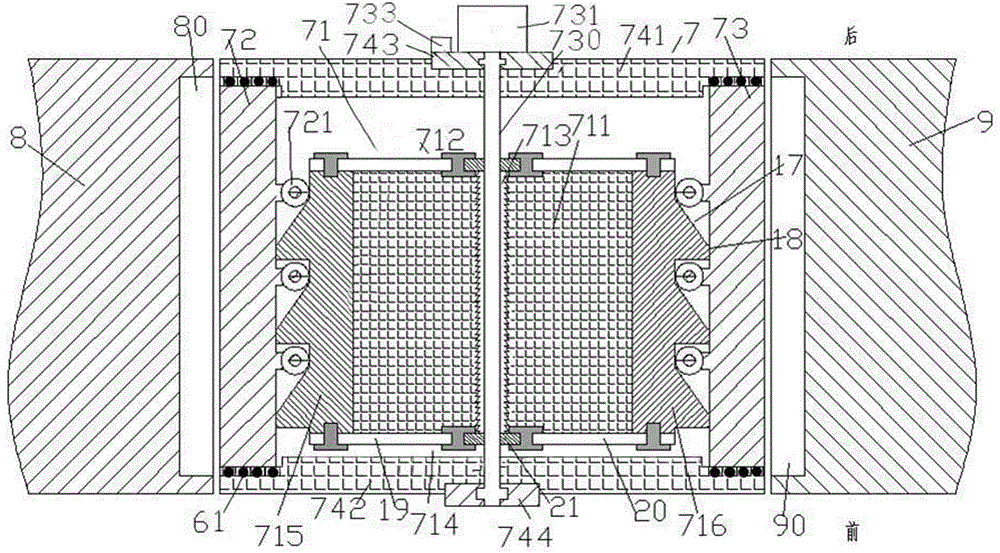

Covering structure for moving gap

InactiveCN105774442AReliable control of telescopic movementStable forceOther connectionsEngineeringWedge shape

The invention provides a covering structure (7) for a moving gap. The covering structure is used for covering the moving gap between a first component (8) and a second component (9) which can be movably connected together. The covering structure (7) comprises an elastic material body (74) and a bearing block drive elastic assembly (71) which can move forwards and backwards horizontally in a cavity in the elastic material body (74). The bearing block drive elastic assembly (71) comprises an elastic jacking force transferring component (711), two wedge-shaped tooth components (715 and 716) which are symmetrically and fixedly arranged on the two sides of the elastic jacking force transferring component (711) and an inner threaded sleeve (713) fixedly arranged at the position of the center axis of the elastic jacking force transferring component (711) through fixing teeth on the periphery, wherein hinging linkage board components (712 and 714) are symmetrically arranged on the front side and the rear side of the bearing block drive elastic assembly (71).

Owner:PUJIANG DAKOU TRADING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com