Pivot bearing and an articulated bus

A technology of joint bearings and joints, which is applied in the direction of bearings, flexible bearings, shafts and bearings, and can solve problems such as inability to set up and unsuitable for supporting positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

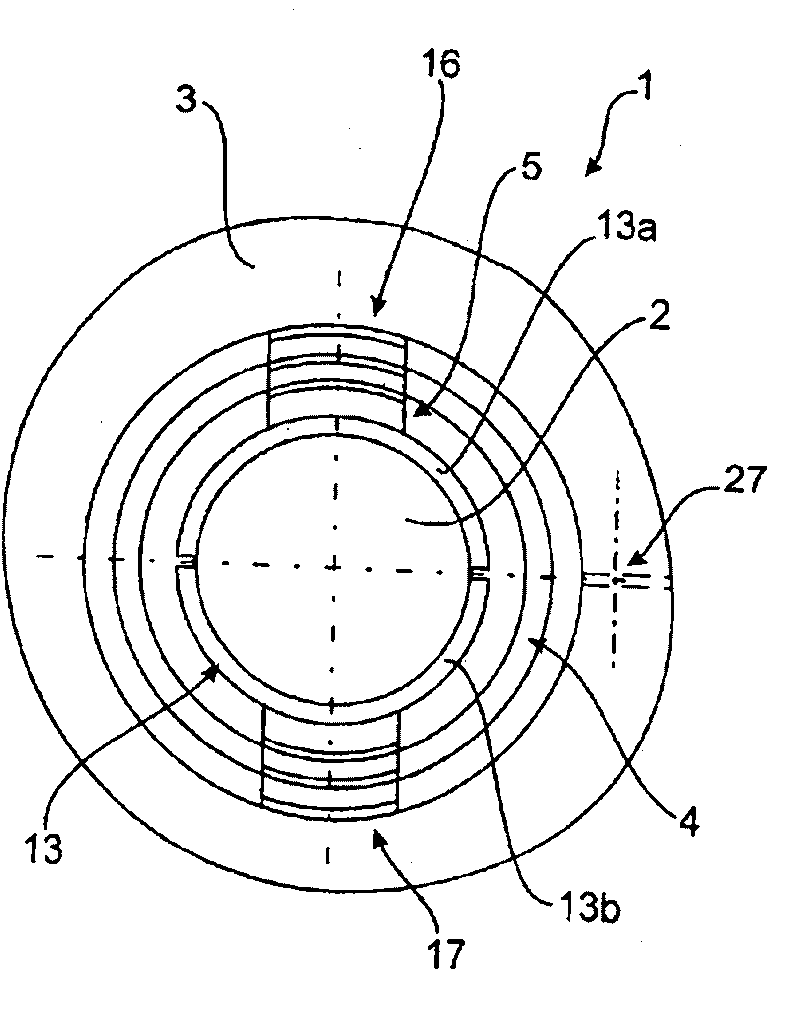

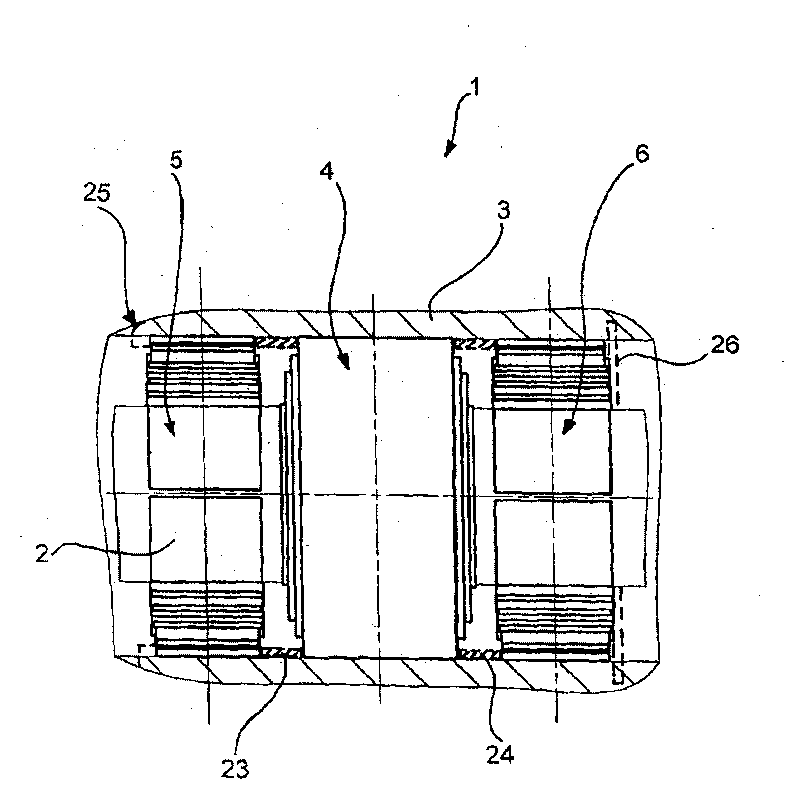

[0032] exist figure 1 and 2 shows a view of a spherical plain bearing 1 according to a first embodiment, comprising a bearing pin 2 as the center of the first bearing part and a receiving sleeve 3 as the second bearing part, wherein the receiving sleeve is in a transverse plane It is arranged on the rear end of the front compartment of an articulated passenger car with a horizontal axis. The bearing pin 2 is part of a connecting swivel joint which is fixedly connected to the driven rear body of the articulated bus.

[0033] On the bearing pin 2 , an intermediate joint sleeve 4 is arranged in a rotationally fixed manner and a first and a second metal sleeve 5 and 6 of identical construction are arranged at a distance from each other at both ends.

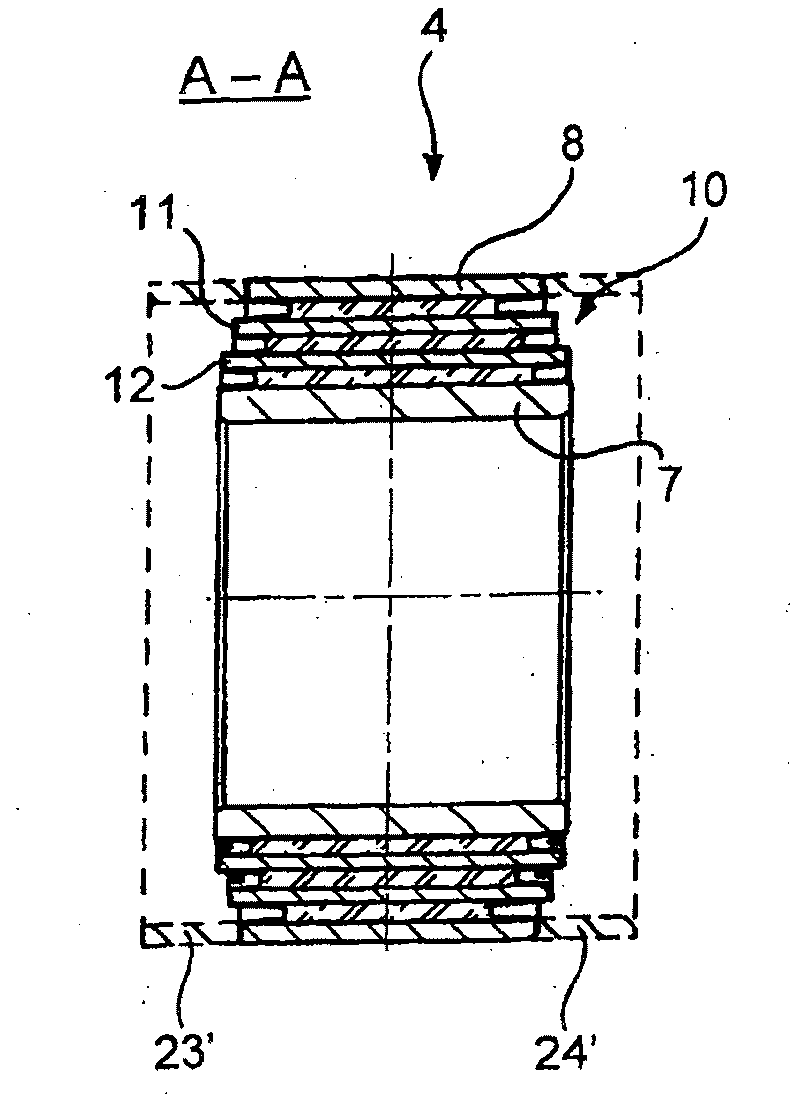

[0034] The structure of the joint sleeve 4 is by means of image 3 and 4 To further explain: the joint sleeve 4 comprises a solid metal inner tube 7 and an oppositely thin-walled outer sheet tube 8 which, in the manufactured stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com