Smart delivery vehicle

A logistics vehicle and intelligent technology, applied in the direction of goods transport vehicles, motor vehicles, vehicle parts, etc., can solve the problems of high labor cost, low distribution efficiency, disordered express delivery and storage, etc., and achieve the effect of reliable and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

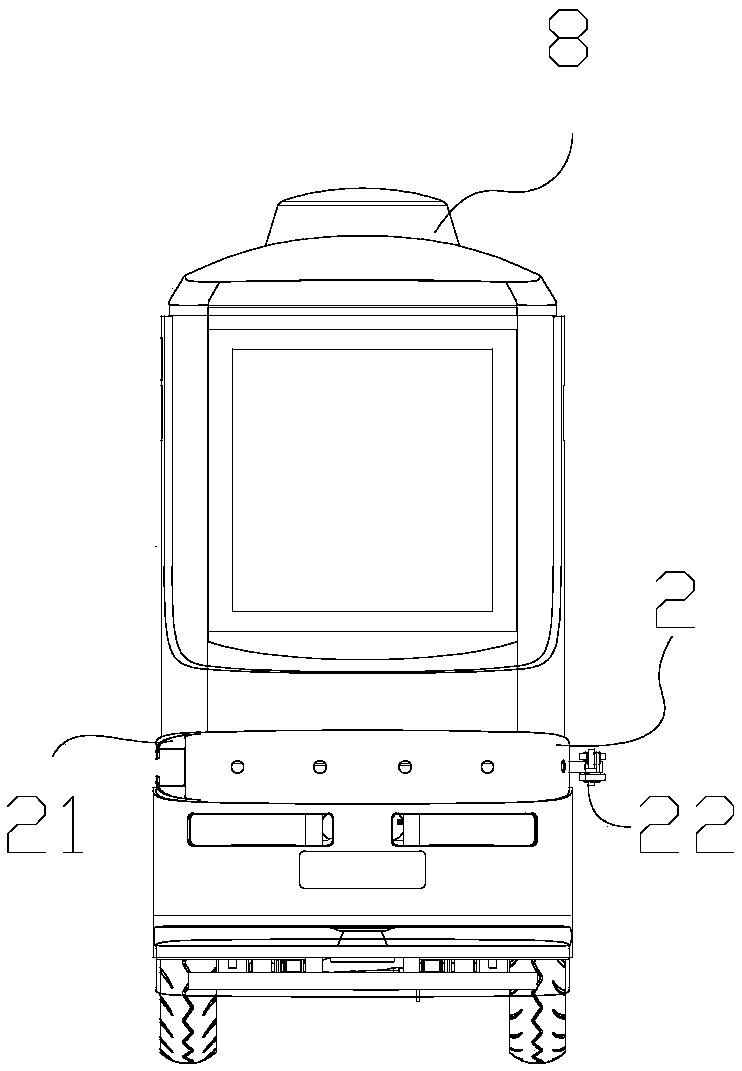

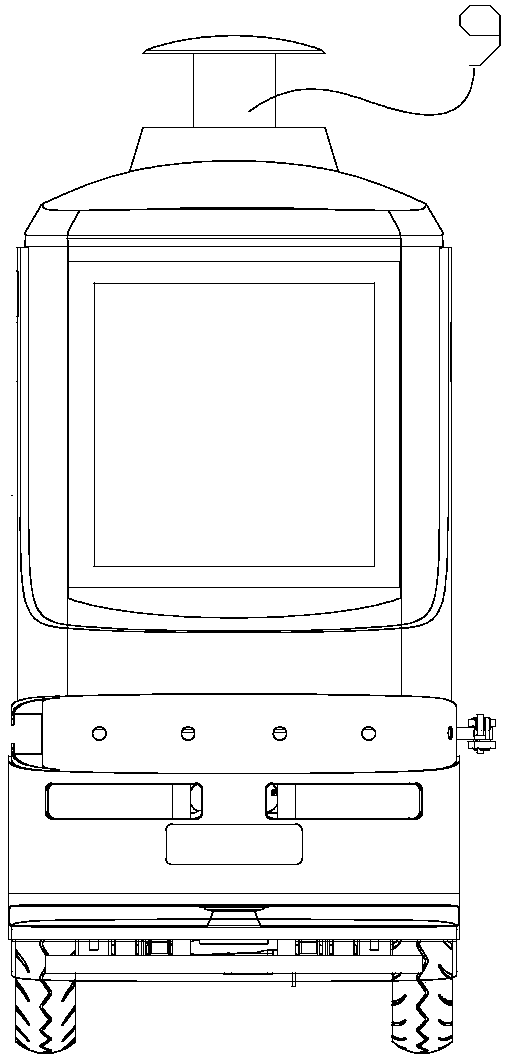

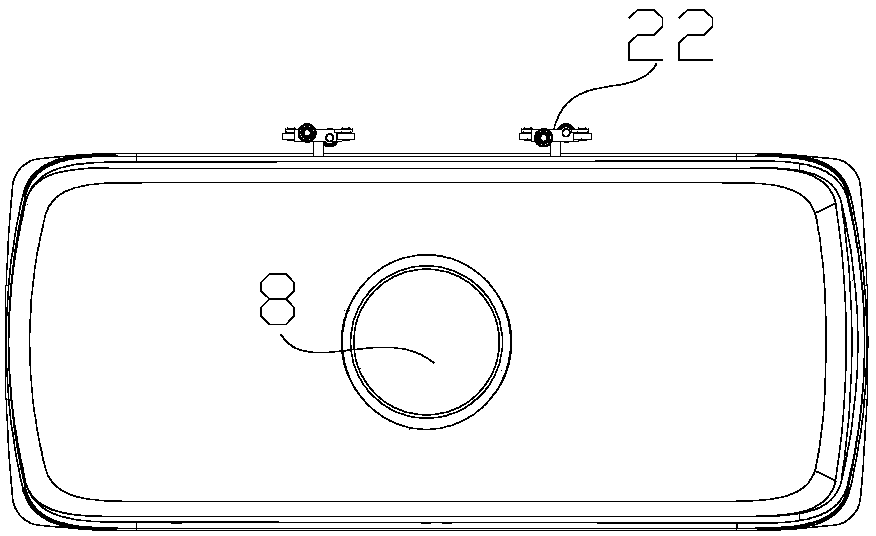

[0055] Such as Figure 1 to Figure 11 , Figure 15 As shown, a smart logistics vehicle in this embodiment includes a vehicle body, which is provided with a box body 1 for placing goods. Part 2; the car body assembly part 2 includes more than one guide rail mechanism 21 and more than one guide wheel mechanism 22, the guide rail mechanism 21 is located on one side of the car body, and the guide wheel mechanism 22 is located on the other side of the car body; the guide rail mechanism 21 cooperates with the guide wheel mechanism 22 on the adjacent car body, and the guide wheel mechanism 22 is stuck in the guide rail mechanism 21 to complete the splicing combination of the adjacent car body.

[0056] In this embodiment, the vehicle body assembly part 2 includes more than one guide rail mechanism 21 and more than one guide wheel mechanism 22, and the guide rail mechanism 21 is provided with a concave T-shaped slot 211 formed to cooperate with the guide wheel mechanism 22 . When t...

Embodiment 2

[0074] Such as Figure 12 As shown, this embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, the connection assembly 6 is an electromagnetic lock part 63, and the electromagnetic lock part 63 can be used to complete the fixing of the self-lifting cabinet on the smart logistics vehicle .

[0075] In this embodiment, the electromagnetic lock part 63 is installed between the storage cavity 3 and the self-lifting cabinet. After power-on, the self-lifting cabinet is sucked tightly on the side wall of the storage cavity 3, thereby locking the self-lifting cabinet in the car.

Embodiment 3

[0077] Such as Figure 13 and Figure 14 As shown, this embodiment is basically the same as Embodiment 1. The difference is that in this embodiment, the limit assembly 7 is designed with a rotating insert 72. When the self-lifting cabinet moves into the smart logistics vehicle and reaches the designated position, The rotating insert 72 snaps into the limit hole matched with the self-lifting cabinet, and the rotating insert 72 automatically rotates 90°, thereby locking the cabinet body in the smart logistics vehicle. When the self-lifting cabinet needs to be taken out or moved out from the smart logistics vehicle, the rotating insert 72 automatically rotates 90° again, and the rotating insert 72 breaks away from the self-lifting cabinet, and the self-lifting cabinet is separated from the smart logistics vehicle.

[0078] In order to further describe the present invention in detail, an application scenario is now provided. When the intelligent logistics vehicle provided by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com