Automatic hitch assembly

a technology of automatic and tongue disengagement, which is applied in the field of hitches, can solve the problems of difficult disengagement from an engaged tongue, unfavorable ergonomics or advantageous use of body weight by the operator, and unfavorable disengagement of the hitch from the tongue, etc., and achieve the effect of improving the previous hitch assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

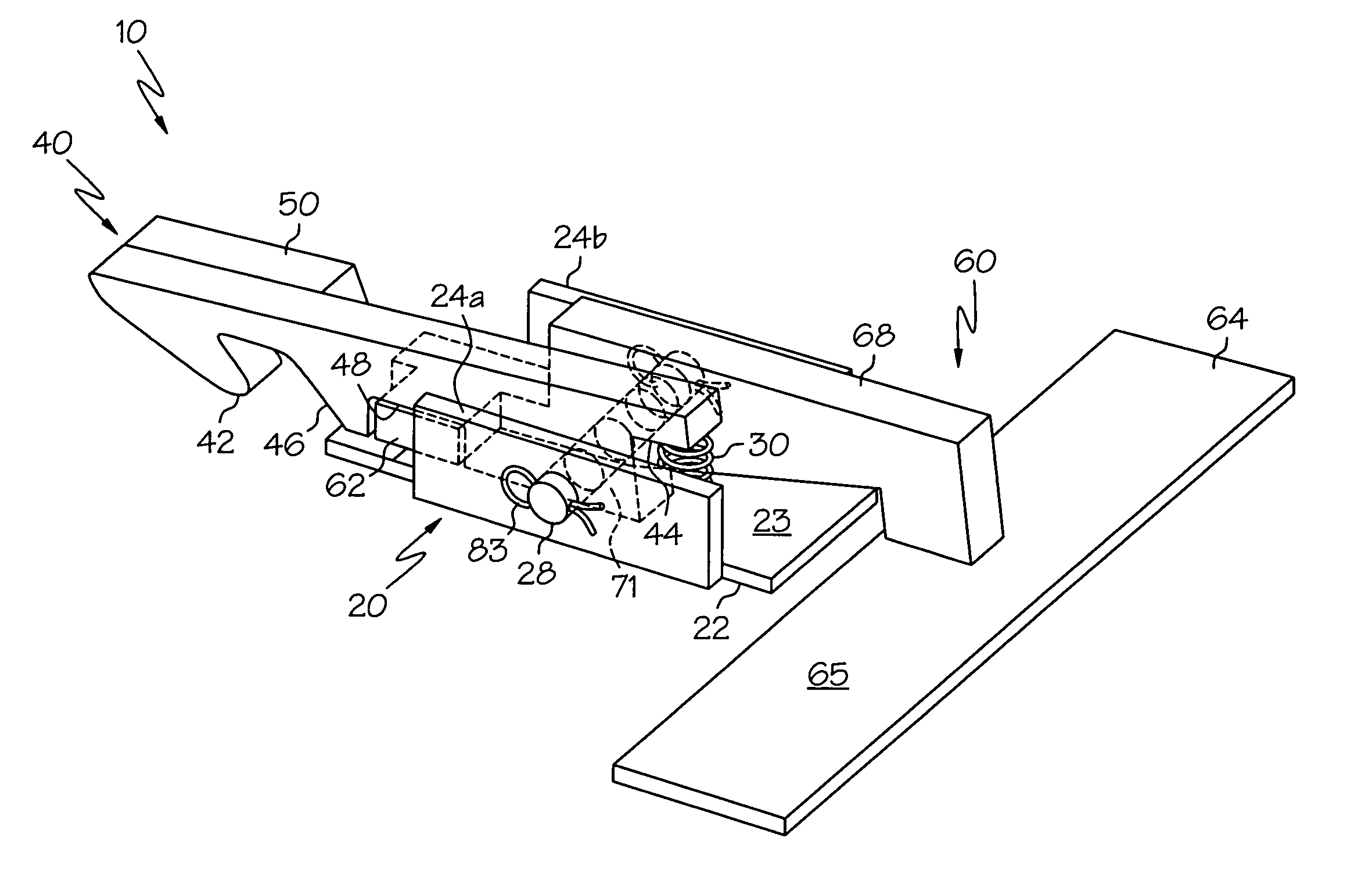

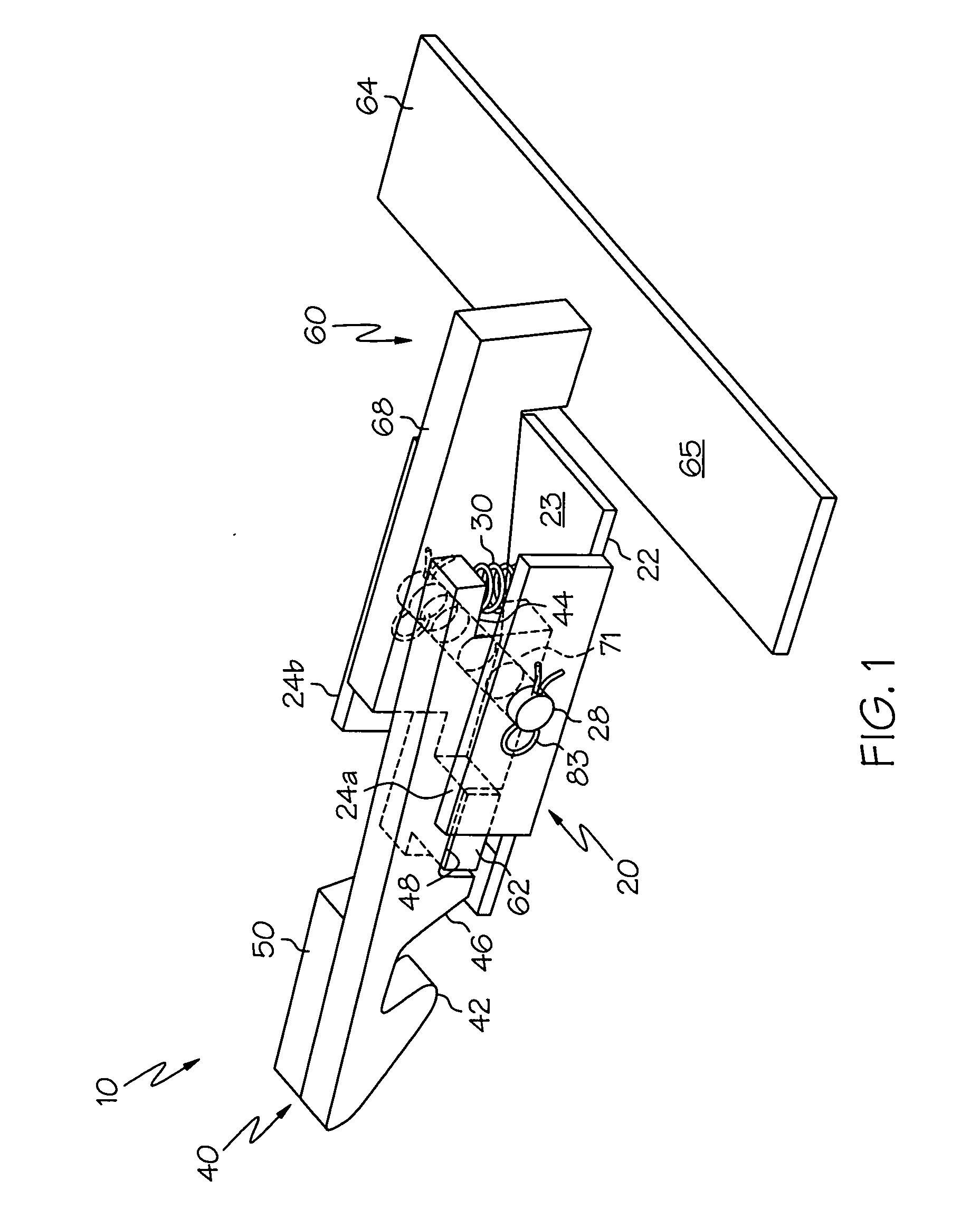

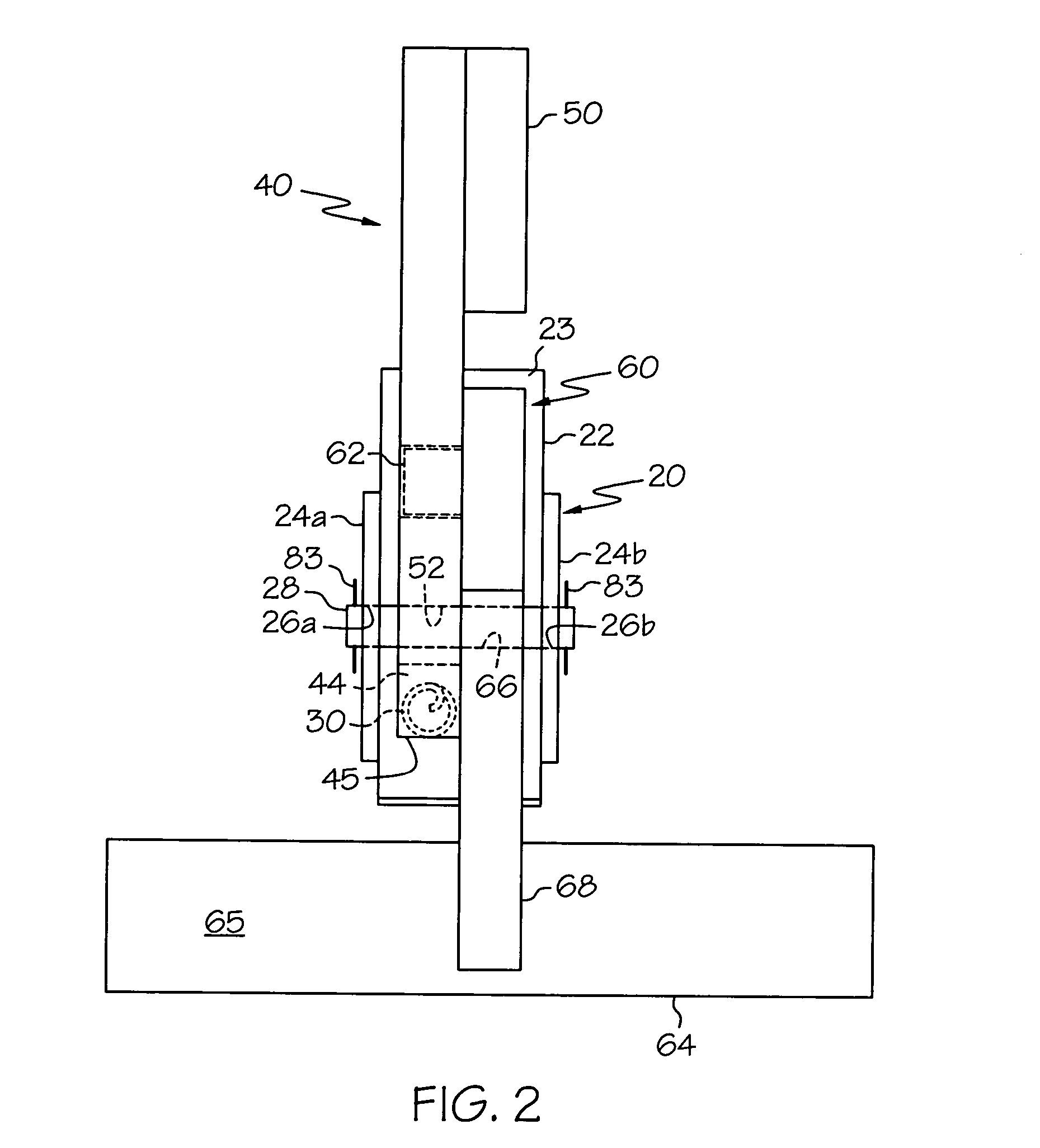

[0014] Referring to the drawing figures in detail, wherein like numerals indicate the same elements throughout the drawing figures, FIG. 1 illustrates an exemplary automatic hitch assembly 10 as generally having a base 20, a jaw assembly 40 and a release mechanism 60. Hitch assembly 10 and components thereof may be comprised of metal, plastic and / or any combination of durable materials.

[0015] As illustrated in FIGS. 1-3, base 20 may comprise a lower plate 22 with two walls 24a and 24b extending upwardly at about a 90° angle therefrom. Lower plate 22 may comprise any length and / or width and include a support surface 23. Support surface 23 may function as a lowermost support or “stop” for jaw assembly 40 adjacent to stopping member 46 when in an engaged position (as illustrated in FIG. 1). In another embodiment, lower surface 22 and support surface 23 may extend to or beyond hook 42 of jaw assembly 40 thereby providing a similar support or “stop” surface for hook 42 and / or a tongue o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com