Flexible penetration resistant composite materials structure with critical gap geometry in a solids layer

a composite material and solids layer technology, applied in the field of protective systems, can solve the problems of too large gap width and too little flexibility, and achieve the effect of preventing or limiting the destructive distortion of the gap and promoting the effective response of the structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

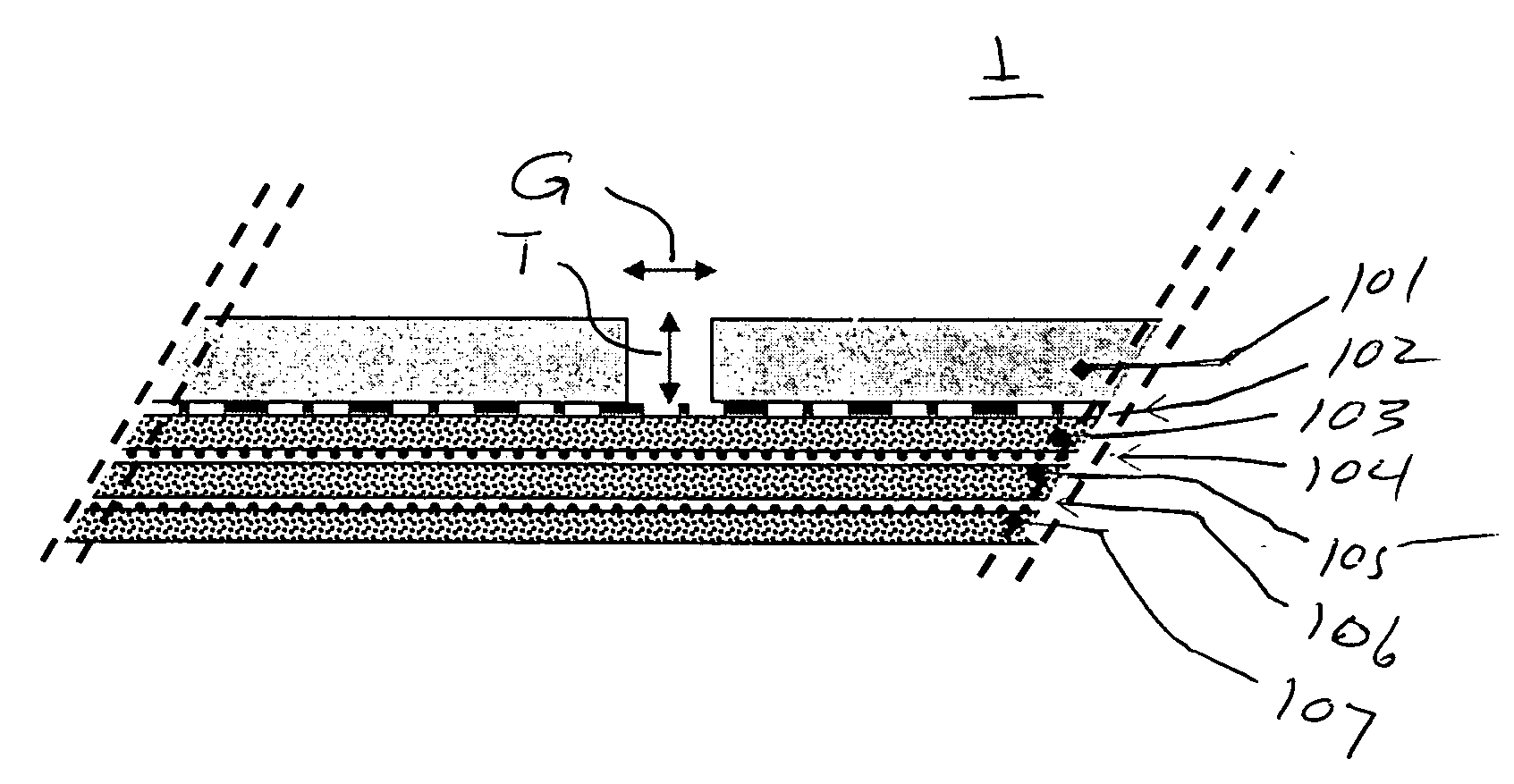

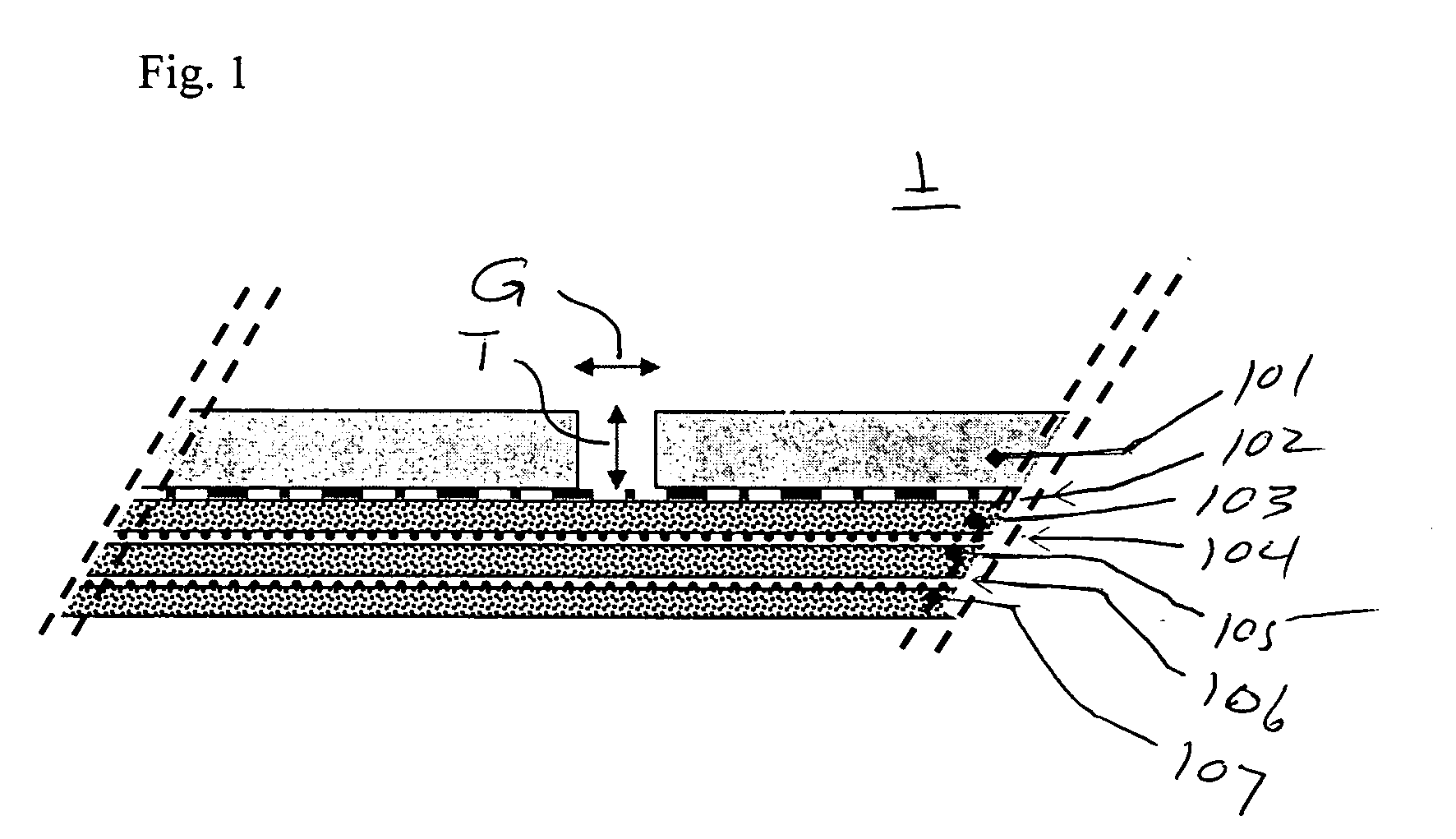

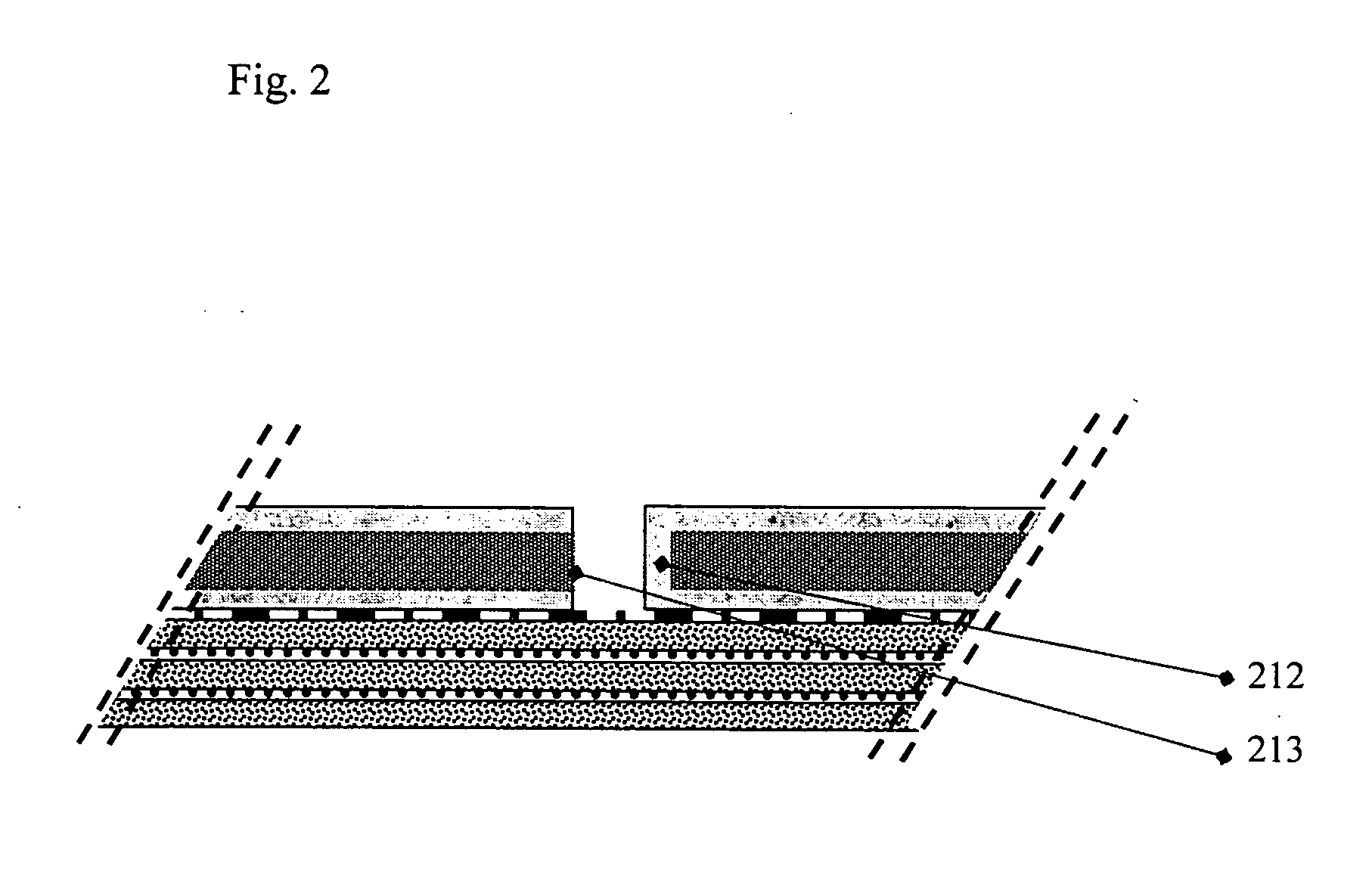

[0026]The design of the critical gap in the solid component of the composite material is described. The use of relatively thin solid layers is preferred in order to allow for small critical gaps. Solid thickness of 0.005 to 0.04 inches are preferred, with preferred gap dimensions of between 50% and 400% of the thickness of the solid.

[0027]The design of the fiber layers component of the composite material is equally important as the solid layer component in the control of the critical gap. The elongation and tensile properties of the fabric layers must be aligned to the critical gap line or axis. Because the gap axis is not always aligned to the typical 0 and 90 degree threadlines common in wovens and fabric laminates, bias laminates are disclosed and found to be useful for alignment control of thread-line to the critical gap axis and pattern. The term fabric layer as used herein can be interpreted as plural and inclusive of multiple fabric or yarn sheet layers or laminates, where a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| impact force | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com