Three-dimensional circular tube conveying belt

A conveyor belt, three-dimensional technology, applied in the field of three-dimensional circular tube conveyor belt, can solve the problems of high kinetic energy requirements, heavy belt body, poor flexibility, etc., and achieve huge economic and social benefits, superior performance, and comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

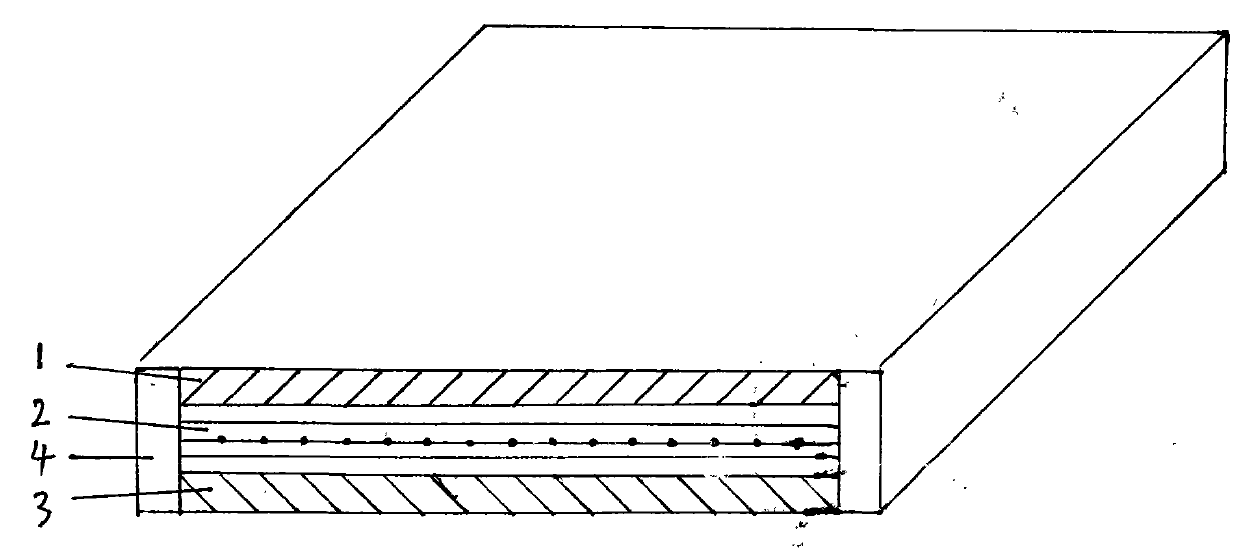

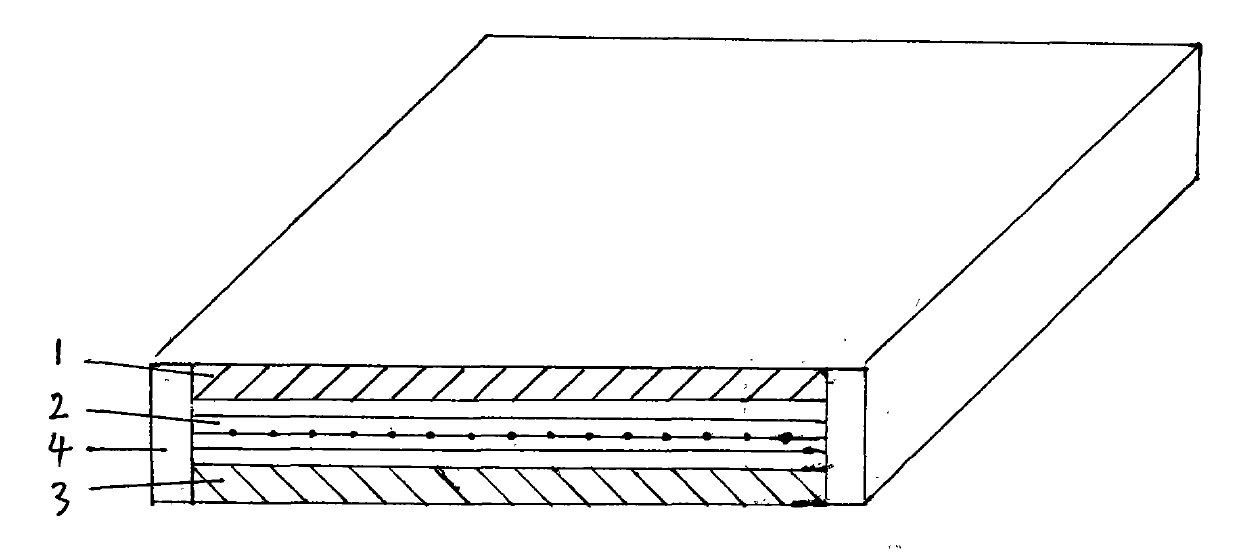

[0020] As shown in the accompanying drawings, the patent of the present invention is composed of an upper cover rubber 1, a skeleton layer 3, a lower cover rubber 2, and an edge rubber 4. The skeleton layer is two to three layers. Glue, after the ropes are arranged at a certain interval, add glue. The skeleton layer 3 is stacked together first, and after the upper side glue 4 is squeezed on both sides, it is laminated with the upper covering glue 1 and the lower covering glue 2.

[0021] The material, strength, and number of structural layers of the skeleton layer are selected according to actual needs.

[0022] The performance and thickness of the upper and lower covering rubbers should be selected according to the actual situation. Generally, the thickness of canvas and cord fabric glue is 0.6-1.5mm, the glue thickness of the ropes arranged at a certain interval is 3-10mm, the thickness of the upper and lower covering glue is 1.5-6mm, and the vulcanization condition is 150°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com