Soil body in situ test device and test method applying same

A technology of in-situ testing and rock and soil mass, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc. Test problems such as complex stress conditions to achieve intuitive measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

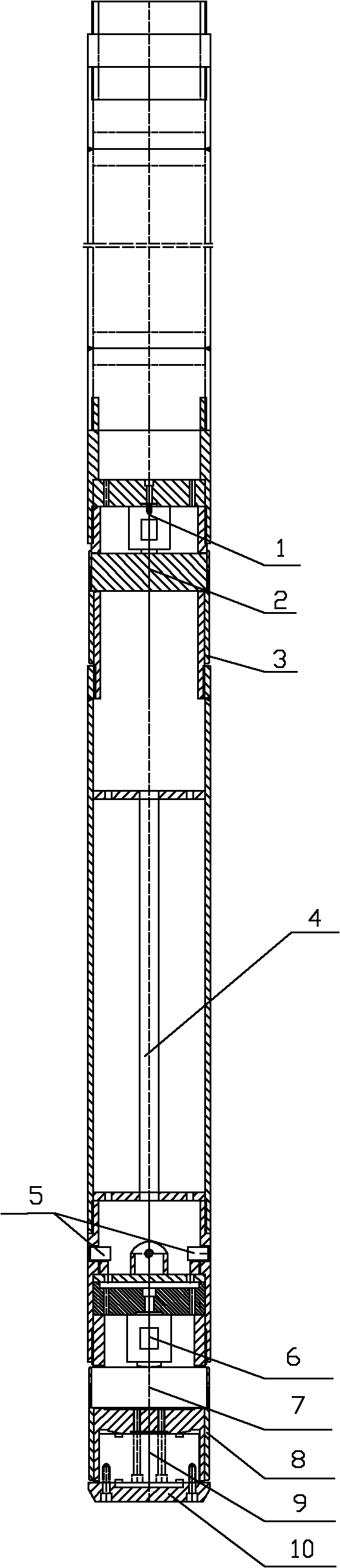

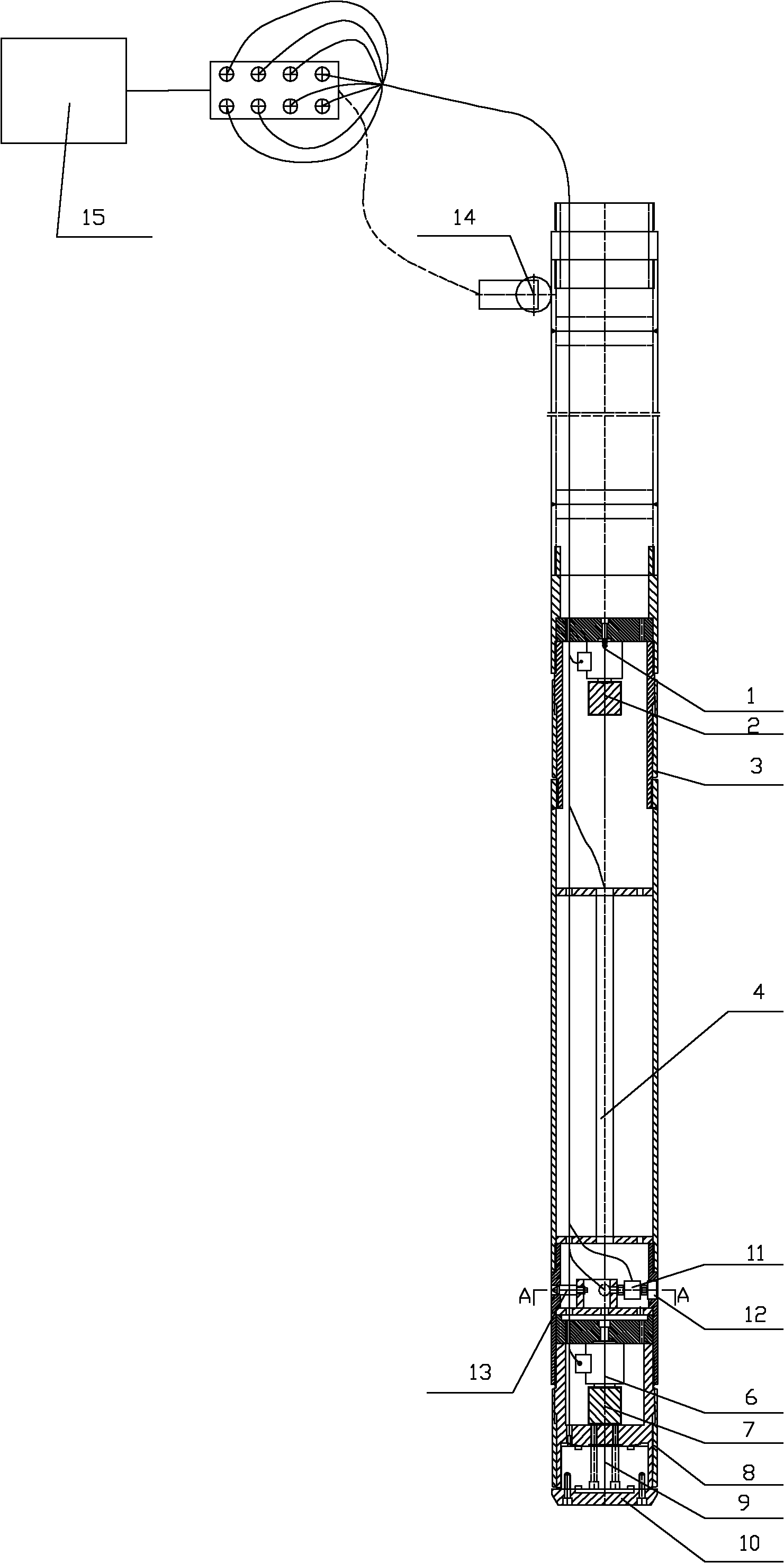

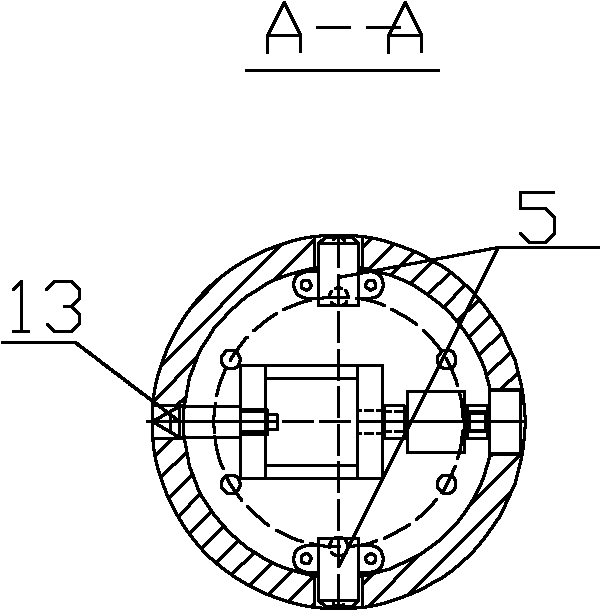

[0031] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings. Figure 1-Figure 3 One embodiment of the in situ testing apparatus for rock and soil mass of the present invention is shown.

[0032] Such as Figure 1-Figure 3 The equipment of this embodiment shown includes a steel pipe with the same shape as the pipe pile. The cross-sectional size and shape of the steel pipe are the same as those of the pipe pile, and the cross-section can be circular or square. A pile tip plate 10 and a first pressure sensor 9 for sensing the pressure on the pile tip plate 10 are arranged at one end of the steel pipe. The pile tip plate 10 is perpendicular to the side wall of the steel pipe. When the pile tip plate is stressed, it presses the first pressure sensor 9 , and the first pressure sensor 9 sends out an electric signal when it is stressed, and the electric signal is received by the data collector 15 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com