Vacuum imprinting apparatus, vacuum press-bonding apparatus, and manufacturing method for laminated optical device

A manufacturing method and a technology of vacuum lamination, applied in the field of imprinting devices, can solve the problems of process instability, insufficient lamination accuracy, thickness variation of optical adhesive layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0140] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

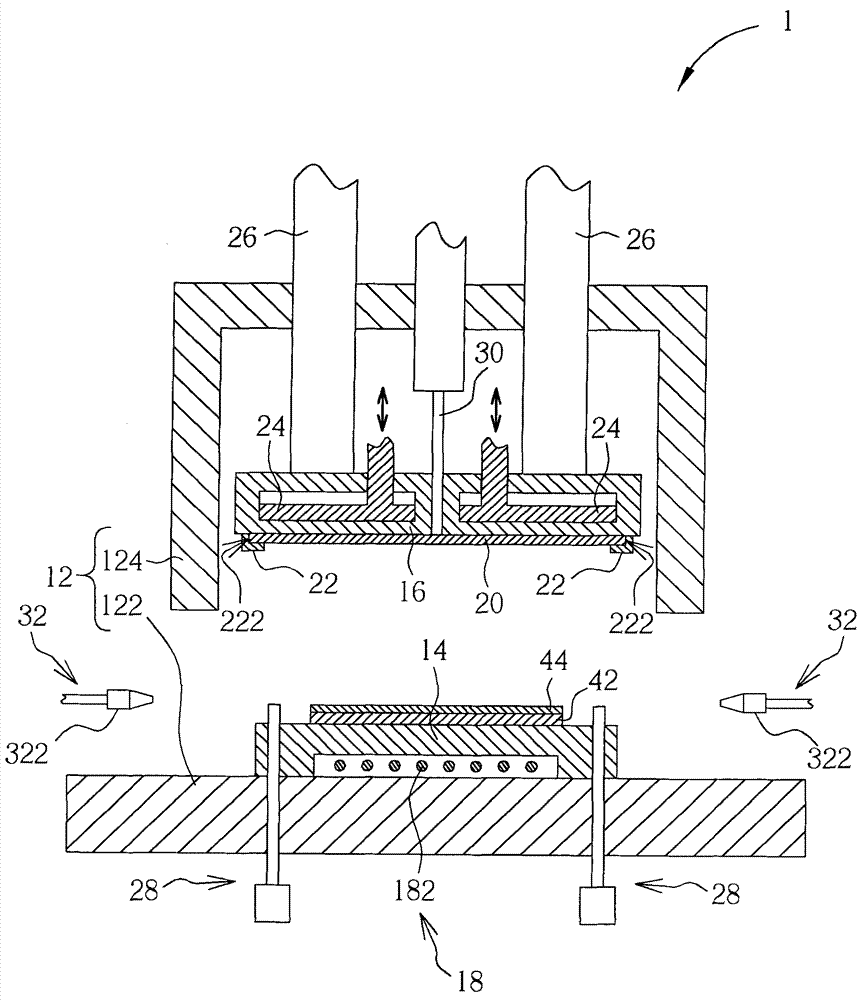

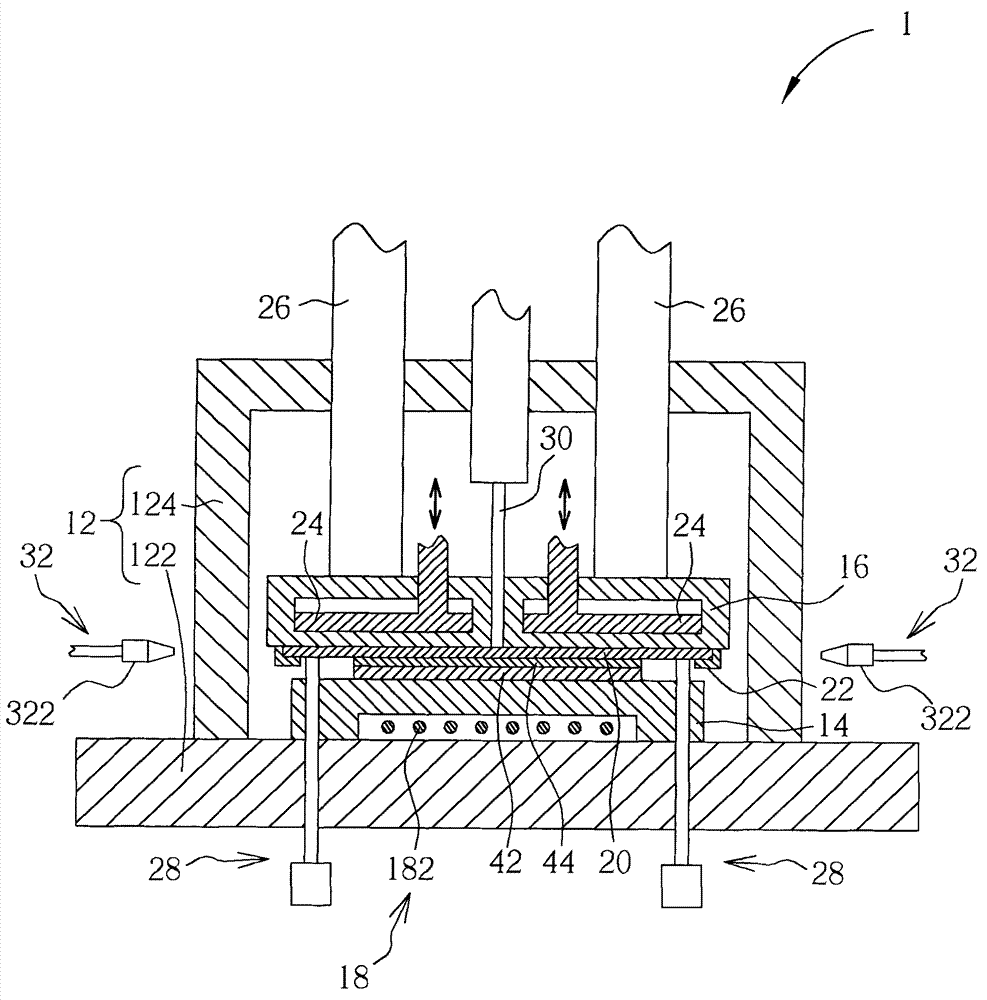

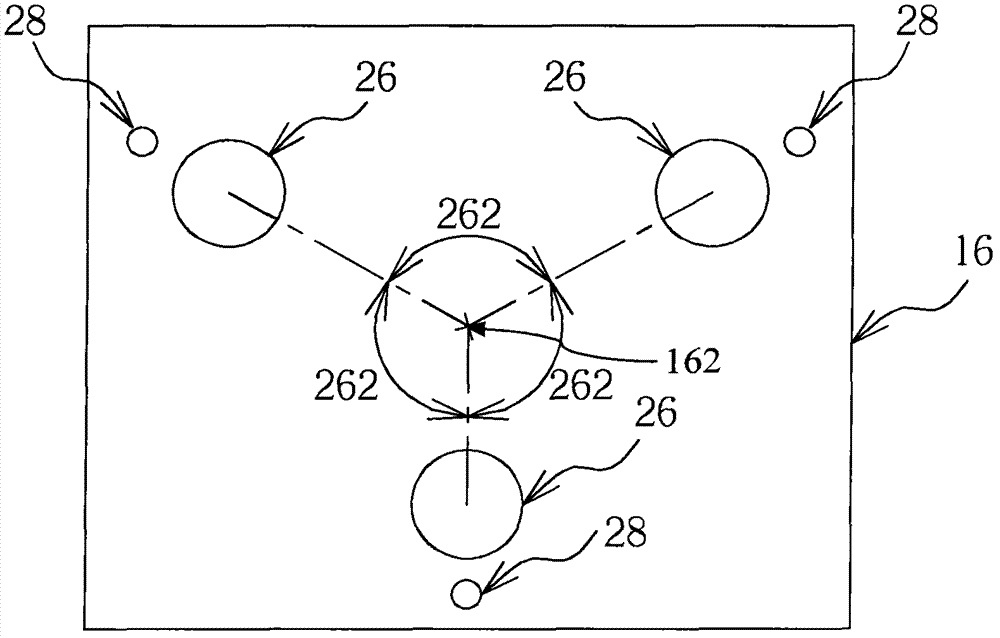

[0141] see figure 1 and figure 2 , figure 1 It is a schematic diagram of a vacuum imprinting device 1 according to a preferred embodiment of the present invention, figure 2 for figure 1 A schematic diagram of the medium-vacuum imprinting device 1 in another state. The vacuum imprinting device 1 includes a vacuum chamber 12 , a loading platform 14 , an loading platform 16 and a curing device 18 . The vacuum chamber 12 is mainly composed of a base plate 122 and a cover body 124. The cover body 124 can be separated from the base plate 122 for the insertion operation of objects; when the base plate 122 and the cover body 124 are closed, as figure 2 As shown, the vacuum chamber 12 can be evacuated, and the evacuation device is a prior art, and will not be further described and shown in the figure. The loading platform 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com