Method for manufacturing ozone-gas-dissolved water and cleaning method for electronic materials

A manufacturing method and technology for dissolving water, which can be used in cleaning methods using liquids, semiconductor/solid-state device manufacturing, chemical instruments and methods, etc., and can solve problems such as large sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

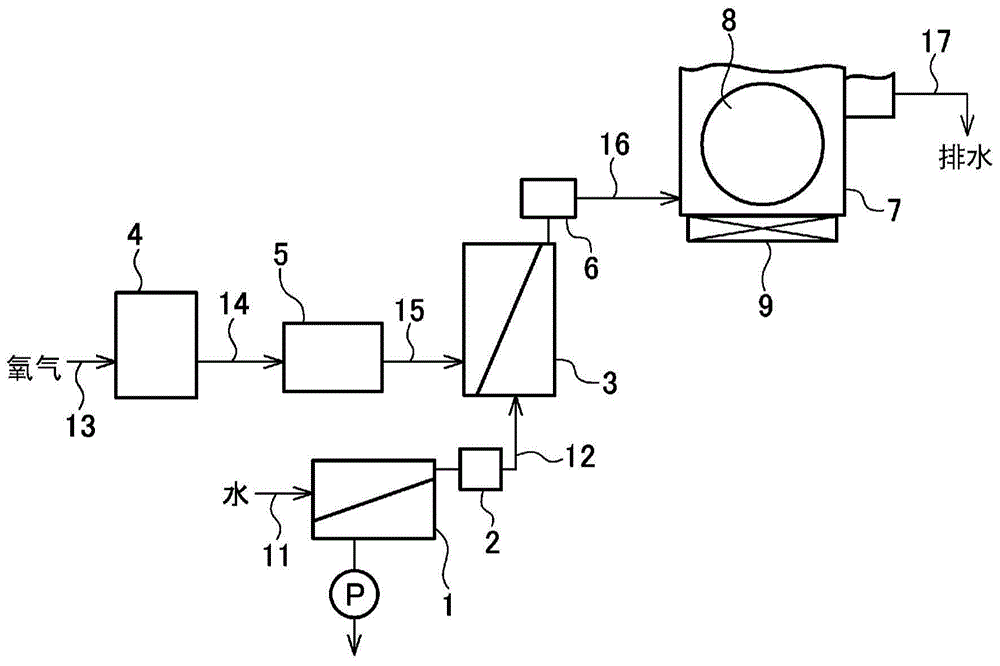

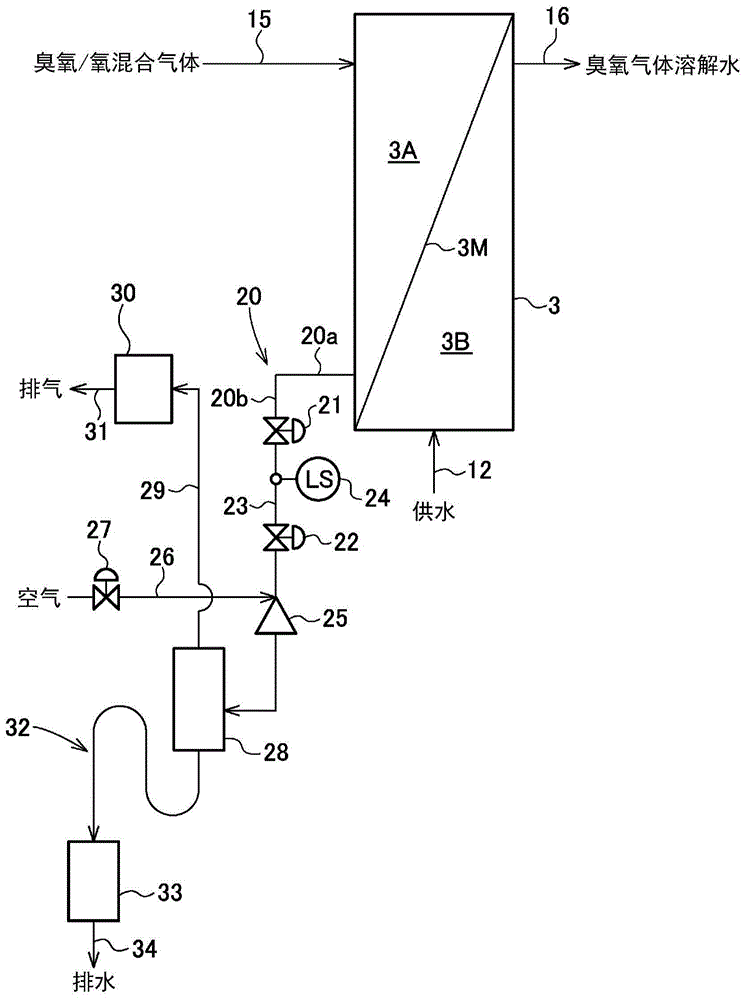

[0098] according to figure 1 The shown ozone gas-dissolved water supply system performs production of ozone gas-dissolved water and washing of objects to be cleaned.

[0099] The apparatus used is described below.

[0100] Degassing membrane module: "Liqui-Cel G248 (リキセル G248)" manufactured by Polypore;

[0101] Gas-dissolving membrane module: "GNH-01R" manufactured by Japan GORE-TEX Company (Japango Artex Corporation);

[0102] Ozone generator: "GR-RB" manufactured by Sumitomo Precision Industries, Ltd.

[0103] As supply water (pure water), degassing treatment is performed in the degassing membrane module 1 , and water with a dissolved oxygen concentration of about 10 ppb is supplied to the gas-dissolving membrane module 3 . The water supply volume was set to 10 L / min (L / min), and the water temperature of the water supply and the place of use was set to 25°C. The amount of oxygen supplied to the ozone generator 5 was set at 280 NmL / min from the saturation solubility (sat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com