Chip transfer substrate and chip transfer method

A chip transfer and substrate technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of chip efficiency, yield rate and transfer accuracy that are difficult to meet the requirements of micro-component production, so as to improve transfer accuracy and Effects of transfer efficiency, improvement of process precision, and reduction of spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

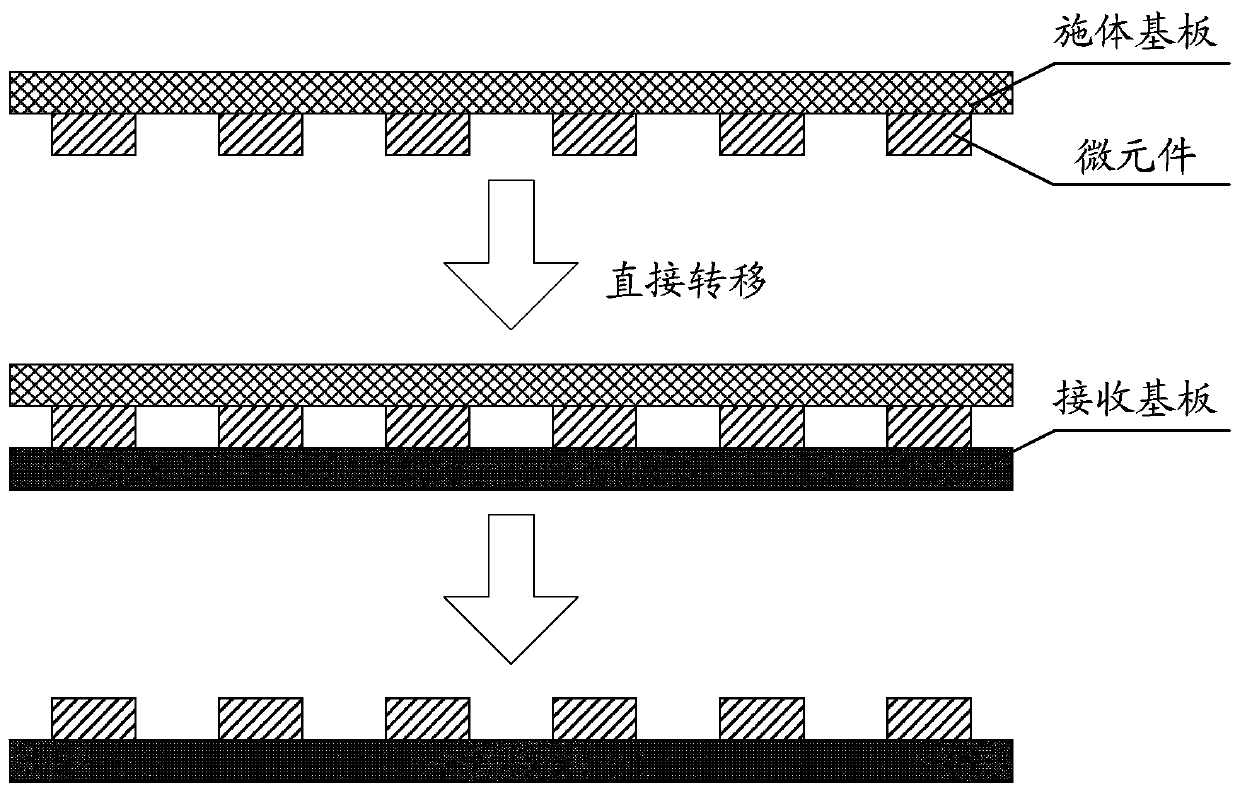

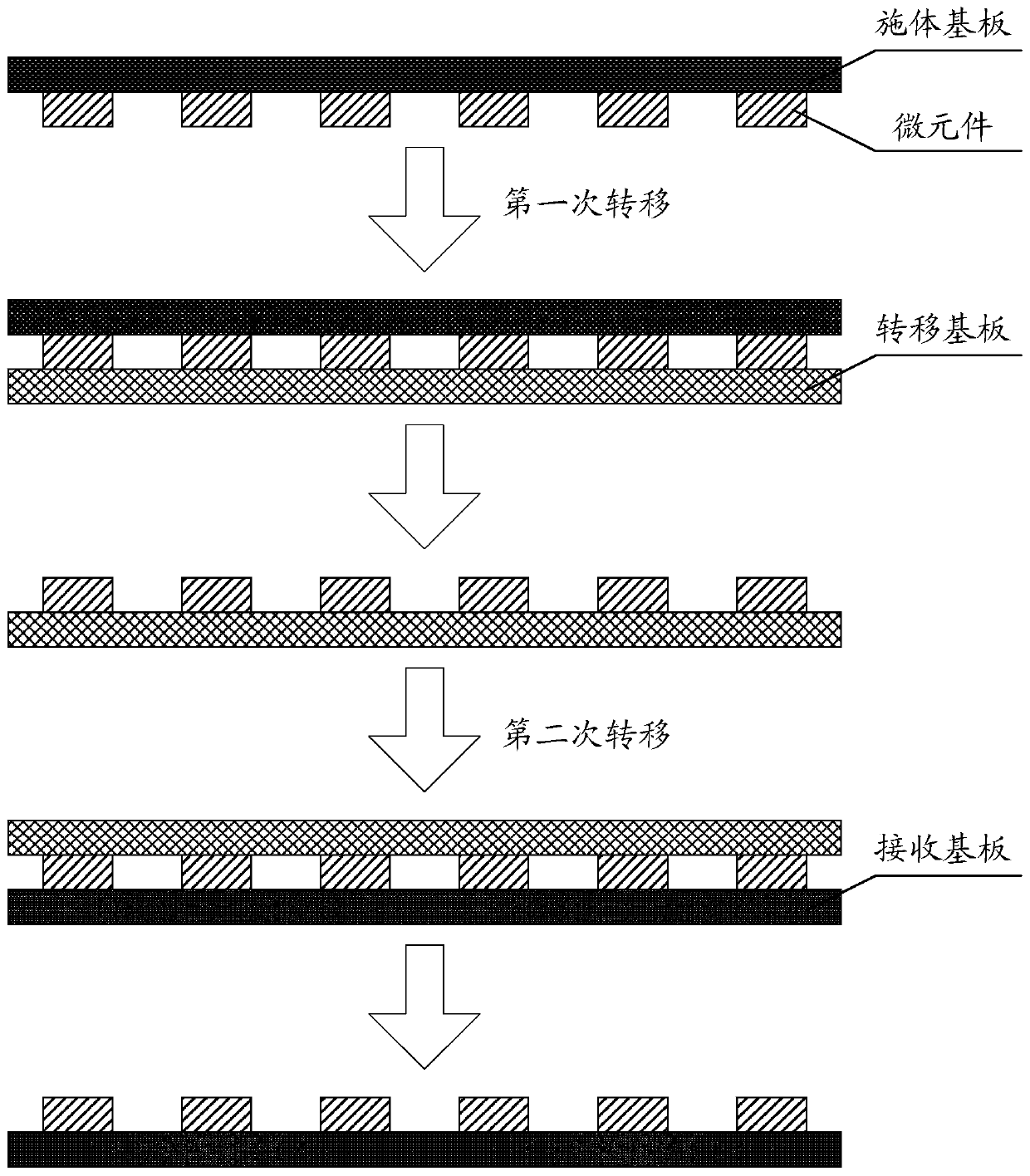

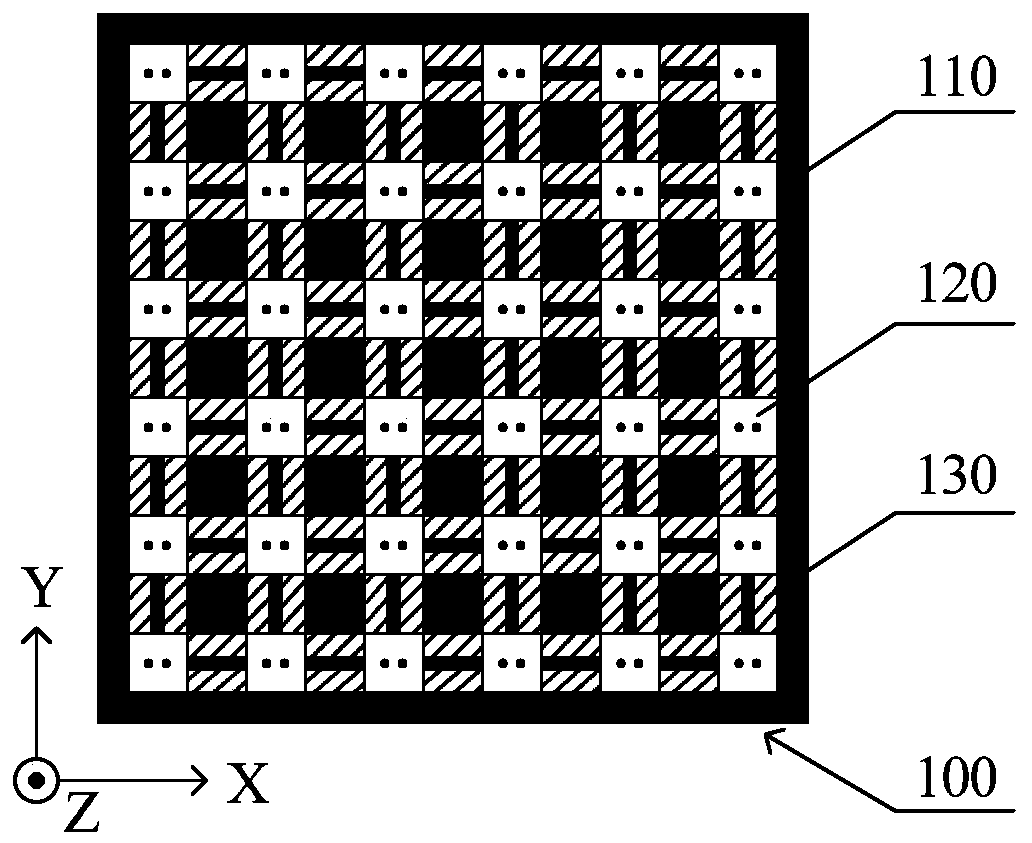

[0053]In addition to the liquid crystal display (Liquid Crystal Display, referred to as: LCD) technology, self-luminous organic electroluminescent display (Organic Light-Emitting Diode, referred to as: OLED) technology, Mirco-LED technology and other technologies are developing rapidly. , Great potential to replace LCD. Micro-LED technology is a display technology that miniaturizes and matrixes the traditional structure, and uses integrated circuit technology to produce a driving circuit to realize the addressing control and individual driving of each pixel. Because the brig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com