Magnesite/dolomite microwave light-burning device and method

A magnesite and dolomite technology, applied in lime production and other directions, can solve the problems of poor product quality, serious pollution, waste of energy and other problems, and achieve the effects of fast heating speed, high degree of automation and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

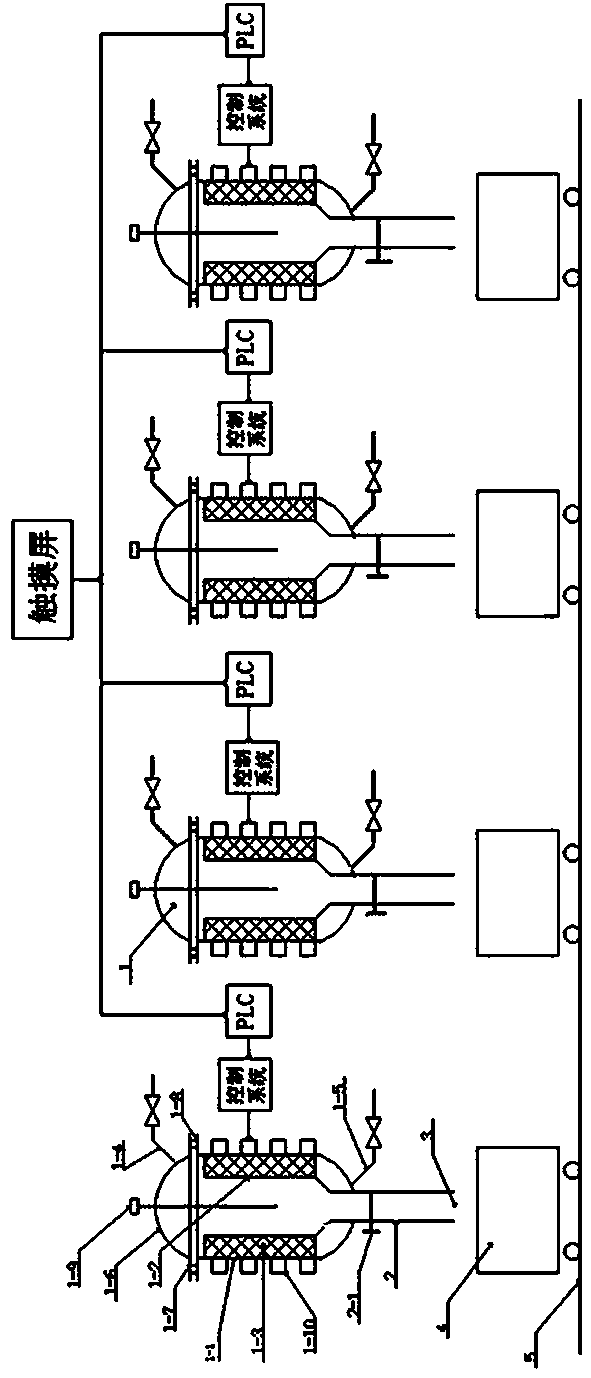

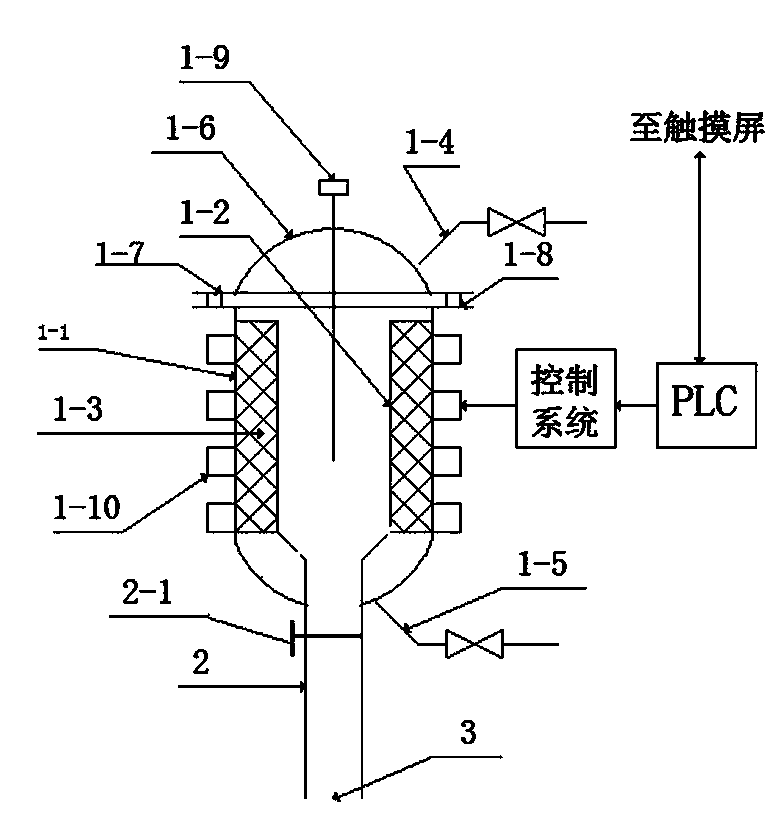

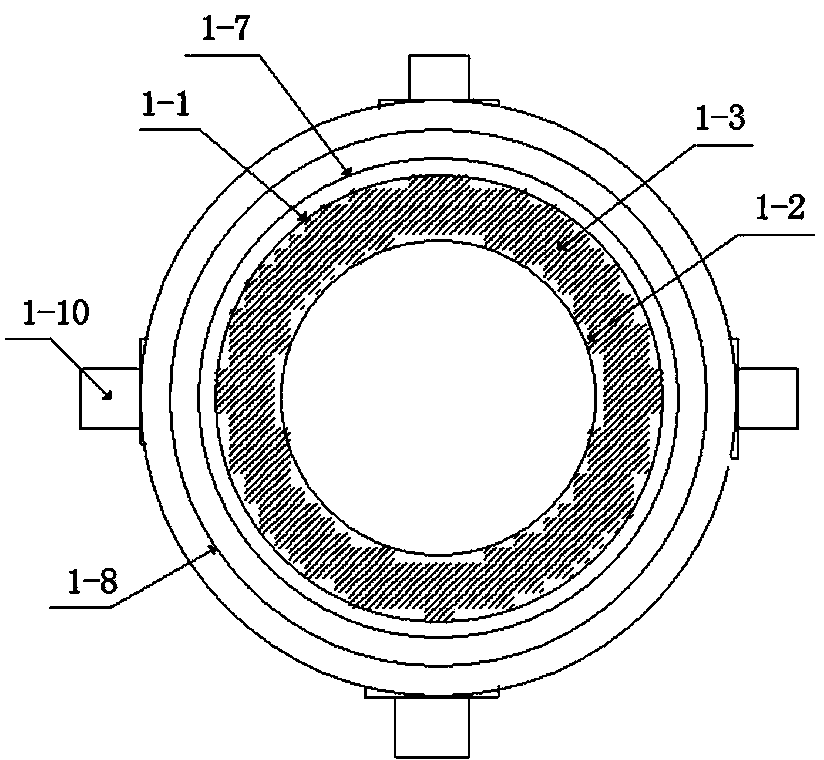

[0038] Example 1: A microwave heating device for light-burning magnesite and dolomite, see Figure 1-3 , Including microwave heating furnace, control circuit and PLC, microwave heating furnace 1 includes furnace body 1-1, inner cavity 1-2, furnace cover 1-6, discharge tube 2 and microwave source 1-10; several microwave sources 1 -10 is uniformly distributed on the outside of the furnace body 1-1 in a circular shape; the inner cavity 1-2 of the microwave heating furnace is a cylindrical cavity, and the cavity 1-2 is equipped with a thermocouple 1-9, and the cavity is wrapped around the heat preservation Material 1-3, the lower part of the inner cavity 1-2 is connected with the discharge pipe 2. The discharge pipe 2 is provided with a discharge valve 2-1; the furnace cover 1-6 is provided with an exhaust pipe 1-4, and the furnace body 1 The bottom of -1 is provided with a drain pipe 1-5; the product of microwave heat treatment is discharged from the discharge port 3 through the di...

Example Embodiment

[0042] Example 2: A method for light-burning magnesite using the microwave device of Example 1, including the following steps (see Figure 1-Figure 6 ):

[0043] (1) In this example, four microwave heating furnaces are used, namely furnace No. 1, furnace No. 2, furnace No. 3 and furnace No. 4. They are connected in parallel through the PLC control circuit to crush magnesite to particles smaller than 20 mm. Measure 300 kg into 4 microwave heating furnaces, cover the furnace cover and seal it well;

[0044] (2) Turn on the microwave heating furnace to heat the materials. The power of the microwave heating furnace is 30-40KW. The output power of the microwave oven is adjusted to make the material heat up at a rate of 5℃ per minute. The temperature in the No. 1, No. 2, No. 3 and No. 4 furnaces are respectively detected to make them After reaching 840°C, keep it at this temperature for 20 minutes; the gas generated during heating is discharged from the exhaust pipe, and the water gene...

Example Embodiment

[0048] Example 3: The method of lightly burning dolomite using the microwave device of Example 1 is basically the same as Example 2, except that:

[0049] (1) In this example, six microwave heating furnaces are used. The six microwave heating furnaces are connected in parallel through the PLC control circuit. After the dolomite is crushed to particles smaller than 20mm, 300 kg are respectively added to the six microwave heating furnaces, and the furnace is covered. Cover and seal well;

[0050] (2) Turn on the microwave heating furnace to heat the materials. Adjust the output power of the microwave oven, make the material heat up at a rate of 10°C per minute, and detect the temperature in the six heating furnaces respectively to reach 860°C, and then keep it at this temperature for 30 minutes;

[0051] (3) After heating, turn off the microwave oven and open the discharge valve. The material will be discharged from the discharge port through the discharge pipe and transported away in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com