Organic electroluminescence device

An electroluminescent device and electroluminescent technology, which is applied in the direction of electro-solid devices, electrical components, semiconductor devices, etc., can solve the problems of complex preparation process of hole transport layer, achieve high product yield, reduce the number of alignments, improve The effect of process accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The preparation method of the organic electroluminescent device comprises the following steps:

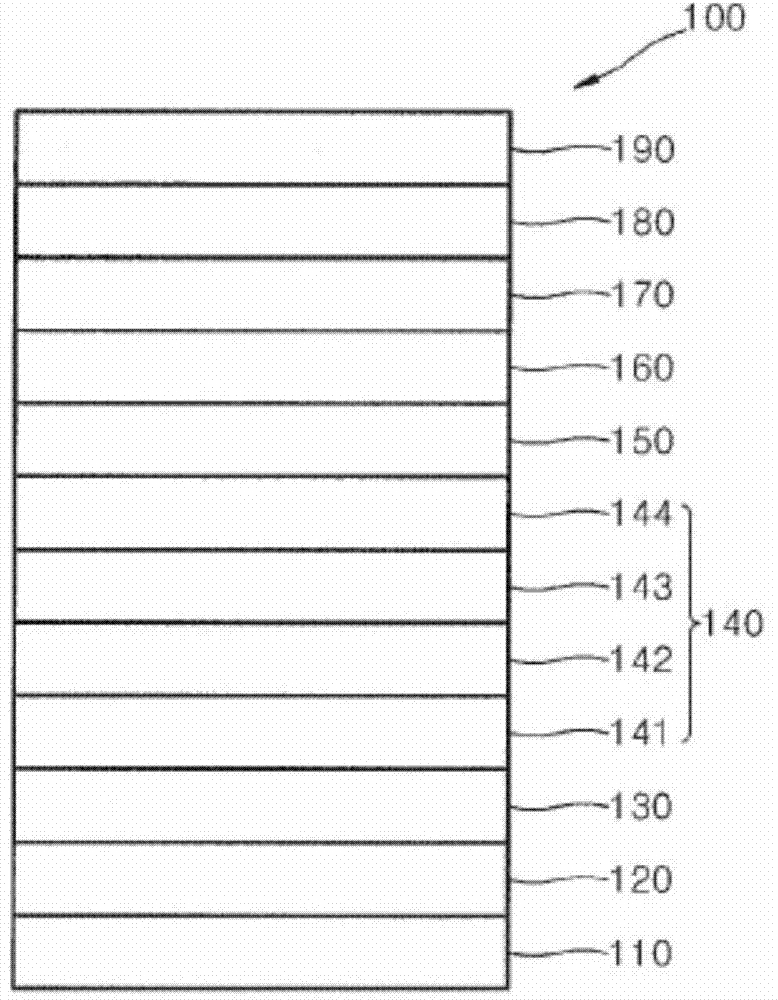

[0058] In the preparation process of the organic electroluminescence device of the present invention, the preparation of the first electrode layer 1, the second electrode layer 8, the hole injection layer 2, the light-emitting unit layer and the second electrode layer 8 are all conventional techniques in the art. For the hole transport layer 3, the first hole transport material and the second hole transport material can be deposited by using an open mask.

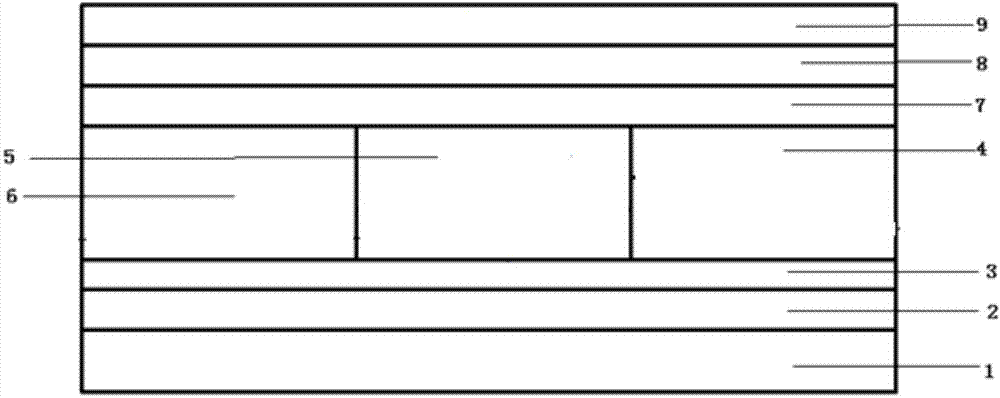

[0059] As a preferred embodiment, such as image 3 As shown, the hole transport layer includes a first hole transport layer 31 and a second hole transport layer 32 disposed on the first hole transport layer 31, and the first hole transport layer 31 is composed of Prepared from the first hole transport material, the second hole transport layer 32 is prepared from the first hole transport material and the second hole trans...

Embodiment 1

[0090] Example 1 Red light emitting device

[0091] The structure of device 1:

[0092] ITO(40nm) / HIL:3%HAT(170nm) / HTL-1:50%HTL-2(20nm) / CBP:5%Ir(piq) 3 (30nm) / Bphen(5nm) / Bphen:50%liq(30nm)Mg:Ag(2nm) / Ag(18nm) / Alq 3 (65nm)

[0093] Table 1 The performance test structure of the above three green light devices is as follows

[0094]

[0095] It can be found from Example 1 that the co-doping of the HTL layer improves the current efficiency, reduces the driving voltage, and prolongs the lifetime.

Embodiment 2

[0101] Example 2 Green light emitting device

[0102] The structure of device 2:

[0103] ITO(40nm) / HIL:3%HAT(140nm) / HTL-1:50%HTL-2(20nm) / CBP:5%Ir(ppy) 3 30nm) / Bphen(5nm) / Bphen:50%liq(30nm)Mg:Ag(2nm) / Ag(18nm) / Alq 3 (65nm)

[0104] According to the requirements of device performance, the proportion of HTL-1 can be adjusted from 10% to 90%.

[0105] Table 2 The performance test structure of the above three devices is as follows

[0106]

[0107] From Example 2, it can be found that the co-doping of the HTL layer improves the current efficiency, reduces the driving voltage, and prolongs the lifetime.

[0108] The structure of the red light-emitting device of Examples 3-10 is the same as that of Example 1, and the structure of the green light-emitting device of Examples 11-18 is the same as that of Example 2, and the composition of the red optical compensation layer and the green optical compensation layer is as follows :

[0109]

[0110] Example 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com