Organic light emitting diode and its preparation method

A light-emitting diode and organic technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of OLED light output efficiency reduction, working temperature rise, impact on performance and life, etc., and achieve a wide range of graphic reproduction, The effect of reducing the temperature rise of the device and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

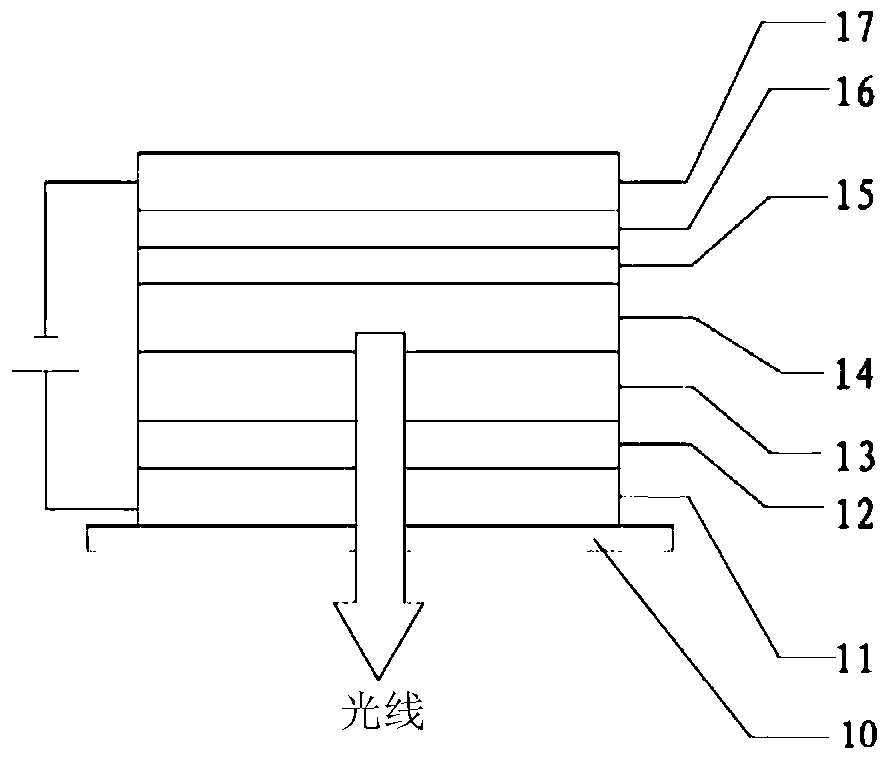

[0052] An organic light-emitting diode composed of a cathode, an organic electroluminescent unit and an anode, and a plasma nano waveguide filter reflector is prepared on the cathode to increase the light extraction rate of the organic light-emitting diode.

Embodiment 2

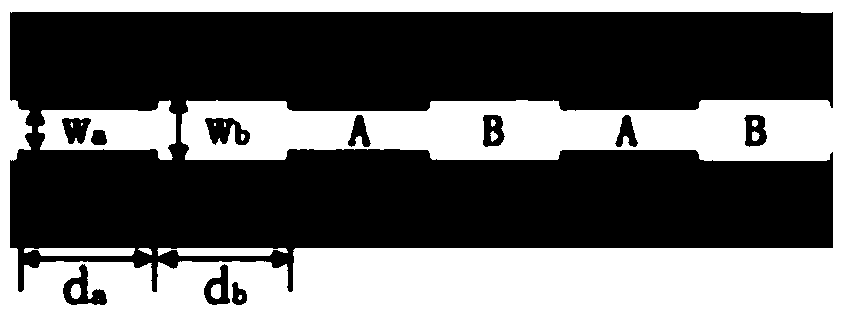

[0054] An organic light-emitting diode composed of a cathode, an electron transport layer, a light-emitting layer, a hole transport layer and an anode in sequence, and an M-I-M plasmonic waveguide filter reflector that can generate a band gap in the visible wavelength range is prepared on the cathode, then this Organic light-emitting diodes have a high visible light output rate.

Embodiment 3

[0056] An organic light-emitting diode composed of a cathode, an electron injection layer, an electron transport layer, a light-emitting layer, a hole transport layer, a hole injection layer, and an anode in turn, and prepared on the cathode can generate a number of wavelengths (the one that is relatively missing in the light emitted by the anode) ) combined selective band gap M-I-M plasma waveguide filter reflector, the organic light emitting diode has a uniform visible spectrum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com