Patents

Literature

88 results about "Plasmonic waveguide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

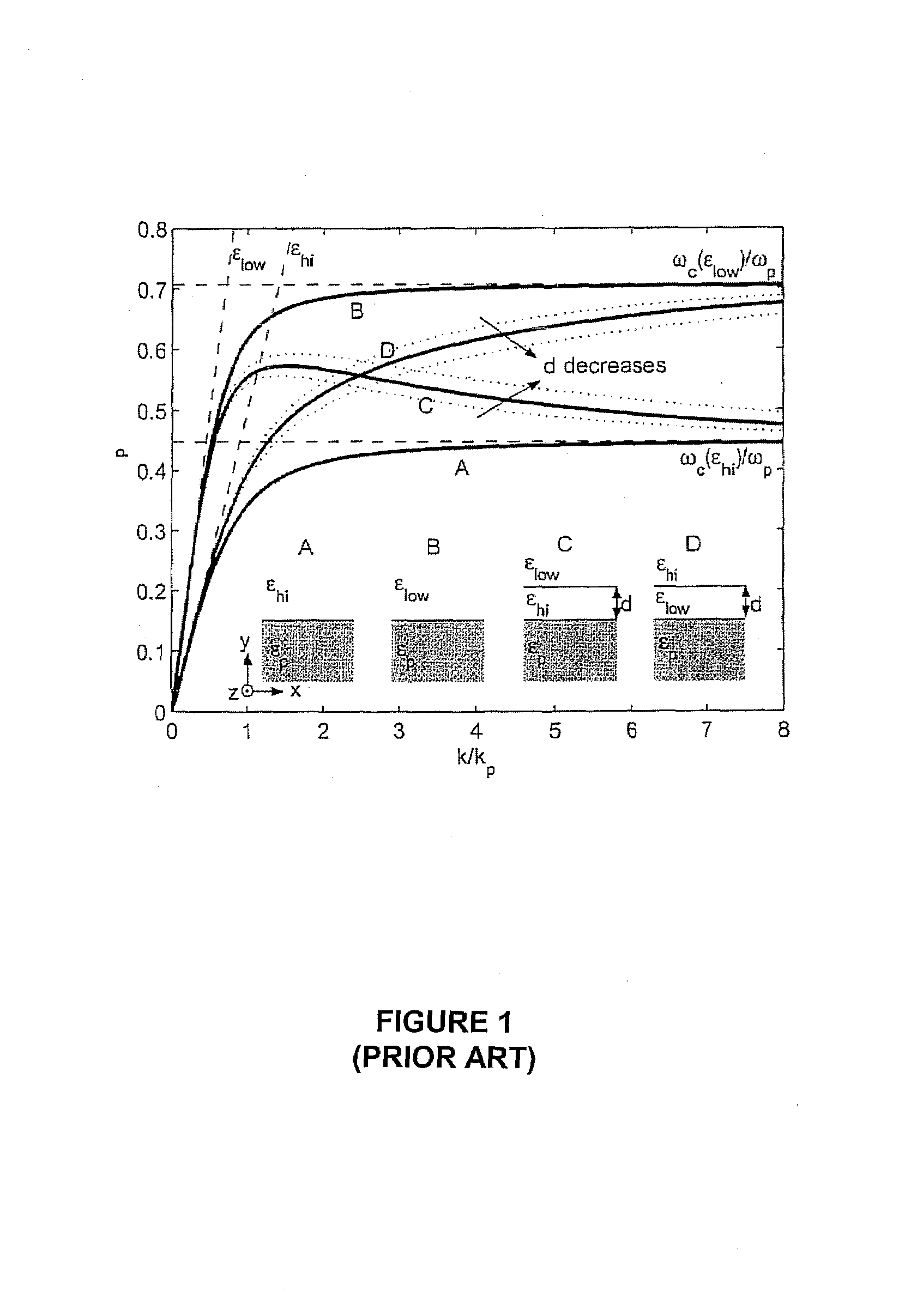

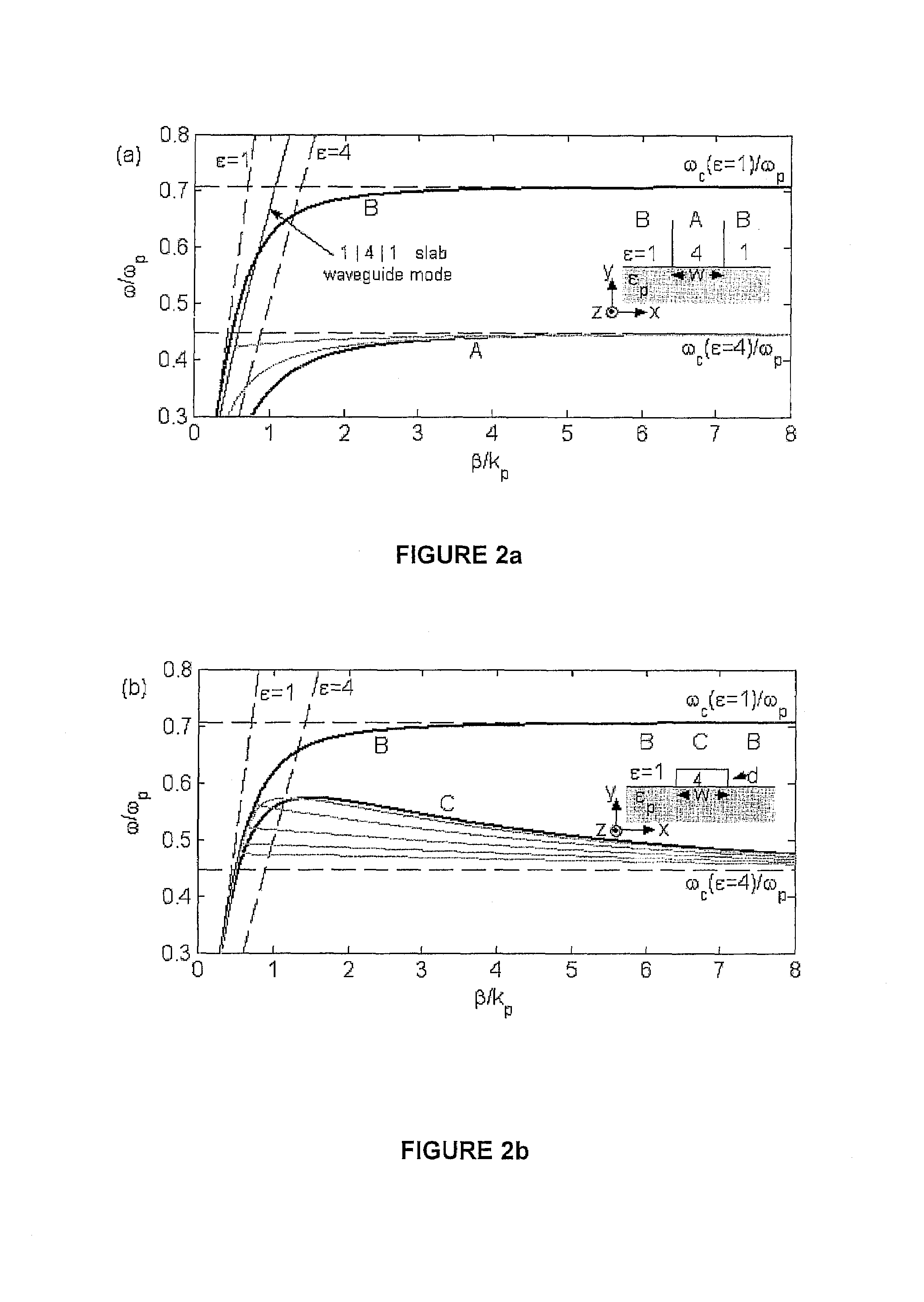

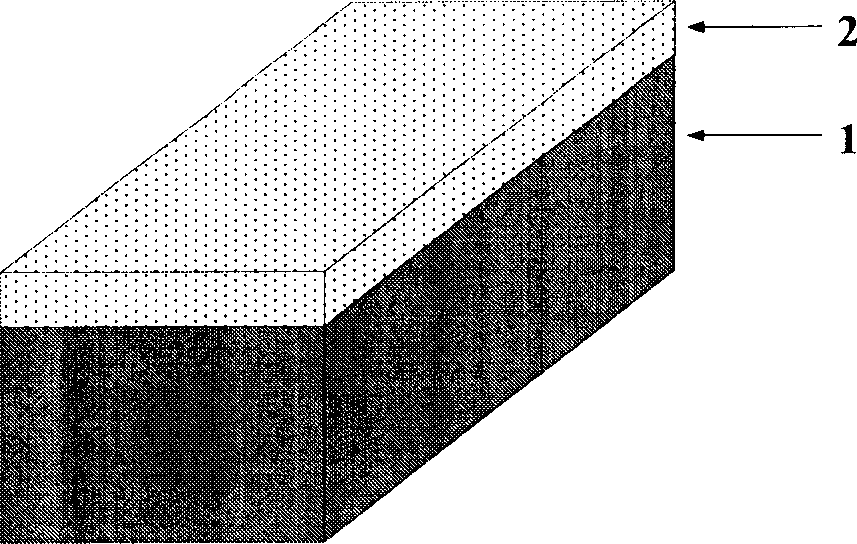

A hybrid plasmonic waveguide is an optical waveguide that achieves strong light confinement by coupling the light guided by a dielectric waveguide and a plasmonic waveguide. It is formed by separating a medium of high refractive index (usually silicon) from a metal surface (usually gold or silver) by a small gap.

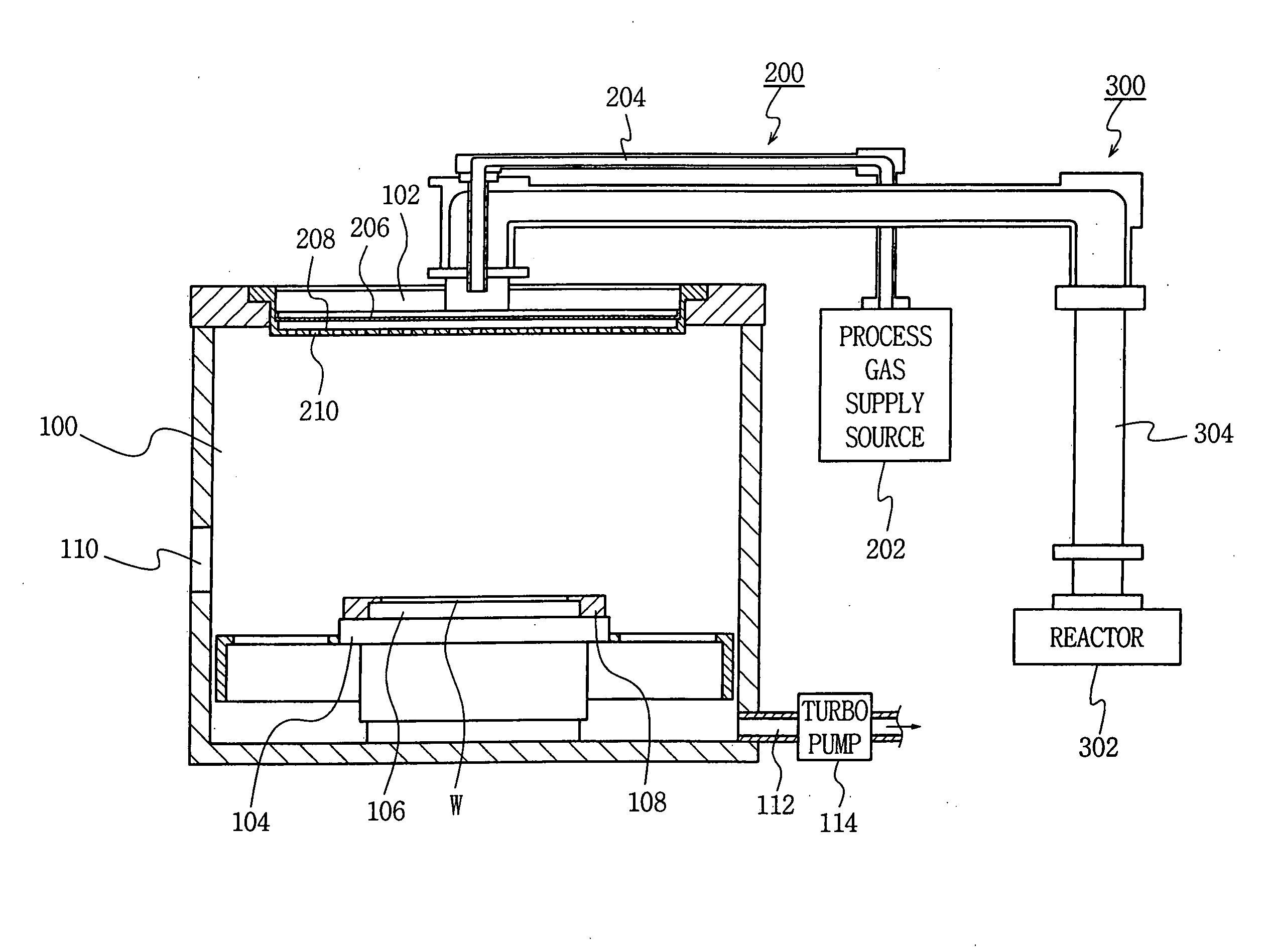

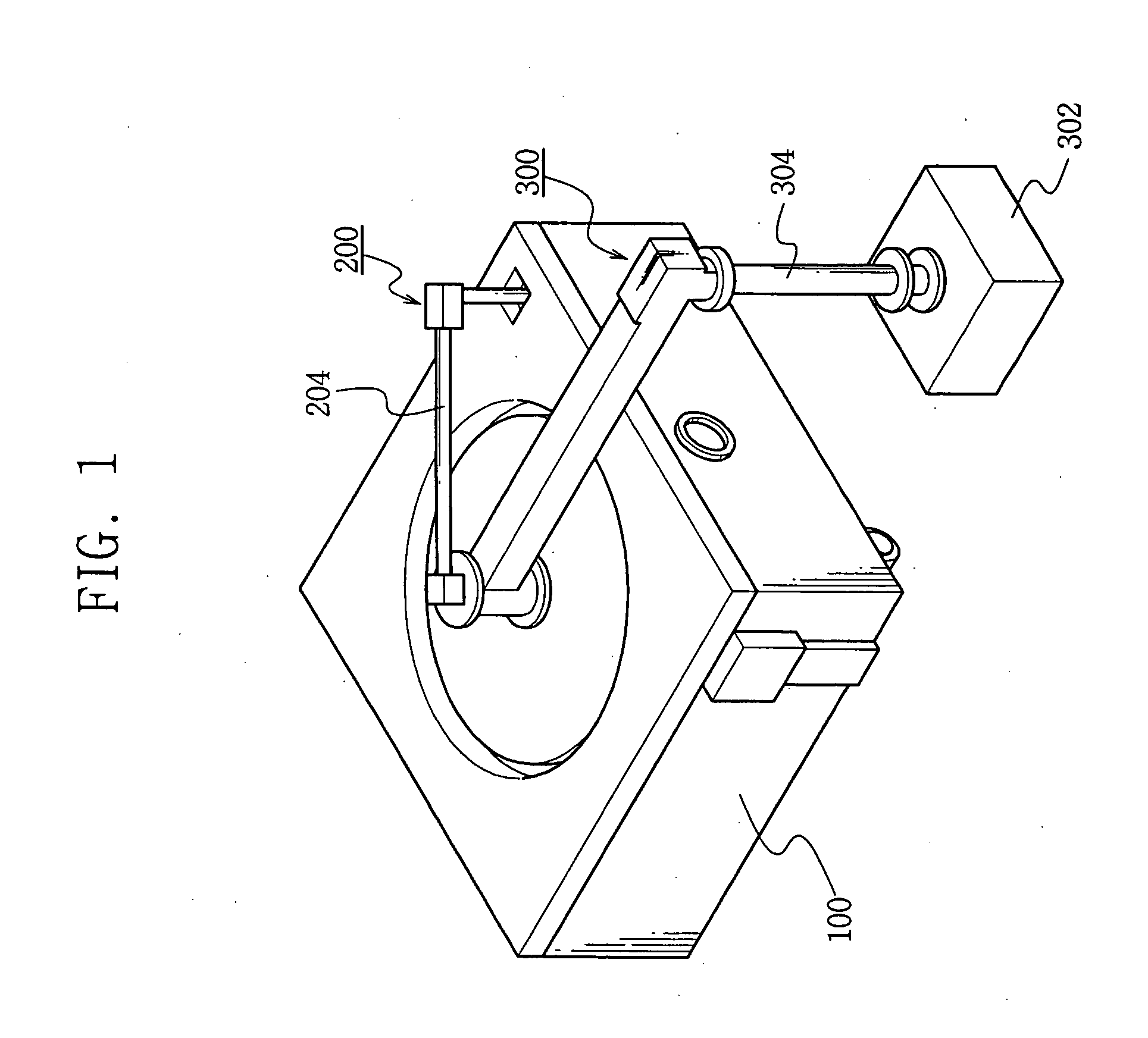

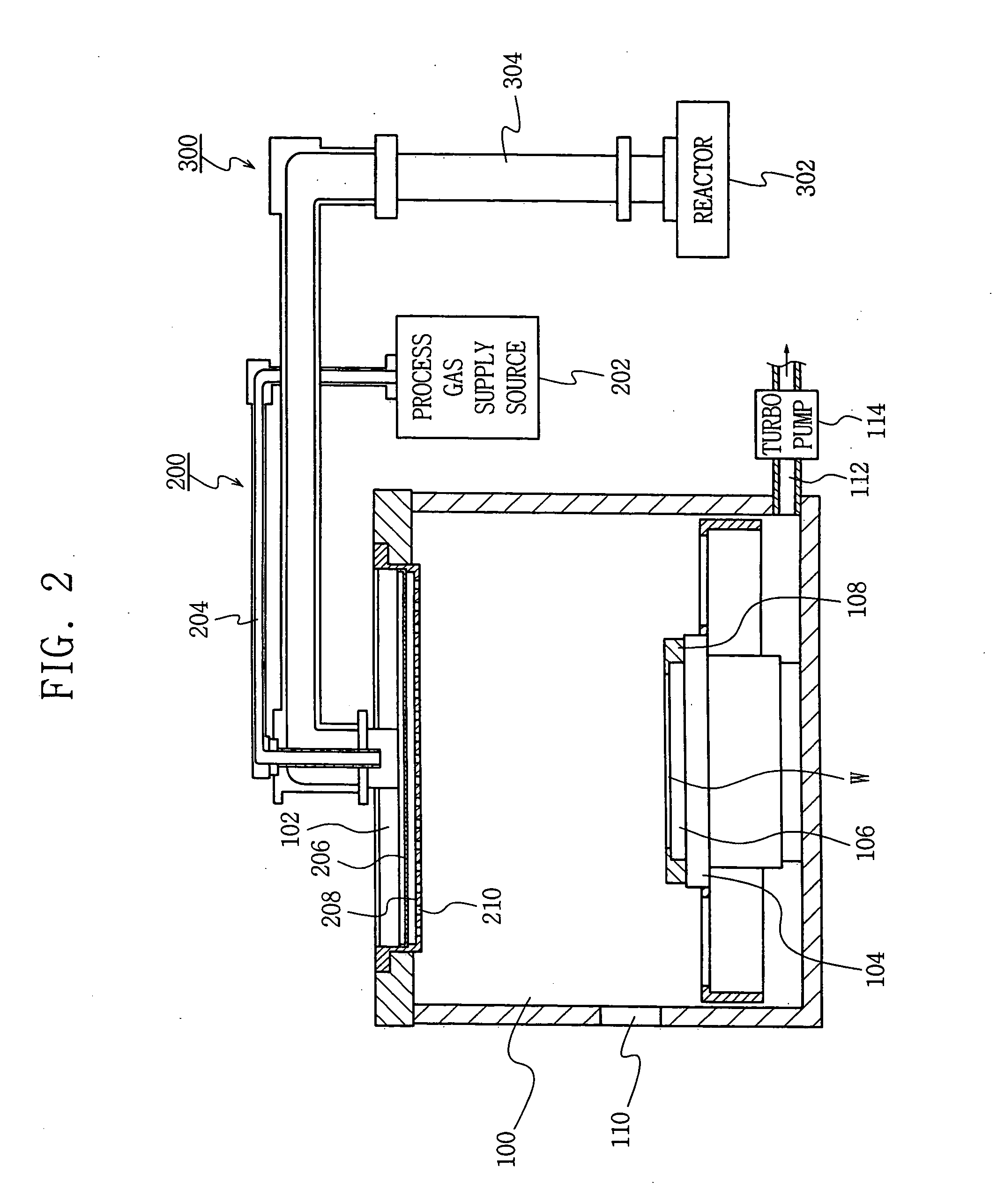

Semiconductor device manufacturing apparatus and method of using the same

InactiveUS20070266946A1Short amount of timeElectric discharge tubesChemical vapor deposition coatingPlasmonic waveguideRemote plasma

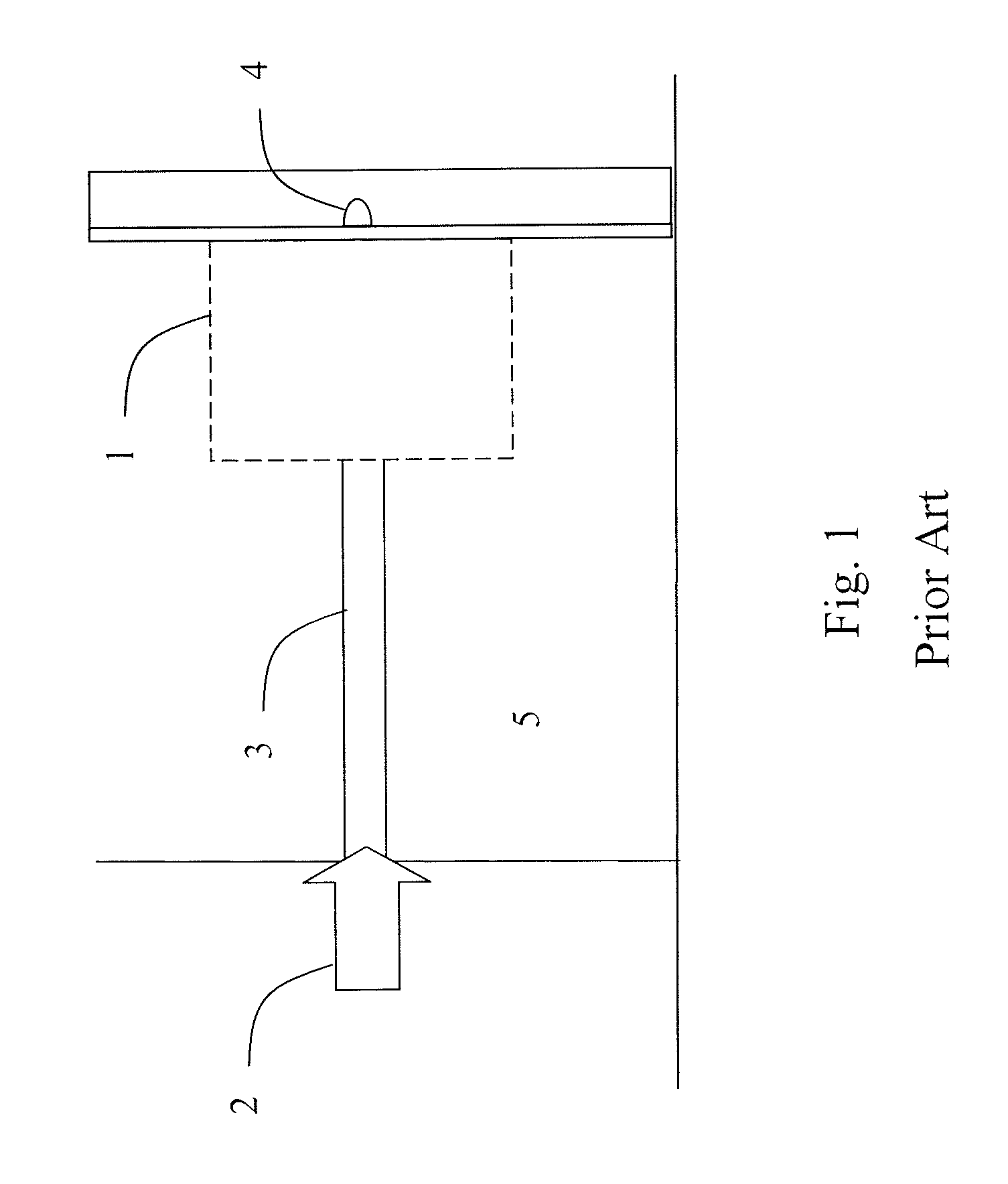

A semiconductor device manufacturing apparatus and a method for use in the manufacturing of such devices minimize the amount of particles which accumulate in the process chamber of the apparatus and clean the interior of the process chamber with a high degree of effectiveness. The semiconductor device manufacturing apparatus has a showerhead located at an upper portion of the process chamber, a plate-like gas diffuser disposed in the showerhead, and both a fluid supply line and a plasma waveguide connected to the showerhead. After a substrate is processed in the process chamber using process gas delivered to the showerhead through the fluid supply line, plasma is supplied into the upper portion of the process chamber from a remote plasma reactor via the plasma waveguide.

Owner:SAMSUNG ELECTRONICS CO LTD

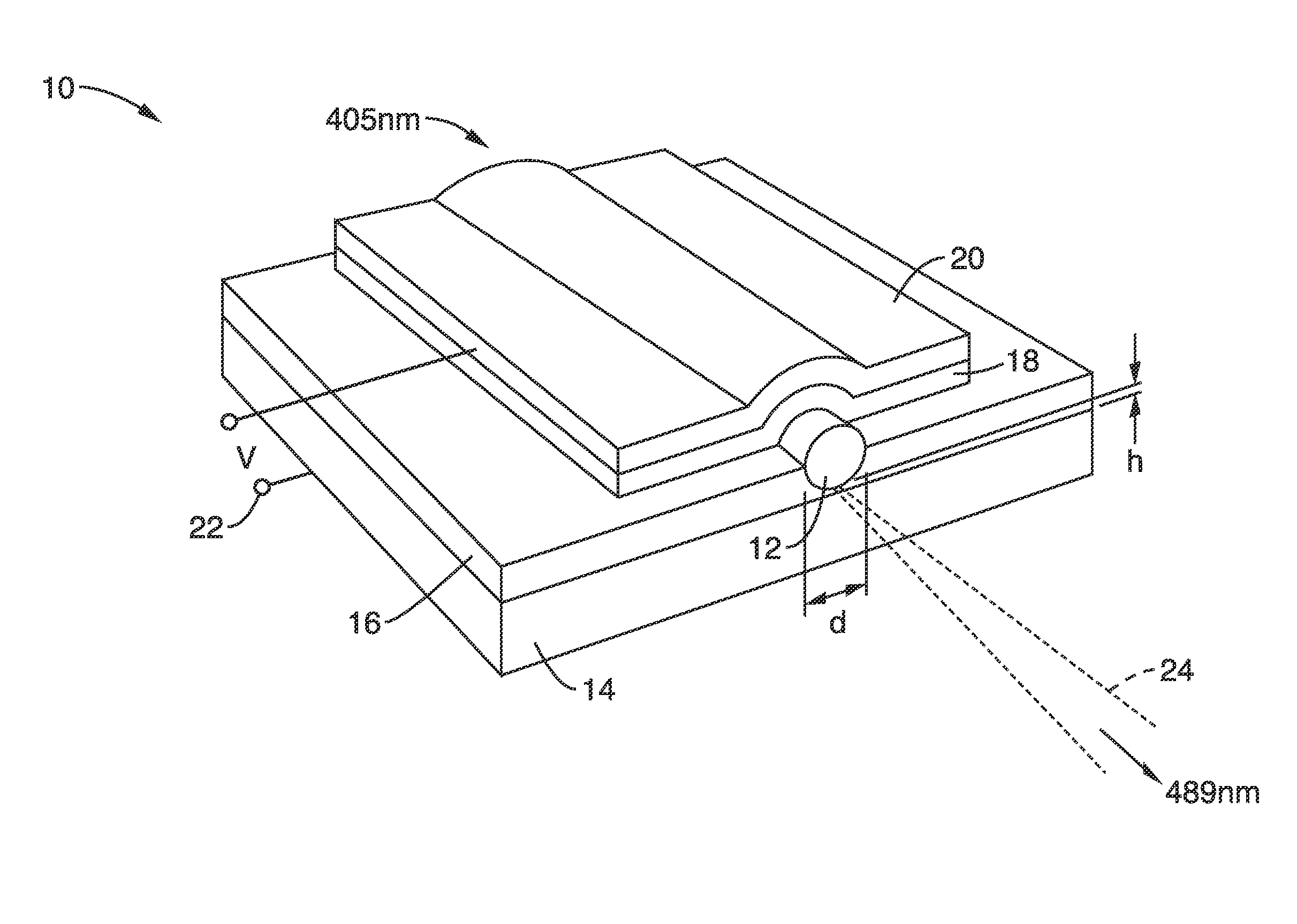

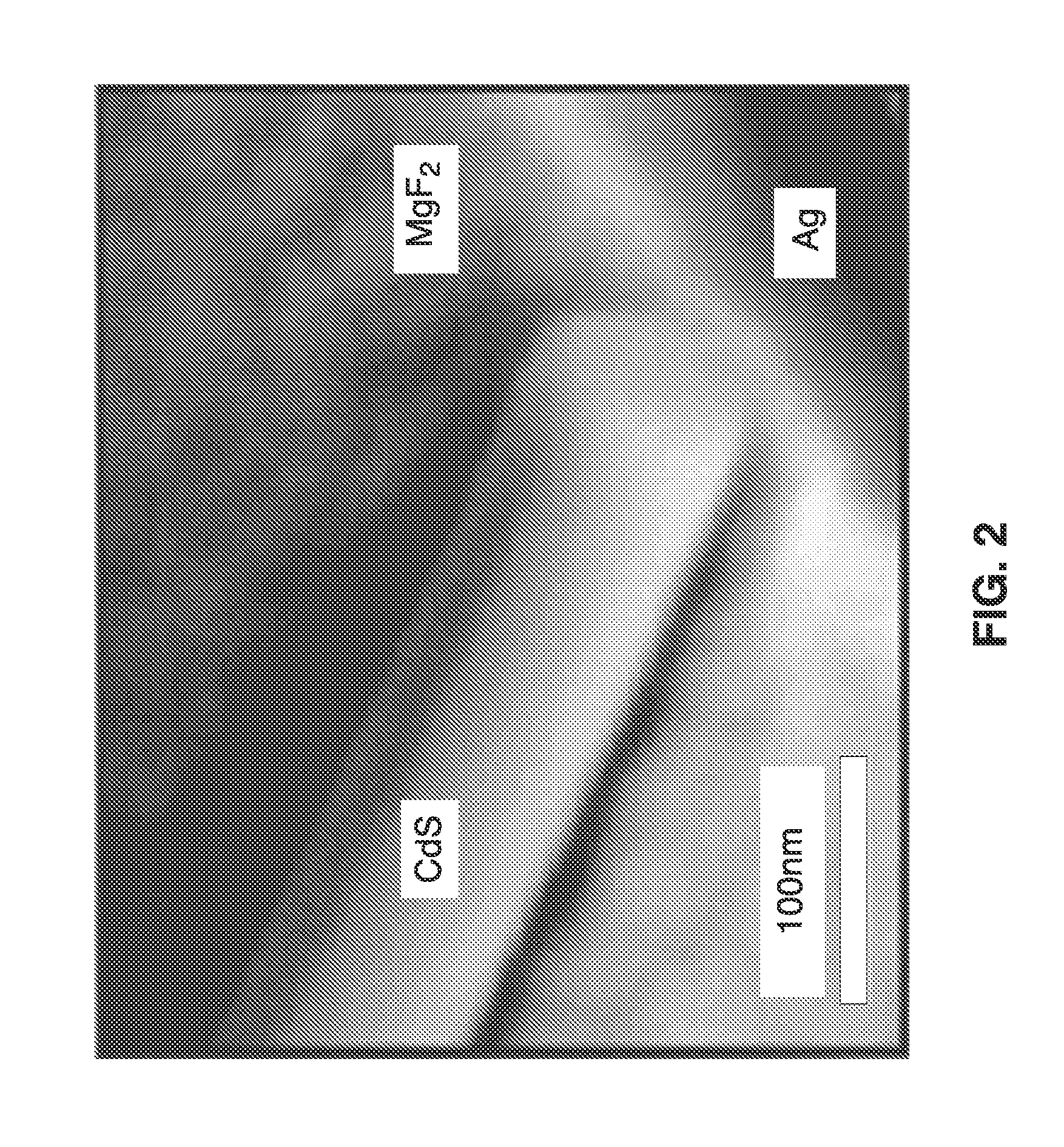

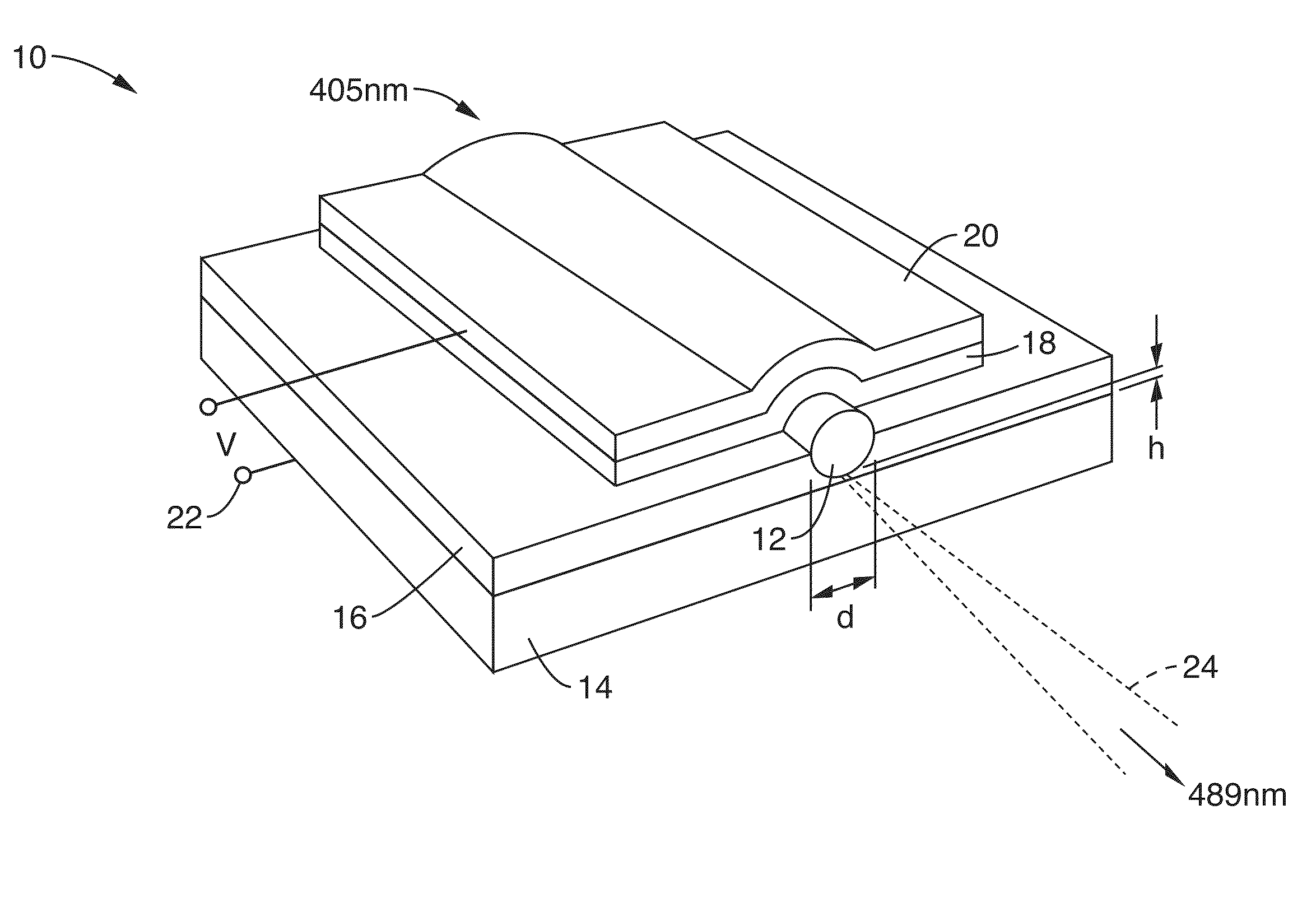

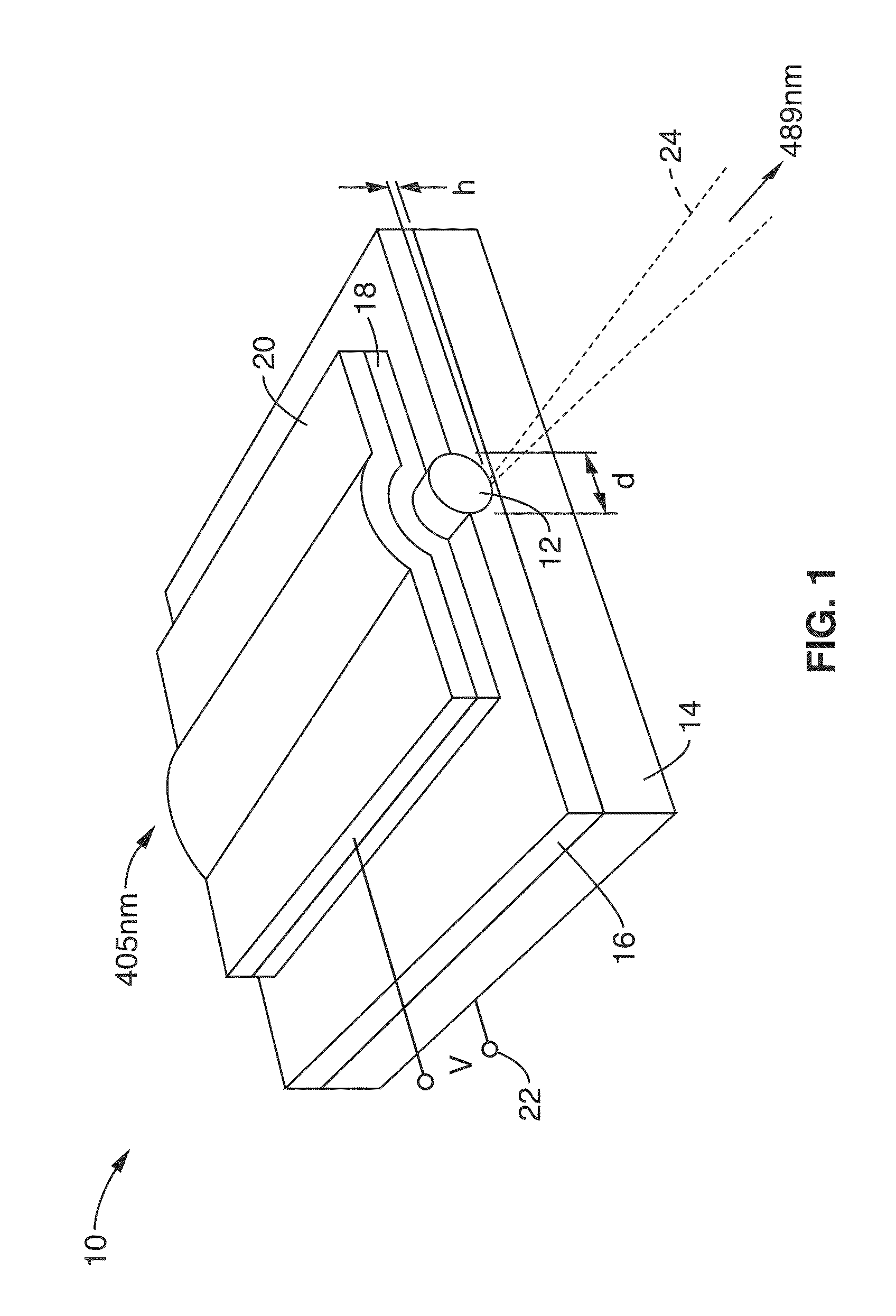

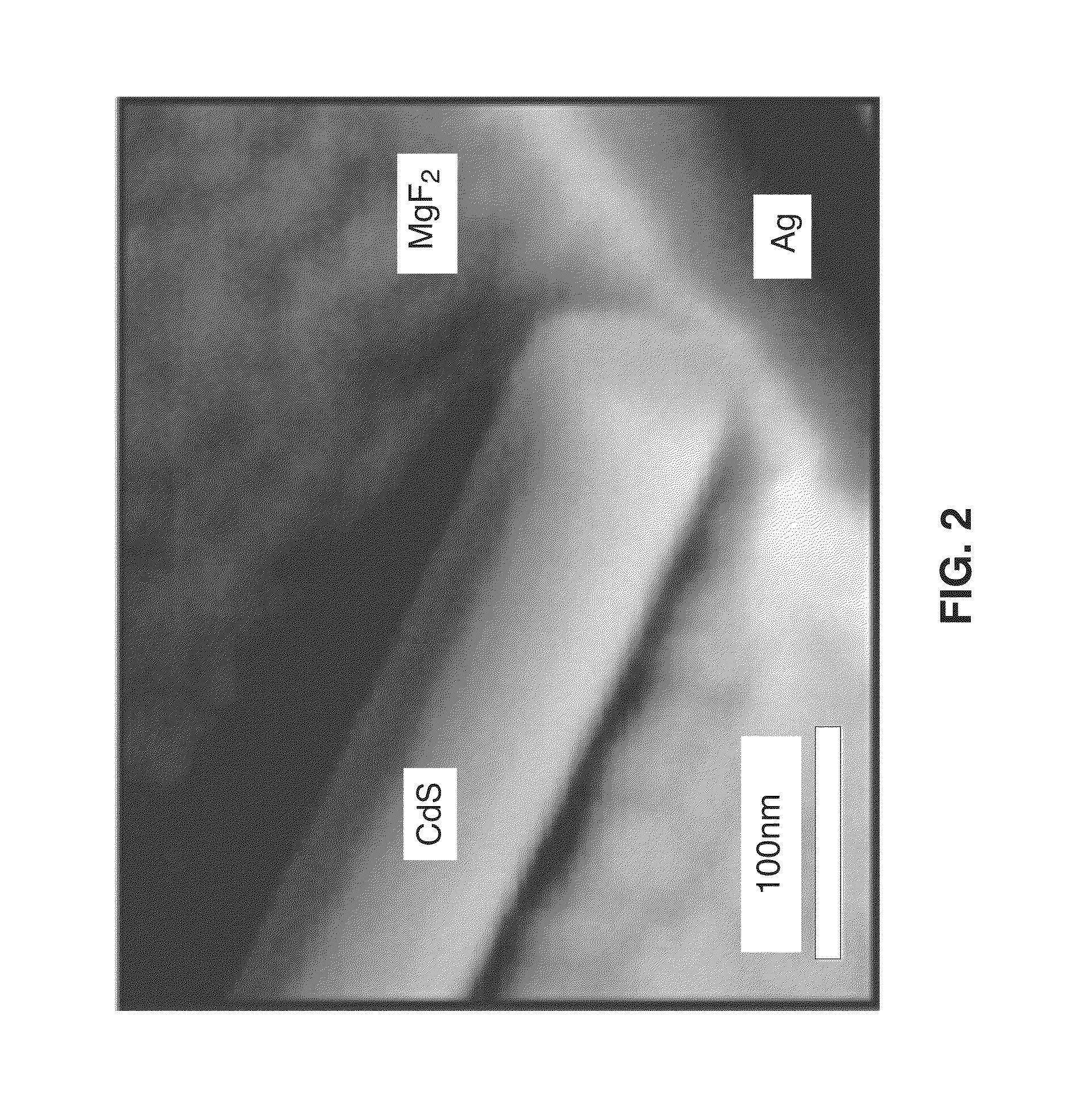

Plasmon lasers at deep subwavelength scale

ActiveUS20130148682A1Efficient generation of sub-wavelength high intensity lightWide modulation bandwidthOptical wave guidanceLaser detailsModulation bandwidthPlasmonic waveguide

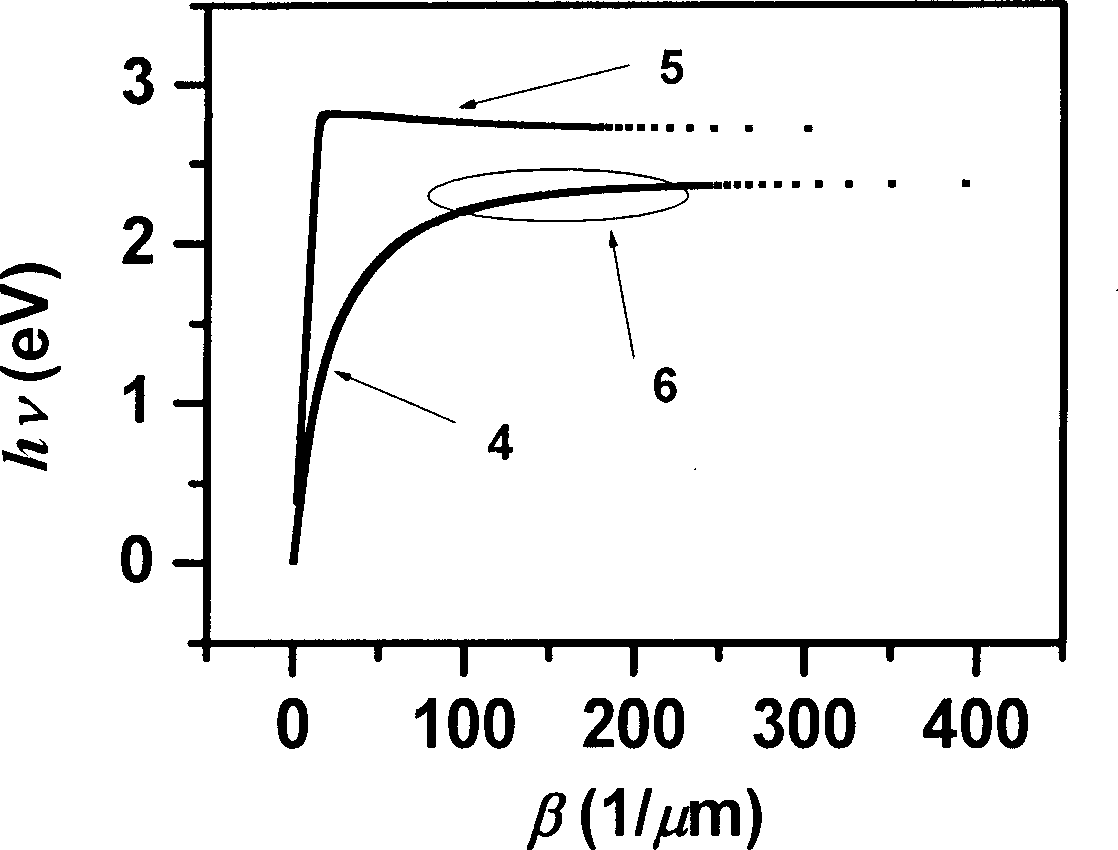

Hybrid plasmonic waveguides are described that employ a high-gain semiconductor nanostructure functioning as a gain medium that is separated from a metal substrate surface by a nanoscale thickness thick low-index gap. The waveguides are capable of efficient generation of sub-wavelength high intensity light and have the potential for large modulation bandwidth >1 THz.

Owner:RGT UNIV OF CALIFORNIA

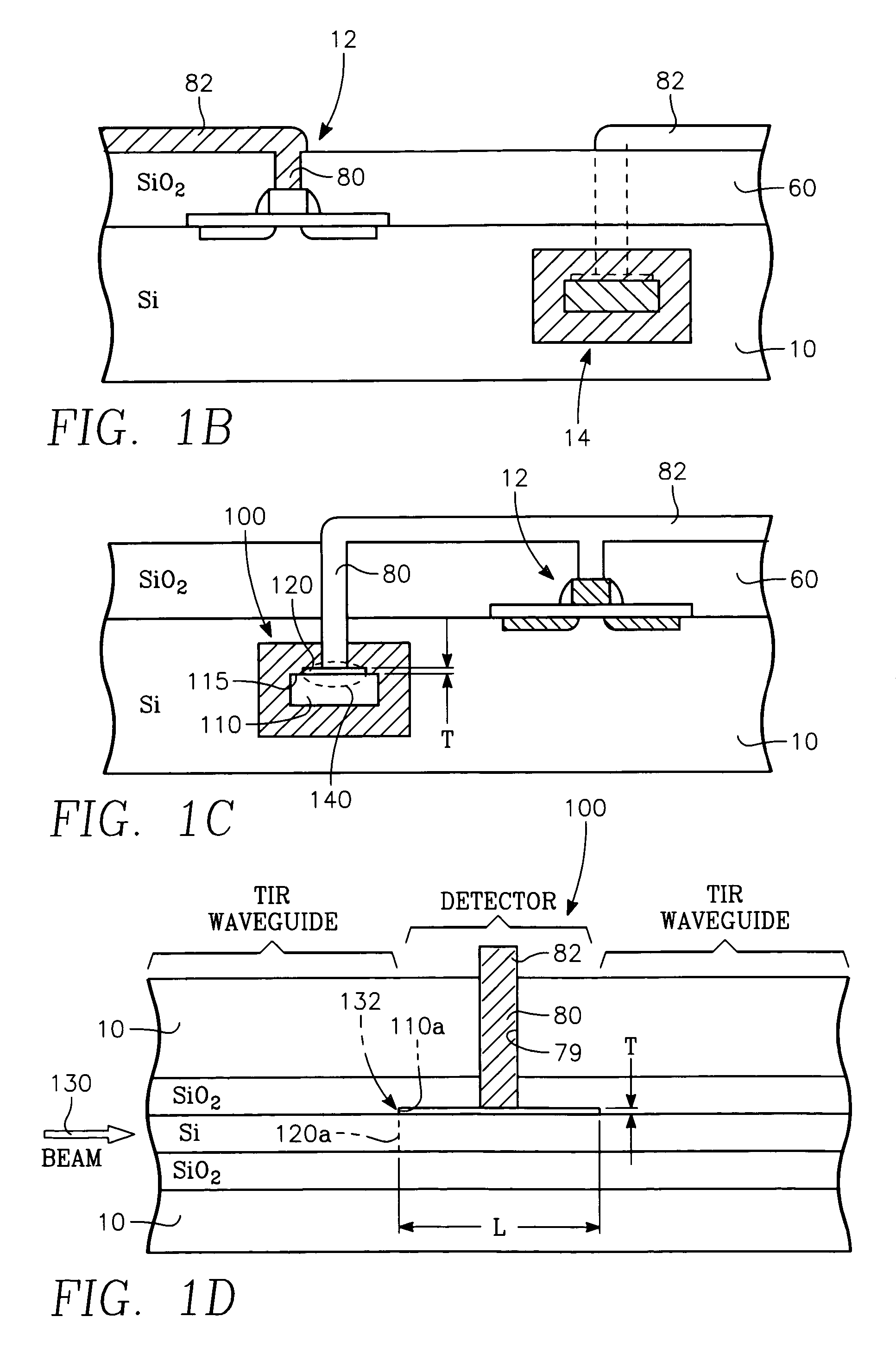

Planar integrated circuit including a plasmon waveguide-fed Schottky barrier detector and transistors connected therewith

InactiveUS7170142B2Easy to controlHigh precisionNanoopticsCoupling light guidesPlasmonic waveguideSchottky barrier

A planar integrated circuit includes a semiconductor substrate having a substrate surface and a trench in the substrate, a waveguide medium in the trench having a top surface and a light propagation axis, the trench having a sufficient depth for the waveguide medium to be at or below said substrate surface, and at least one Schottky barrier electrode formed on the top surface of said waveguide medium and defining a Schottky barrier detector consisting of the electrode and the portion of the waveguide medium underlying the Schottky barrier electrode, at least the underlying portion of the waveguide medium being a semiconductor and defining an electrode-semiconductor interface parallel to the light propagation axis so that light of a predetermined wavelength from said waveguide medium propagates along the interface as a plasmon-polariton wave.

Owner:APPLIED MATERIALS INC

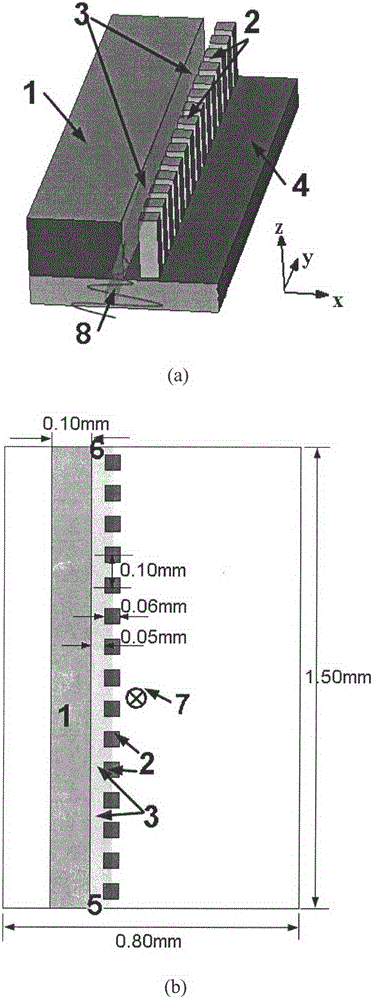

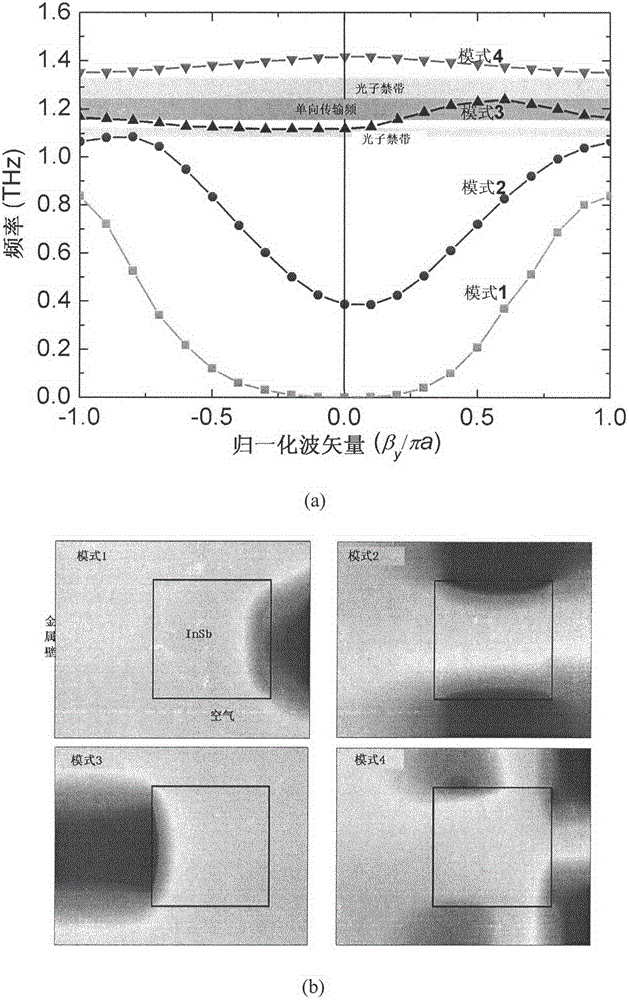

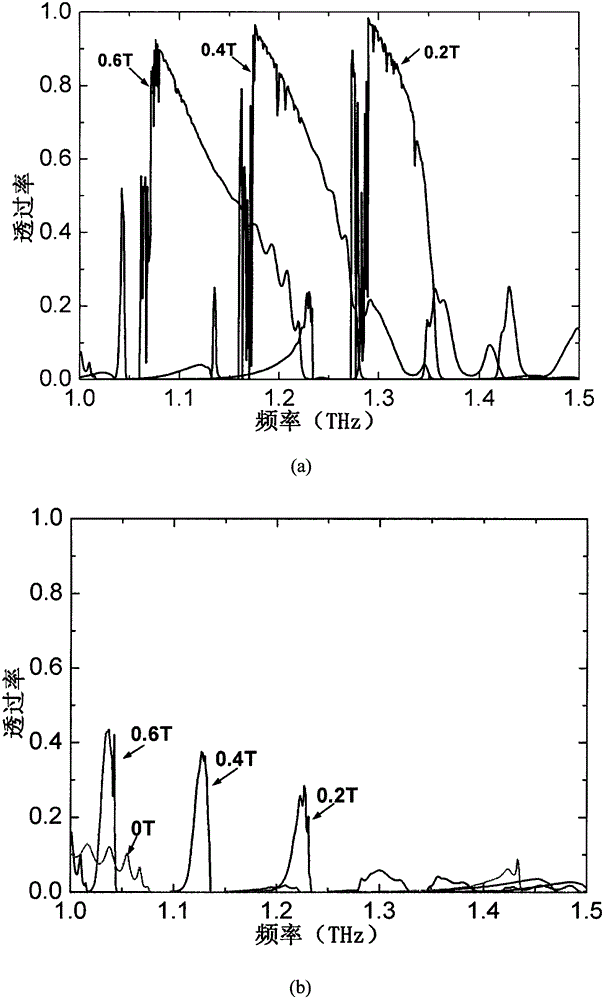

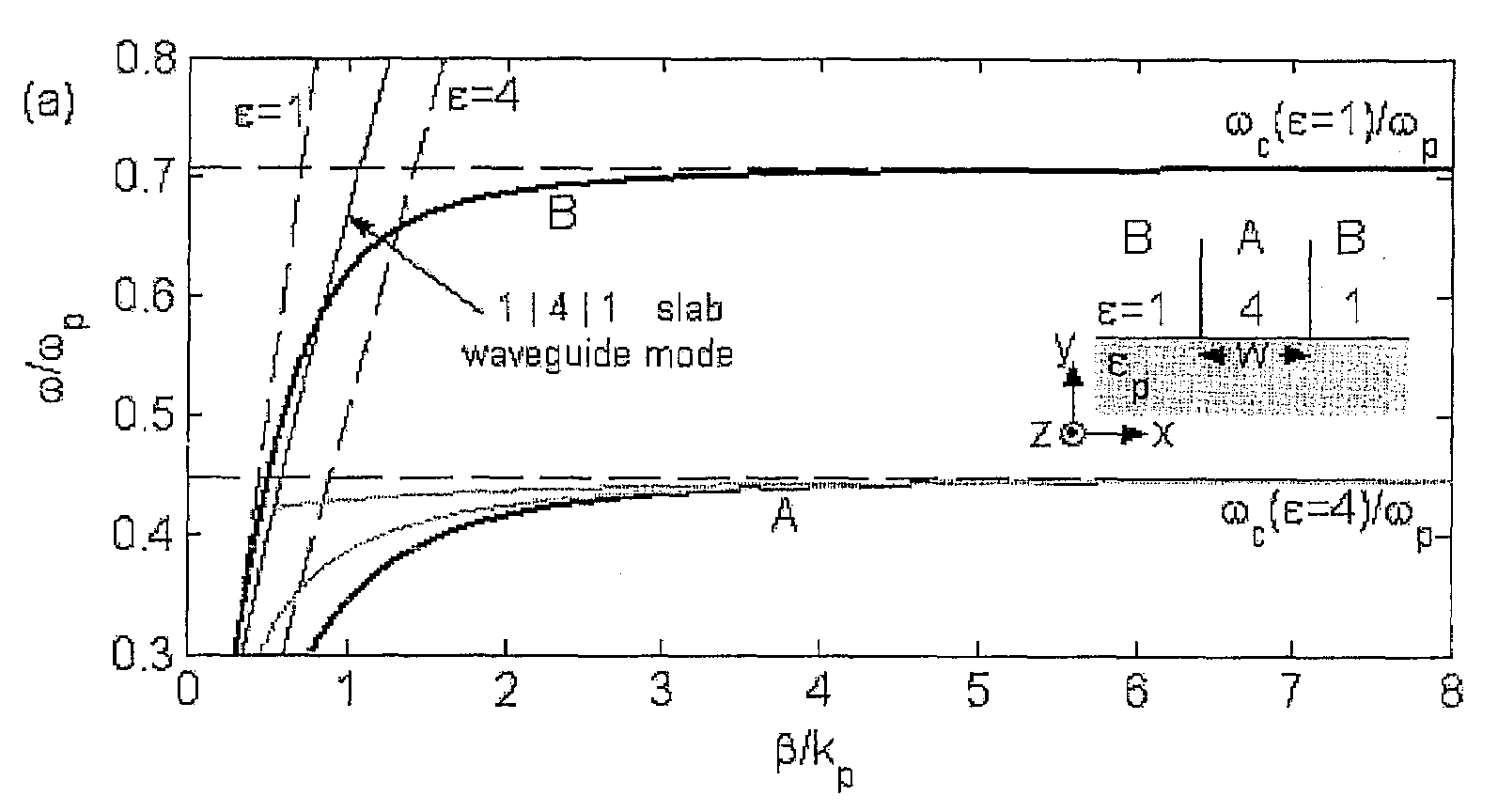

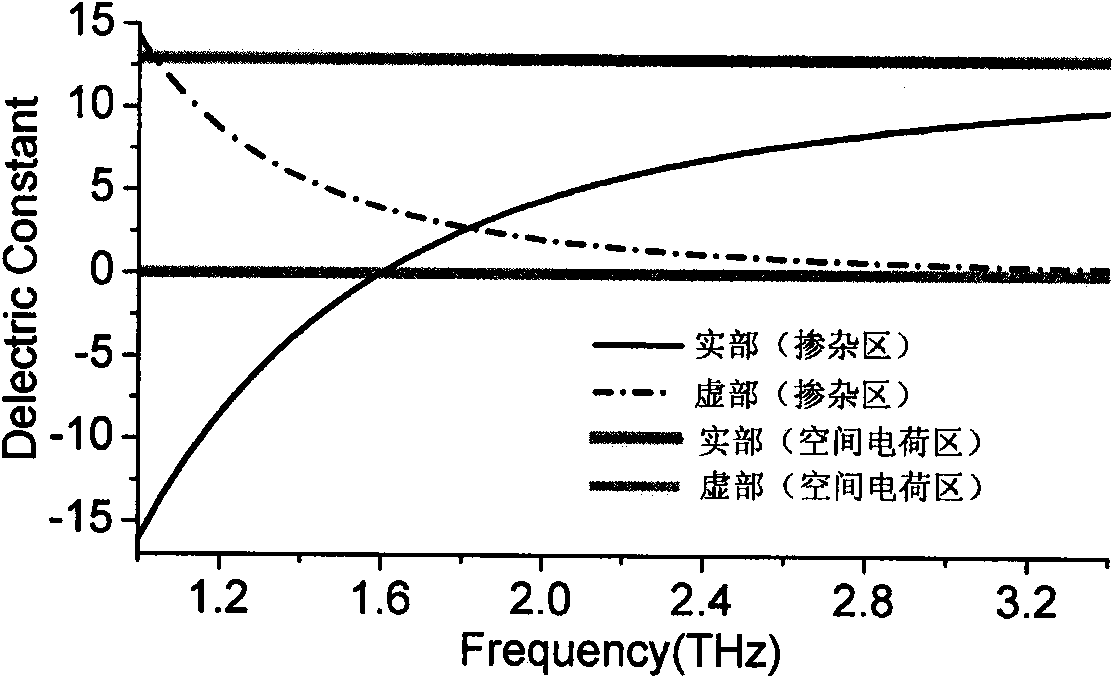

Terahertz isolator of magnetic surface plasma waveguide

InactiveCN102916238AEnhanced one-way transmission performanceImprove isolationWaveguide type devicesWaveguideTransmission quality

The invention discloses a terahertz isolator device of a magnetic surface plasma waveguide and a control method thereof. The asymmetric and periodic surface plasma waveguide is formed by a metal wall and a semiconductor indium antimonide pillar array. By exerting an external magnetic field under low temperature, the indium antimonide shows the revolving electrical property, and the structure can generate a magnetic surface plasma mode, so that the function of unidirectional isolation transmission of the terahertz wave can be achieved. The unidirectional transmission working frequency range is higher than 1THz, the bandwidth is larger than 80 GHz, the isolation reaches 90dB, the insertion loss is lower than 0.25dB, and tuning on the working frequency range can be performed by controlling the external magnetic field strength. Under the temperature of 186K, the frequency of the external magnetic field can be adjusted to 0.7T from 0.1T, and the central working frequency of a unidirectional transmission frequency band of the device can be tuned to 1THz from 1.42THz. The terahertz isolator is low in loss, high in isolation, tunable in broadband and capable of reducing echo and scattered noises in a terahertz application system and improving transmission quality of the terahertz beam.

Owner:NANKAI UNIV

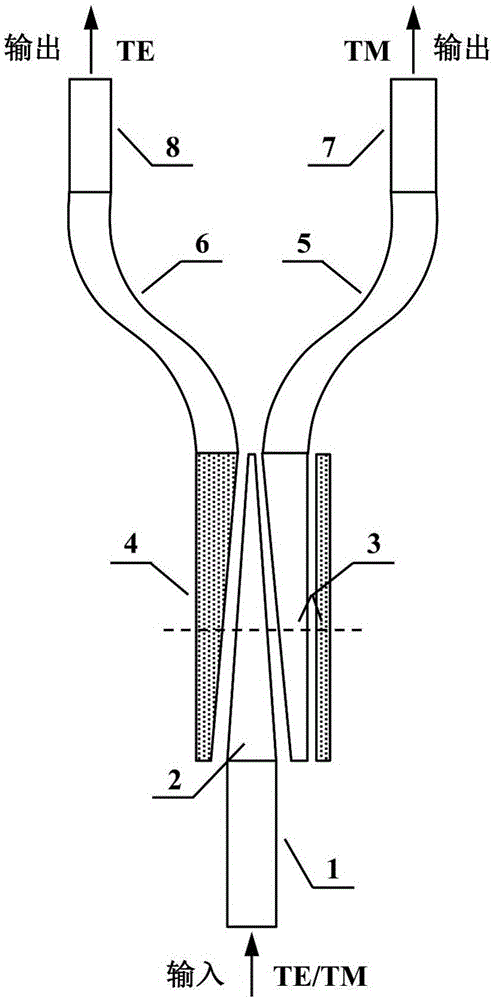

Silicon-based nanowire polarization beam splitter based on mode evolution principle

ActiveCN105093408APolarization beam splitting efficiency is highImprove working bandwidthOptical light guidesPlasmonic waveguideNanowire

The invention discloses a silicon-based nanowire polarization beam splitter based on the mode evolution principle, and can be used for the fields of integrated optics and silicon-based photonics. A vertical hybrid plasma waveguide (3) and a horizontal hybrid plasma waveguide (4) are respectively arranged at the two sides of a tapered transitional waveguide (2), and distance to the tapered transitional waveguide (2) is maintained to be consistent. An input waveguide (1) is connected at the lower end of the tapered transitional waveguide (2). A first S-shaped waveguide (5) is connected at the upper end of the vertical hybrid plasma waveguide (3). A first output waveguide (7) is connected at the upper end of the first S-shaped waveguide (5). A second S-shaped waveguide (6) is connected at the upper end of the horizontal hybrid plasma waveguide (4). A second output waveguide (8) is connected at the upper end of the second S-shaped waveguide (6). The device has advantages of being high in polarization beam splitting efficiency, low in loss, high in manufacturing tolerance and high in work bandwidth, and can also be used for constructing an on-chip polarization diversity scheme so as to realize polarization independent transmission.

Owner:SOUTHEAST UNIV

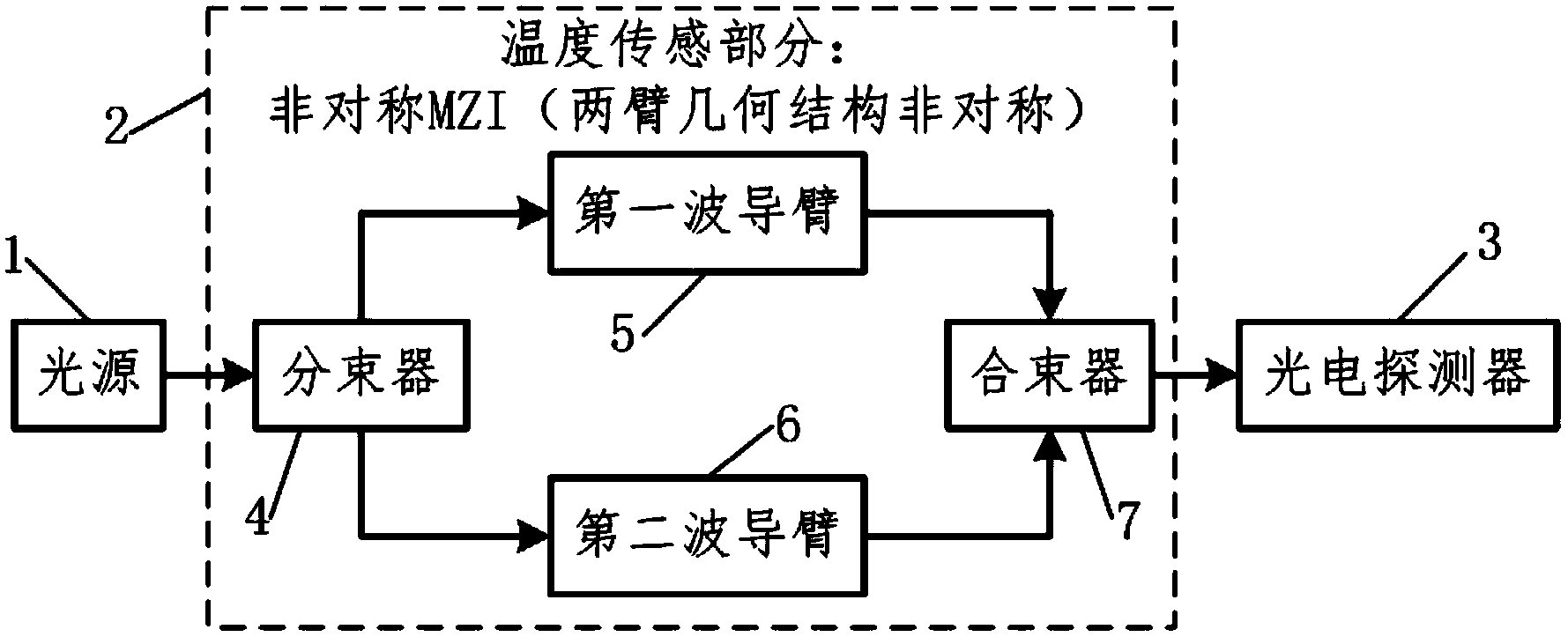

Photoelectric temperature sensor

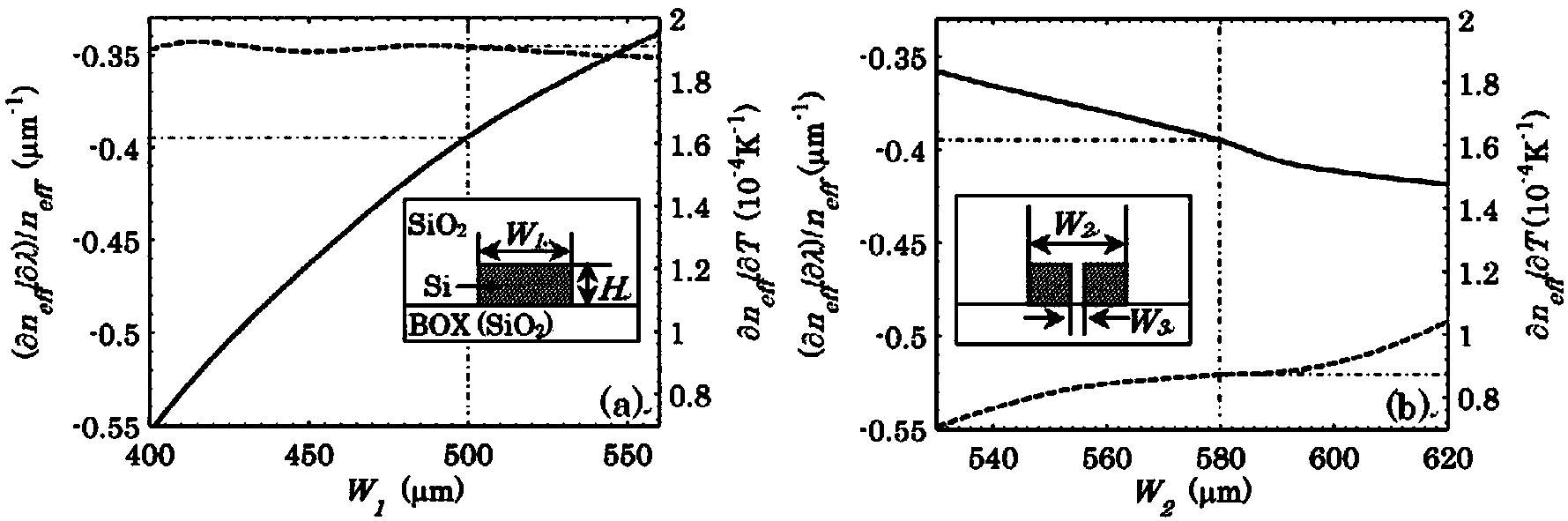

ActiveCN103884450AReduce demandLow costThermometers using physical/chemical changesPlasmonic waveguideElectrical conductor

The invention relates to the technical field of integrated photoelectronics, in particular to a photoelectric temperature sensor in order to solve the technical problems. Thus, the light source requirement of the photoelectric temperature sensor is lowered, and the cost of a whole temperature sensing system is reduced. The photoelectric temperature sensor is composed of a light source, an optical temperature sensing part and a photoelectric detection part. The optical temperature sensing part is obtained through an asymmetric Mach-Zehnder interferometer. Two arms of the asymmetric Mach-Zehnder interferometer are of an asymmetric geometric structure, the optical phase difference of the two arms is within the range from -2 pi to 2 pi, and the asymmetric geometric structure of the two arms is implemented by selecting different types of waveguides such as a ridged waveguide, a channel waveguide and a strip-shaped waveguide or by selecting the same type of waveguides with different structural parameters. The waveguides of the asymmetric Mach-Zehnder interferometer are non-good conductor material waveguides or surface plasma waveguides combined by non-good conductor material and metal, wherein the non-good conductor material comprises mediums, organic matter and the like.

Owner:北京爱杰光电科技有限公司

Electrooptic modulator

ActiveUS20180081204A1Reliable light modulationHigh crystallinityNon-linear opticsPlasmonic waveguideInter layer

An electro-optic element includes a first waveguide, which is a plasmonic waveguide, including a first core having a ferroelectric material and a cladding having a first cladding portion. The first cladding portion includes, at a first interface with the ferroelectric material, a first cladding material. The electro-optic element includes a first and a second electrode for producing an electric field in the ferroelectric material when a voltage is applied between the first and second electrodes, for modulating a real part of a refractive index of the ferroelectric material. The element includes, in addition, a crystalline substrate on which the ferroelectric material is epitaxially grown with zero or one or more intermediate layers present between the substrate and the ferroelectric material. The element may have a second waveguide, which is a photonic waveguide, including for enabling evanescent coupling between the first and second waveguides.

Owner:ETH ZZURICH

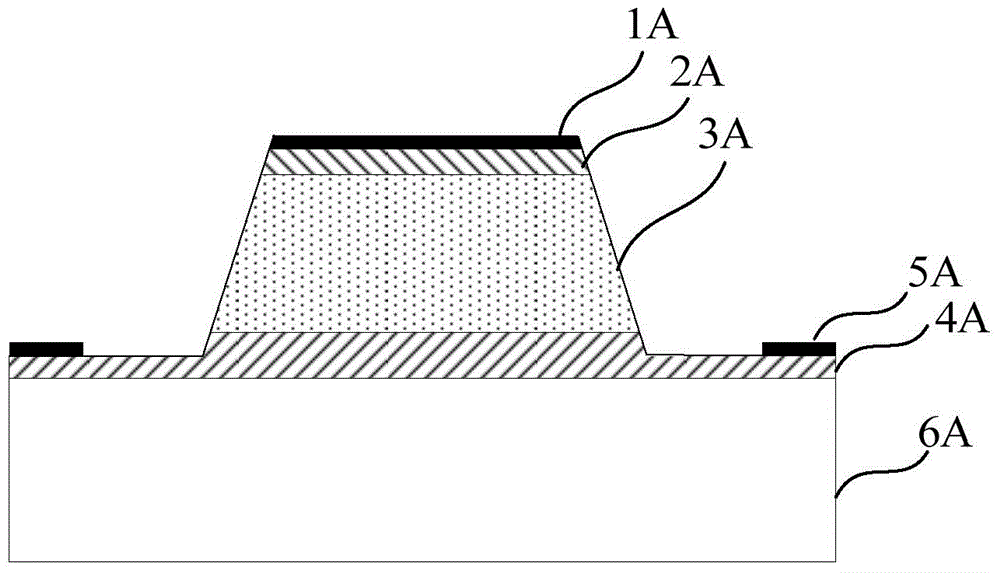

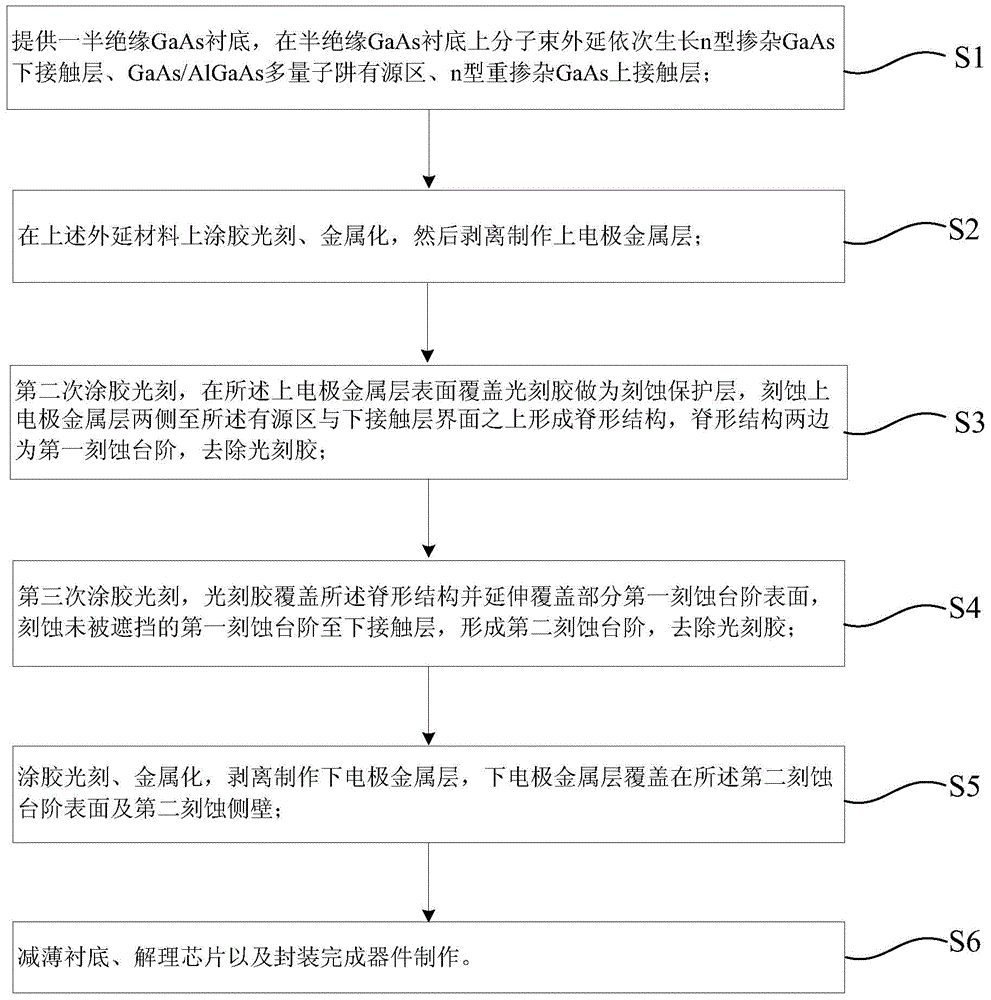

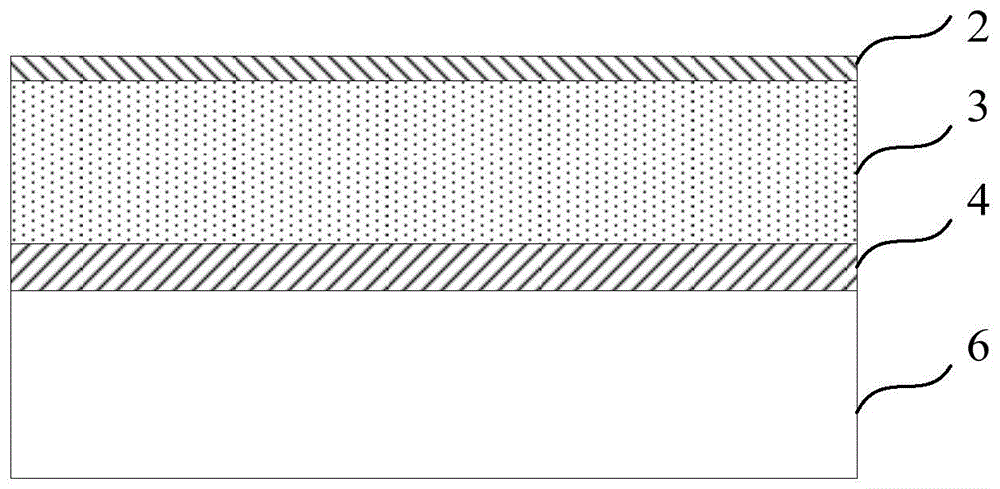

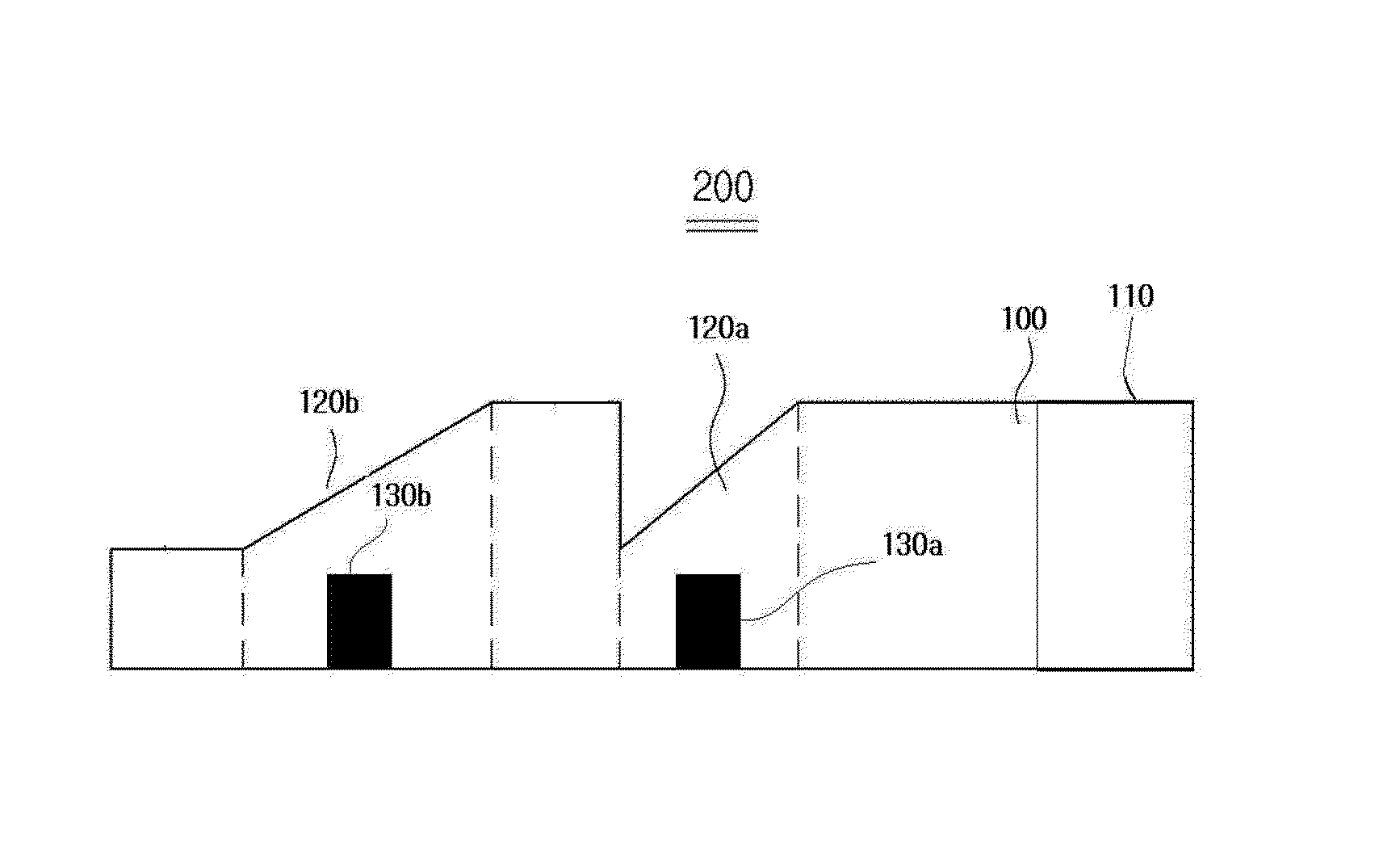

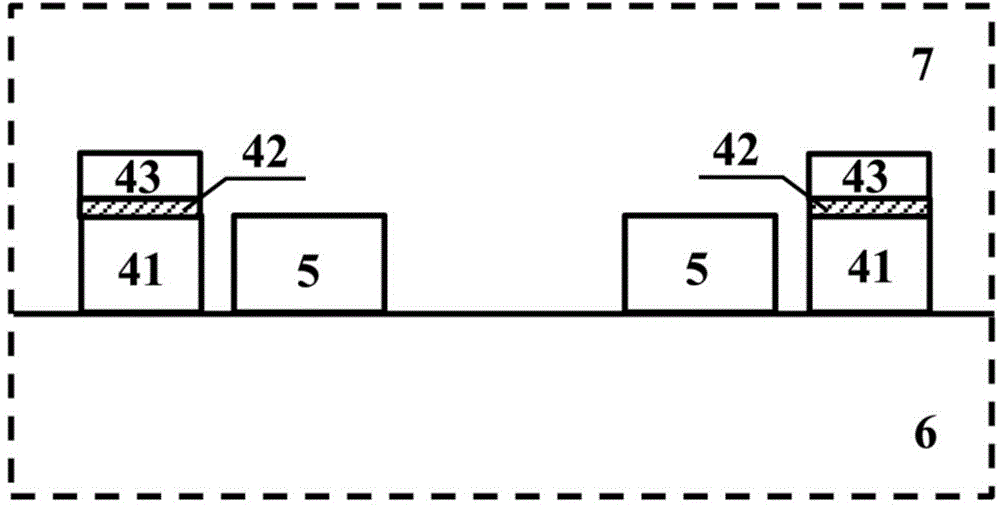

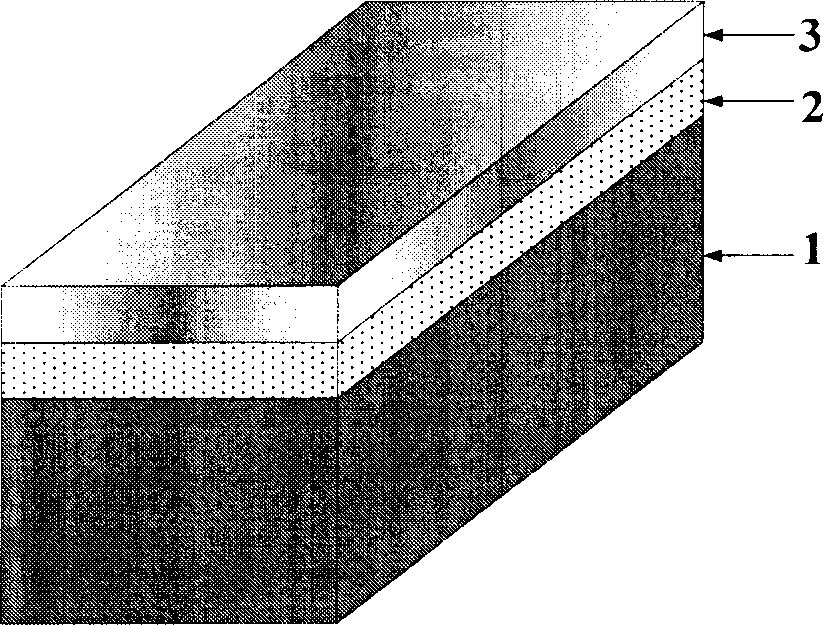

Manufacturing method of semi-insulating surface plasma waveguide Terahertz quantum cascaded laser device

ActiveCN105449521AImprove yieldGood electrical contactOptical wave guidanceLaser detailsEtchingContact layer

The invention relates to a manufacturing method of a semi-insulating surface plasma waveguide Terahertz quantum cascaded laser device. The manufacturing method at least comprises the steps that: a molecular beam epitaxy grows a lower contact layer, a multiple quantum well active region and an upper contact layer on a semi-insulating GaAs substrate in sequence; an upper electrode metal layer is manufactured on epitaxial materials through photoetching, metalizing and stripping; a photoresist covers the upper electrode metal layer, and the active region is etched to form a ridge structure; the photoresist covers the entire ridge structure, the parts from the uncovered region to the lower contact layer are etched; a lower electrode metal layer is manufactured on both sides of a ridge waveguide through photoetching, metalizing and stripping; and the substrate is thinned, a chip is cleaved and the packaging is completed. The etching of the ridge waveguide is carried out in two steps, the two steps of etching form two downward steps, and the lower electrode metal layer covers the second etched step and second etched side walls to achieve good electrical contact between the lower electrode metal layer and the lower contact layer. The manufacturing method reduces requirements on etching thickness precision and evenness of ridge waveguide manufacturing through adding one step of photoetching process, increases rate of finished products in device processing, and reduces transverse series resistance introduced by the contact layers.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Surface-plasmon index guided (SPIG) waveguides and surface-plasmon effective index guided (SPEIG) waveguides

ActiveUS7184641B2Enhanced couplingNanoopticsOptical waveguide light guidePlasmonic waveguideCoupling

Owner:MASSACHUSETTS INST OF TECH

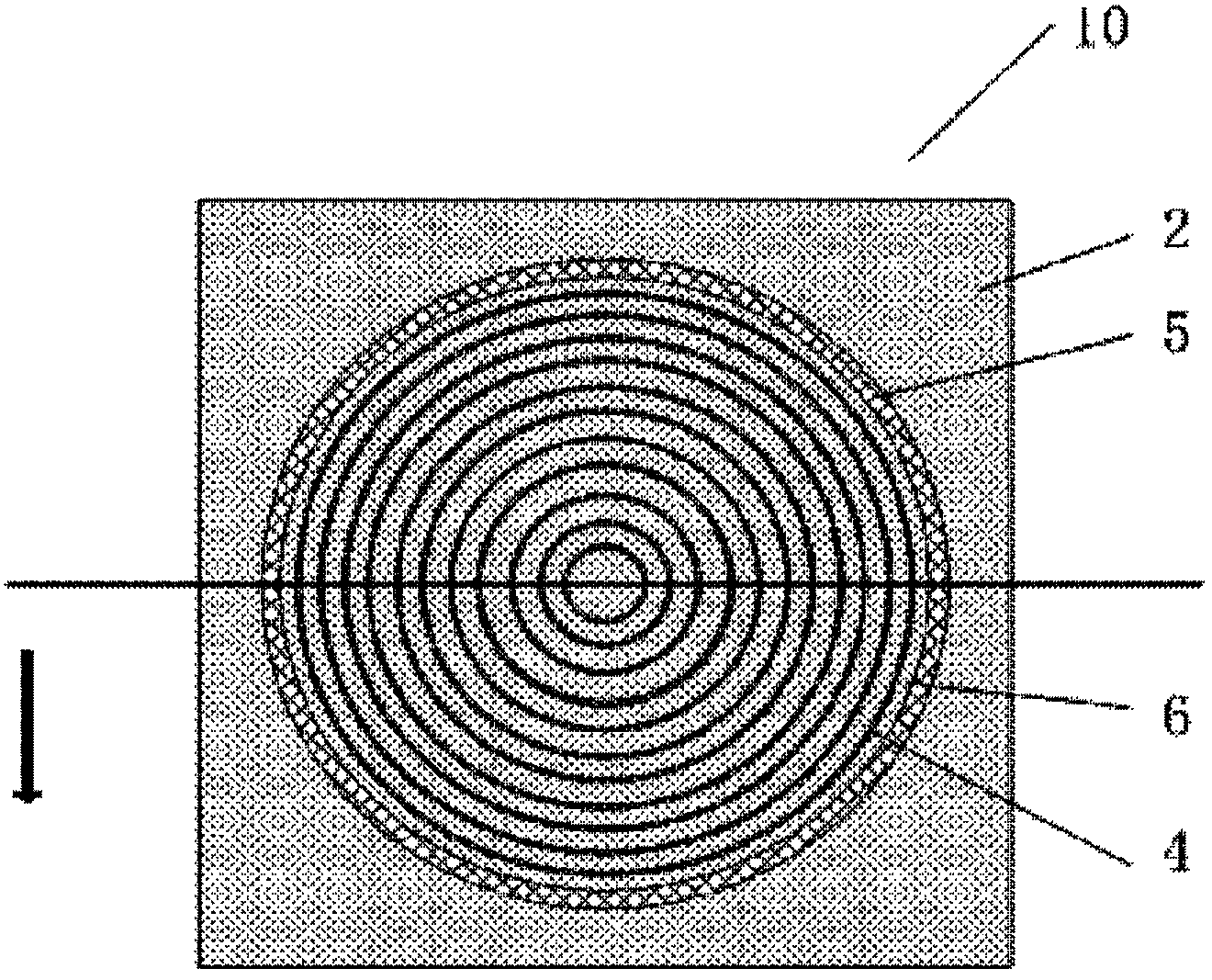

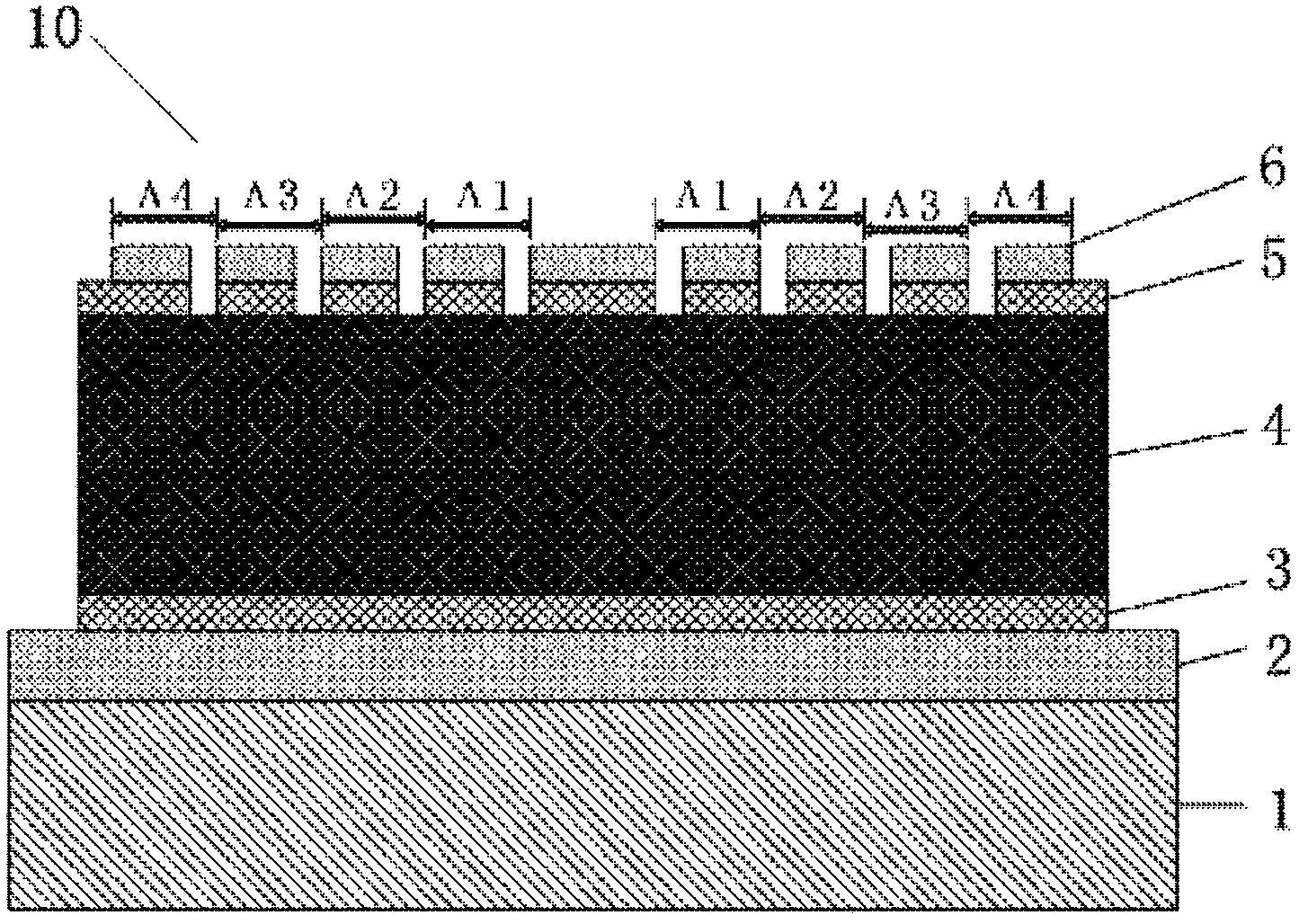

High-power low-divergence-angle semiconductor terahertz vertical plane emitting laser

ActiveCN103633559AImproved far-field divergenceIncrease surface emission output powerLaser detailsLaser output parameters controlVertical planeGrating

A high-power low-divergence-angle semiconductor terahertz vertical plane emitting laser comprises a highly-doped receiving substrate, a lower metal waveguide optical confinement layer, a lower contact layer, an active layer, an upper contact layer and an upper metal layer. The lower metal waveguide optical limit layer is formed by metal thermal bonding and located on the receiving substrate. The lower contact layer is located on the lower metal waveguide optical confinement layer. The active layer grows on the lower contact layer. The upper contact layer grows on the active layer and is made into a quasi-periodic geometric progression concentric circle grating structure. The upper metal layer is disposed on the upper contact layer through electron beam evaporation and made into a quasi-periodic geometric progression concentric circle grating structure. The lower metal layer and the lower contact layer form a lower plasma waveguide. The upper metal layer and the upper contact layer form an upper plasma waveguide. The upper plasma waveguide and the lower plasma waveguide form a double-sided metal waveguide structure. The lower contact layer, the active layer, the upper contact layer and the upper metal layer are made into an annular structure, and the annular active layer form an annular resonant cavity.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

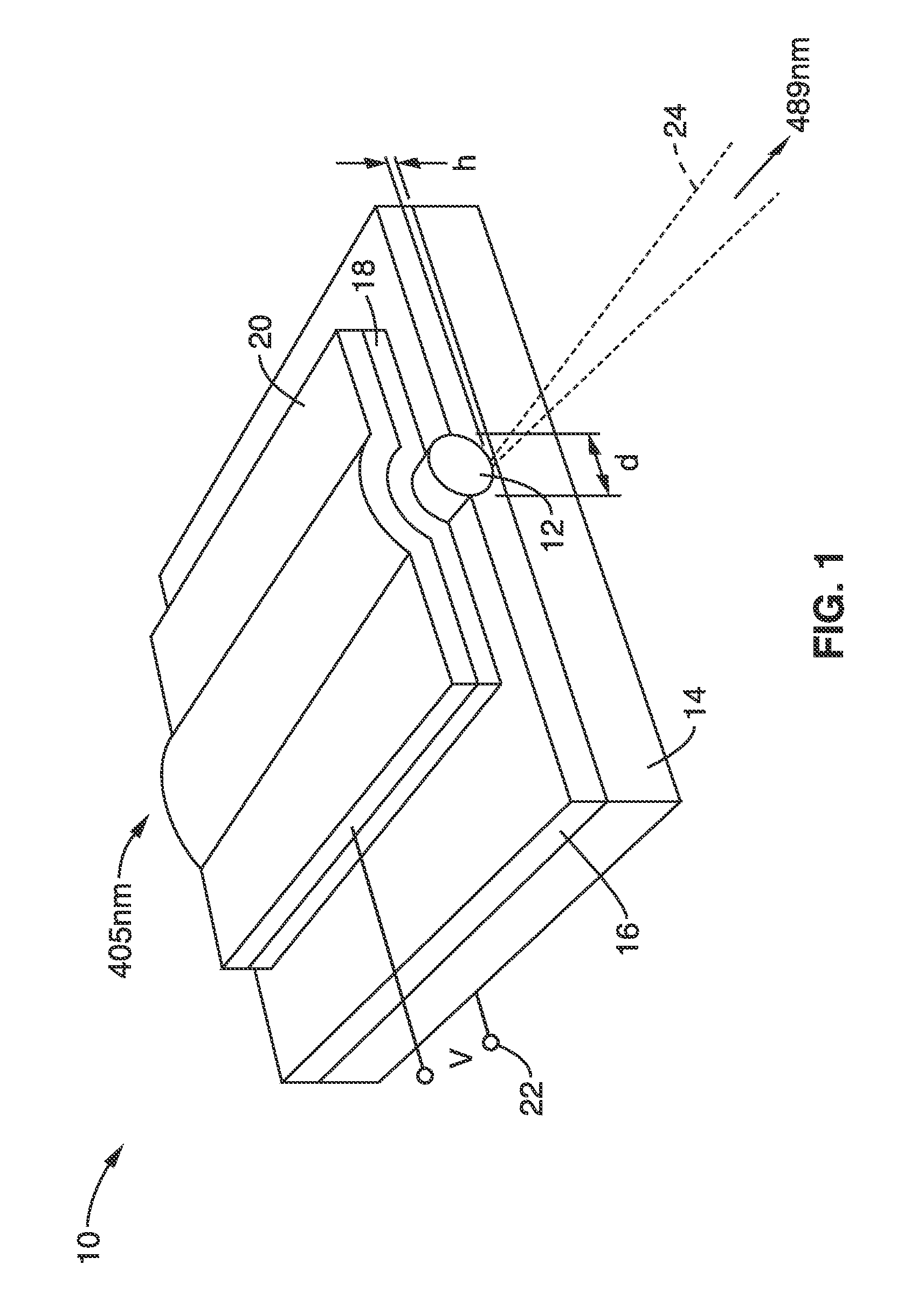

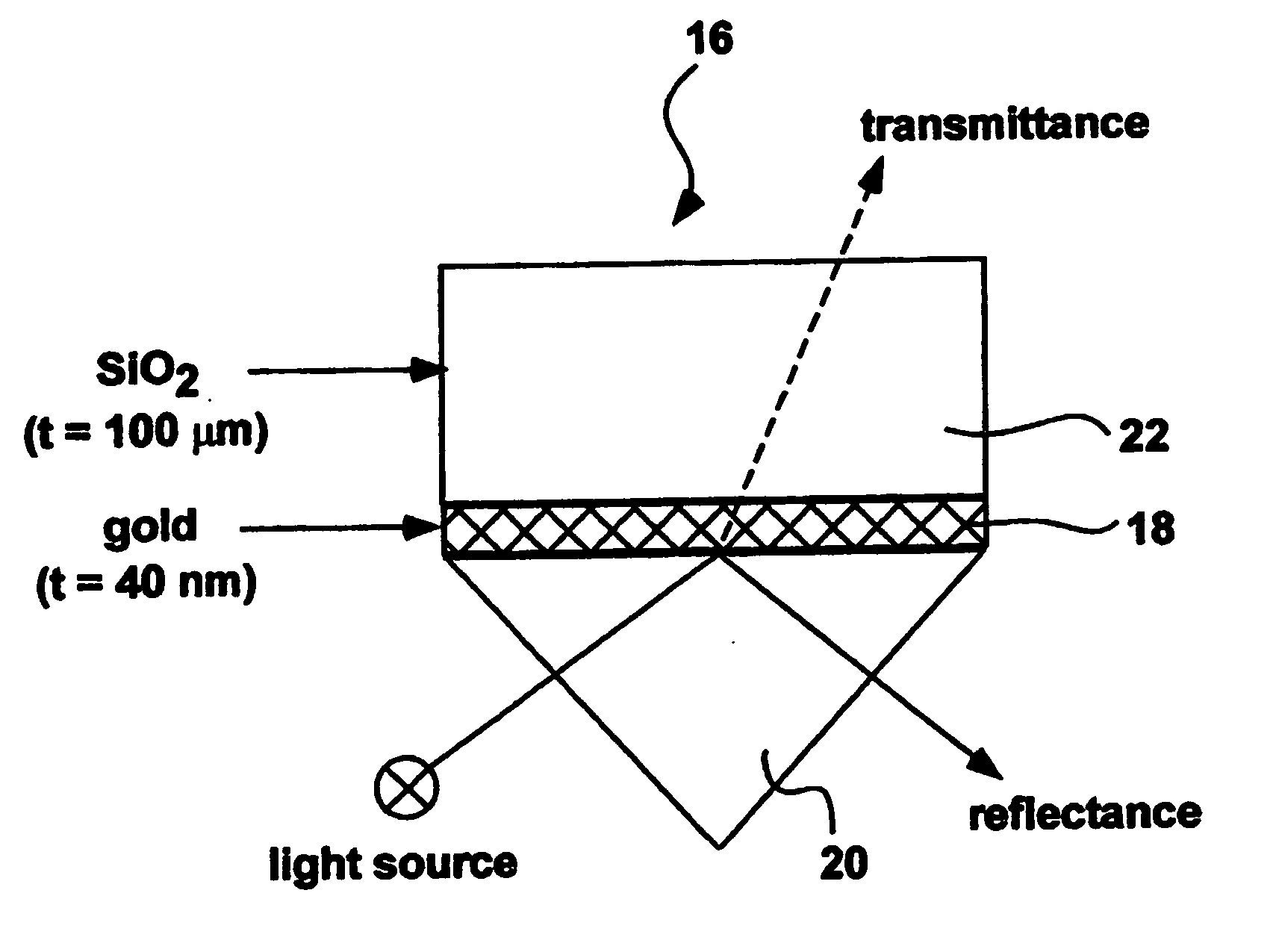

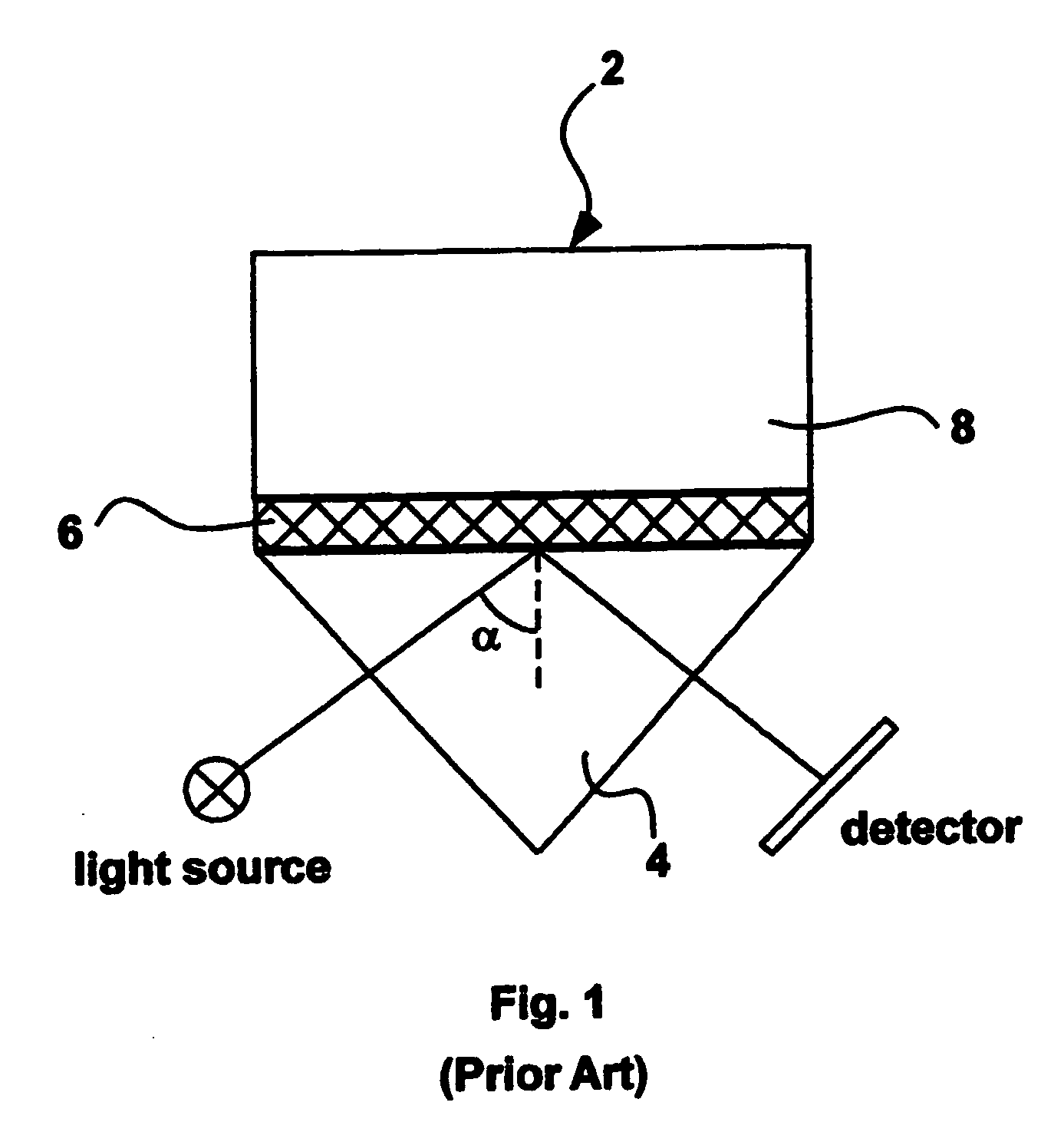

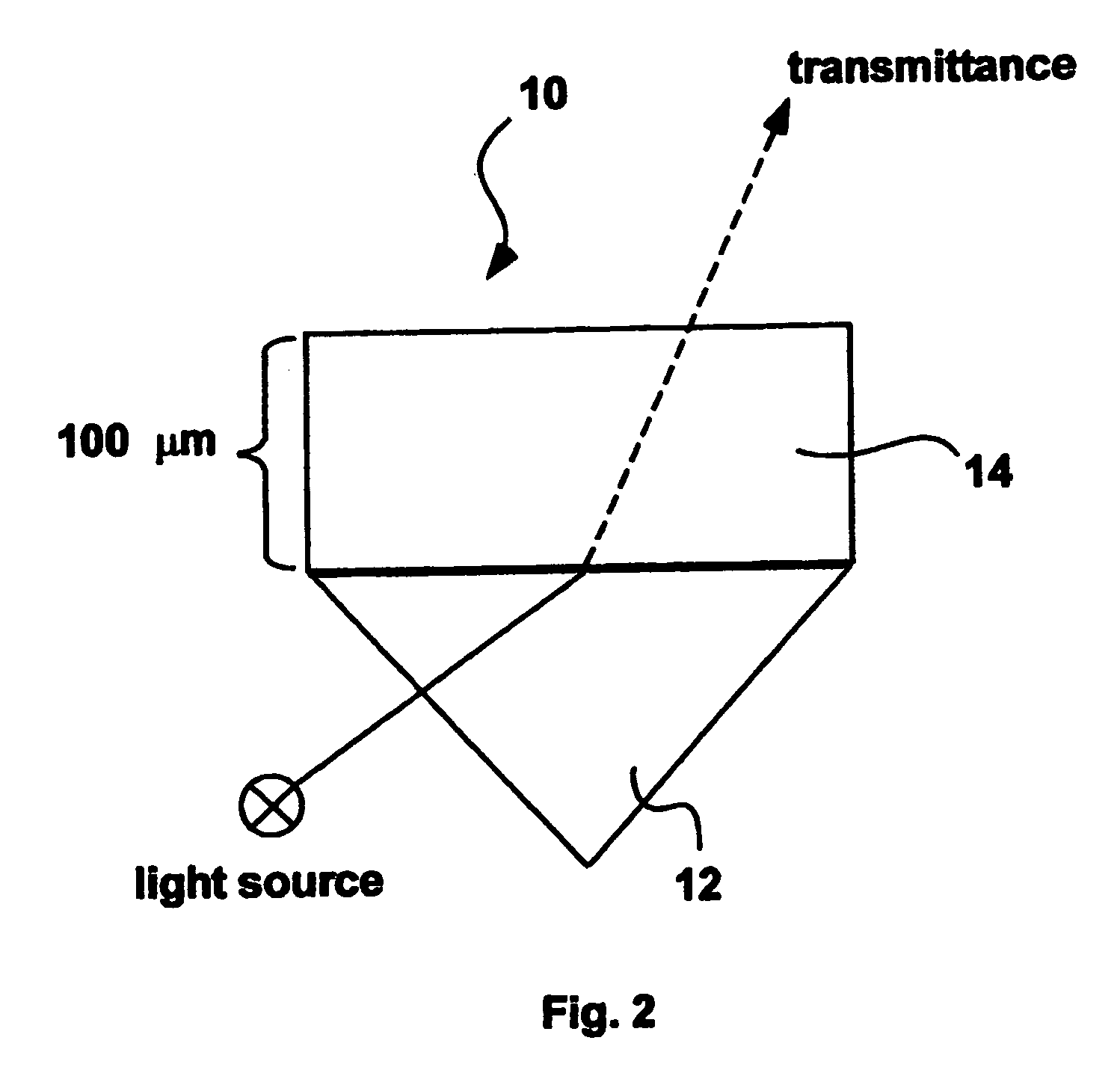

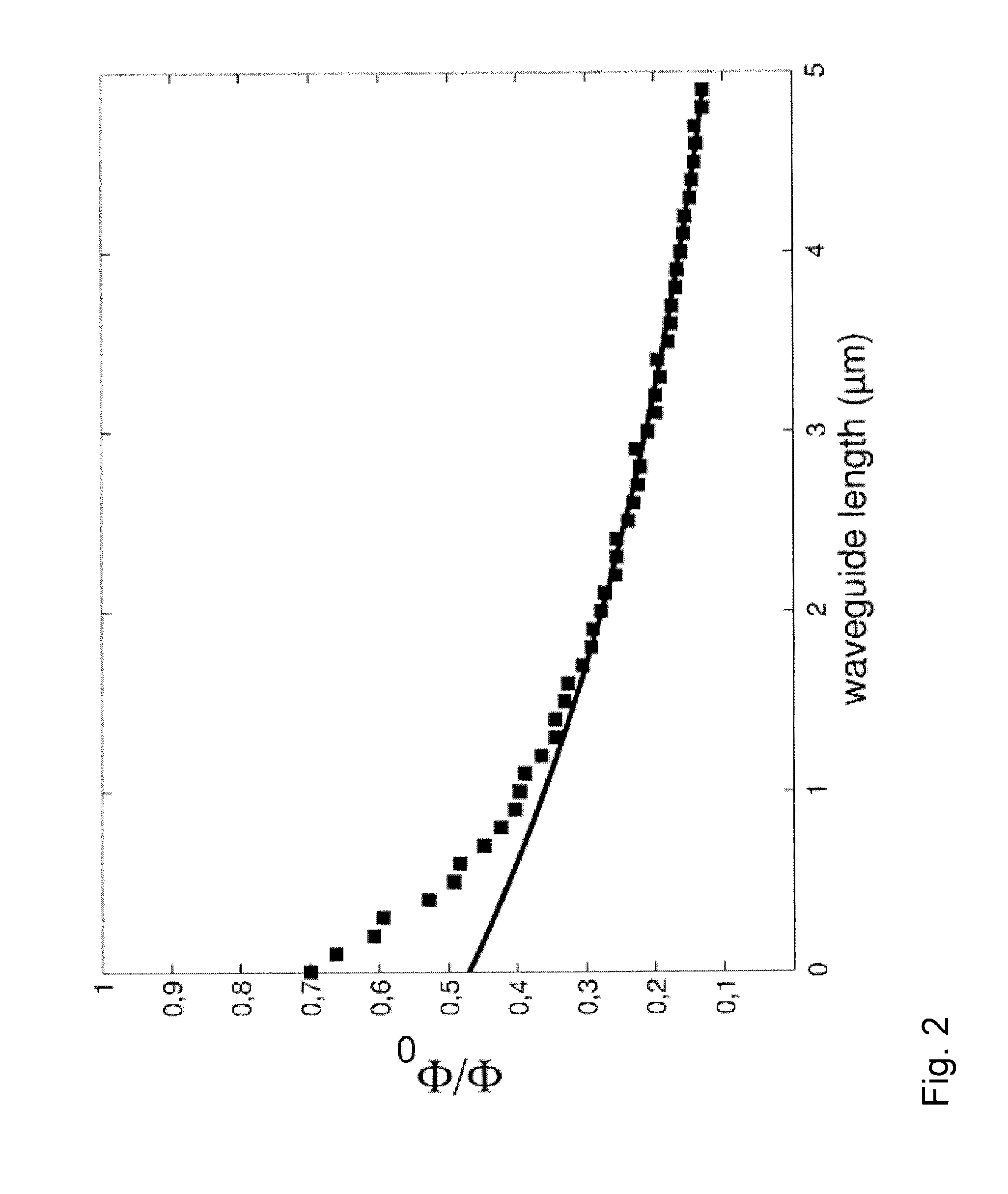

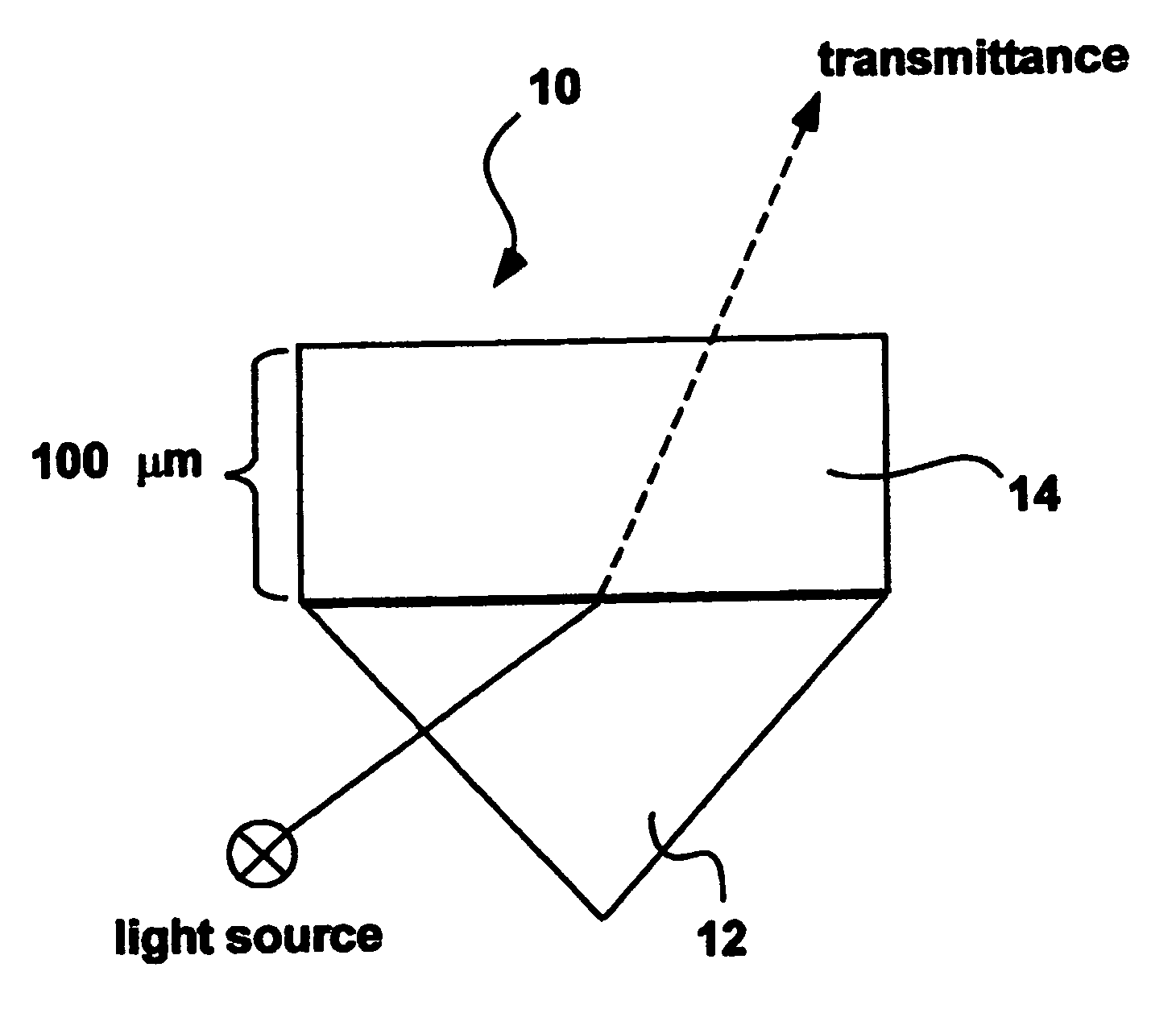

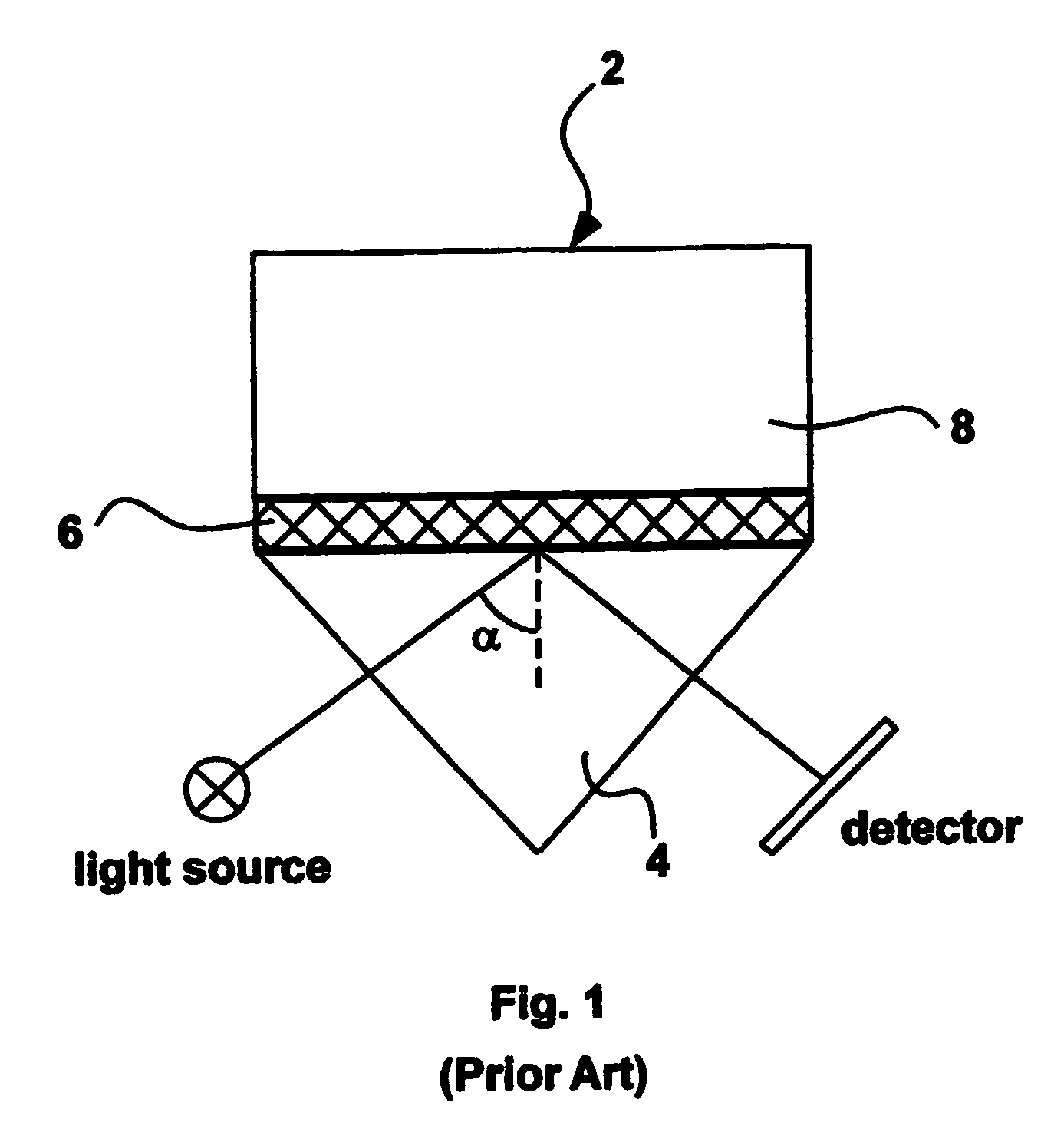

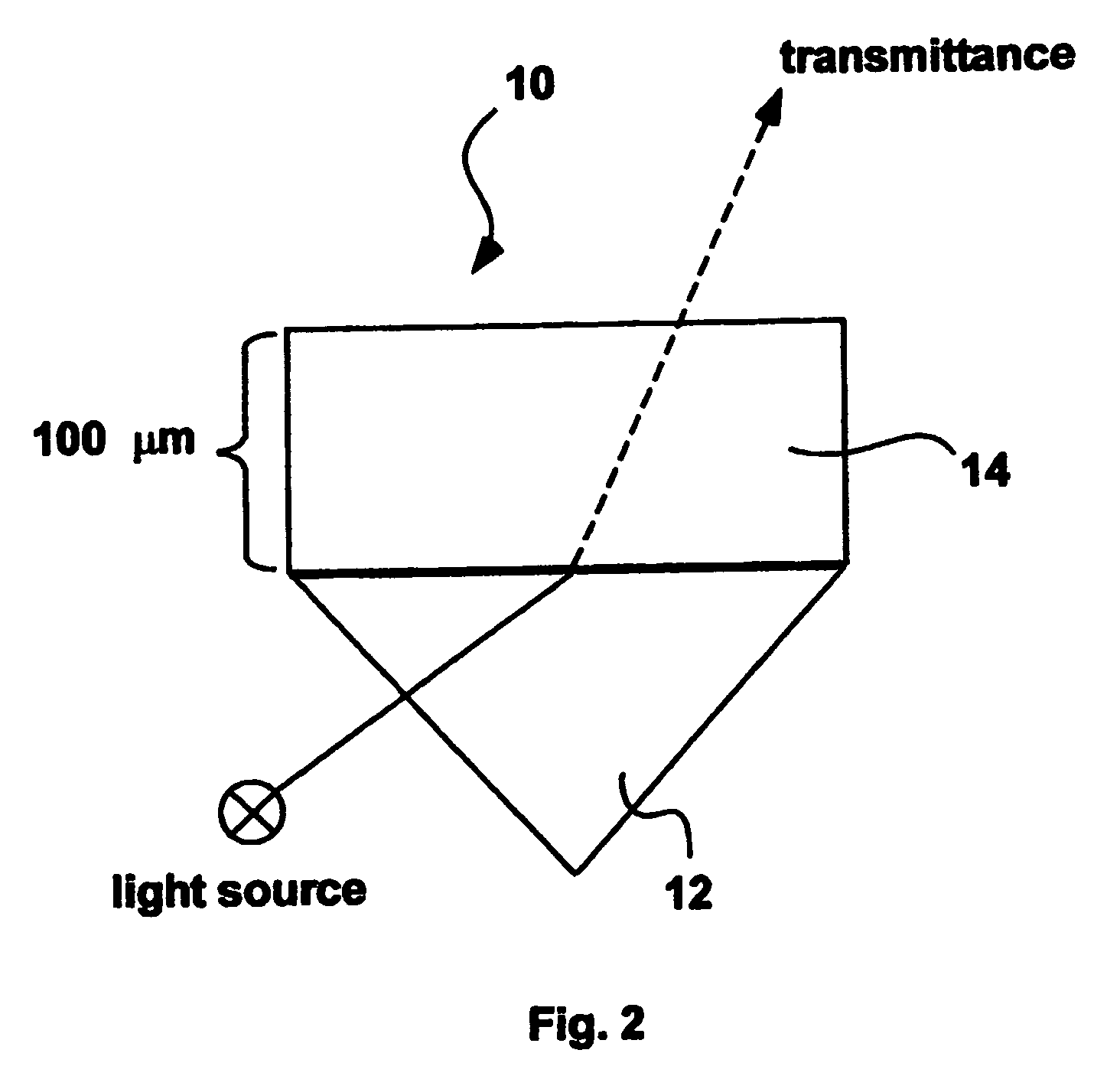

Sensor device for interference and plasmon-waveguide/interference spectroscopy

InactiveUS20070030489A1Improve observabilityAvoid damageRadiation pyrometryInterferometric spectrometryDielectricPlasmonic waveguide

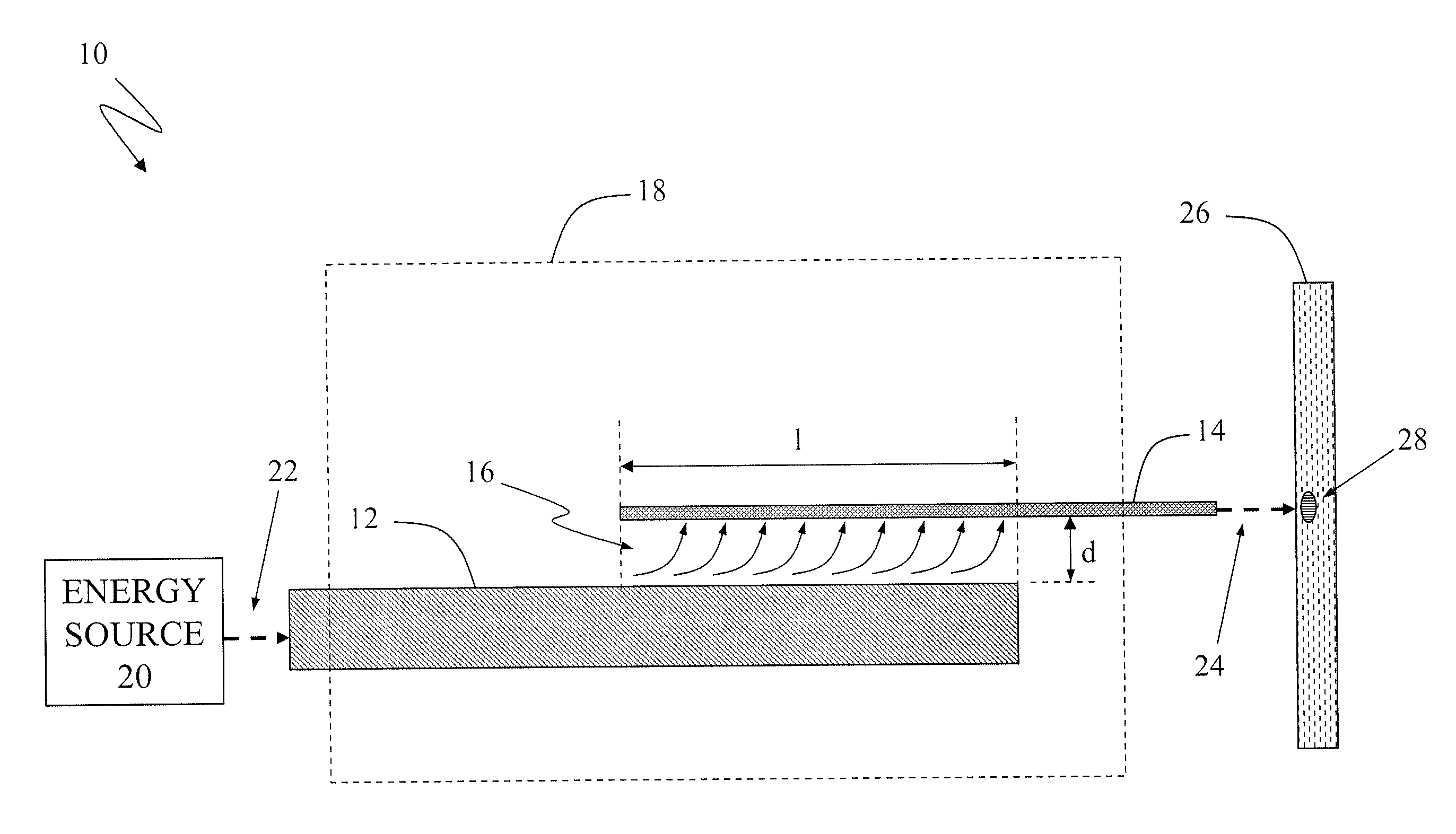

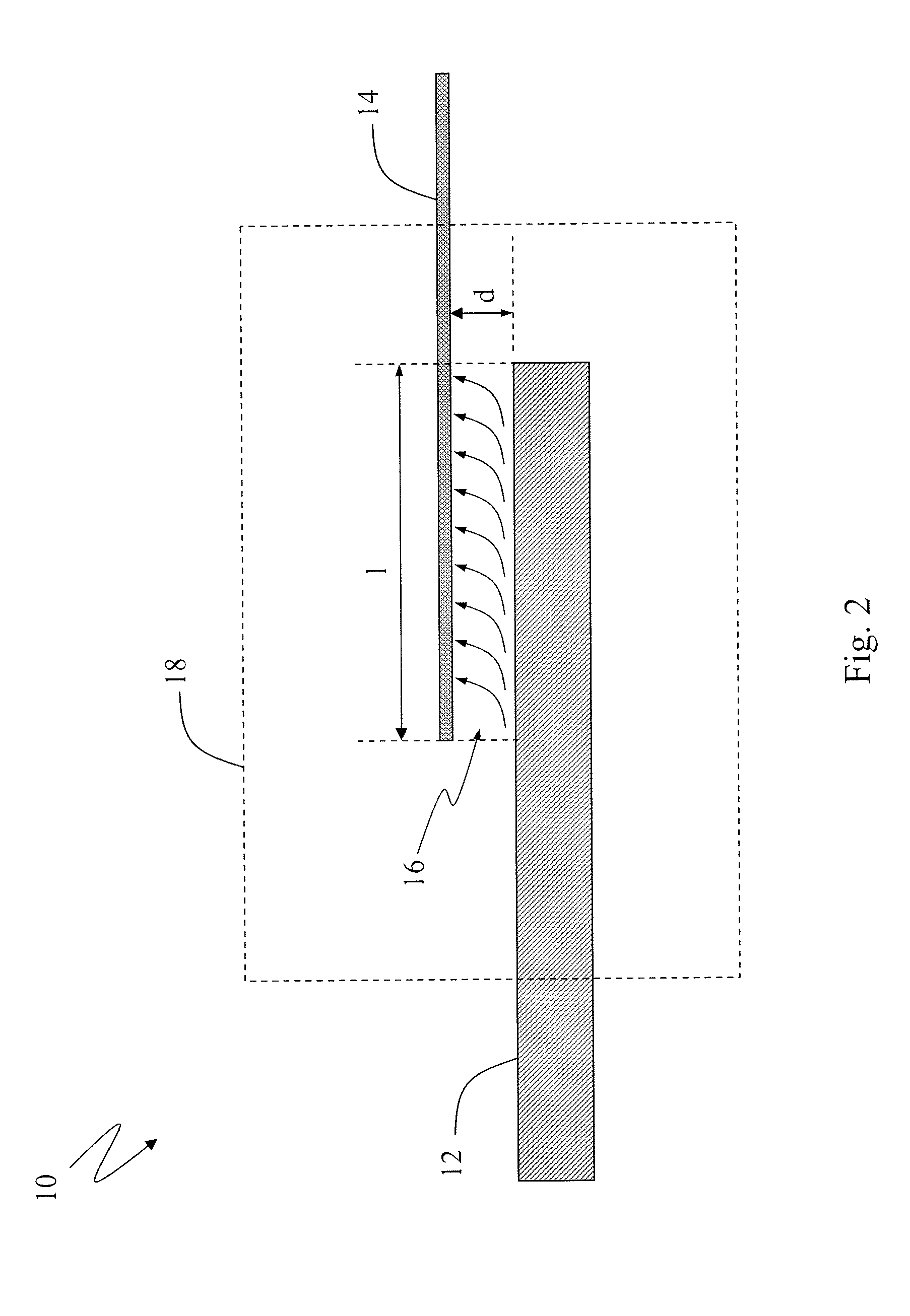

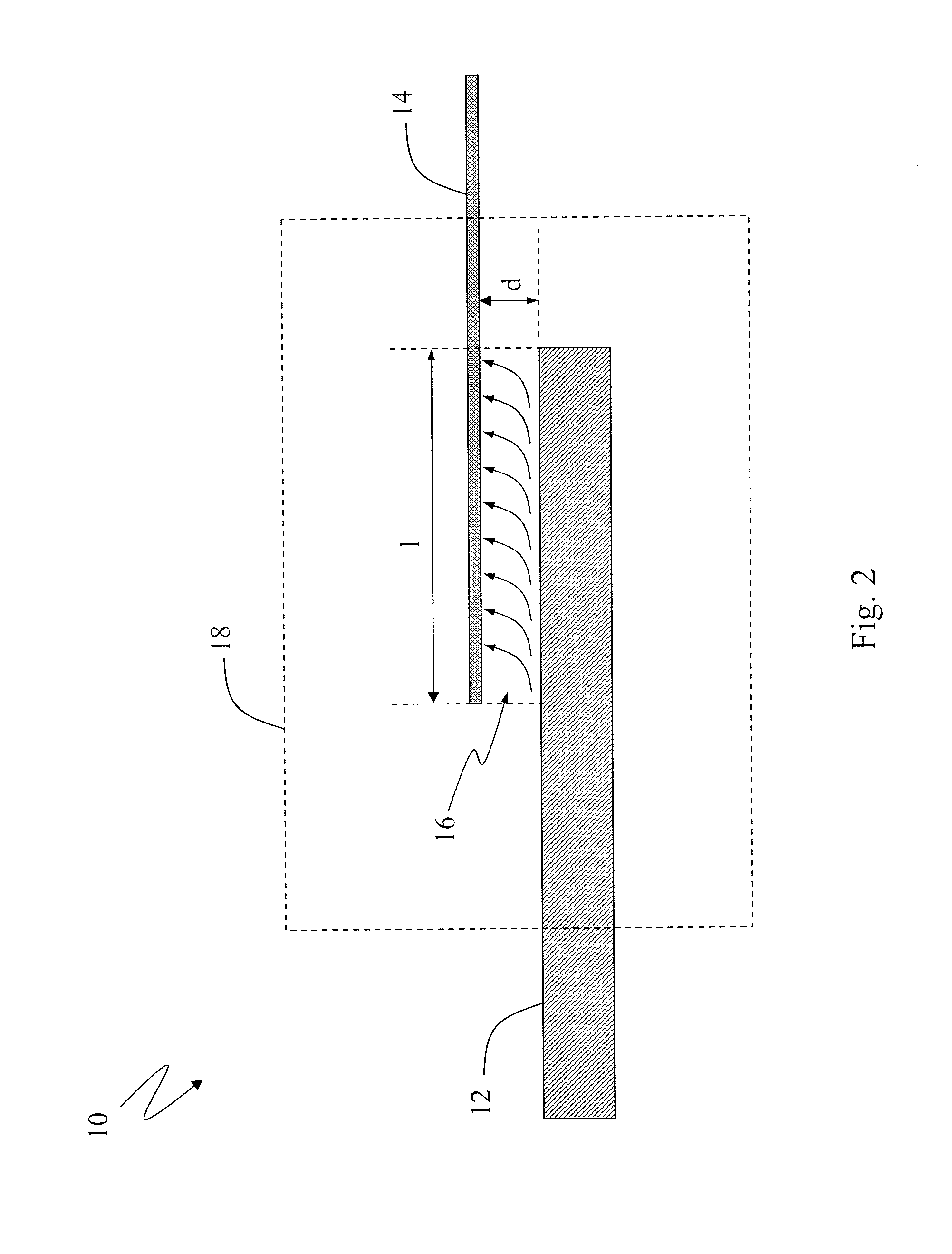

Methods for measuring a property of a sample material present at an interface of an emerging medium in a spectroscopic device include a sensor (10) featuring at least one dielectric member (14) disposed upon a entrant medium (12), with the dielectric member being of an optical thickness selected to produce an observable interference effect for an incident angle of light below the critical angle of total internal reflection at the interface with the dielectric member (14). The dielectric member (14) of the sensor device (10) may be modified and functionalized for binding of a sample analyte by disposing a sensing surface area (38, 40, 42) upon it. Moreover, an metal layer (18) may be added to an entrant medium (20) to produce a sensor (16) that generates observable optical phenomena both above (resonance) and below (interference) a given critical angle.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

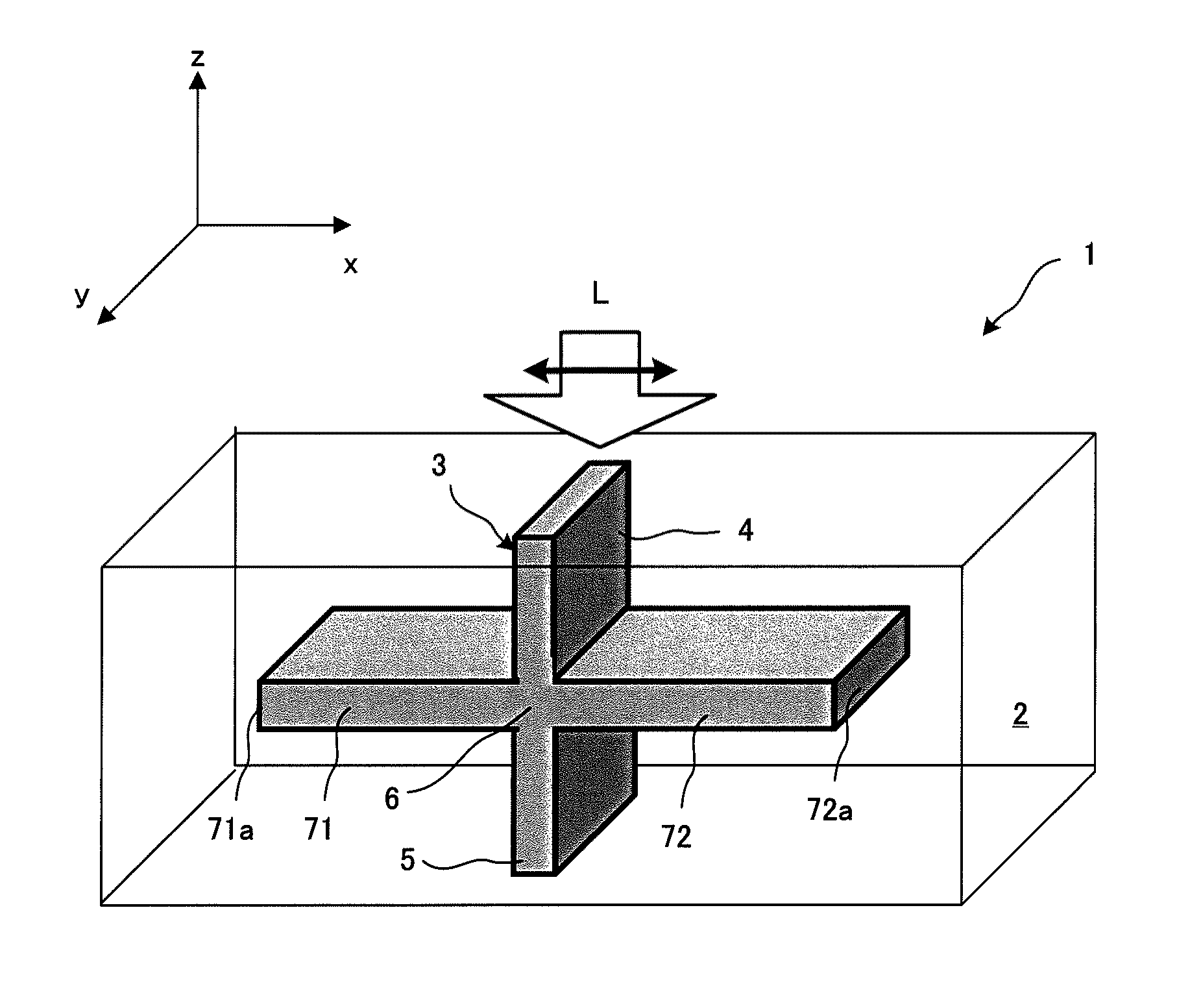

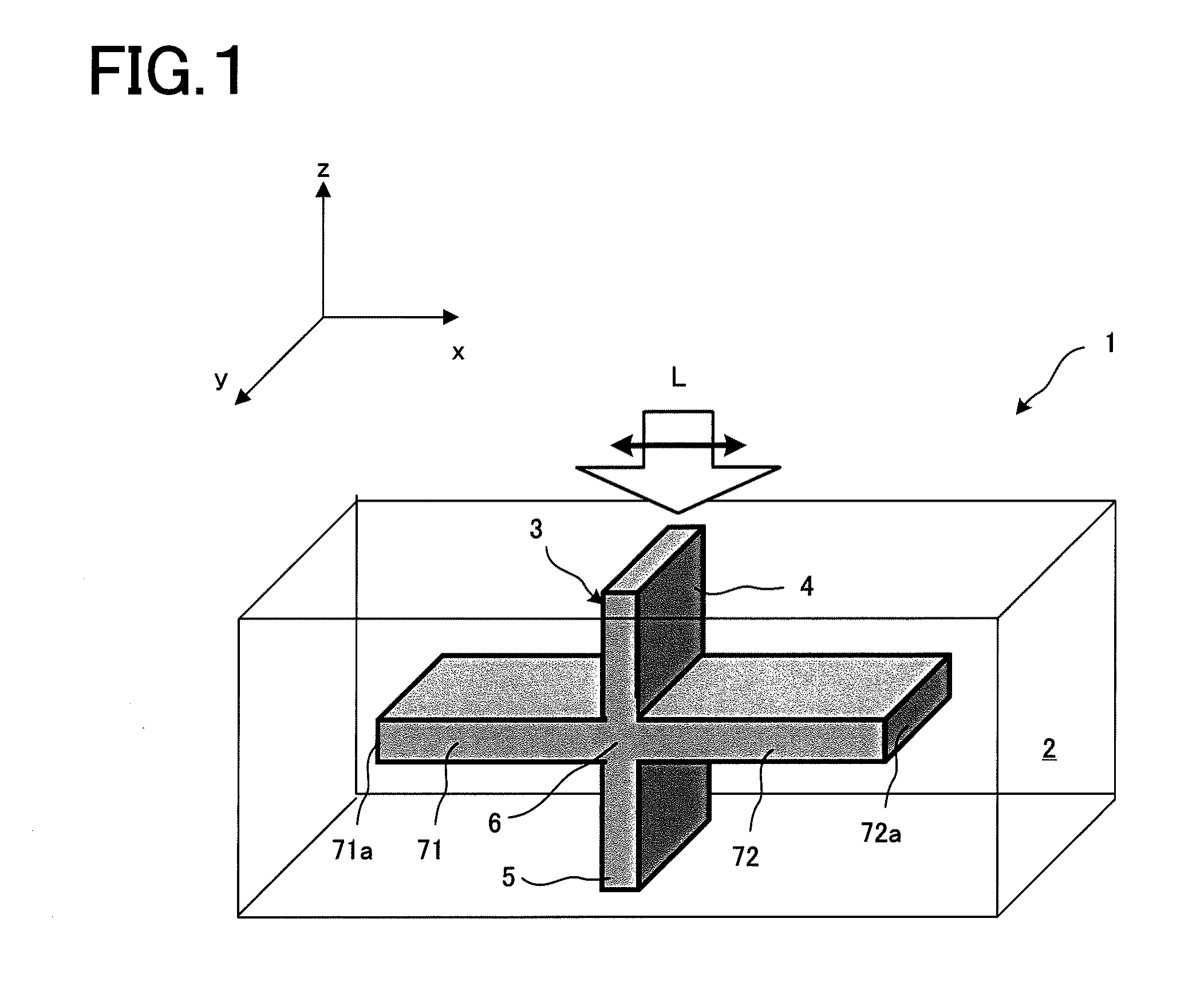

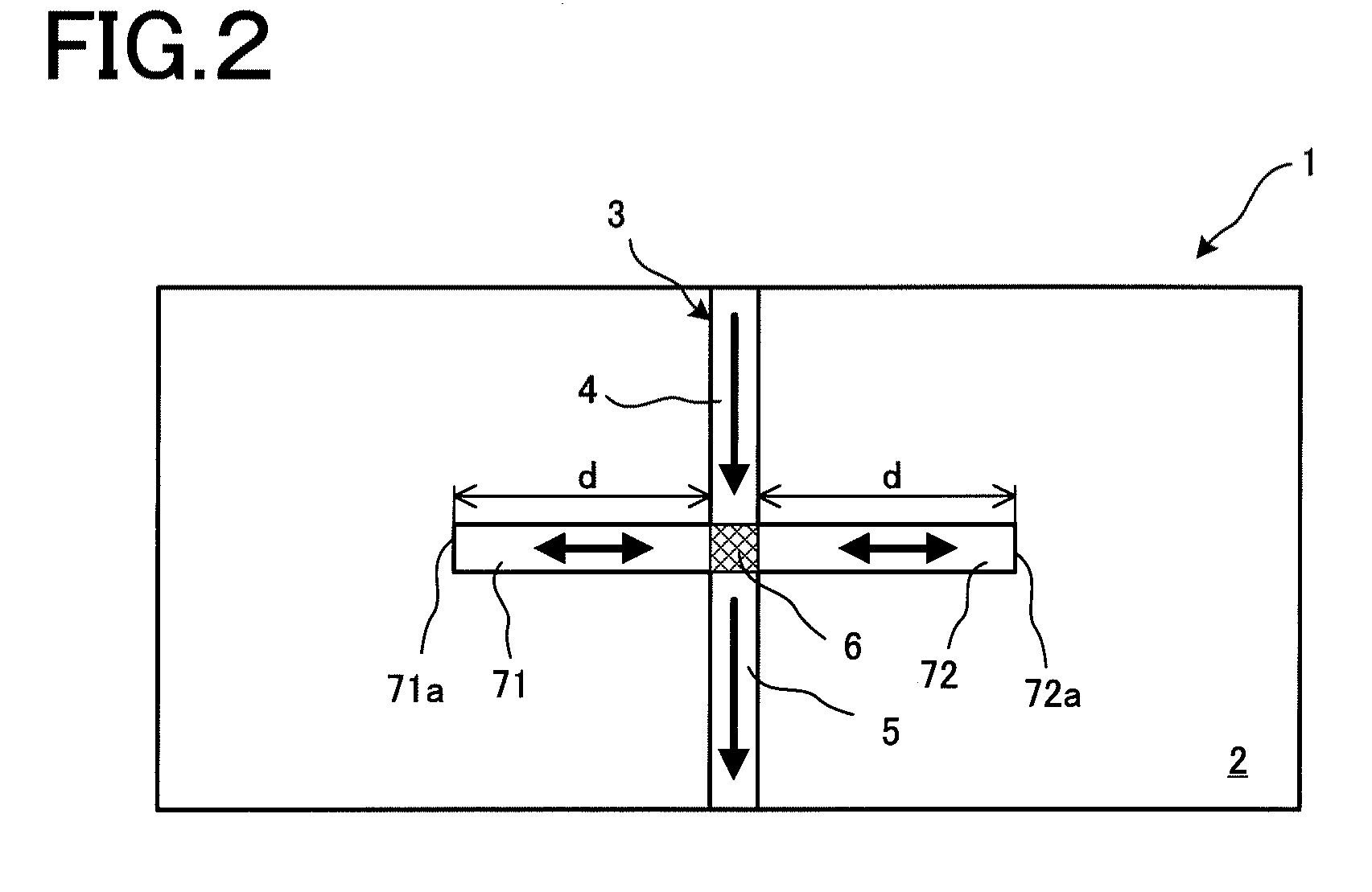

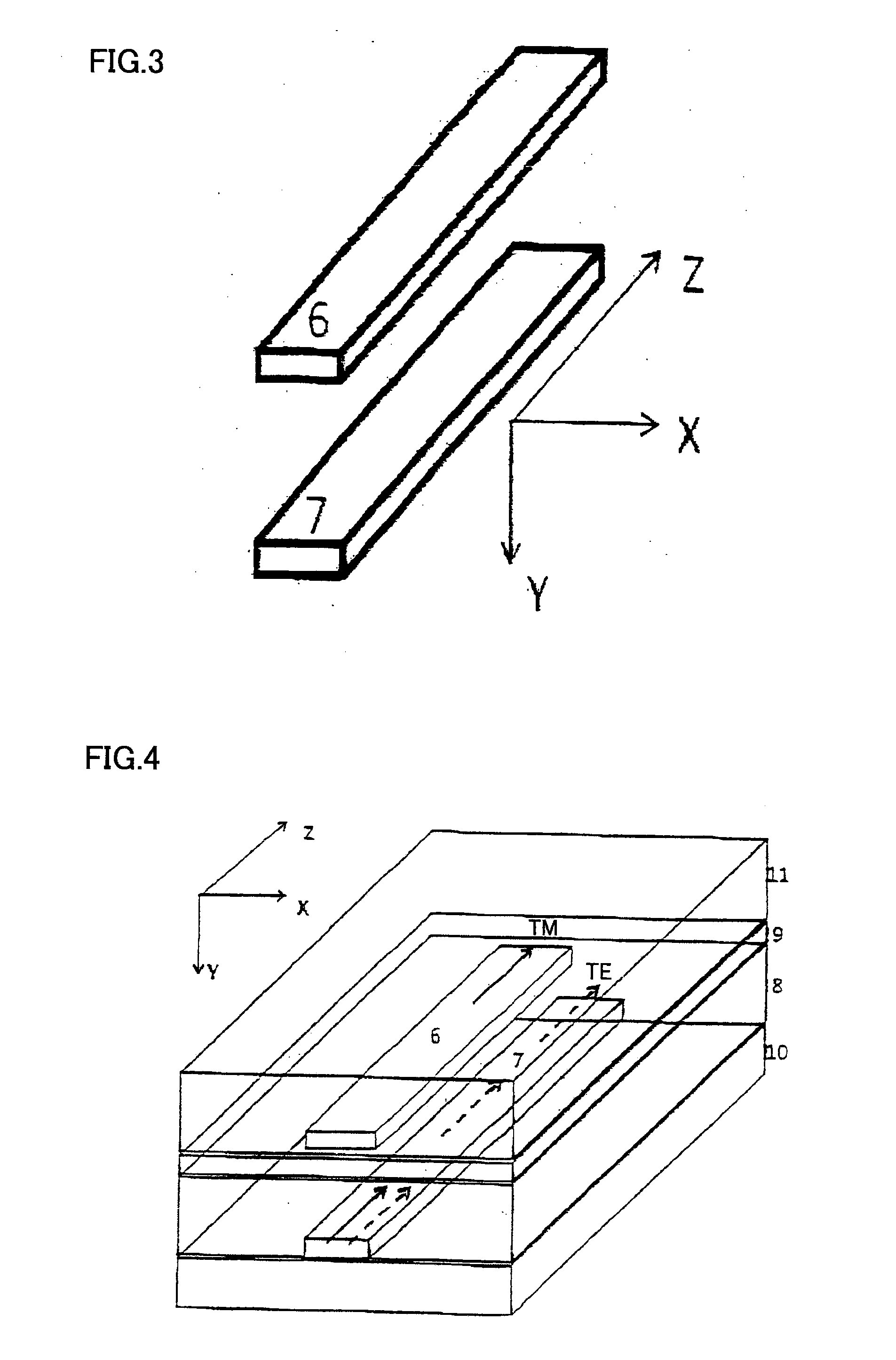

Plasmon waveguide and optical element using the same

InactiveUS20110103742A1Simple structureGood wavelength selectivityCladded optical fibreNanoopticsPlasmonic waveguideLength wave

Disclosed is a plasmon waveguide including cladding (2) consisted of metal, and a dielectric core (3) which is formed of a transparent material, surrounded by or sandwiched by the cladding (2), and has at least one cross-section having a thickness no more than the wavelength of the incident light. The plasmon waveguide is provided with: a incident-side plasmon waveguide (4) into which light (L) is incident; an emission-side plasmon waveguide (5) from which light (L) is emitted; a connection portion (6) connecting the incident-side plasmon waveguide (4) and emission-side plasmon waveguide (5); and a plasmon interference structure (7) which extends from the connection portion (6) in the direction intersecting the incident-side plasmon waveguide (4) or the emission-side plasmon waveguide (5), and has a terminal (7a) at which light (L) is reflected.

Owner:KEIO UNIV

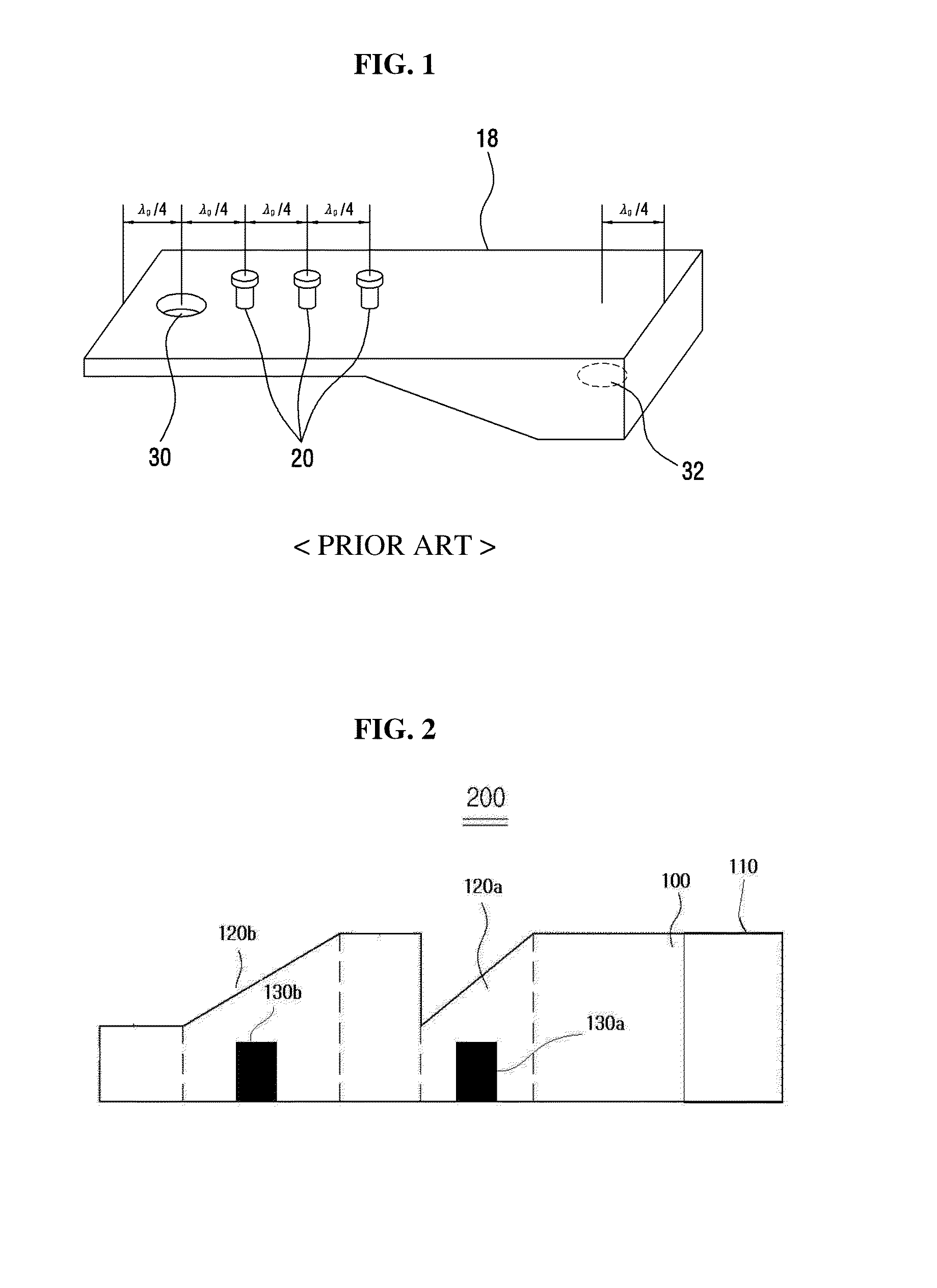

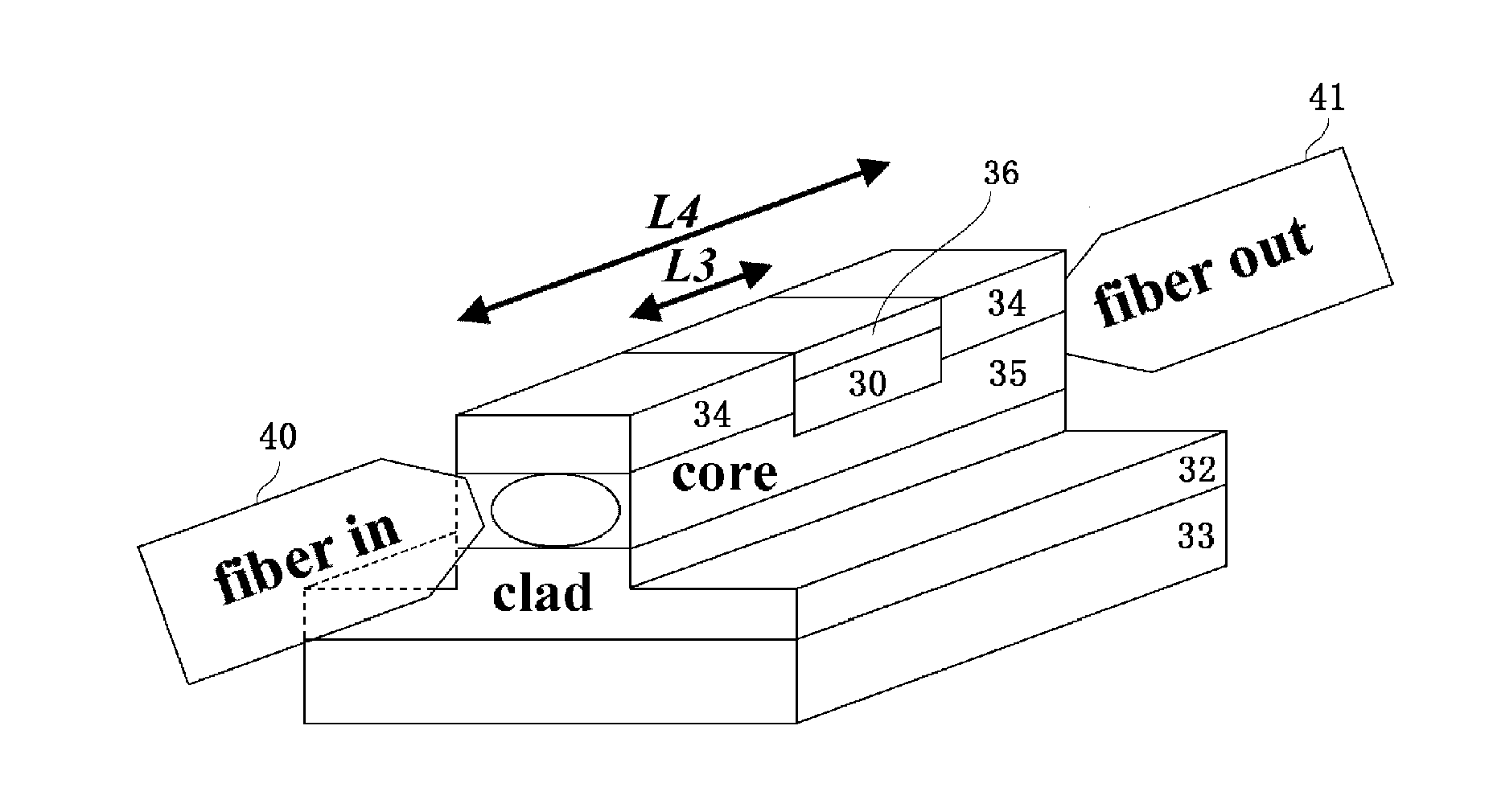

Plasma wavguide using step part and block part

ActiveUS20140292195A1Improved economic and technical efficiencyMaximize the effectMultiple-port networksStructural circuit elementsPlasmonic waveguideMicrowave

In a magnetron and a plasma waveguide through which a microwave oscillated from the magnetron moves, there is provided a plasma waveguide including a plurality of step parts formed at any one side on an inner side surface of the waveguide, and a block part of a predetermined height formed at any other side on the inner side surface of the waveguide, wherein the block part is formed at a side opposite to a boundary part between the plurality of step parts.

Owner:TRIPLE CORES TECH CO LTD

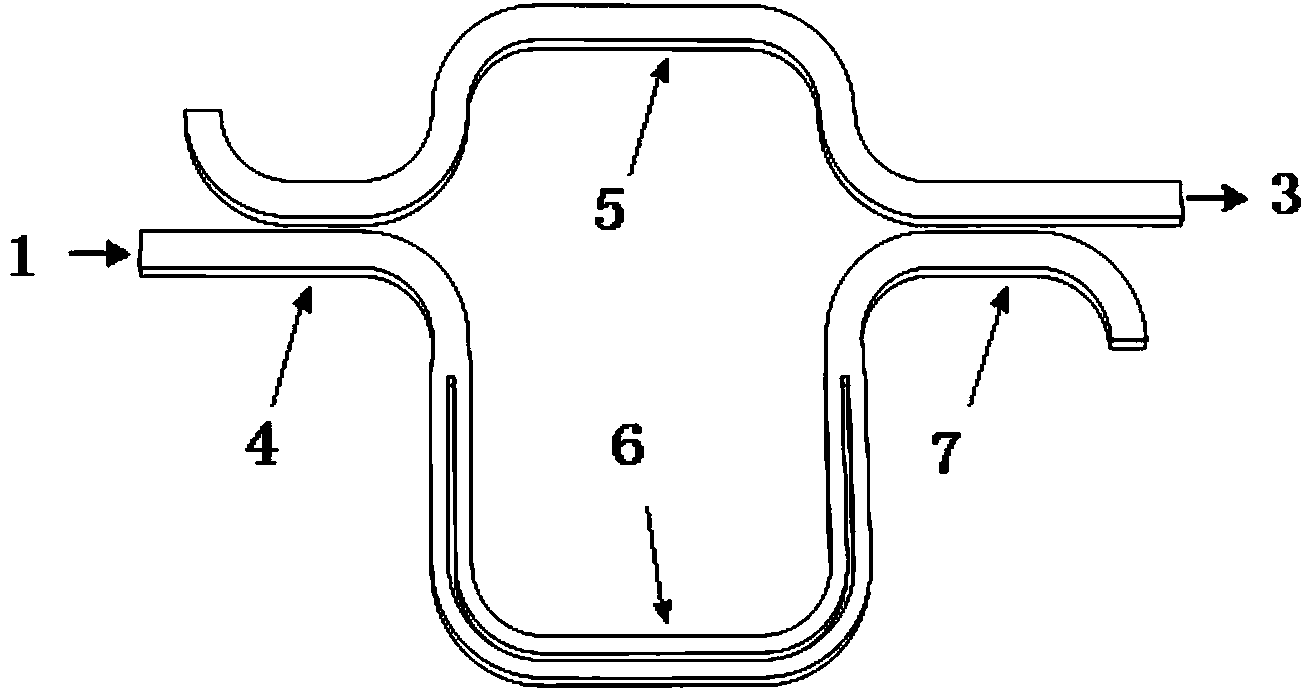

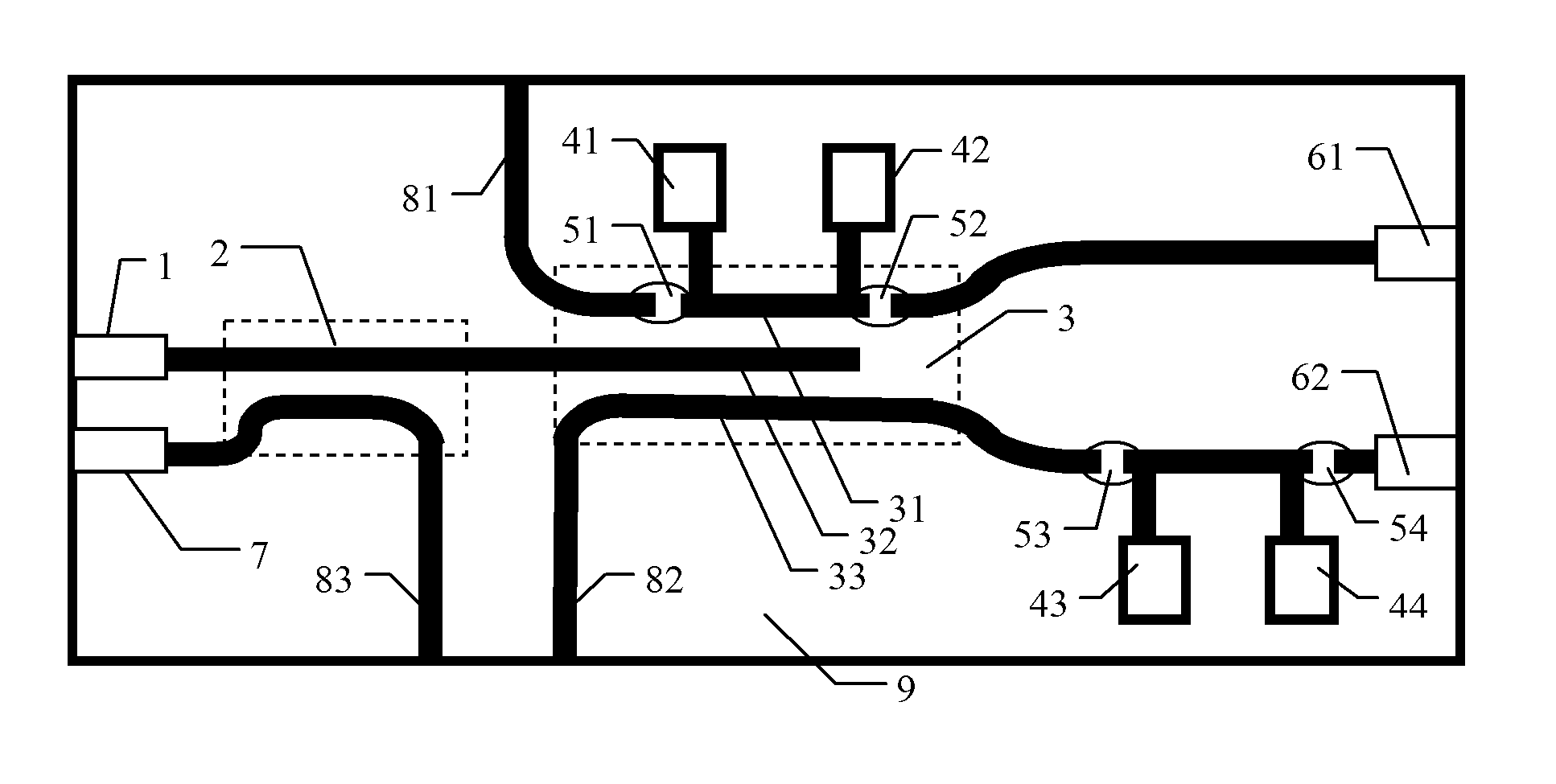

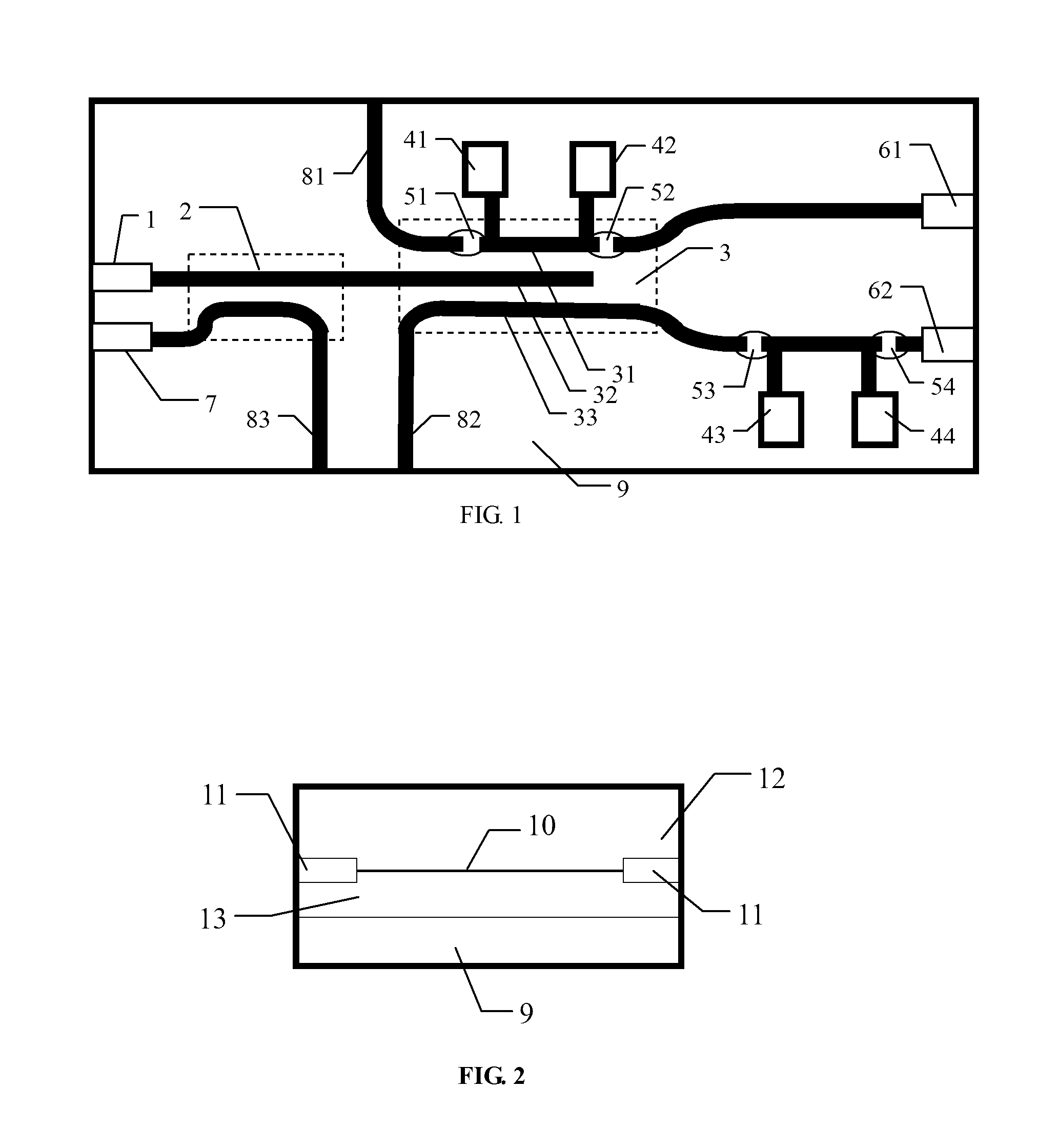

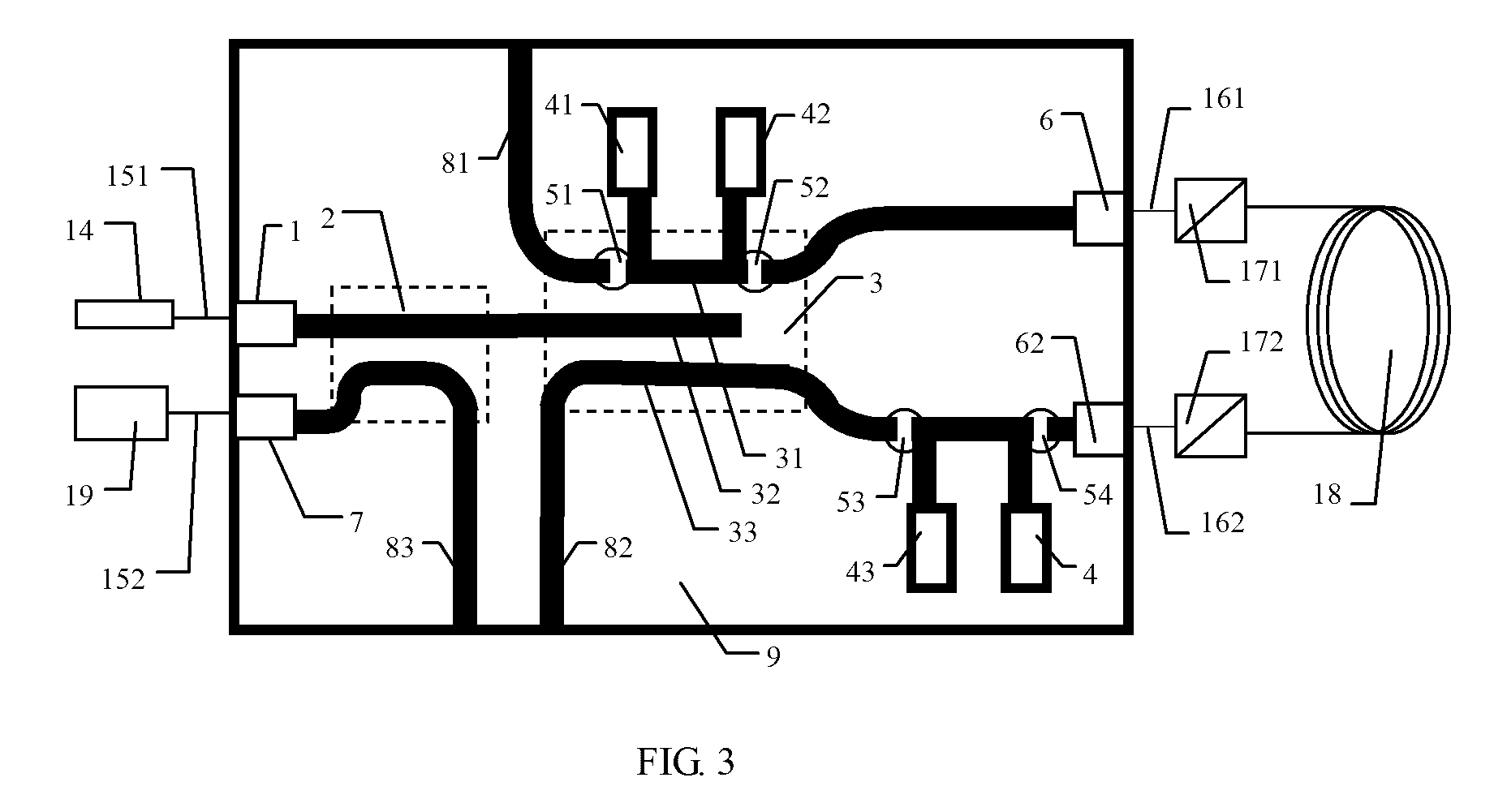

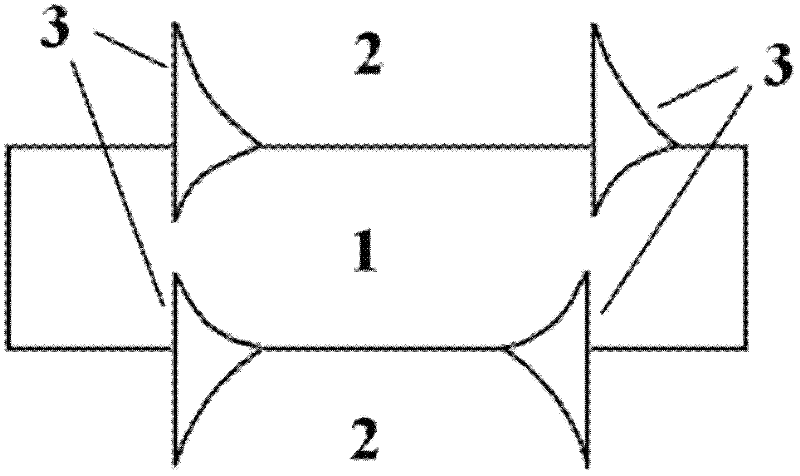

Integrated optical fiber gyroscope chip based on surface plasmon polariton waveguide

ActiveUS20120051691A1Small sizeLow costSagnac effect gyrometersOptical waveguide light guideFiberPlasmonic waveguide

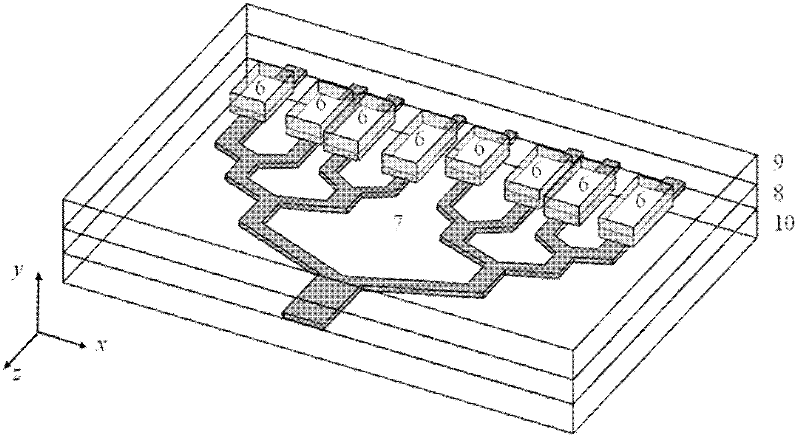

An integrated optical fiber gyroscope chip based on surface Plasmon Polariton waveguide is an integrated optical fiber gyroscope chip in which optical signal is transmitted through the surface Plasmon Polariton waveguide and the polymer optical waveguide which are connected with each other, and it is used in the optical fiber gyroscope field. From the input end to the output end, the optical fiber gyroscope chip sequentially has: an input waveguide (1) and the third output waveguide (7), a directional coupler (2), a symmetrical triple waveguide splitter (3), the first output waveguide (61) and the second output waveguide (62), wherein the input waveguide (1), the first output waveguide (61), the second output waveguide (62) and the third output waveguide (7) are polymer optical waveguides, but the directional coupler (2) and the symmetrical triple waveguide splitter (3) are made from the surface Plasmon Polariton waveguide. The chip utilizes the transmission characteristics of the surface Plasmon Polariton waveguide to realize the single polarization of long-distance transmission of the optical signal, and directly modulates the surface Plasmon Polariton waveguide core layer, and removes influence of the leakage light to the precision of the fiber gyroscope through the specific structure.

Owner:SOUTHEAST UNIV

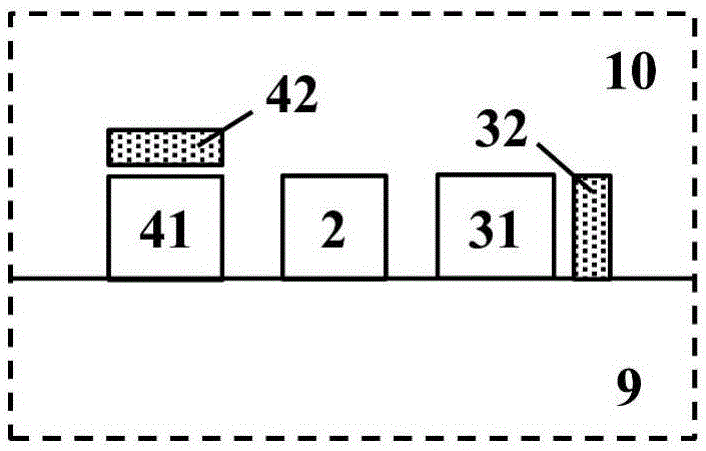

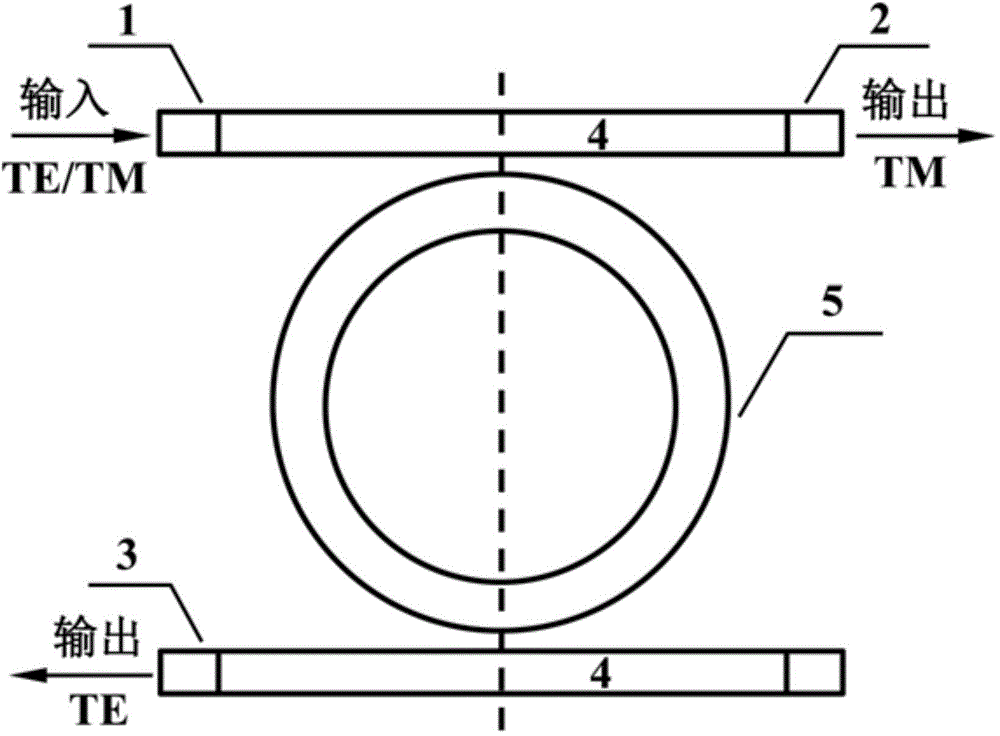

Silicon-based microring polarization demultiplexer

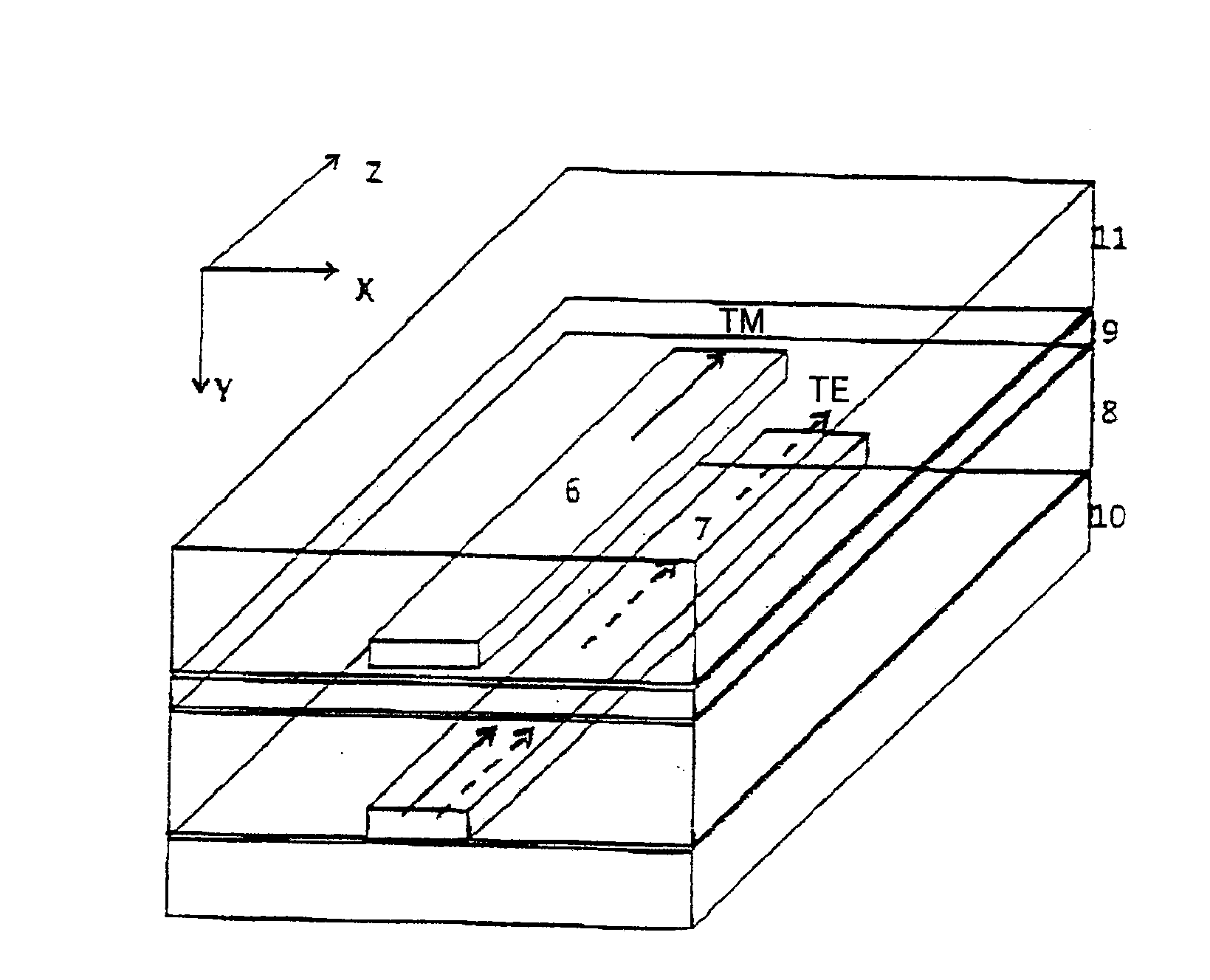

ActiveCN104459879AEnhanced Polarization DependencyImprove demultiplexing efficiencyOptical waveguide light guidePlasmonic waveguideTransverse magnetic

The invention discloses a silicon-based microring polarization demultiplexer which comprises a silicon substrate and a wrapping layer. The silicon-based microring polarization demultiplexer is characterized by comprising an input waveguide, a transverse electric mode output waveguide, a transverse magnetic mode output waveguide, hybrid plasma waveguides and a microring; the substrate is located at the inner bottom of the wrapping layer, and the hybrid plasma waveguides and the microring are located on the surface of the substrate; each hybrid plasma waveguide comprises a dielectric waveguide, a filling layer and a metal covering layer in sequence from bottom to top; the dielectric waveguides are closely attached to the substrate; the input waveguide is connected with the transverse magnetic mode output waveguide through one hybrid plasma waveguide; the transverse electric mode output waveguide is connected with the other hybrid plasma waveguide, and the microring is located between the two hybrid plasma waveguides. The silicon-based microring polarization demultiplexer has the advantages of being high in polarization demultiplexing efficiency, compact in structure, low in manufacturing difficulty, relatively low in price, capable of being compatible with a wavelength division multiplexing system based on a microring resonator and the like.

Owner:SOUTHEAST UNIV

Porous silicon light-emitting device

InactiveCN1889282AImprove internal quantum efficiencyAvoid intrinsic absorptionSemiconductor devicesPlasmonic waveguideInterconnection

Present invention relates to porous silica luminescence device, belonging to optoelectronics technique field. It features utilizing surface plasma wave Purcell effect enhancing porous silica luminescence. It contains forming surface plasmaguide on porous silica layer, porous silica emissive light coupling to surface plasmaguide- guided mode, then scattering to free air. Due to surface plasmaguide- guided mode density of states is very large, porous silica spontaneous radiation is greatly enhanced, therefore luminous efficiency raising greatly, this make the porous silica becoming the important material used in high efficiency silica-based support luminescence device, and capable of being used in photoelectricity integrating and light interconnection.

Owner:TSINGHUA UNIV

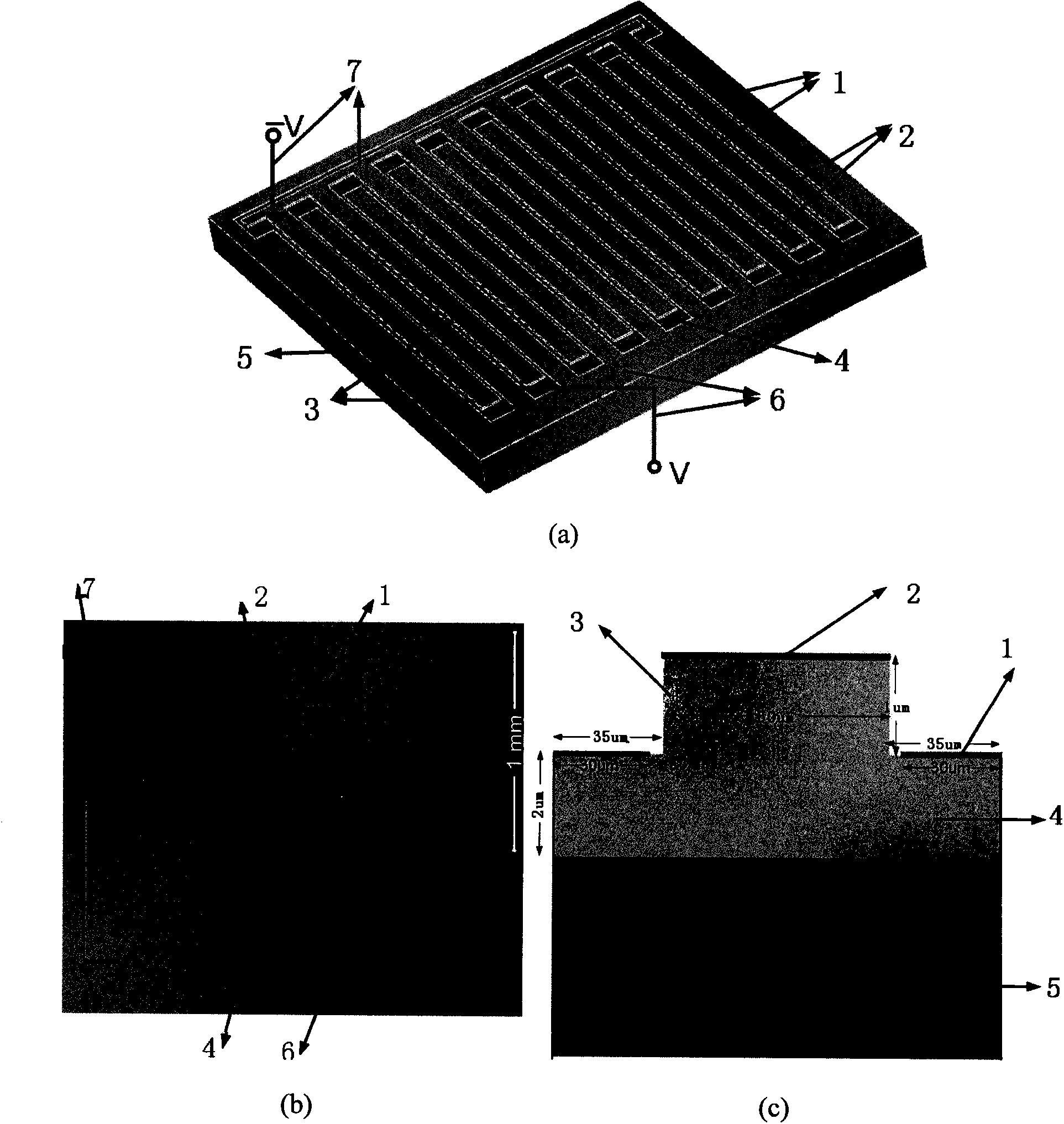

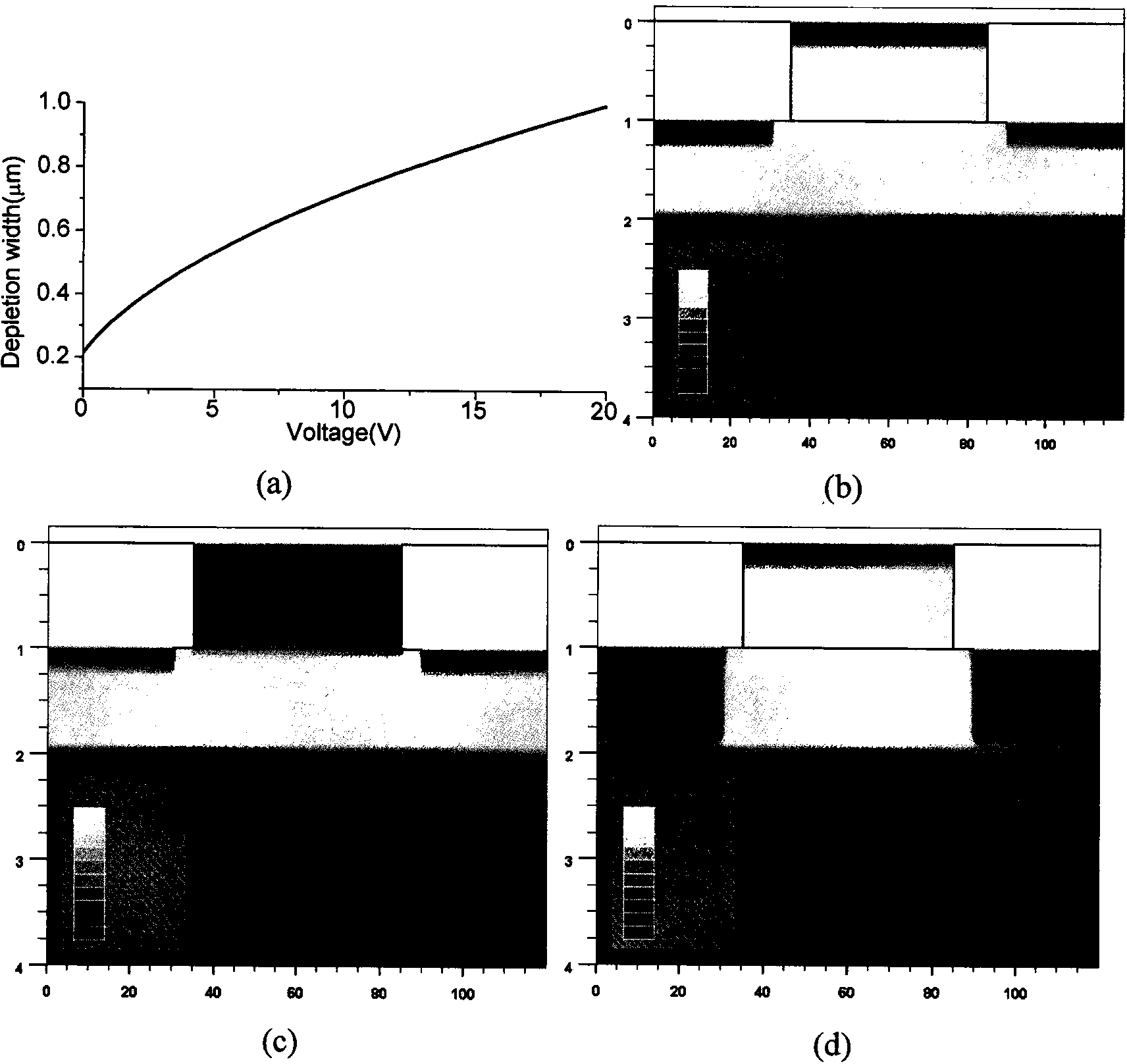

Schottky gate array type terahertz modulator

InactiveCN103457669ARealize the modulation functionRich scope of workElectromagnetic transmittersNon-linear opticsModulation functionElectron

The invention discloses a Schottky gate array type terahertz modulator and a regulation and control method thereof. A periodic gate type metal-semiconductor surface plasmon waveguide structure is adopted, the characteristics of Schottky contact formed by a metal-semiconductor interface and superposition of the Schottky contact and terahertz surface plasmon polariton position are utilized, a positive electrode and a negative electrode are led in and voltage is exerted, so that the terahertz modulation function of the Schottky gate array type terahertz modulator is achieved. The Schottky gate array type terahertz modulator combines a waveguide optical microstructure with a semiconductor electron device together, so that the Schottky gate array type terahertz modulator is well integrated with other electronic components and systems, and the optical functions of terahertz wave transmission and resonance oscillation are achieved. The Schottky gate array type terahertz modulator works from 2.2THz to 3.2THz, the working frequency can be tuned along with the working voltage, the maximum modulation depth is 16dB, and the highest modulation rate is 22MHz. The Schottky gate array type terahertz modulator is an on-chip electronically-controlled high-speed terahertz modulator which is in a small type and can be integrated, and the application requirements for terahertz broadband wireless communications are met.

Owner:NANKAI UNIV

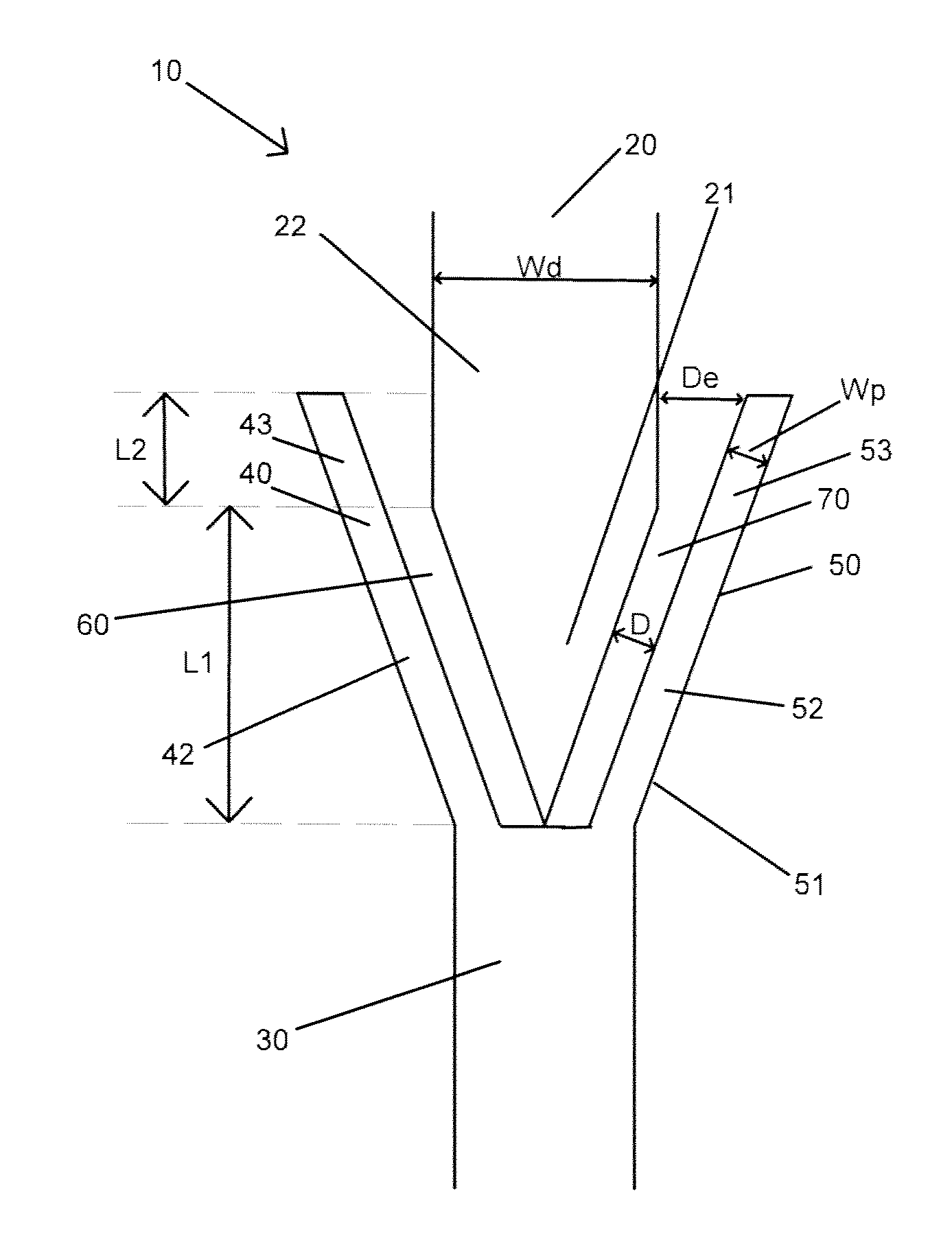

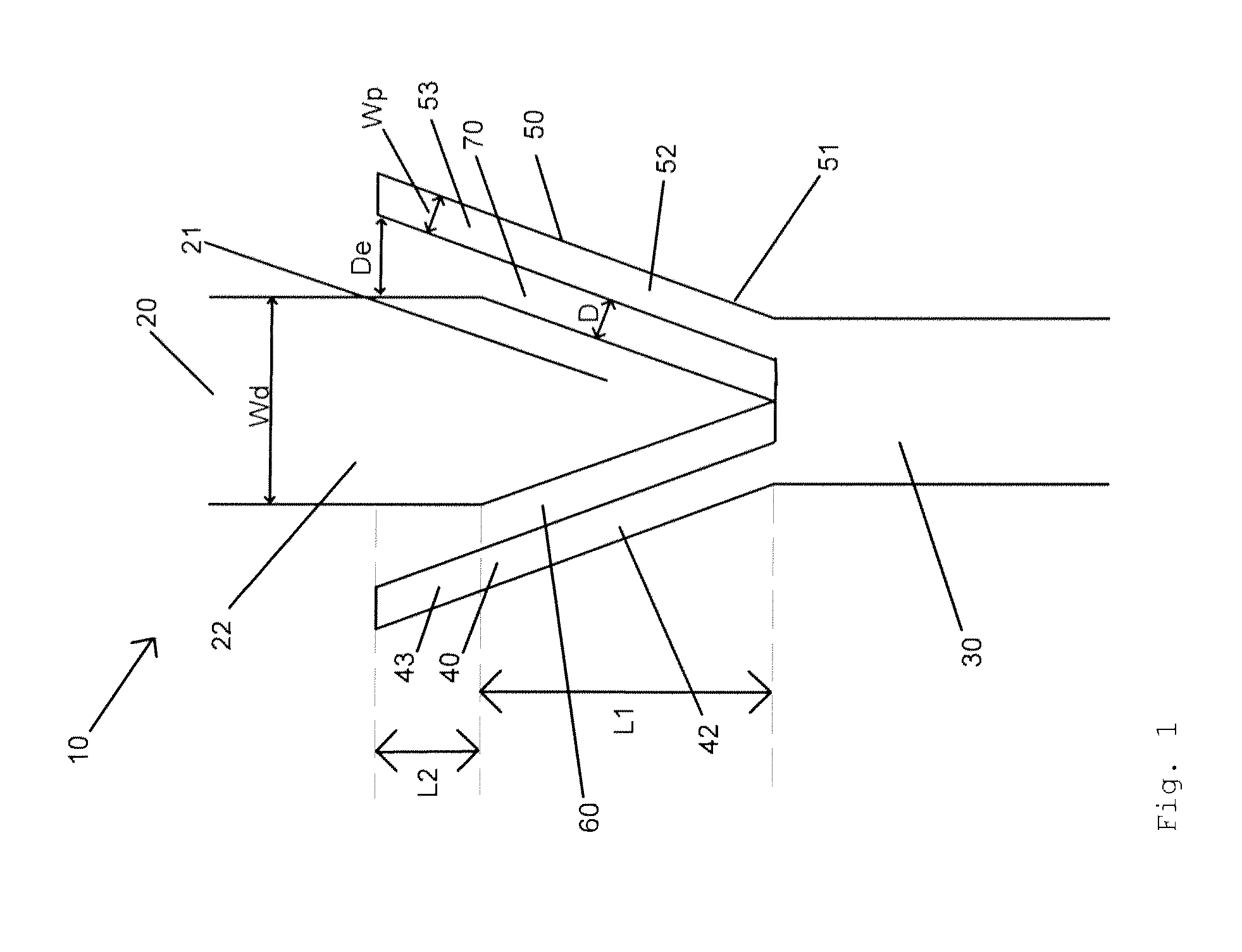

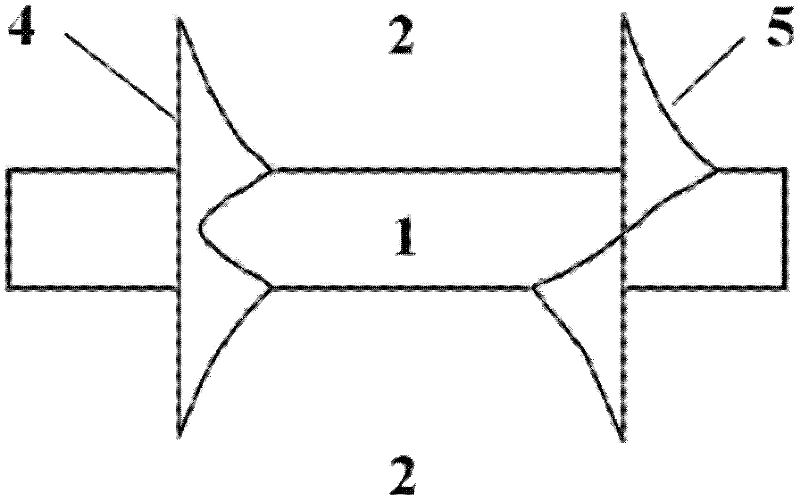

Photon-to-plasmon coupler

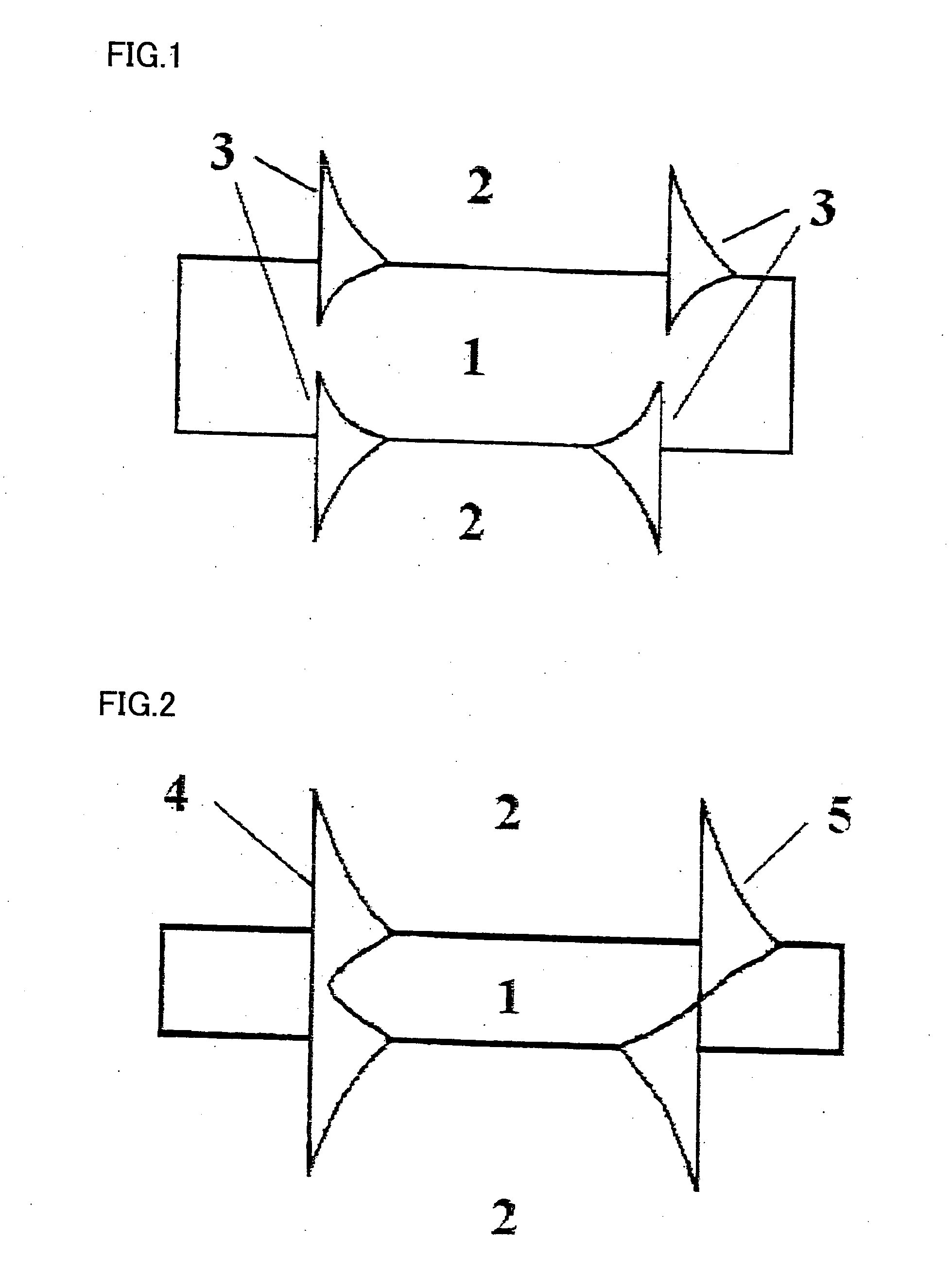

InactiveUS20140233885A1Change widthEasy to makeCoupling light guidesPlasmonic waveguidePlasmonic coupling

An embodiment of the present invention relates to a photon-to-plasmon coupler for converting photons to plasmons or vice versa, said photon-to-plasmon coupler comprisinga photonic waveguide for guiding photons,a plasmonic waveguide for guiding plasmons, andtwo plasmonic strip waveguides,each of said two plasmonic strip waveguides being connected to said plasmonic waveguide and embracing an end section of the photonic waveguide such that each of said plasmonic strip waveguides is optically coupled to the end section of the photonic waveguide.

Owner:HUMBOLDT UNIV BERLIN

Sensor device for interference and plasmon-waveguide/interference spectroscopy

InactiveUS7420682B2Improve observabilityAvoid damagePhase-affecting property measurementsScattering properties measurementsDielectricPlasmonic waveguide

Methods for measuring a property of a sample material present at an interface of an emerging medium in a spectroscopic device include a sensor (10) featuring at least one dielectric member (14) disposed upon a entrant medium (12), with the dielectric member being of an optical thickness selected to produce an observable interference effect for an incident angle of light below the critical angle of total internal reflection at the interface with the dielectric member (14). The dielectric member (14) of the sensor device (10) may be modified and functionalized for binding of a sample analyte by disposing a sensing surface area (38, 40, 42) upon it. Moreover, an metal layer (18) may be added to an entrant medium (20) to produce a sensor (16) that generates observable optical phenomena both above (resonance) and below (interference) a given critical angle.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

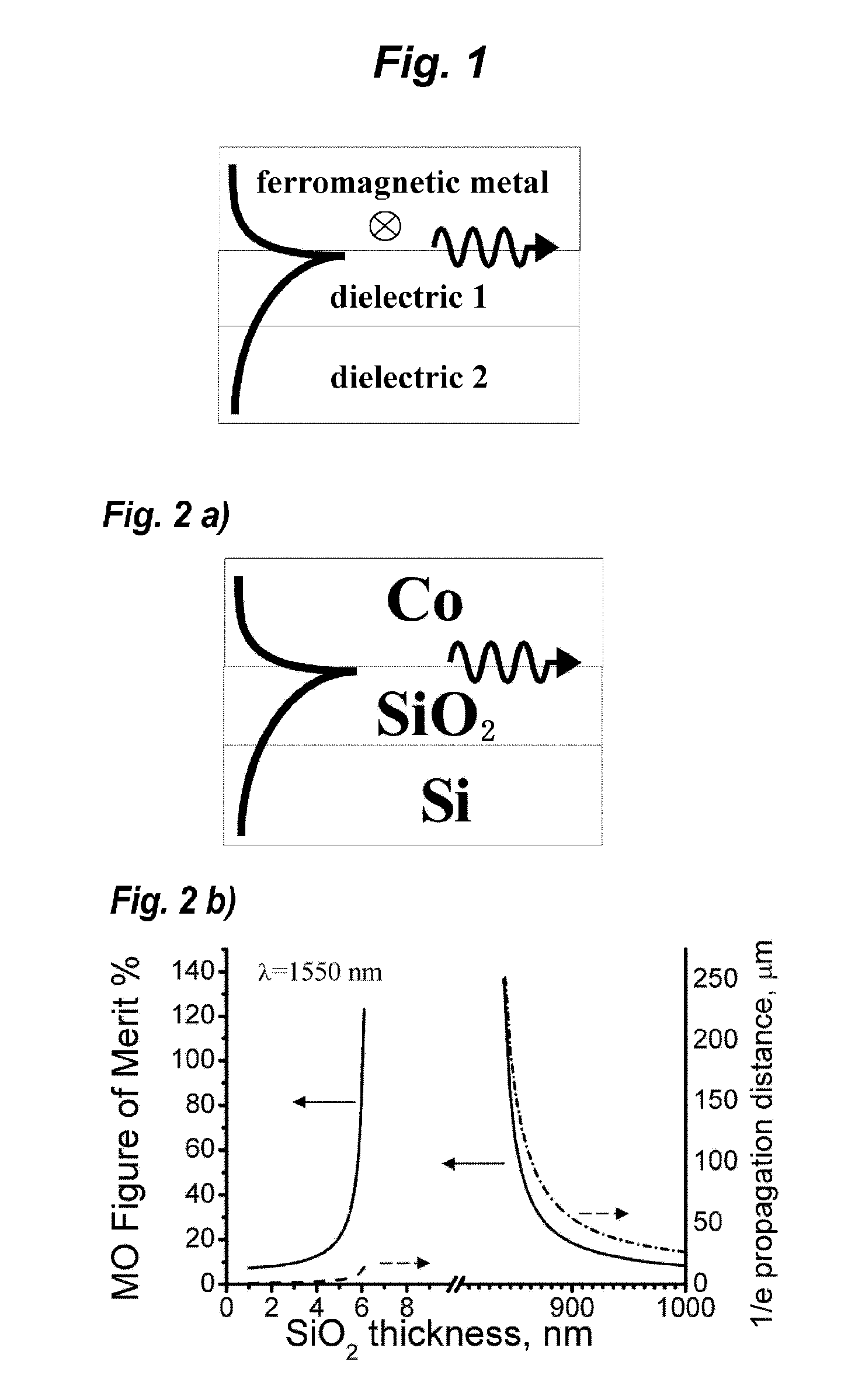

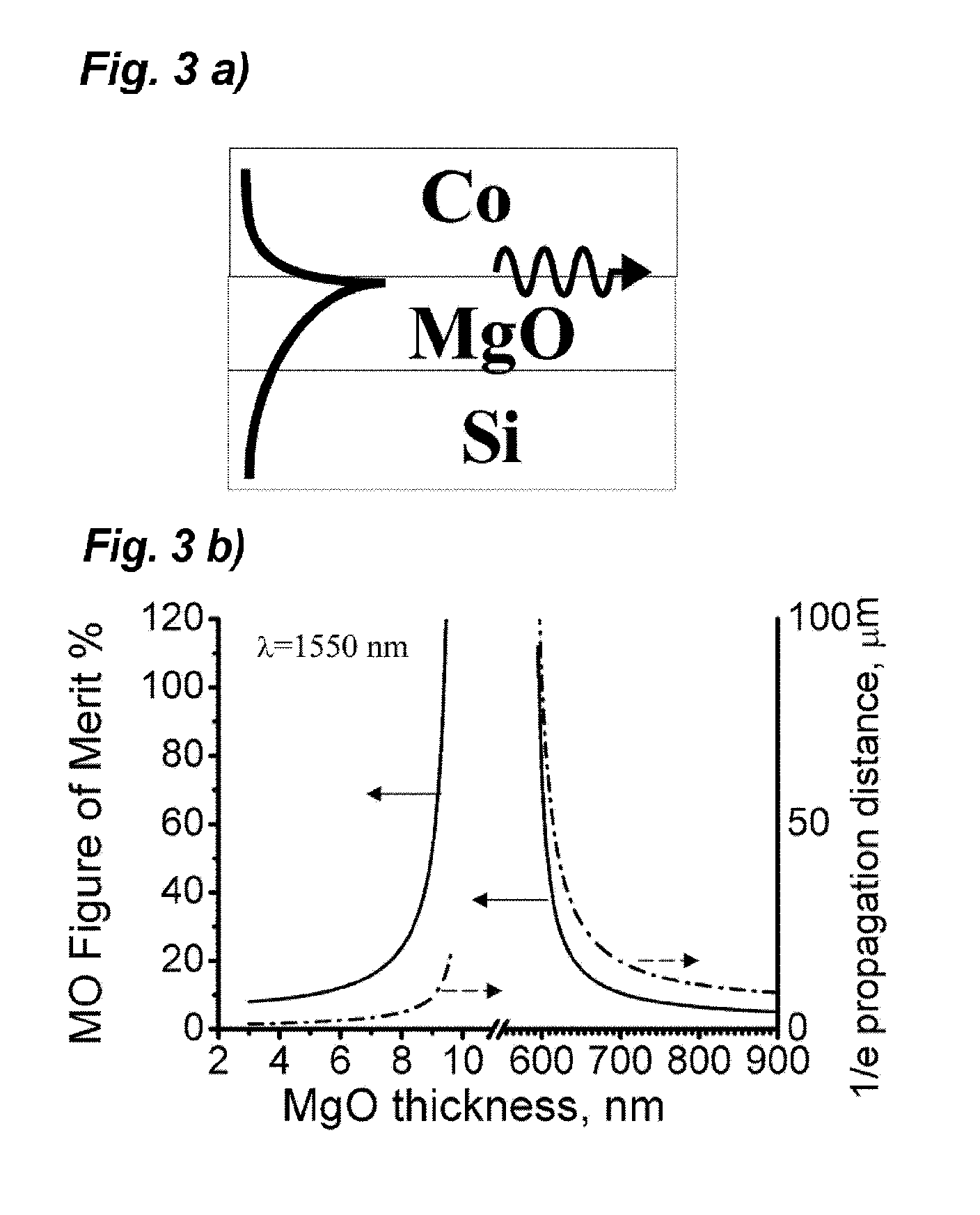

Optical device using a plasmonic waveguide, and optical isolator

An optical device having a plasmonic waveguide, in which the plasmonic waveguide has a layered structure of at least three layers that a ferromagnetic metal layer, a first dielectric layer, and a second dielectric layer are layered in this order, in which the first and second dielectric layers are layers that allow light to be transmitted therethrough, and in which a refractive index of the second dielectric layer is higher than a refractive index of the first dielectric layer; and an optical isolator, having the optical device.

Owner:NAT INST OF ADVANCED IND SCI & TECH

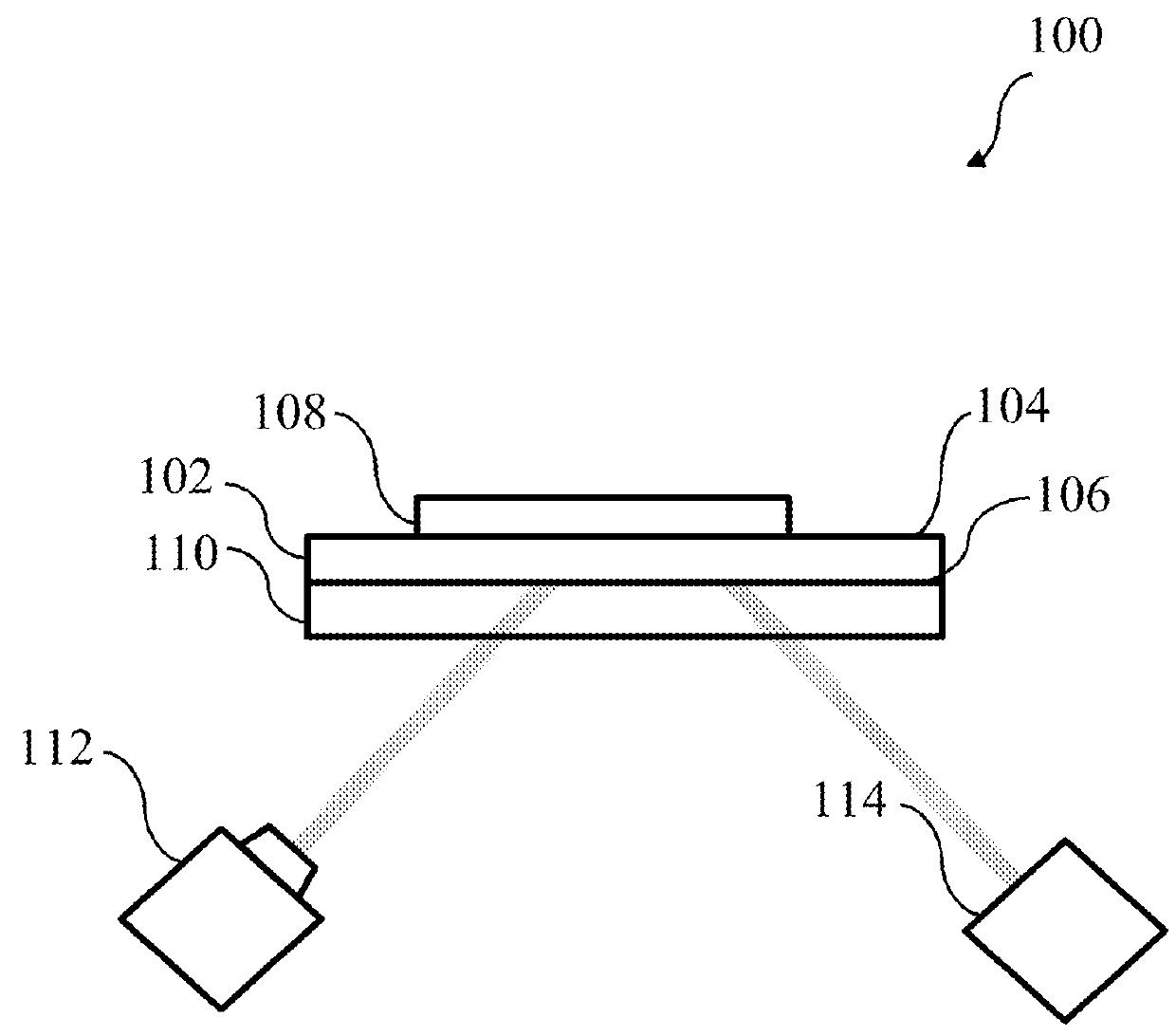

Optical sensing with critically coupled planar waveguide with optional integration of layered two-dimensional materials

ActiveUS20180106724A1Material analysis by observing effect on chemical indicatorCurrent/voltage measurementPlasmonic waveguideRefractive index

An optical sensing system includes a planar optical waveguide having a first surface for detection and a second surface for coupling light. The optical sensing system includes a functional layer integral with the first surface of the planar optical waveguide, and a coupling layer in contact with the second surface of the planar optical waveguide, the coupling layer having a lower refractive index than the planar optical waveguide. The optical sensing system includes an optical source arranged to illuminate at least a portion of the second surface of the planar optical waveguide through the coupling layer with substantially critical optical coupling. The optical sensing system also includes an optical detector arranged to receive a portion of light from the optical source after being reflected from the first surface of the planar optical waveguide and passing through the coupling layer.

Owner:RGT UNIV OF CALIFORNIA

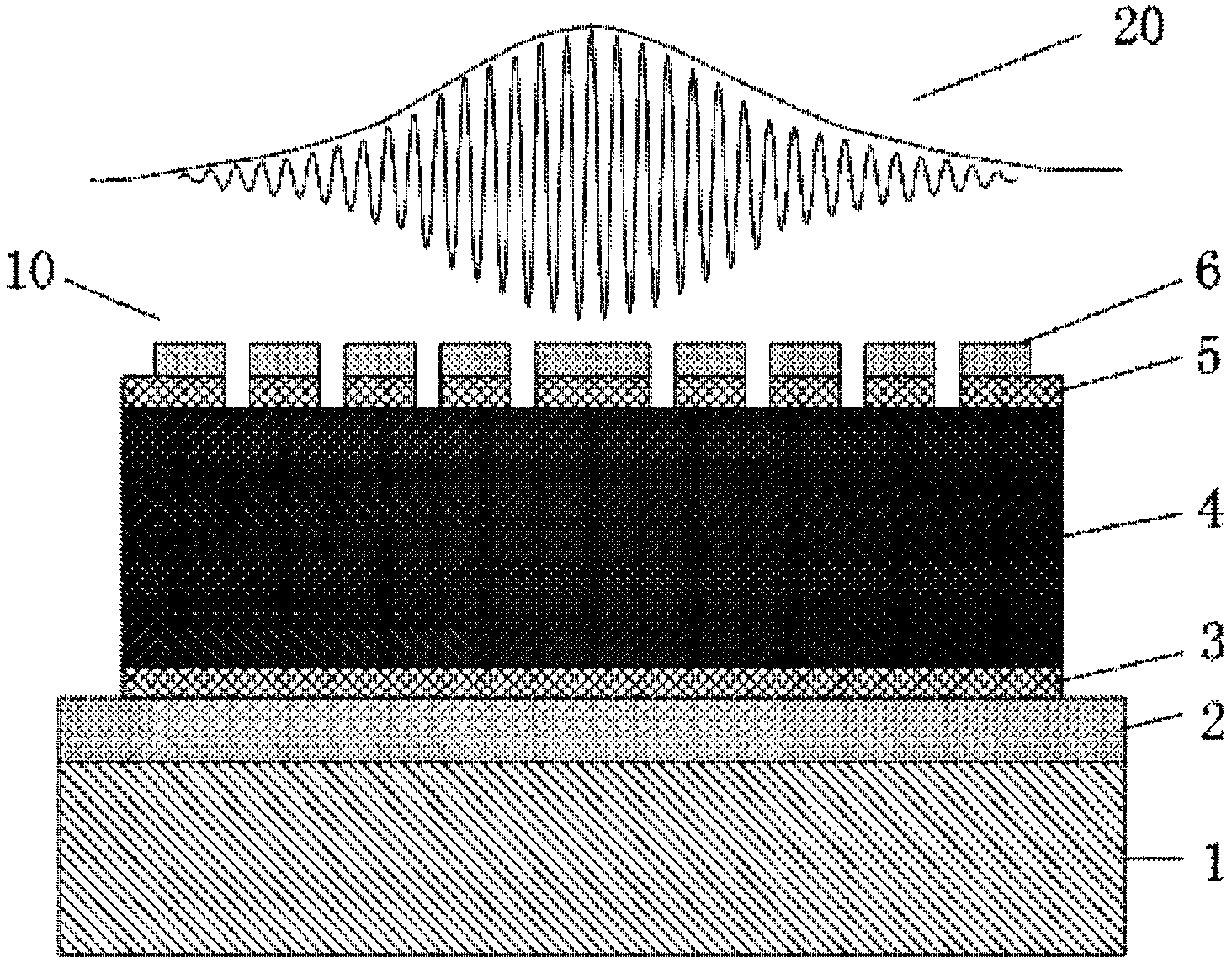

Short-range surface plasma waveguide and dielectric waveguide mixed coupling array type structure

The invention relates to a short-range surface plasma waveguide and dielectric waveguide mixed coupling array type structure which is characterized in that the coupling array type structure comprises a dielectric substrate layer and at least two coupling structures located on the dielectric substrate layer, wherein each of the coupling structures comprises a dielectric waveguide layer and a short-range surface plasma waveguide layer; the dielectric waveguide layer is located on the dielectric substrate layer; the short-range surface plasma waveguide layer is located on the dielectric waveguide layer; and the short-range surface plasma waveguide layer of at least one of the coupling structure and the short-range surface plasma waveguide layer of the other coupling structure are different in thickness. The structure can be used for realizing a high-sensitivity detection chip with an ultrathin material refractive index in a big sensing area.

Owner:TSINGHUA UNIV

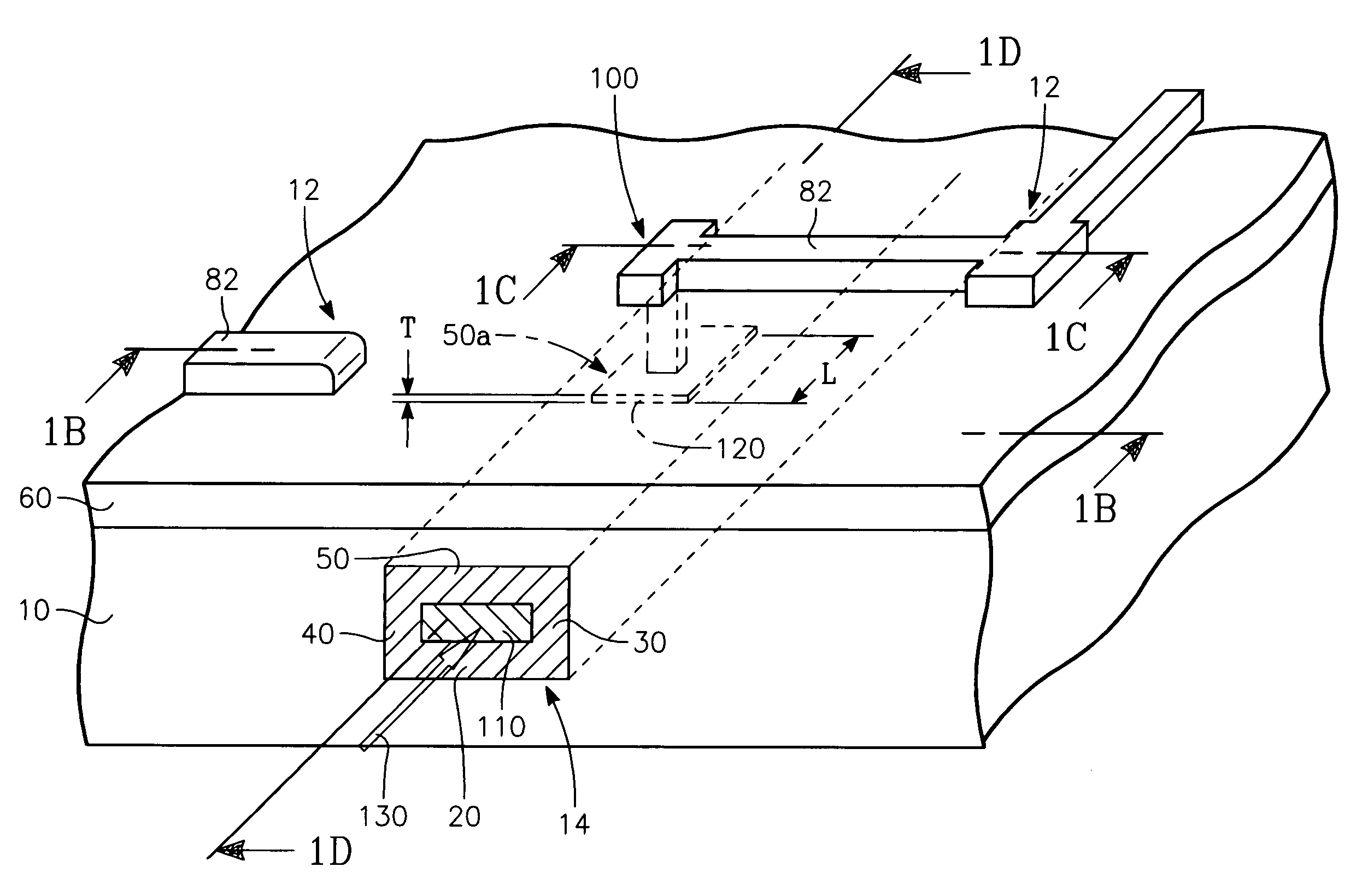

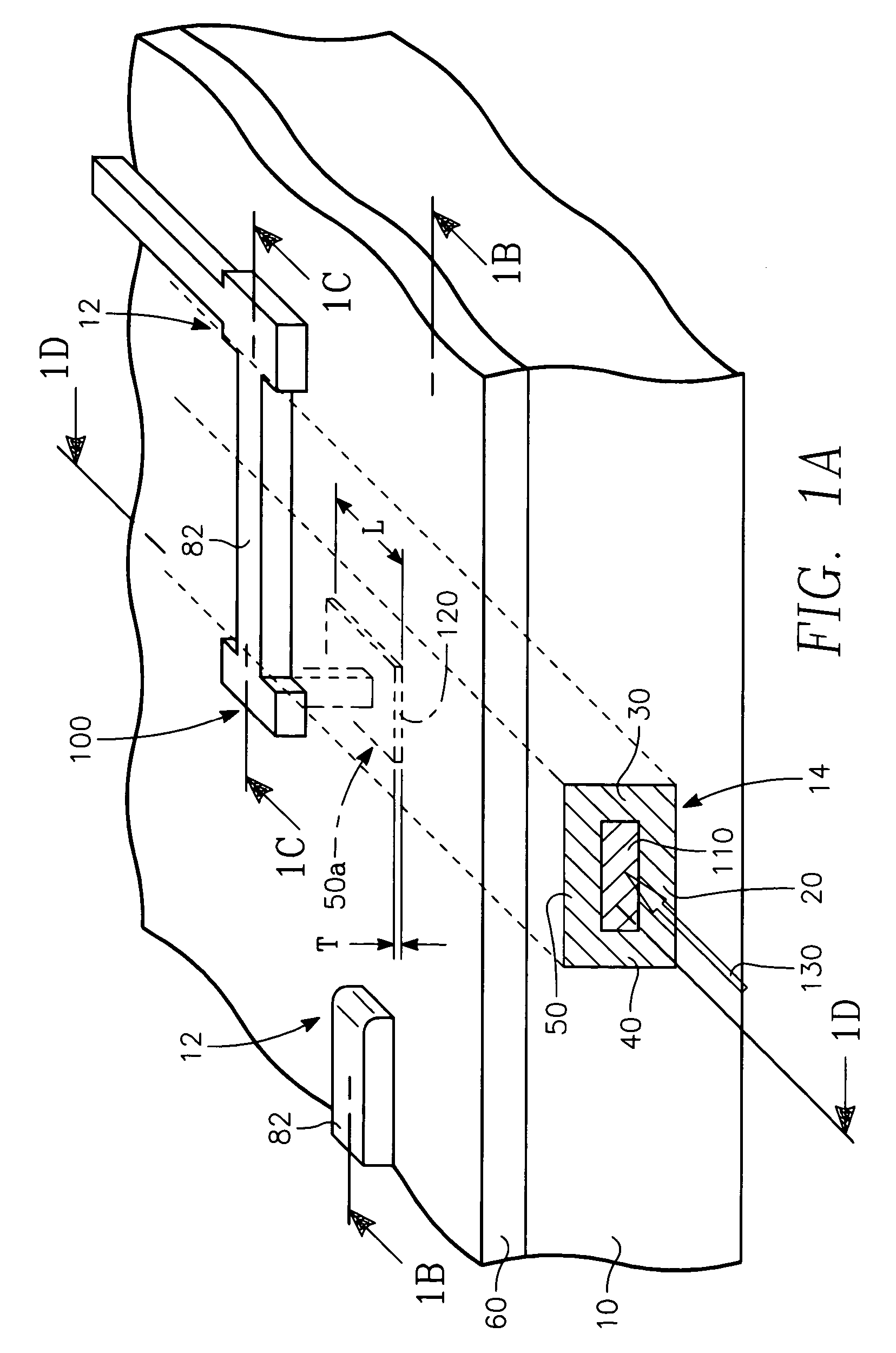

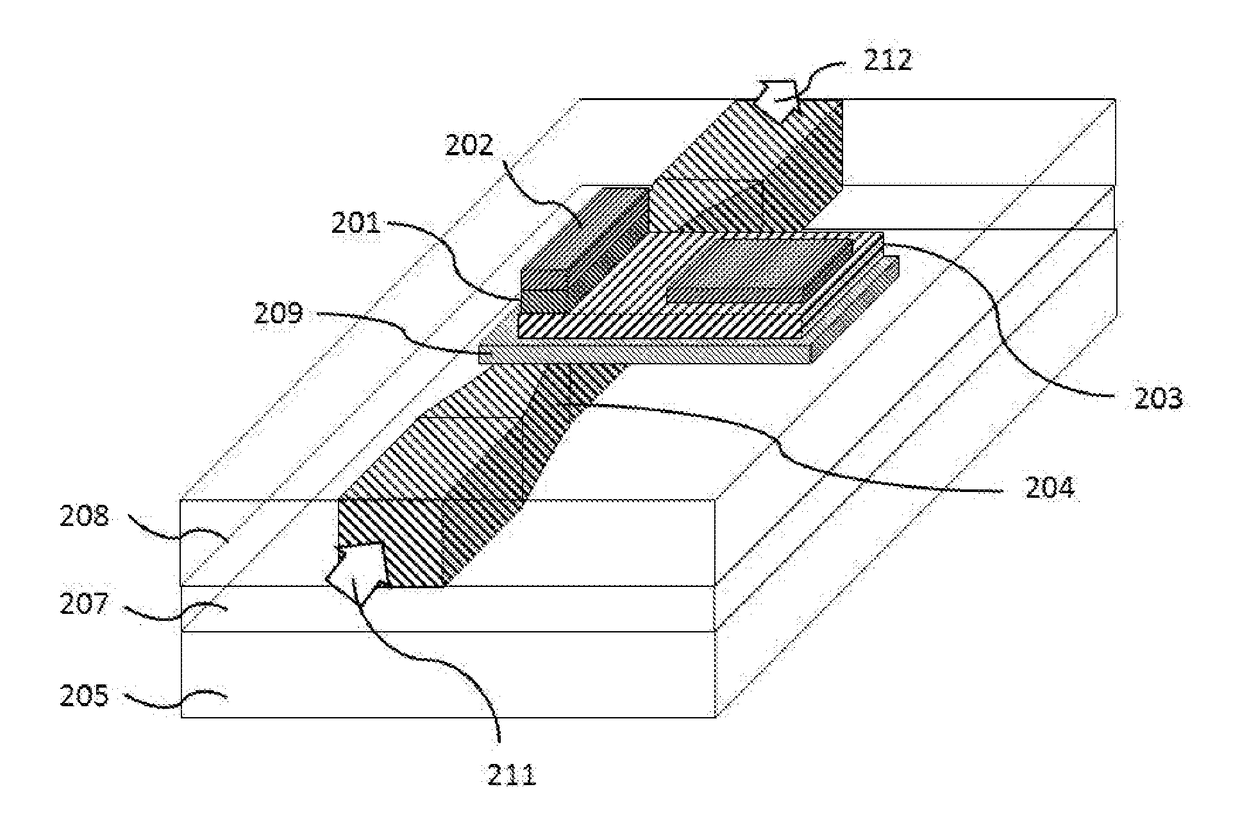

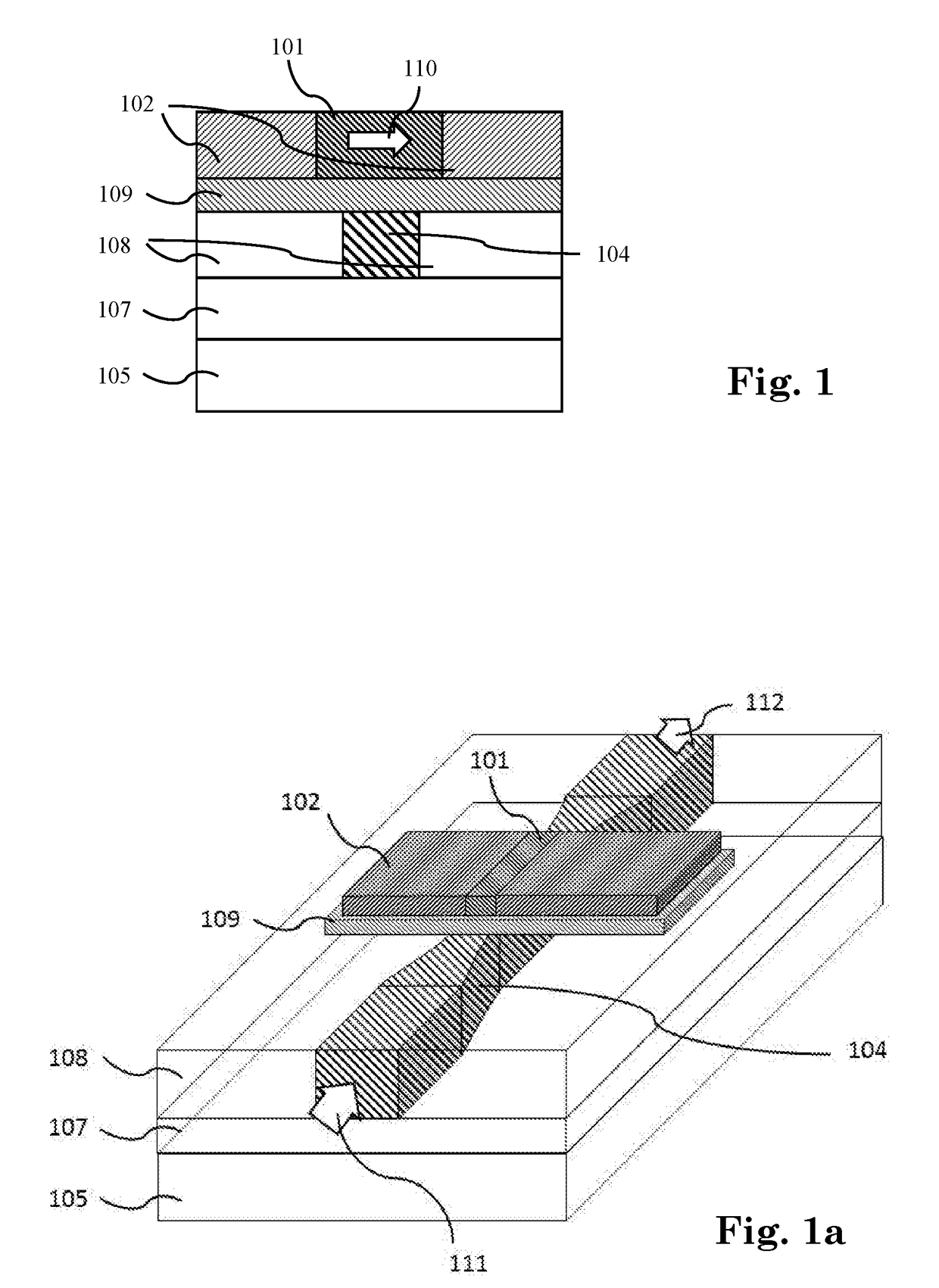

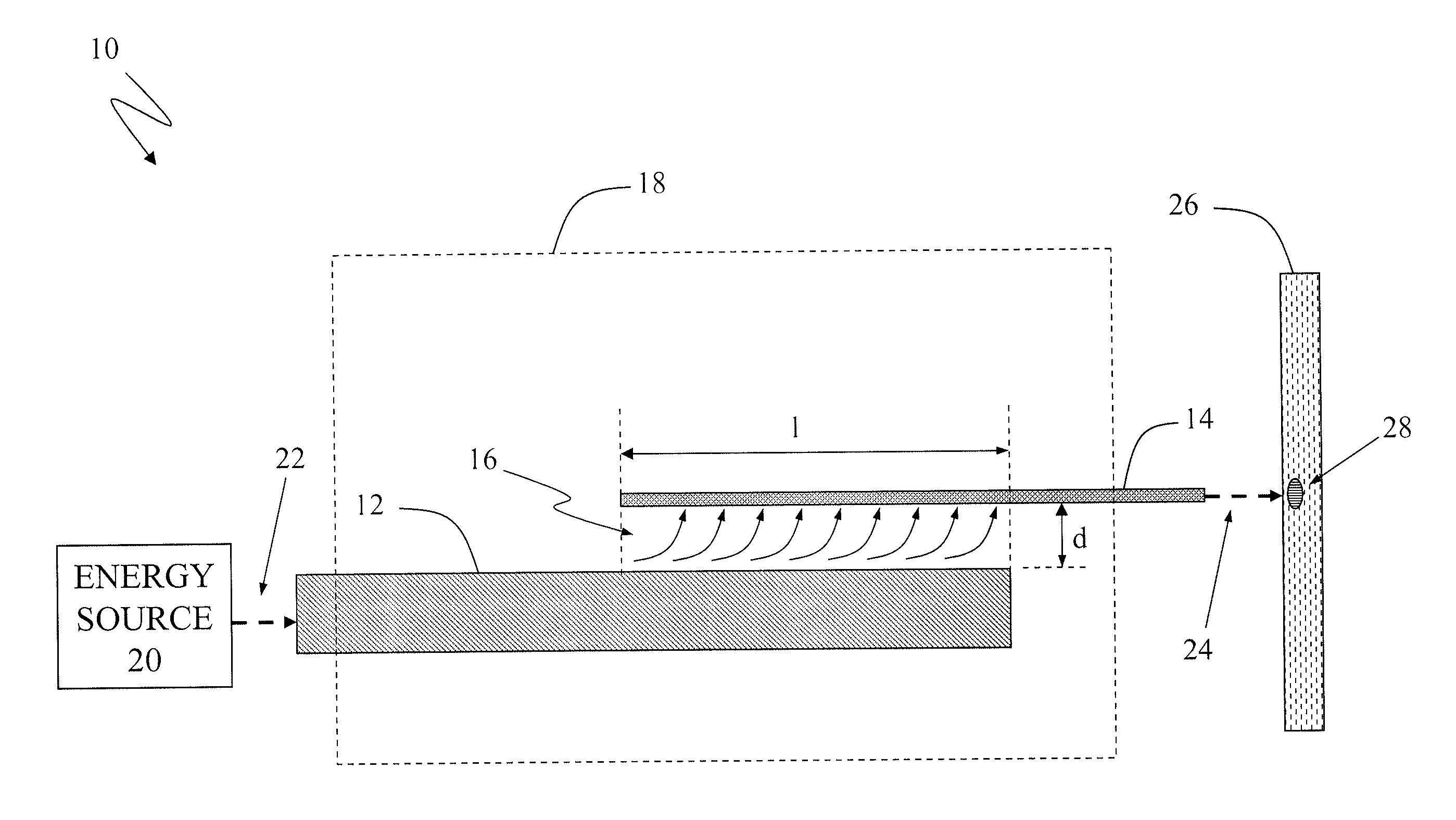

Coupled Plasmonic Waveguides and Associated Apparatuses and Methods

InactiveUS20140099054A1Solve the large impedanceEasy to measureRecord information storageNanoopticsPlasmonic waveguideLength wave

An apparatus and corresponding method in which the apparatus includes a dielectric waveguide and a metallic waveguide. The dielectric waveguide has an effective mode index and a longitudinal dimension. The metallic waveguide has a longitudinal dimension and supports a surface plasmonic mode of propagation for a wavelength lambda. The metallic waveguide and the dielectric waveguide are adjacent to each other and overlap each other by a length along the longitudinal dimensions of both the dielectric waveguide and the metallic waveguide, wherein the length is greater than the wavelength lambda in the metallic waveguide. The metallic waveguide is coupled to the dielectric waveguide where the metallic waveguide and the dielectric waveguide overlap each other.

Owner:CARNEGIE MELLON UNIV

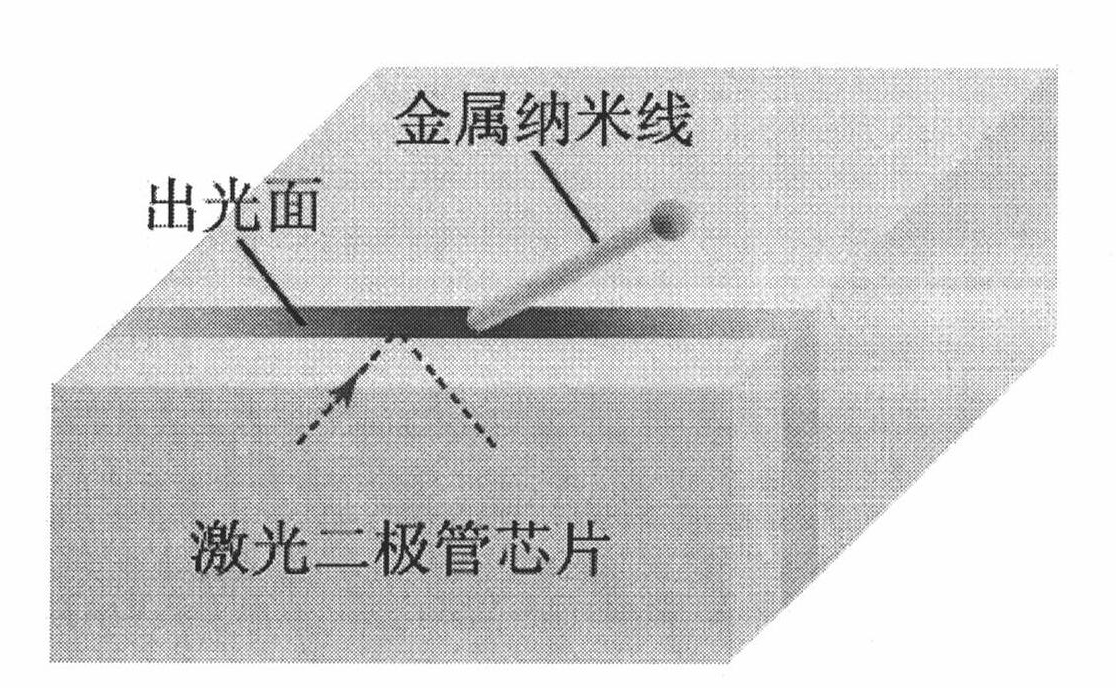

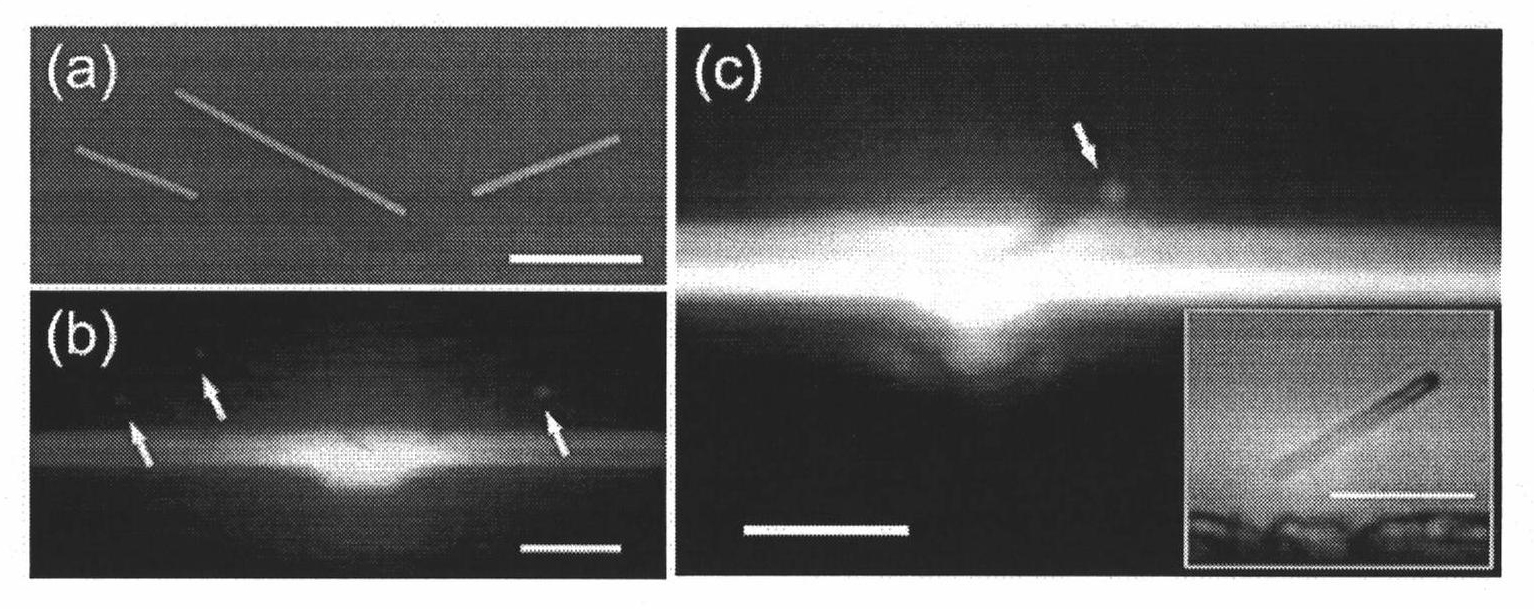

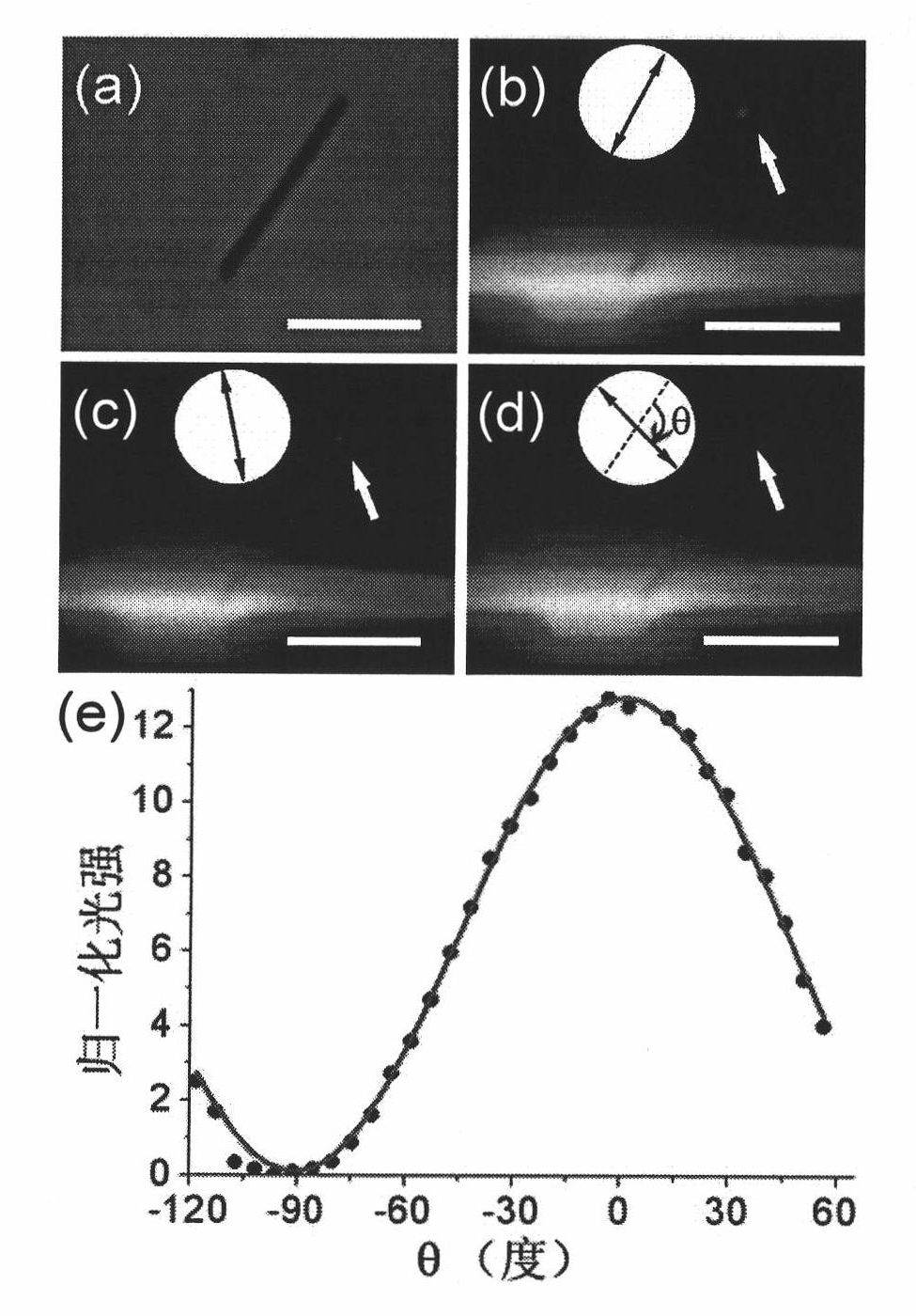

Surface plasma excitation method for chip-integrated metal nanowire

InactiveCN101986175AAchieve integrationHighly integratedOptical waveguide light guidePlasmonic waveguideCoupling

The invention discloses a surface plasma excitation method for chip-integrated metal nanowire, which comprises the following steps: a metal nanowire is arranged on a light emitting surface of a diode chip, and the plasma on an excitation surface is transmitted in the metal nanowires. In the excitation method of the invention, a light source and a plasma waveguide are integrated on the chip directly, thus omitting lens, prismas and other coupling devices in the conventional excitation method of the surface plasma; and linearly polarized light is output by the metal nanowire in the structure, and light intensity output can be adjusted by adjusting direction of the nanowire.

Owner:ZHEJIANG UNIV

Coupled plasmonic waveguides and associated apparatuses and methods

InactiveUS20110280515A1Solve the large impedanceEasy to measureRecord information storageNanoopticsPlasmonic waveguideLength wave

An apparatus and corresponding method in which the apparatus includes a dielectric waveguide and a metallic waveguide. The dielectric waveguide has an effective mode index and a longitudinal dimension. The metallic waveguide has a longitudinal dimension and supports a surface plasmonic mode of propagation for a wavelength lambda. The metallic waveguide and the dielectric waveguide are adjacent to each other and overlap each other by a length along the longitudinal dimensions of both the dielectric waveguide and the metallic waveguide, wherein the length is greater than the wavelength lambda in the metallic waveguide. The metallic waveguide is coupled to the dielectric waveguide where the metallic waveguide and the dielectric waveguide overlap each other.

Owner:CARNEGIE MELLON UNIV

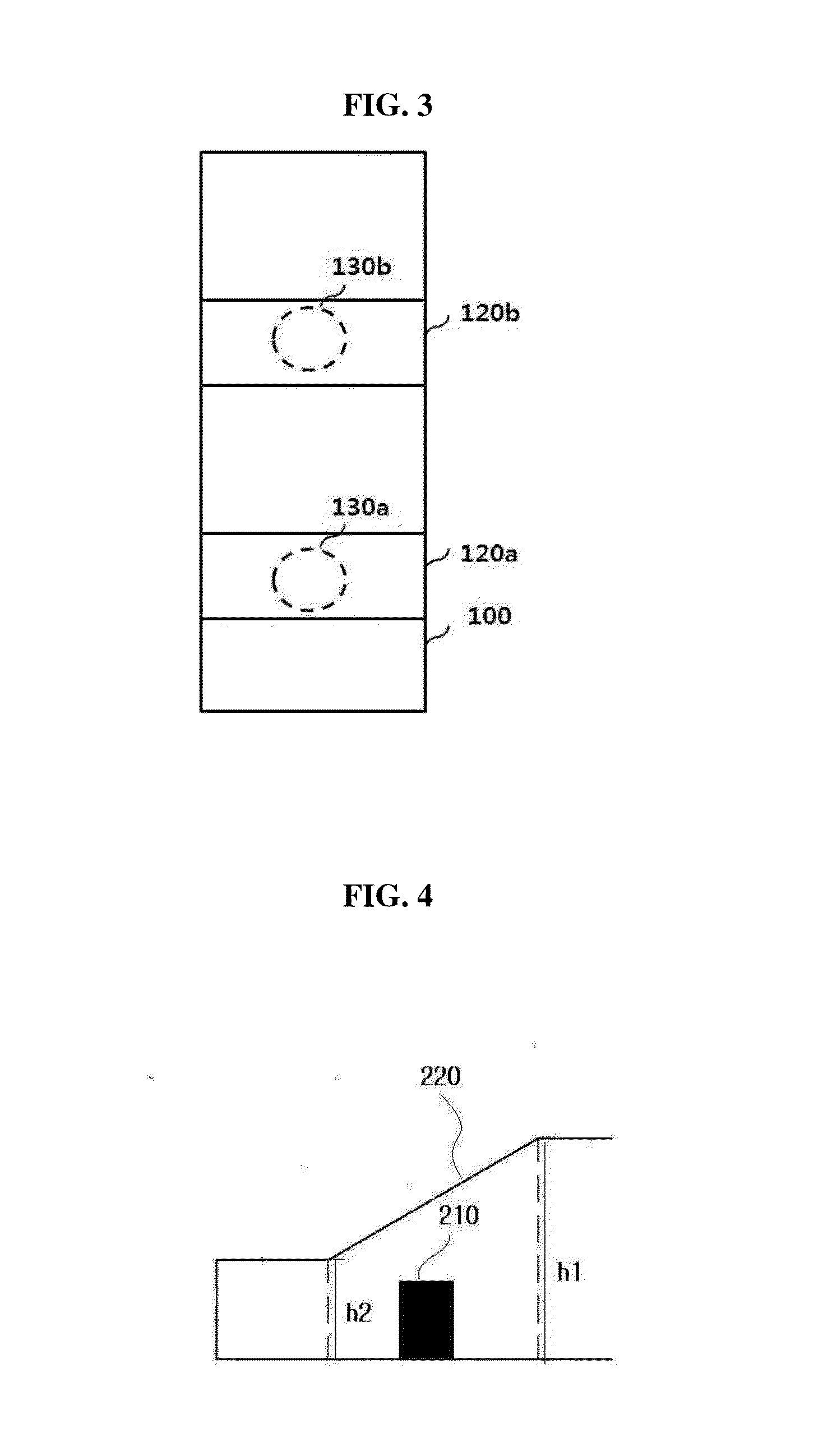

Hybrid Coupling Structure of the short Range Plasmon Polariton and Conventional Dielectric Waveguide, A Coupling Structure of the Long Range Plasmon Polariton and Conventional Dielectric Waveguide, and Applications Thereof

ActiveUS20100310205A1Efficient couplingPhase-affecting property measurementsNanoopticsPlasmonic waveguideCoupling

The present invention provides a hybrid coupling structure of a short range surface plasmon polariton and a conventional dielectric waveguide, including a dielectric substrate layer, a dielectric waveguide layer positioned on the said dielectric substrate layer, a coupling matching layer positioned on the said dielectric waveguide layer and a short range surface plasmon waveguide portion, formed on the said coupling matching layer, for conducting the short range surface plasmon polariton. The present invention also provides a coupling structure of a long range surface plasmon polariton and a dielectric waveguide, including a dielectric substrate layer, a dielectric waveguide layer, a coupling matching layer and a long range surface plasmon waveguide portion upward from below respectively.

Owner:ROHM CO LTD +1

Plasmon lasers at deep subwavelength scale

ActiveUS8509276B2Efficient generation of sub-wavelength high intensity lightPotentialOptical wave guidanceLaser active region structureModulation bandwidthPlasmonic waveguide

Hybrid plasmonic waveguides are described that employ a high-gain semiconductor nanostructure functioning as a gain medium that is separated from a metal substrate surface by a nanoscale thickness thick low-index gap. The waveguides are capable of efficient generation of sub-wavelength high intensity light and have the potential for large modulation bandwidth >1 THz.

Owner:RGT UNIV OF CALIFORNIA

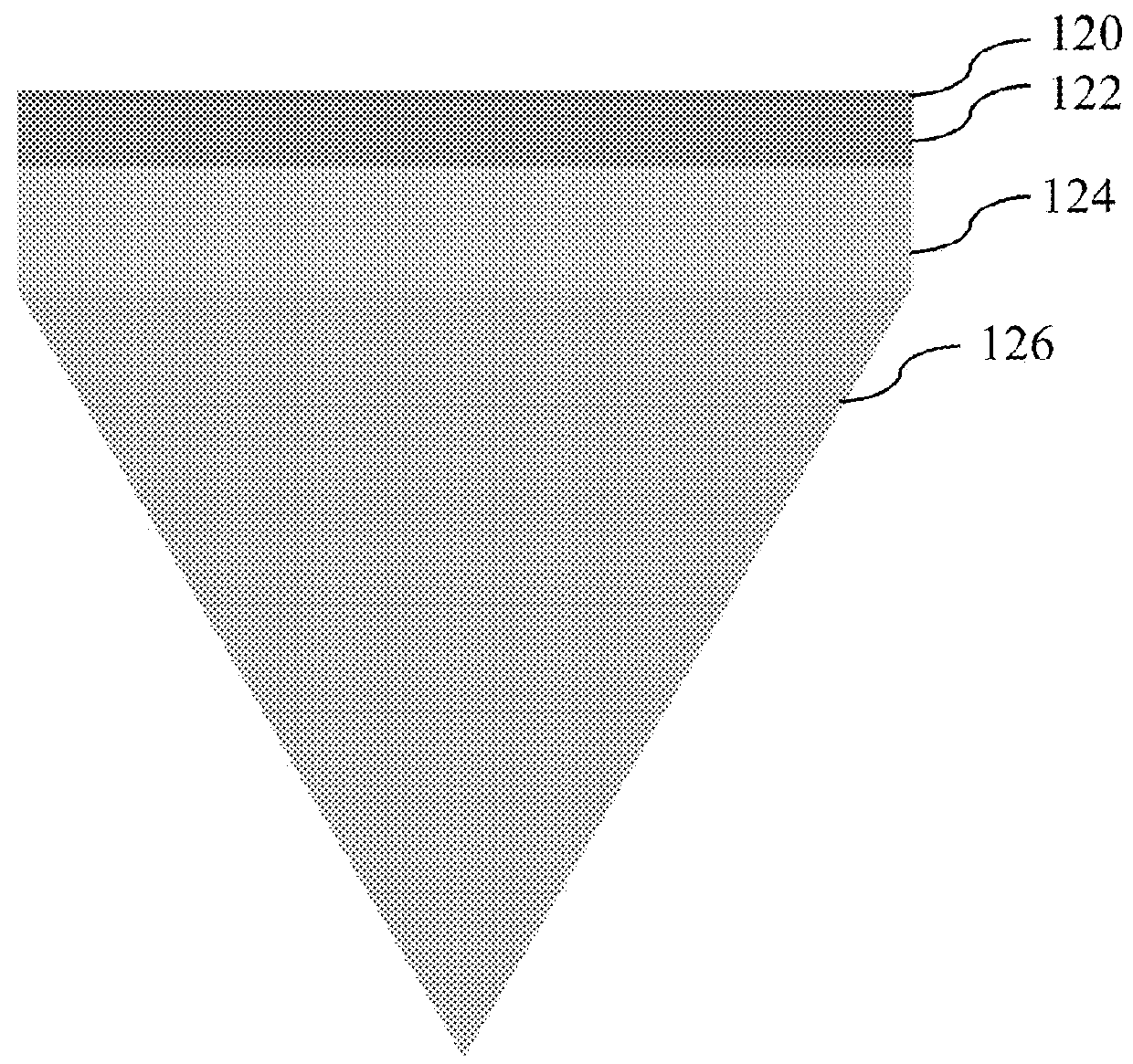

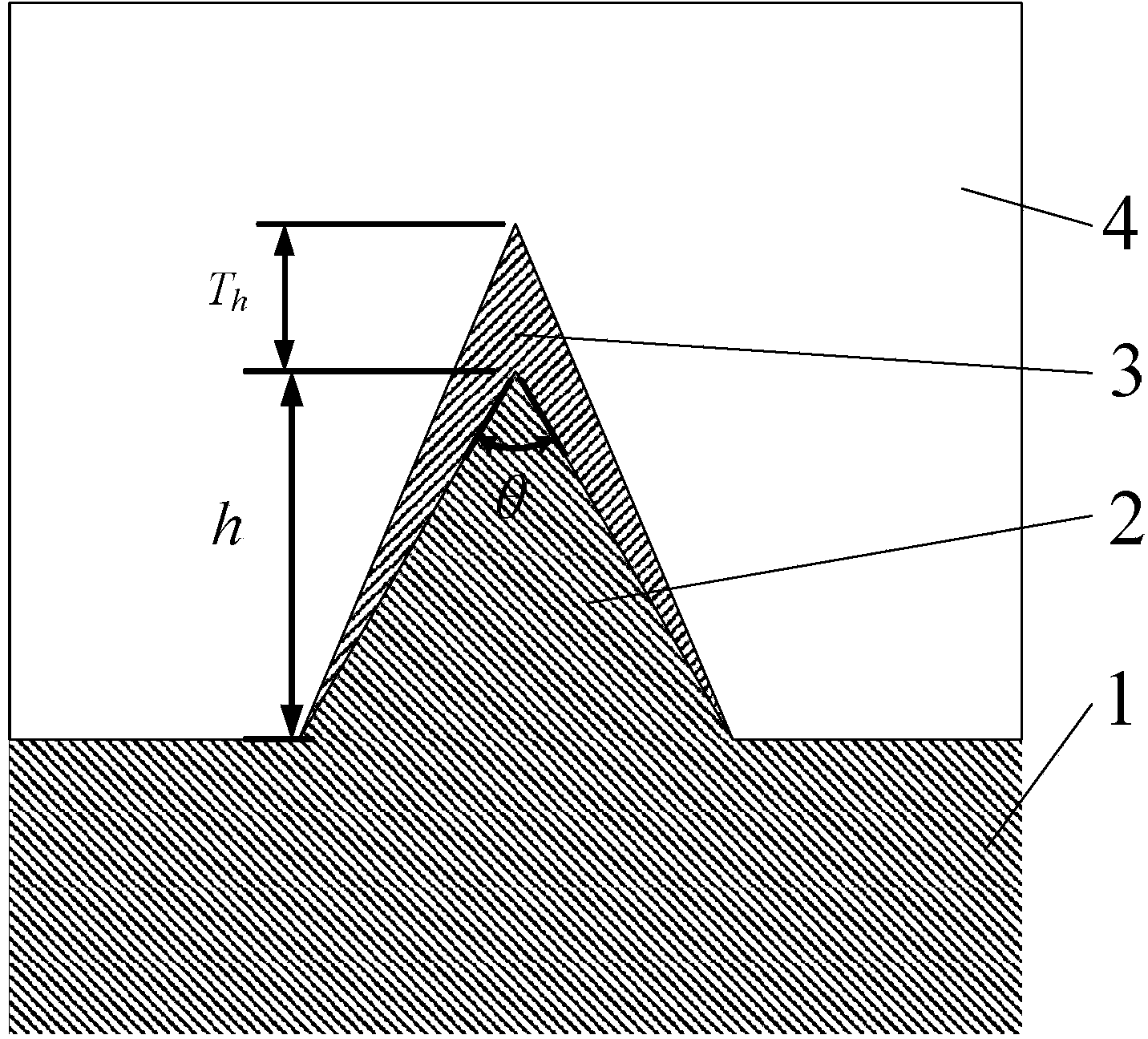

Wedge-type surface plasma waveguide

The invention discloses a wedge-type surface plasma waveguide. The wedge-type surface plasma waveguide comprises a metal substrate and a metal wedge, wherein the metal substrate is made of low-loss metal materials; the metal wedge is arranged on the metal substrate; the cross section of the metal wedge is triangular; a dielectric layer is attached to the sharp end of the metal wedge. The exterior of the dielectric layer is surrounded by a vacuum. The three angles of the triangle of the cross section of the metal wedge are acute angles. The dielectric layer is silicon dioxide or magnesium fluoride. The two side faces and the outer surface, attached to the metal wedge, of the dielectric layer are planes which are thinned gradually from top to bottom. Compared with a single wedge-type surface plasma waveguide under the same conditions, the wedge-type surface plasma waveguide has the advantages that the ratio of the propagation distance of surface plasma wave to the effective mode field area is effectively increased, and the final quality factor is increased by one order of magnitude; the light guide function of the surface plasma waveguide is achieved, the crosstalk between channels is effectively reduced, microminiaturization of a photon circuit is facilitated, and the integration is improved; the waveguide is simple in structure and easy to implement.

Owner:GUILIN UNIV OF ELECTRONIC TECH

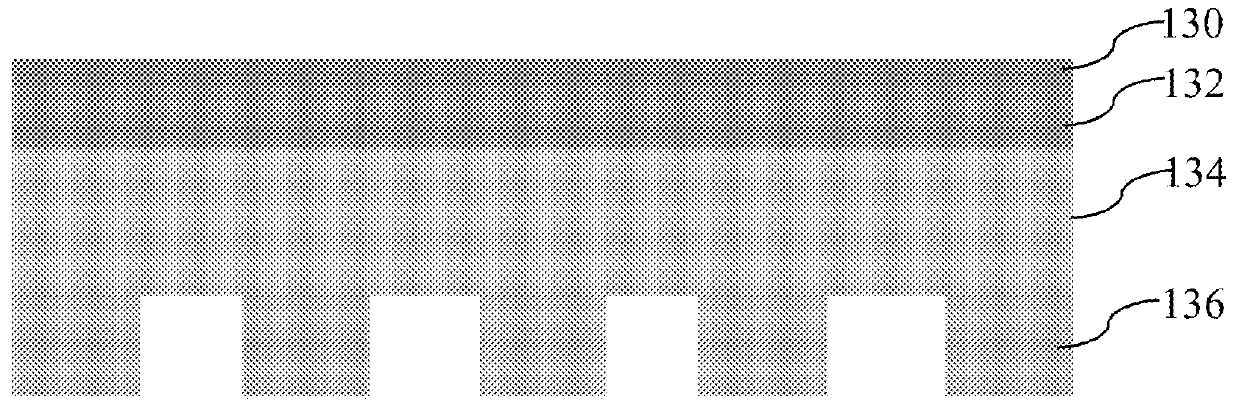

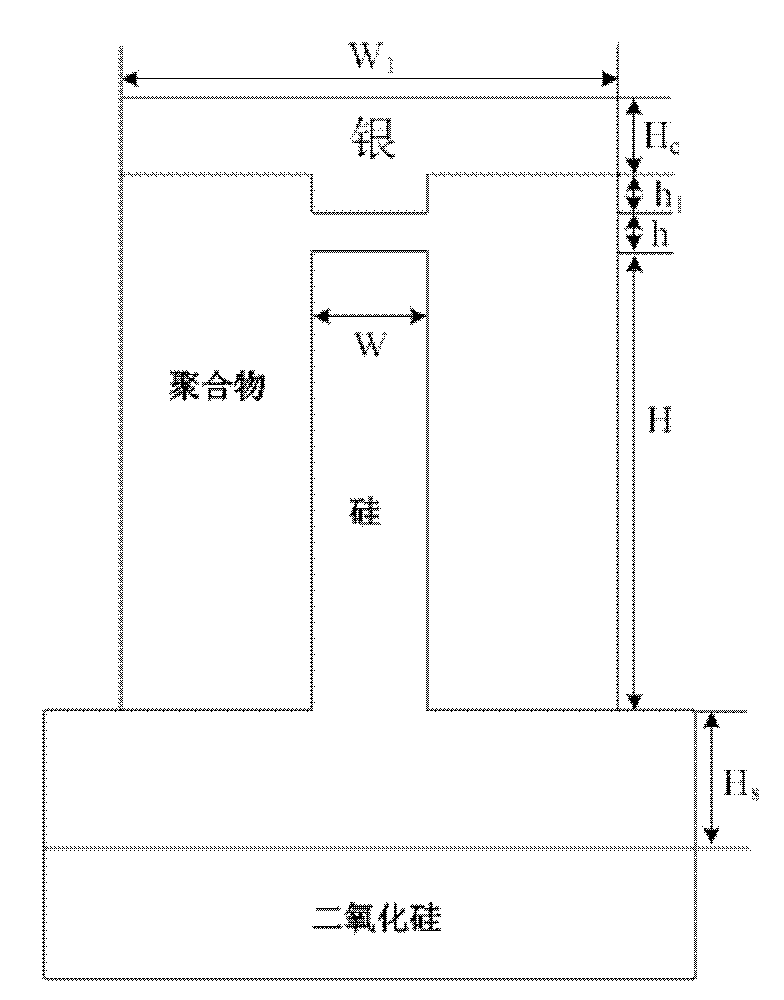

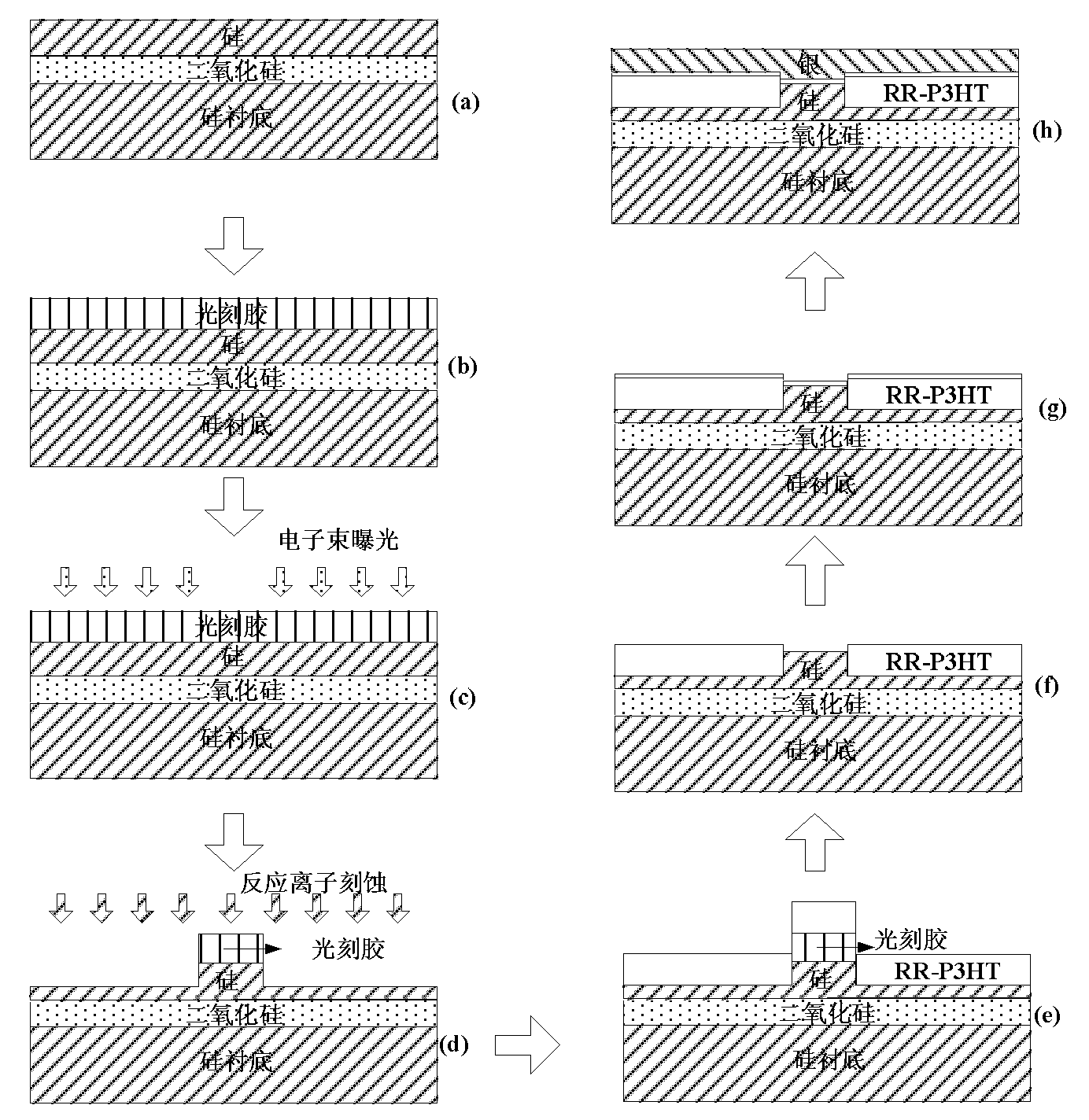

Method for preparing silicon-based surface plasma waveguide having stepped structure

InactiveCN102183816AHigh nonlinear coefficientIncrease widthOptical light guidesPolymer thin filmsMolecular beam deposition

The invention discloses a method for preparing a silicon-based surface plasma waveguide having a stepped structure in the technical field of nanometer semiconductors. The method comprises the following steps of: coating electron beam photoresist on a silicon-on-insulator (SOI) chip, and forming a waveguide pattern on a silicon layer through an electron beam exposure system and a reactive ion etching system; depositing high-nonlinearity polymer-regional regularity poly(3-hexylthiophene) on an SOI ridge waveguide; removing the electron beam photoresist and the high-nonlinearity polymer-regional regularity poly(3-hexylthiophene) thereon, and depositing the high-nonlinearity polymer-regional regularity poly(3-hexylthiophene) for the second time by a molecular beam deposition method; and plating metal silver on a polymer film by a radio frequency sputtering method, and preparing the silicon-based surface plasma waveguide having the stepped structure. The product has a nano-scale mode field and low transmission loss, and is combined with high-nonlinearity polymer materials to realize super-high nonlinearity.

Owner:SHANGHAI JIAO TONG UNIV

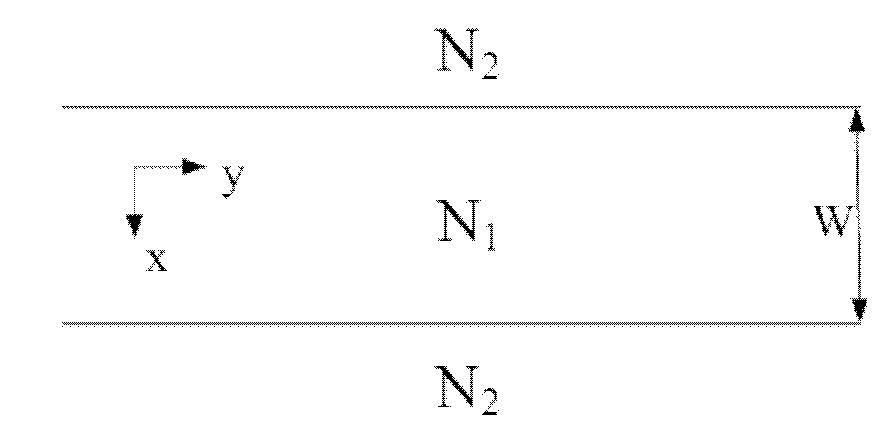

Surface-plasmon index guided (SPIG) waveguides and surface-plasmon effective index guided(SPEIG) waveguides

ActiveUS20050259936A1Easy to integrateBroadband couplingNanoopticsOptical waveguide light guidePlasmonic waveguideCoupling

A new class of surface plasmon waveguides is presented. The basis of these structures is the presence of surface plasmon modes, supported on the interfaces between the dielectric regions and the flat unpatterned surface of a bulk metallic substrate. The waveguides discussed here are promising to have significant applications in the field of nanophotonics by being able to simultaneously shrink length, time and energy scales, allowing for easy coupling over their entire bandwidth of operation, and exhibiting minimal absorption losses limited only by the intrinsic loss of the metallic substrate. These principles can be used for many frequency regimes (from GHz and lower, all the way to optical).

Owner:MASSACHUSETTS INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com