Surface plasma excitation method for chip-integrated metal nanowire

A technology of surface plasmons and metal nanowires, applied in light guides, optics, instruments, etc., can solve problems such as the inability to achieve chip integration, and achieve the effect of improving integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and examples, and the purpose and effect of the present invention will become more obvious.

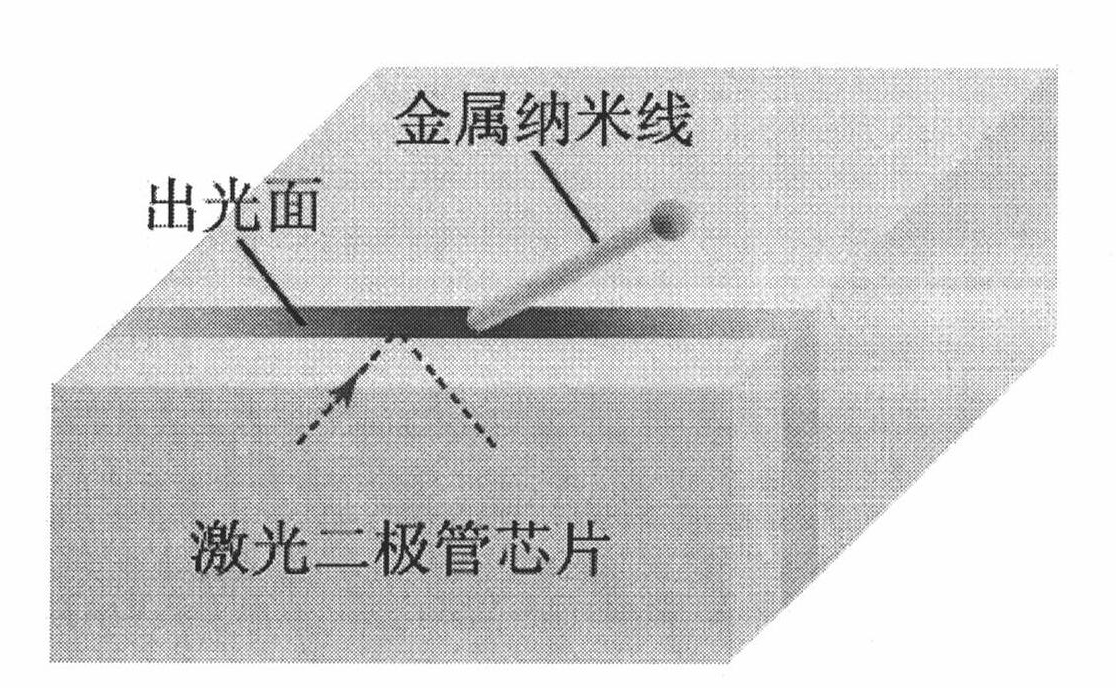

[0012] Such as figure 1 As shown, in the present invention, one end of the metal nanowire is placed on the light-emitting surface of the laser diode chip to excite the transmission of surface plasmons in the metal nanowire, and at the other end of the metal nanowire, the surface plasmon is coupled into free space light emission come out.

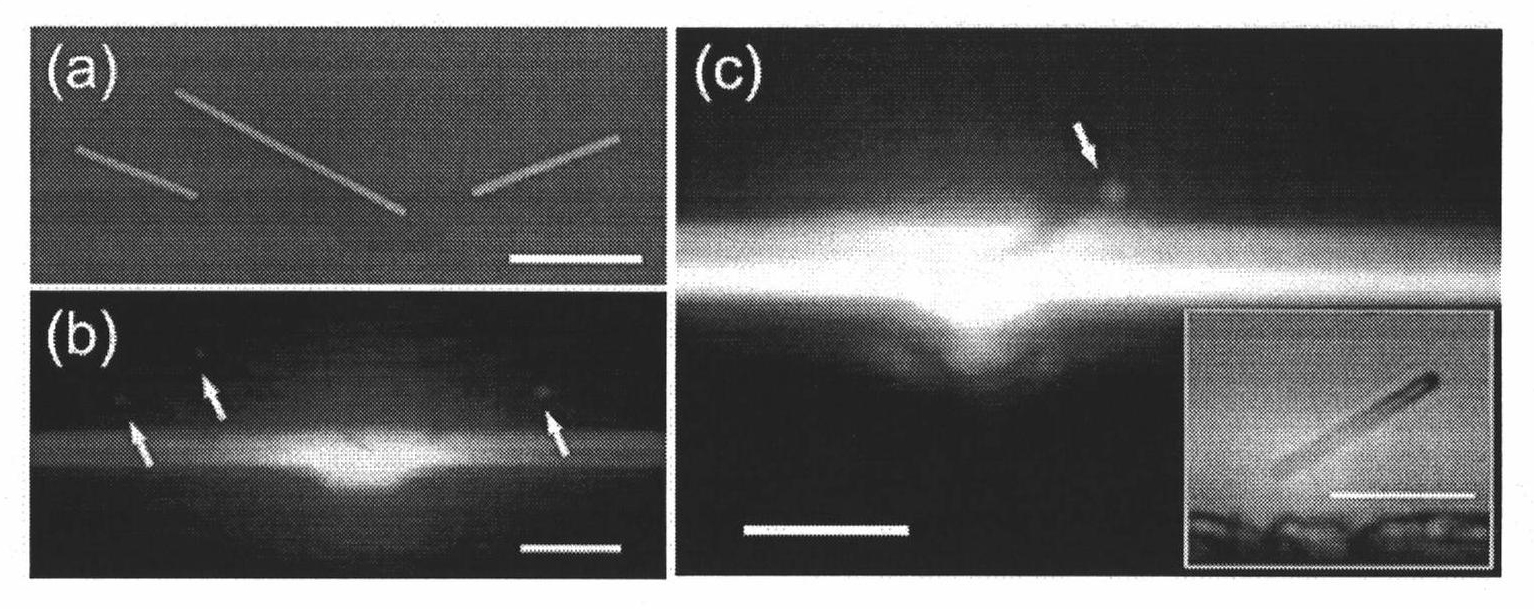

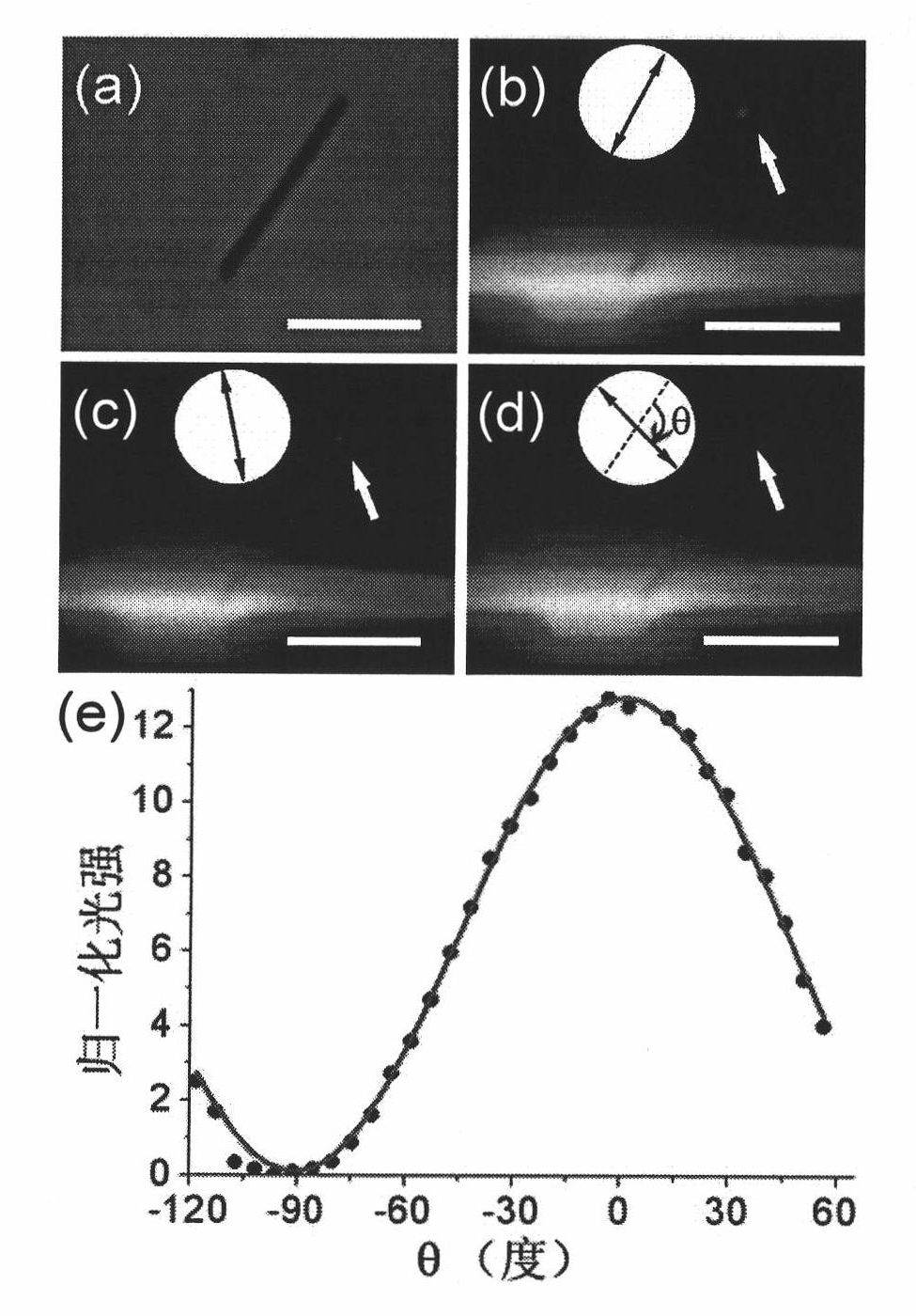

[0013] The diameter of the metal nanowire is 50-1000nm. Said laser diode is a general commercial laser diode with a wavelength of 400-2000nm. Such as figure 2 The laser diode used in (b) is the DL-3147-065 type red laser diode (center wavelength about 650nm) of Japan Sanyo Company, figure 2 (c) uses the RLD78NZH1 type infrared laser diode (center wavelength of about 785nm) of Rohm Company. The structure can be multiple or single nanowire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com