Planar waveguide structure laser ceramic material and preparation method thereof

A technology of laser ceramics and slab waveguides, which is applied in the direction of lasers, laser components, and the structure/shape of active media, can solve the problems of high difficulty in processing micron-level core layers, complex preparation processes, and expensive special equipment, etc., to facilitate industrialization Large-scale production, increased laser power, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of the slab waveguide structure laser ceramics comprises the following steps:

[0054] a) According to R 3 Al 5 o 12 with (Ln x R 1-x ) 3 Al 5 o 12 Weigh the raw material powder according to the stoichiometric ratio and transfer it to two ball mill tanks A and B respectively;

[0055] b) Mix the raw material powders in ball mill tanks A and B with solvent and dispersant respectively, and ball mill to prepare two primary slurries;

[0056] c) Add binder and plasticizer to two primary slurries respectively, and perform secondary ball milling to obtain two final slurries;

[0057] d) preparing the two final slurries obtained in step c) into casting films respectively;

[0058] e) Cut and laminate the dried cast film according to the design requirements to prepare ceramic green bodies;

[0059] f) Debinding and cold isostatic pressing of the laminated blank;

[0060] g) Sintering the green body after cold isostatic pressing to obtain a slab...

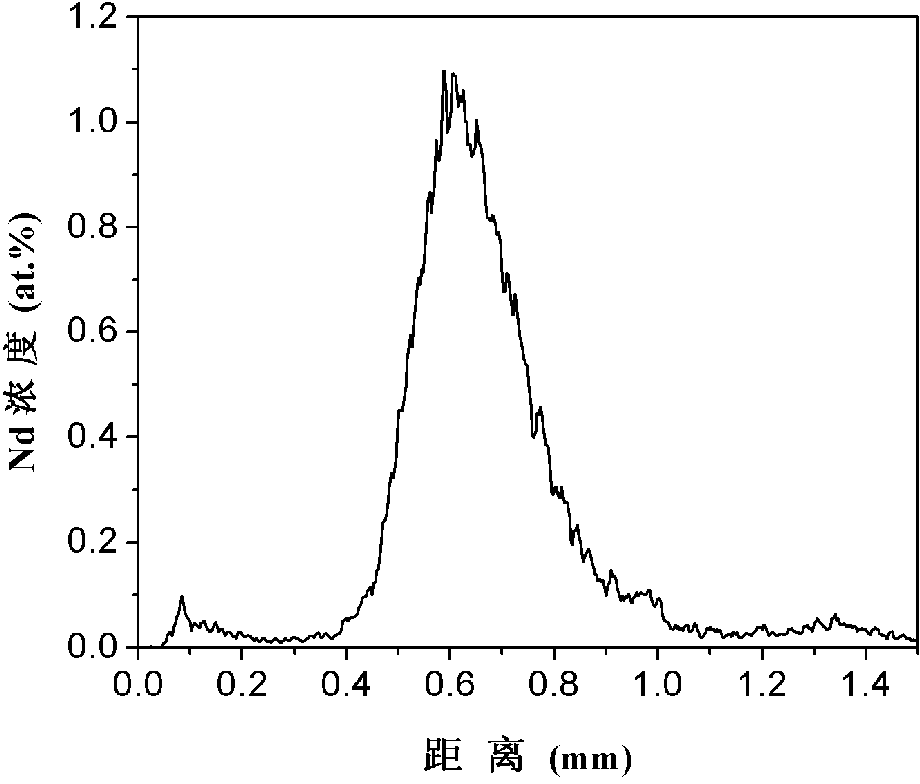

Embodiment 1

[0100] Follow Y 3 al 5 o 12 The stoichiometric ratio of high-purity commercial Al 2 o 3 Powder 25.4903g, Y 2 o 3 33.8715g of powder is poured into high-purity alumina ball mill tank A. Then follow (Y 0.98 Nd 0.02 ) 3 al 5 o 12 The stoichiometric ratio weighs Al 2 o 3 Powder 25.4903g, Y 2 o 3Powder 33.1941g, Nd 2 o 3 1.0094g of powder is poured into high-purity alumina ball mill tank B. Add 0.2968g and 0.2980g of sintering aids TEOS, 0.2980g, MgO0.0297g, 1.2g of herring oil, 18g of absolute ethanol, and 6.5g of xylene into two ball milling tanks A and B respectively, and prepare a primary slurry by mixing and ball milling. The ball milling time is 12 hours. Add 4.75 g of binder polyvinyl butyral, 2.35 g of plasticizer polyethylene glycol and butyl benzyl phthalate, and ball mill and mix for 12 hours to prepare the final slurry. The homogeneously mixed slurry is moved into the vacuum degassing system and undergoes vacuum treatment to eliminate the air bubbles ...

Embodiment 2

[0102] Follow Y 3 Al 5 o 12 The stoichiometric ratio of high-purity commercial Al 2 o 3 Powder 25.4903g, Y 2 o 3 33.8715g of powder is poured into high-purity alumina ball mill tank A. Then follow (Y 0.99 Nd 0.01 ) 3 Al 5 o 12 The stoichiometric ratio weighs Al 2 o 3 Powder 25.4903g, Y 2 o 3 Powder 33.5328g, Nd 2 o 3 Pour 0.5047g of powder into high-purity alumina ball mill tank B. Add 0.4749g and 0.4762g of sintering aids TEOS, 0.0476g and 0.0475g of MgO, 0.6g of herring oil, 12g of absolute ethanol, and 12g of xylene to two ball milling tanks A and B respectively, and mix and ball mill to prepare a Slurry, ball milling time 10 hours. Add 4.76 g of binder polyvinyl butyral, 2.38 g of plasticizer polyethylene glycol and butyl benzyl phthalate, and ball mill and mix for 15 hours to prepare the final slurry. The homogeneously mixed slurry is moved into the vacuum degassing system, and after vacuum treatment, the air bubbles in the slurry are removed. The dega...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com