Wet process device for etching wafer, and wet process etching method

A wet etching and wafer technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of uneven etching on the wafer surface, lower process accuracy, and affect product yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

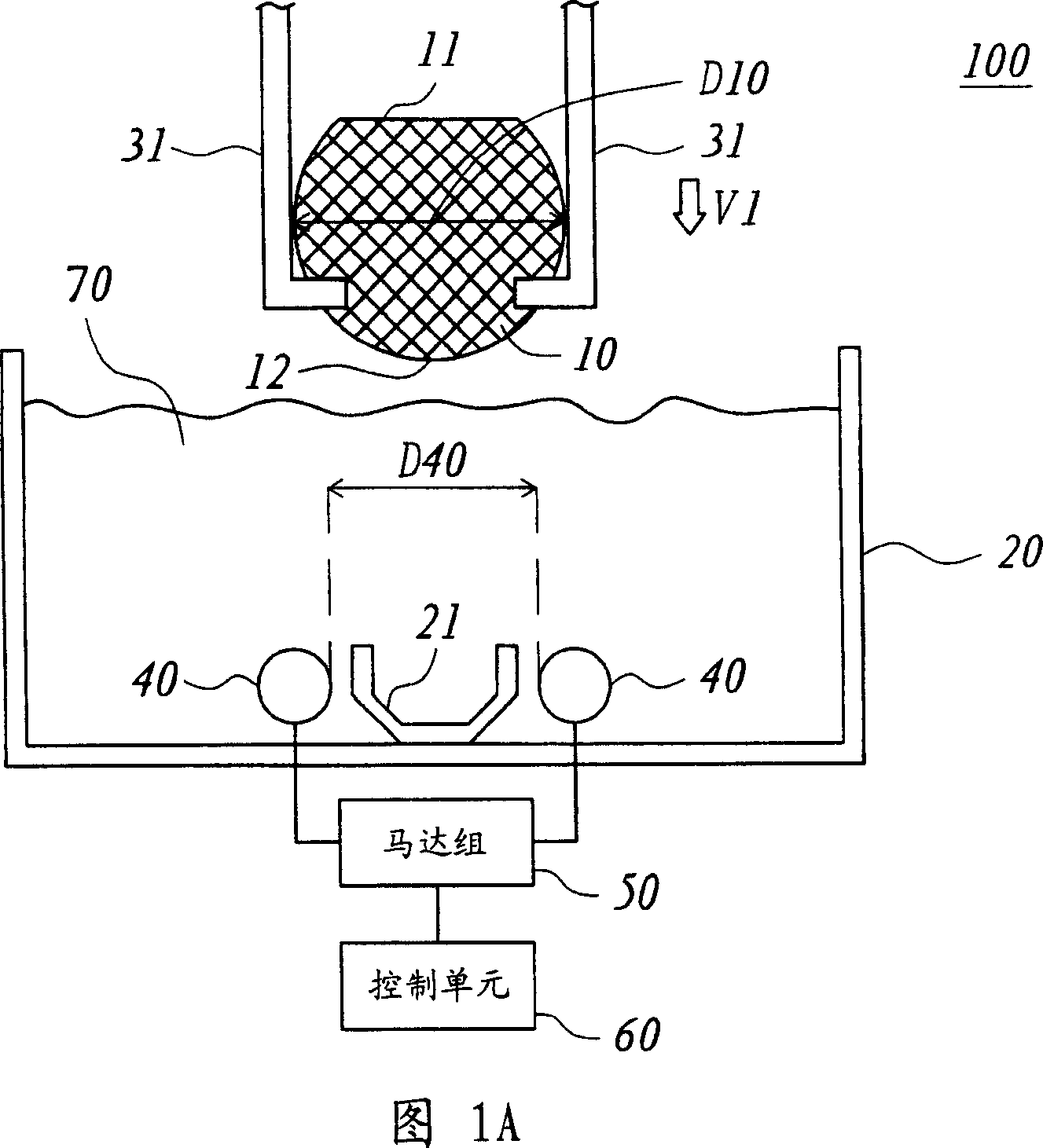

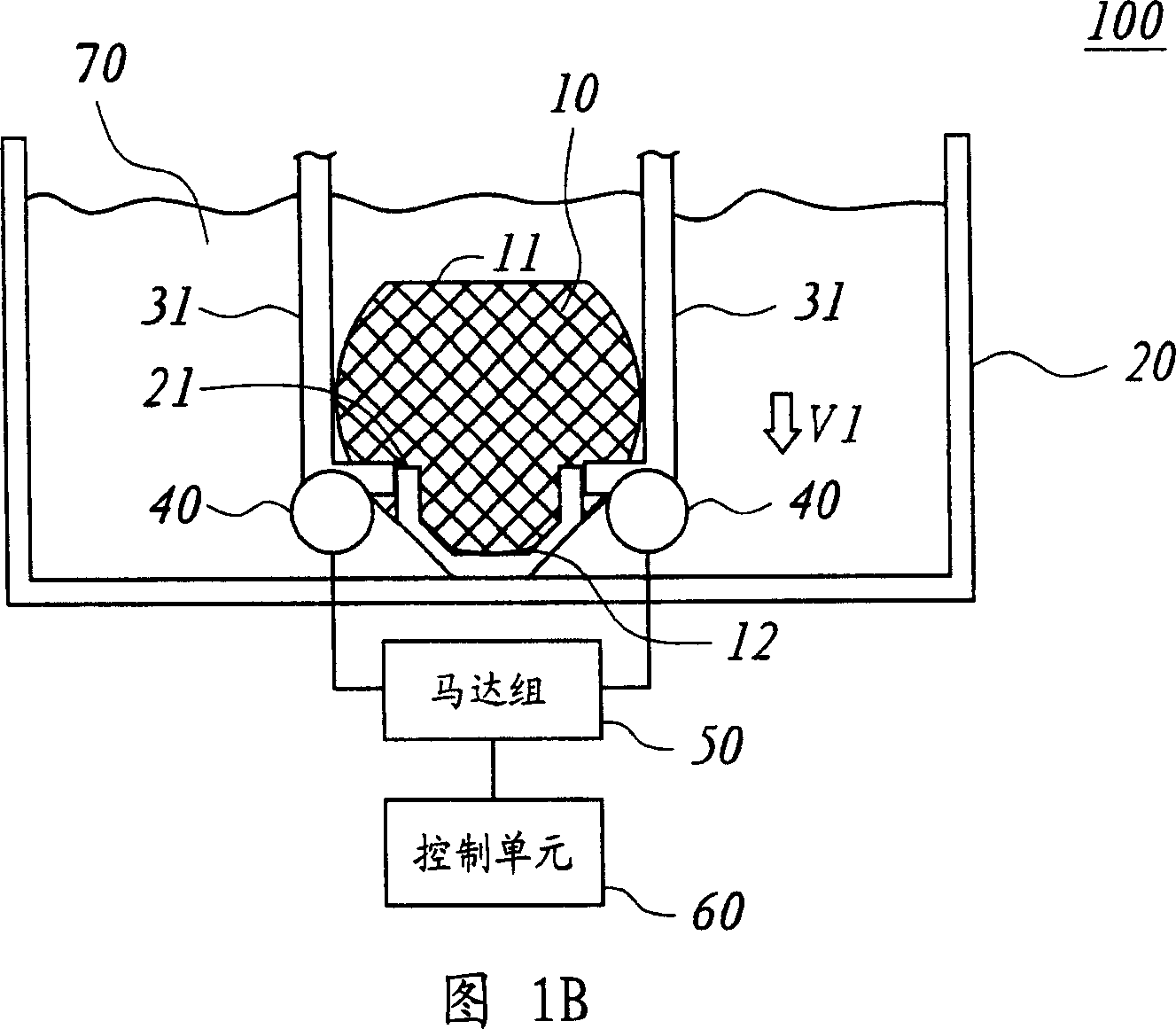

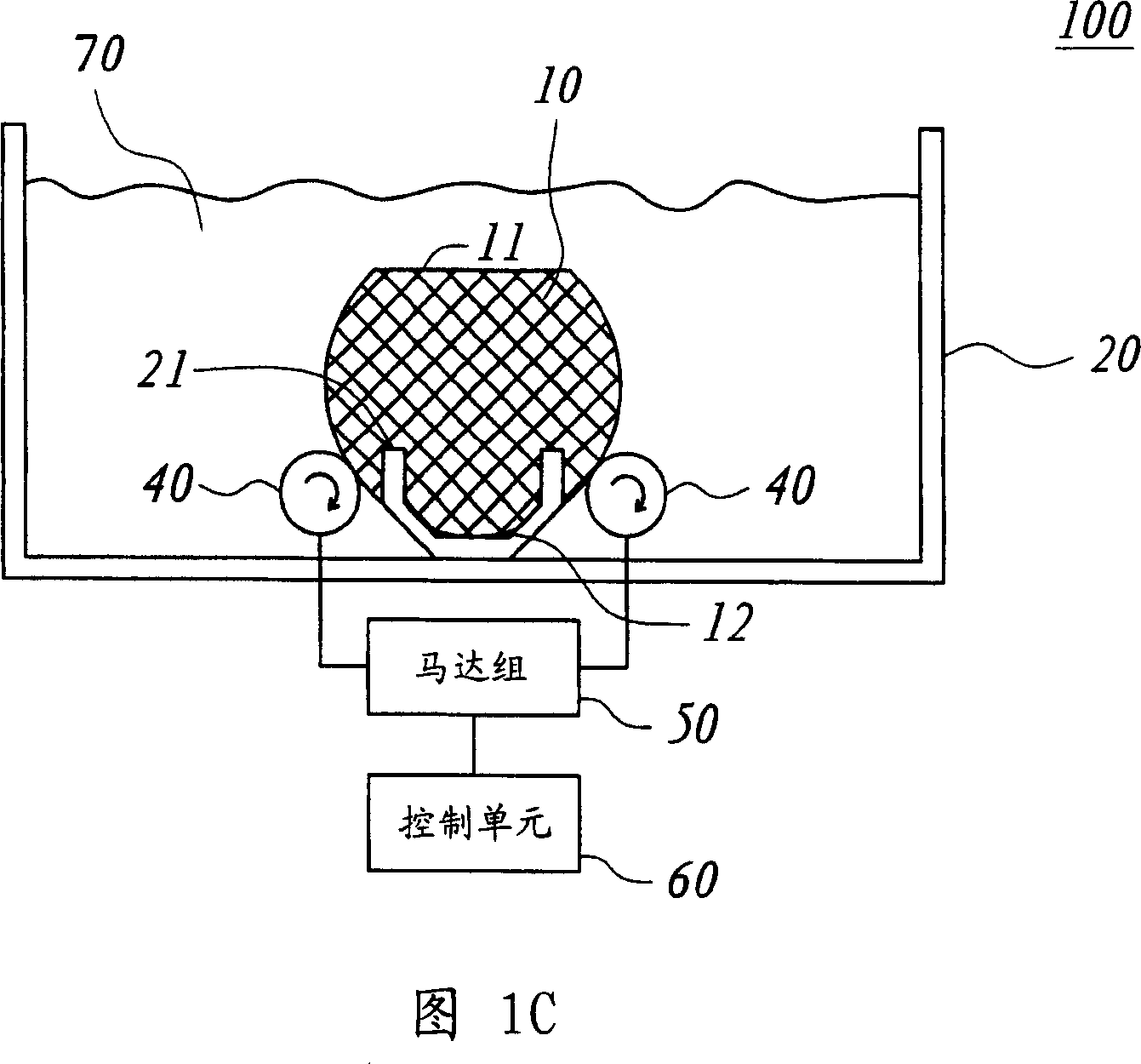

[0035] Please refer to FIGS. 1A-1E and FIG. 2 at the same time. FIGS. 1A-1E are schematic diagrams of a wafer wet etching device according to a wafer wet etching method according to a preferred embodiment of the present invention. FIG. 2 is a schematic diagram illustrating the orientation of the wafer and the spinner. The wafer wet etching device 100 includes an etching tank 20 , a clamp 31 and a rotating mechanism. The etching tank 20 is used for accommodating an etching solution 70, and the etching solution 70 can be an acidic solution or an alkaline solution. The clamp 31 is used for clamping a wafer 10 into and out of the etchant 70 . In this embodiment, the gripper 31 is described by taking a robot arm as an example. The rotating mechanism is disposed in the etching tank 20 for rotating the wafer 10 in the etching solution 70 . In this embodiment, the rotating mechanism is described by taking two rotating columns 40 as an example.

[0036] The two rotating columns 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com