Comprehensive thinning treatment process for liquid crystal display screen

A liquid crystal display and processing technology, applied in the field of comprehensive thinning processing of liquid crystal display, can solve the problems of different solubility, uneven etching effect, hindering further reaction between hydrofluoric acid and glass, etc. Uniform, easy to observe and handle the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

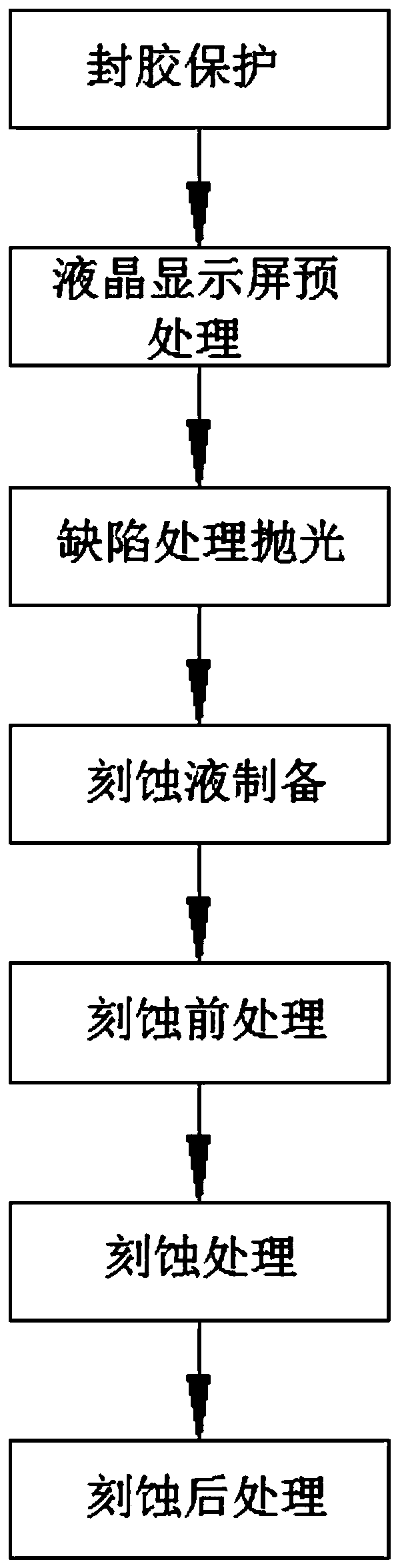

[0023] according to figure 1 As shown, this embodiment provides a comprehensive thinning treatment process for liquid crystal display, including the following steps:

[0024] Step 1: Sealing protection, apply a layer of frame glue on the side of the LCD screen, then put the LCD screen into an oven, and dry it for 10-15 minutes at a temperature of 170°C to cure the frame glue , to prevent the etchant from penetrating into the liquid crystal display, and then apply photoresist on the electrode end of the liquid crystal display, put it in an oven, and dry it for 5-15 minutes at a temperature of 70°C to make the photoresist The resist is cured to prevent the etchant from corroding the lead electrodes;

[0025] Step 2: Pretreatment of the liquid crystal display screen, take a concentration of 40% hydrofluoric acid, a concentration of 50% hydrochloric acid and clean water to make a mixed solution, put the liquid crystal display screen into a tank filled with the mixed solution and ...

Embodiment 2

[0035] according to figure 1 As shown, this embodiment provides a comprehensive thinning treatment process for liquid crystal display, including the following steps:

[0036] Step 1: Sealing protection, apply a layer of frame glue on the side of the LCD screen, then put the LCD screen into an oven, and dry it for 10-15 minutes at a temperature of 170°C to cure the frame glue , to prevent the etchant from penetrating into the liquid crystal display, and then apply photoresist on the electrode end of the liquid crystal display, put it in an oven, and dry it for 5-15 minutes at a temperature of 70°C to make the photoresist The resist is cured to prevent the etchant from corroding the lead electrodes;

[0037] Step 2: Liquid crystal display pretreatment, take the hydrofluoric acid with the concentration of 40%, the hydrochloric acid with the concentration of 50% and clean water to make a mixed solution, put the liquid crystal display into the tank with the mixed solution and soak...

Embodiment 3

[0047] according to figure 1 As shown, this embodiment provides a comprehensive thinning treatment process for liquid crystal display, including the following steps:

[0048] Step 1: Sealing protection, apply a layer of frame glue on the side of the LCD screen, then put the LCD screen into an oven, and dry it for 10-15 minutes at a temperature of 170°C to cure the frame glue , to prevent the etchant from penetrating into the liquid crystal display, and then apply photoresist on the electrode end of the liquid crystal display, put it in an oven, and dry it for 5-15 minutes at a temperature of 70°C to make the photoresist The resist is cured to prevent the etchant from corroding the lead electrodes;

[0049] Step 2: Pretreatment of the liquid crystal display screen, take a concentration of 40% hydrofluoric acid, a concentration of 50% hydrochloric acid and clean water to make a mixed solution, put the liquid crystal display screen into a tank filled with the mixed solution and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com