Method for preventing montmorillonite from stripping in aqueous solution

A technology of montmorillonite and aqueous solution, which is applied in the field of surface chemistry, can solve the problems of increased specific surface area and large consumption of reagents, and achieve the effects of reducing mud entrainment, improving efficiency and reducing consumption of reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The montmorillonite mineral used in this example is natural high-purity sodium-based montmorillonite.

[0015] The method step that prevents smectite from peeling off in aqueous solution is as follows:

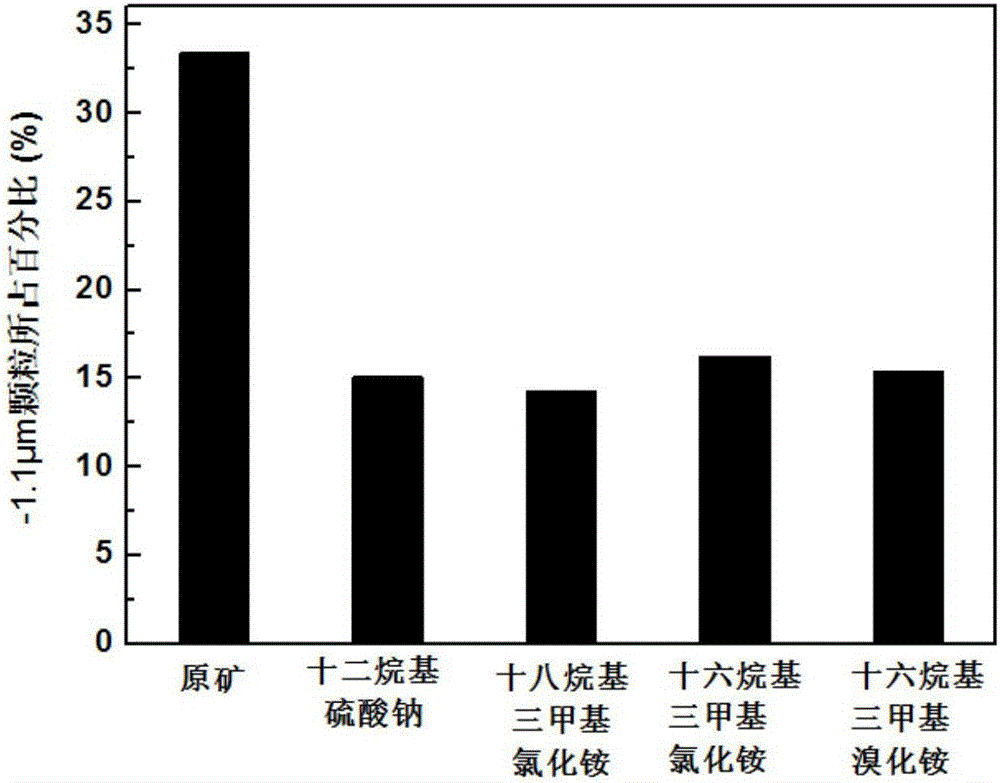

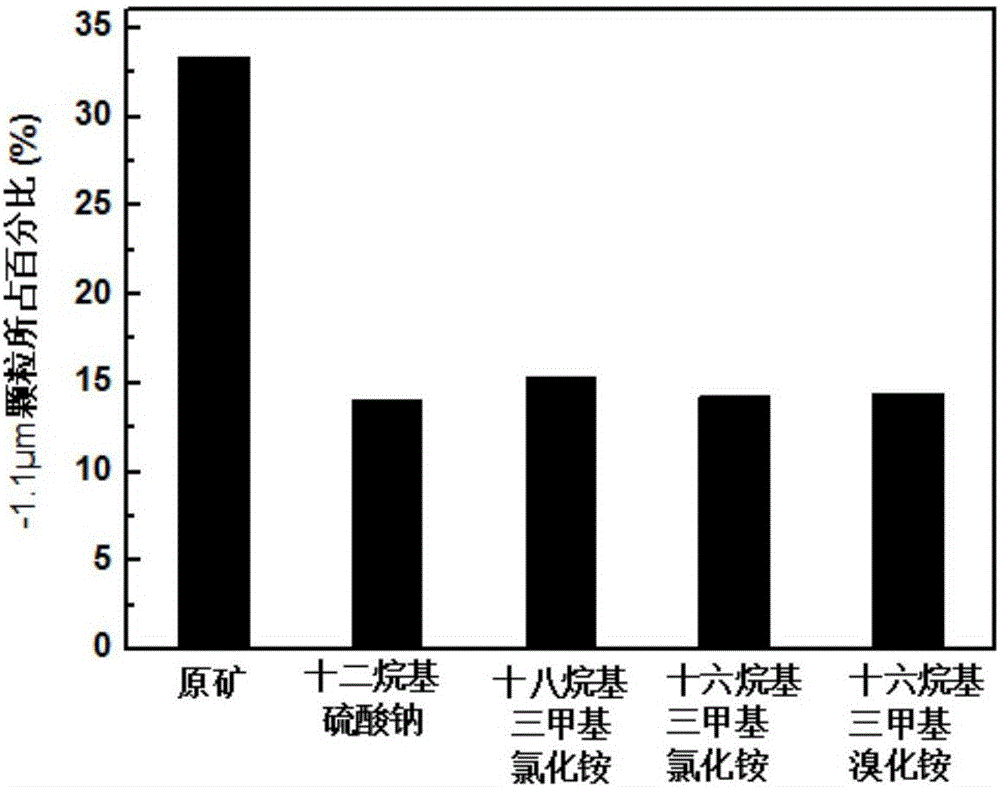

[0016] Use 0.2g of sodium lauryl sulfate, octadecyltrimethylammonium chloride, cetyltrimethylammonium chloride or cetyltrimethylammonium bromide as the agent, and dissolve the agent in The concentration of 40g / L, 80g / L drug solutions were obtained in water, and then 1g of sodium montmorillonite with a particle size of less than 40 μm was mixed with the drug solution, placed in a grinding machine and stirred at a speed of 150 rev / min for 60 minutes, and then Take out the montmorillonite. At this time, the end surface of the montmorillonite has absorbed the drug, and the end surface has become hydrophobic. When the montmorillonite is immersed in water, water molecules cannot enter the interlayer of the montmorillonite, and the distance between the montmorillonite layers w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com