Glass substrate and preparation method thereof

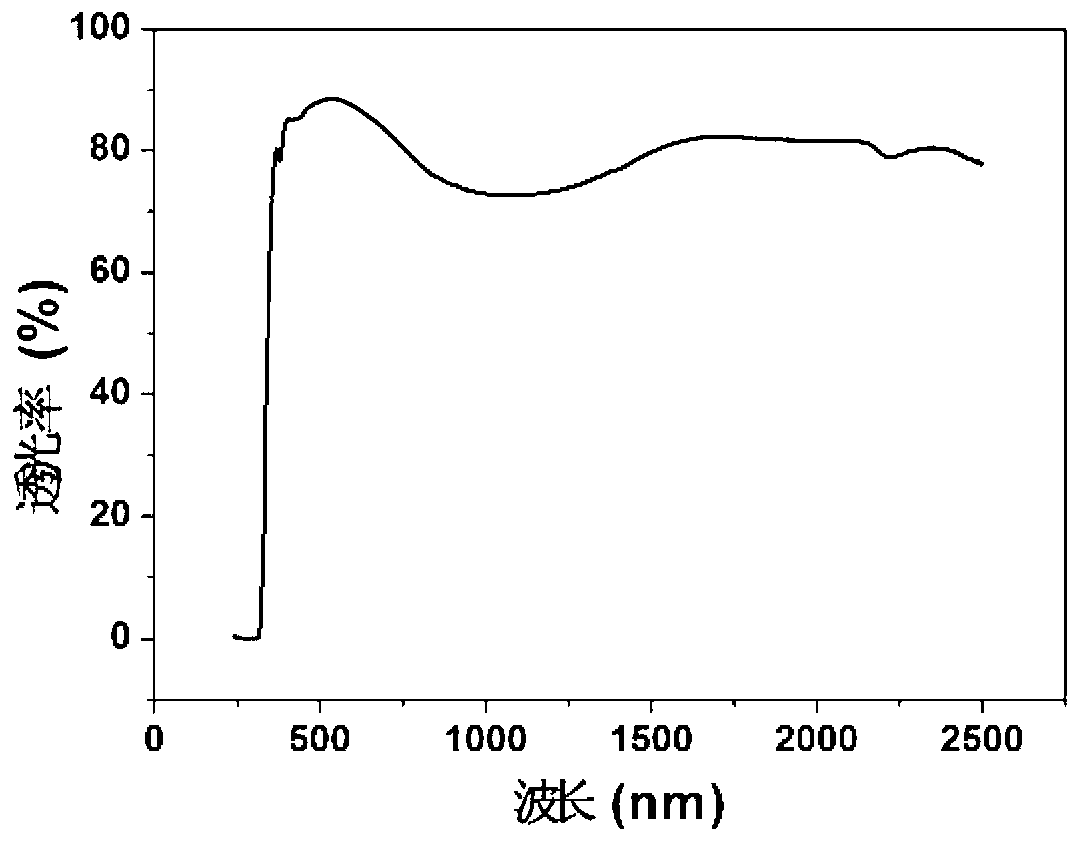

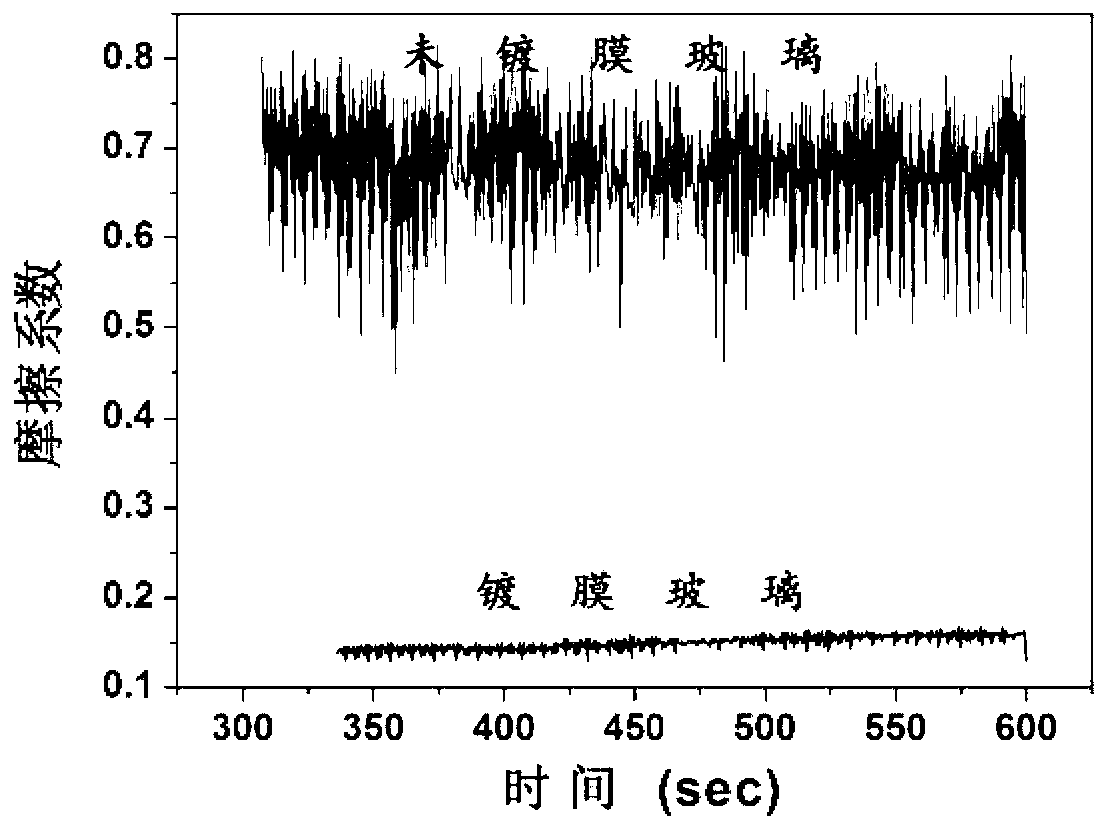

A glass substrate and ultra-clear glass technology, applied in the field of glass substrate and its preparation, can solve problems such as difficulty in ensuring transparency in the visible light band, film release, and restrictions on the development and application of diamond-like films, and achieve good visible light transmittance and durability. Abrasiveness, the effect of reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Prepared with ordinary soda lime silica glass Na 2 O CaO 6SiO 2 Ultra-thin transparent hard DLC film as the substrate.

[0046] Step 1: Prepare the glass substrate

[0047] Cut a common glass substrate with a length of 40 mm, a width of 40 mm, and a thickness of 6 mm, wash it with deionized water, isopropanol, and deionized water for 10 minutes each, and then dry it with nitrogen for use.

[0048] Step Two: Plasma Cleaning

[0049] Put the glass substrate prepared for use in the first step into the coating chamber, pay attention to put the glass substrate on the negative potential end, close the door to vacuum, and pump the background vacuum to 2×10 -4 Pa, 30sccm of high-purity oxygen is introduced. After the gas flow is stable, turn on the radio frequency power supply, start the glow at 200W, and perform oxygen plasma cleaning for 3 minutes. After cleaning, put the glass substrate in a vacuum for 5 minutes. cool down.

[0050] The third step: plasma deposition coa...

Embodiment 2

[0057] An ultra-thin transparent and rigid DLC film with 2mm ultra-clear glass as the substrate was prepared.

[0058] Step 1: Prepare the glass substrate

[0059] Cut an ultra-clear glass substrate with a length of 700 mm, a width of 400 mm, and a thickness of 2 mm, wash it with deionized water, isopropanol, and deionized water for 15 minutes each, and then dry it with nitrogen for use.

[0060] Step Two: Plasma Cleaning

[0061] Put the glass substrate prepared for use in the first step into the coating chamber, pay attention to put the glass substrate on the negative potential end, close the door to vacuum, and pump the background vacuum to 2.5×10 -4 Pa, 50sccm of high-purity argon gas is introduced. After the gas flow is stable, turn on the radio frequency power supply, start the glow at a power of 300W, and perform argon plasma cleaning for 6 minutes. Cool the surface.

[0062] The third step: plasma deposition coating

[0063] After cleaning, stop feeding argon gas, ...

Embodiment 3

[0067] An ultra-thin transparent and rigid DLC film with 5mm quartz glass as the substrate was prepared.

[0068] Step 1: Prepare the glass substrate

[0069] Quartz glass substrates with a length of 25 mm, a width of 75 mm, and a thickness of 5 mm were cut, washed with deionized water, isopropanol, and deionized water for 12 minutes each, and then dried with nitrogen for use.

[0070] Step Two: Plasma Cleaning

[0071] Put the glass substrate prepared for use in the first step into the coating chamber, pay attention to put the glass substrate on the negative potential end, close the door to vacuum, and pump the background vacuum to 4×10 -4 Pa, 5 sccm of high-purity argon gas was introduced, and after the gas flow was stable, the radio frequency power was turned on, and the argon plasma cleaning was carried out at a power of 50W for 4 minutes. After cleaning, the glass substrate was left to stand in vacuum for 8 minutes. Cool the surface.

[0072] The third step: plasma dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com