Double hydrophobic layer air cathode used for metal/air battery

An air battery and air cathode technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as electrolyte drying up, affecting electrode stability, and complicated preparation process, so as to reduce the entry of water in the air and improve stability , the effect of preventing peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

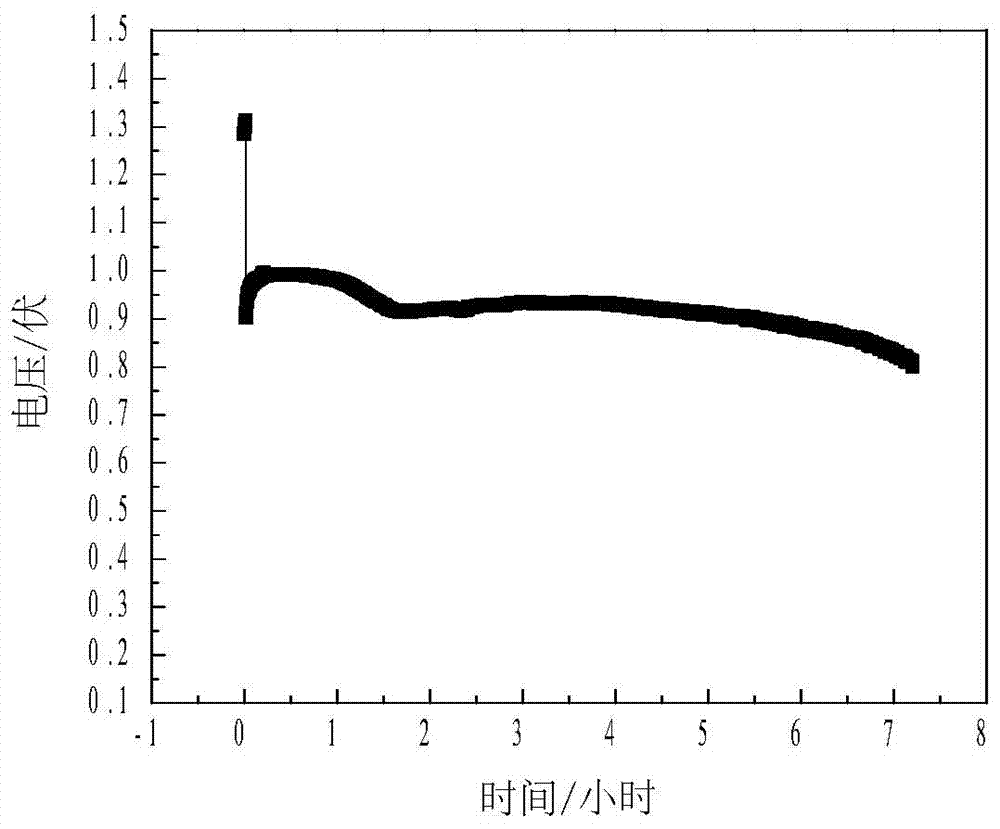

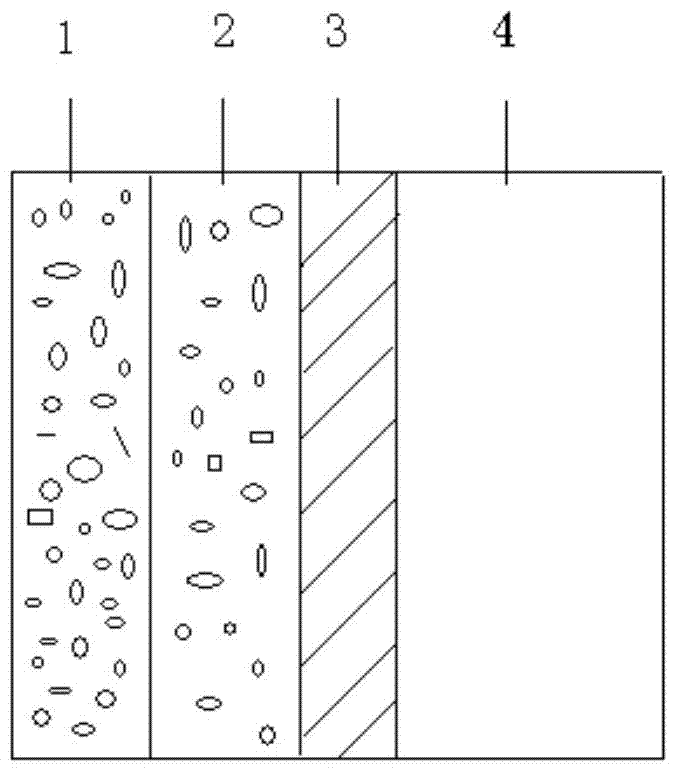

Embodiment 1

[0021] The air cathode includes the first hydrophobic and air-permeable layer, the second hydrophobic and air-permeable layer, the current collector and the catalytic layer laminated in sequence. The porosity of the first hydrophobic and air-permeable layer is 70.5%, and the porosity of the second hydrophobic and air-permeable layer is 64.5%. . The first hydrophobic and air-permeable layer is prepared by mixing acetylene black and PTFE through rolling process, the content of PTFE is 70%, and the thickness of the first hydrophobic and air-permeable layer is 0.30mm; the second hydrophobic and air-permeable layer is made of acetylene black and PTFE through rolling process Prepared, the PTFE content is 60%, the thickness of the second hydrophobic and air-permeable layer is 0.25mm; the thickness of the first hydrophobic and air-permeable layer is 0.5mm;

[0022] The current-collecting layer is a stretched nickel mesh coated with a catalyst paste on the surface. The composition and ...

Embodiment 2

[0028] The structure of the air cathode in this embodiment is the same as the above structure, wherein the porosity of the first hydrophobic and air-permeable layer is 65%, and the porosity of the second hydrophobic and air-permeable layer is 55.5%.

Embodiment 3

[0030] The structure of the air cathode in this embodiment is the same as the above structure, wherein the porosity of the first hydrophobic and air-permeable layer is 40.6%, and the porosity of the second hydrophobic and air-permeable layer is 34.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com