Device capable of scraping optical cable factice effectively

An optical cable and ointment technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of cable core tying yarn blockage, optical cable appearance defects, hidden safety hazards, etc., to facilitate disassembly and maintenance, and solve serious wear and tear of cable cores , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

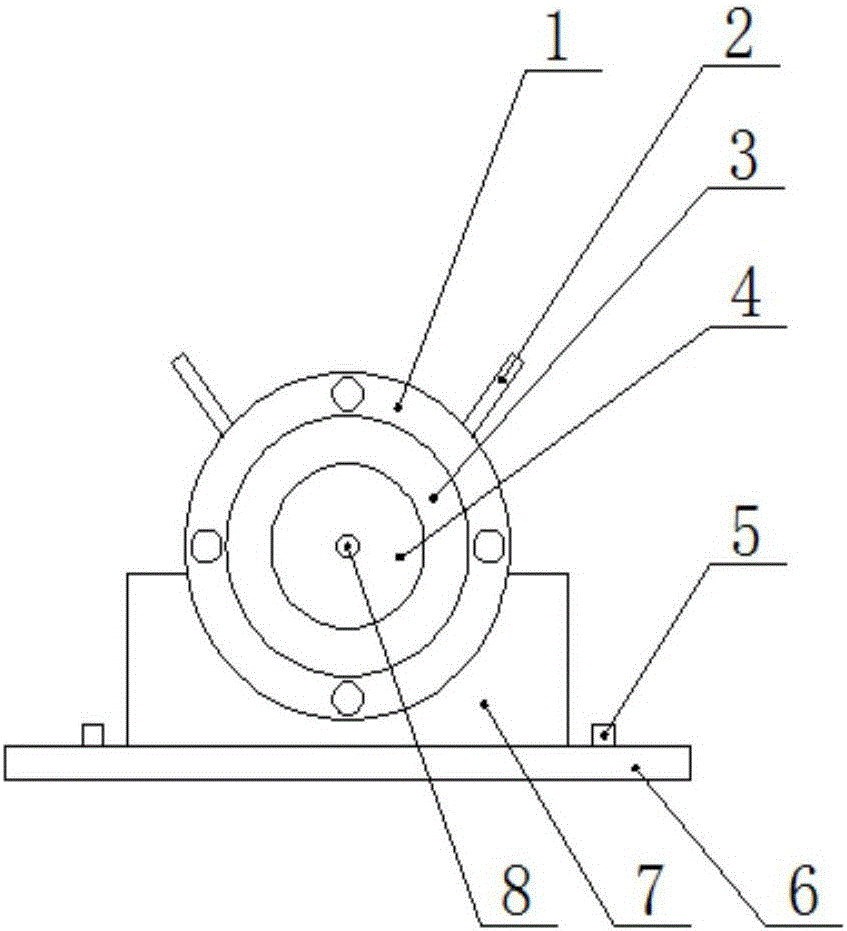

[0020] A device that can effectively cover optical cable grease, such as figure 1 As shown, it includes a support plate 6, a bracket 7, a flange 1, an inner sleeve bearing 4 and an outer sleeve bearing 3, the support is vertically fixed on the support plate, and a semicircular groove is provided on the upper side of the support plate. The flange is fixed in the semicircular groove, the outer sleeve bearing is coaxially set in the flange, and the inner sleeve bearing is coaxially threaded in the outer sleeve bearing.

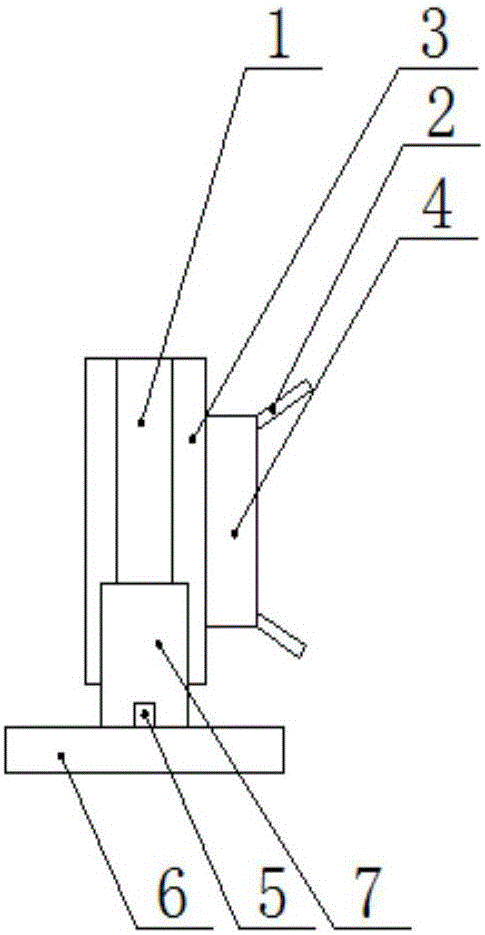

[0021] Such as figure 2 As shown, the length of the outer sleeve bearing is greater than the length of the flange, the length of the inner sleeve bearing is greater than the length of the outer sleeve bearing, and there is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com