Coaxle electric connector

An electrical connector, coaxial technology, applied in the direction of conductive connection, connection, two-pole connection, etc., can solve the problems of reducing the contact function of the connector, reducing the height, entering the gap, etc., to avoid the entry of molten solder, etc. The effect of improving the holding force and engaging force, and improving the holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

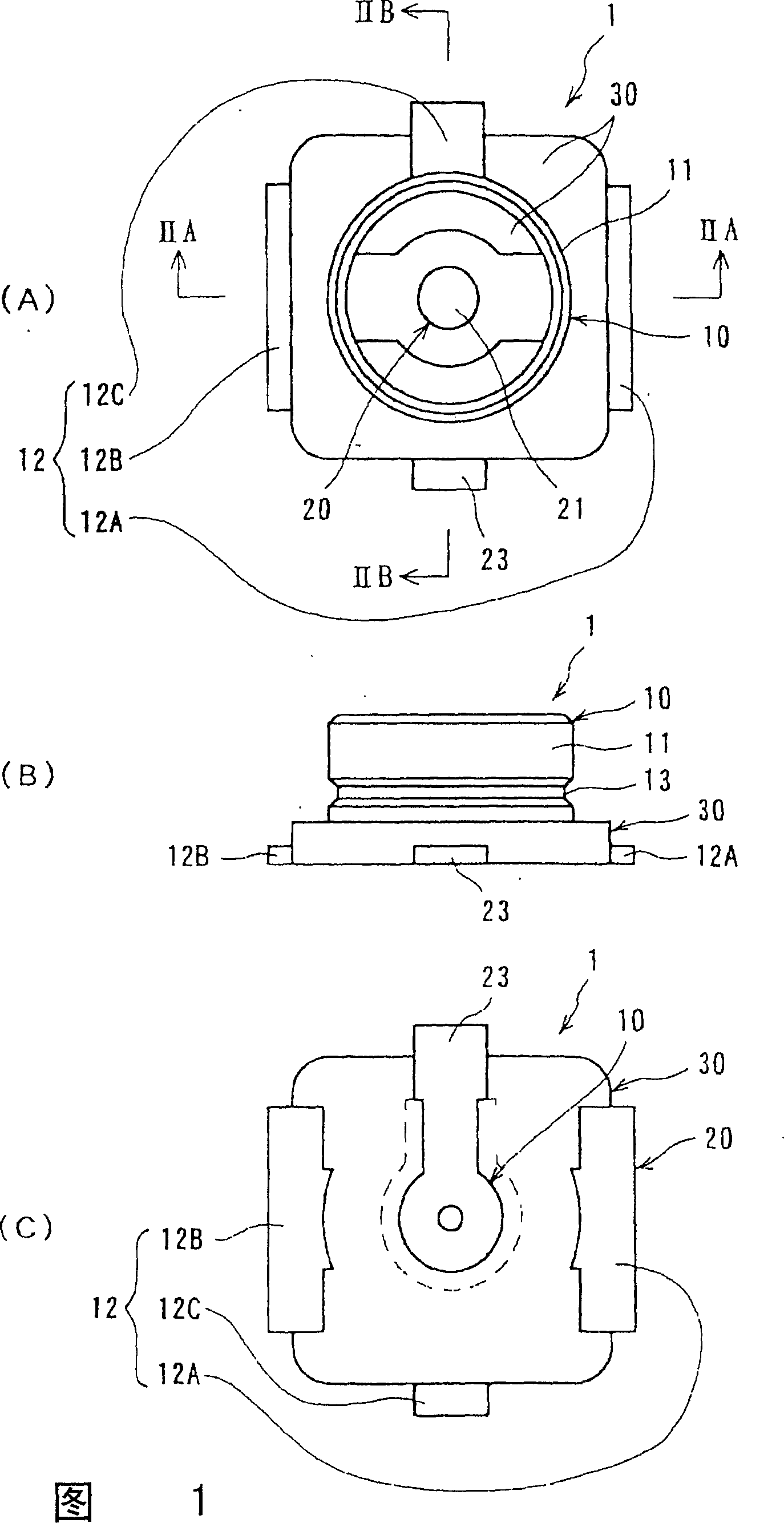

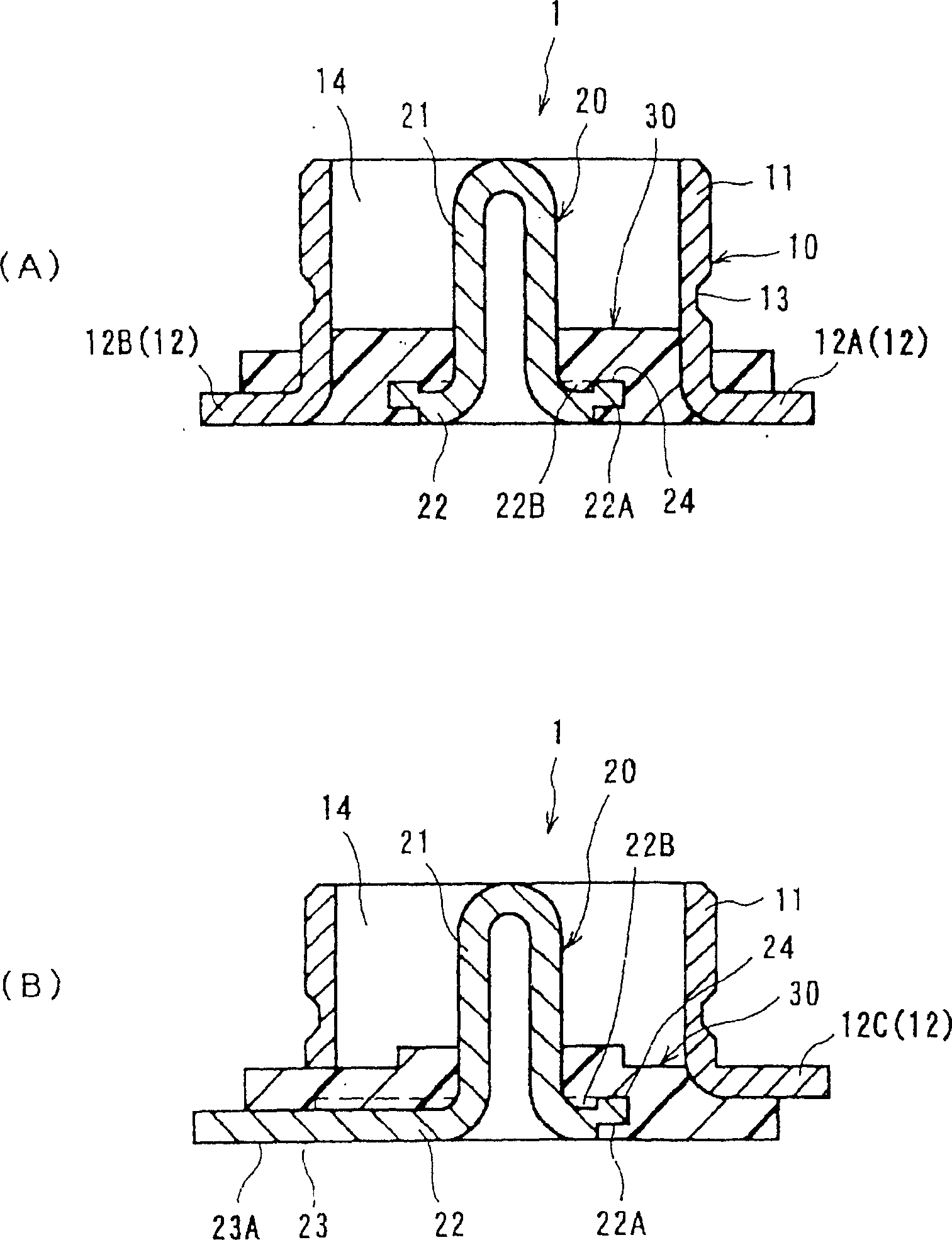

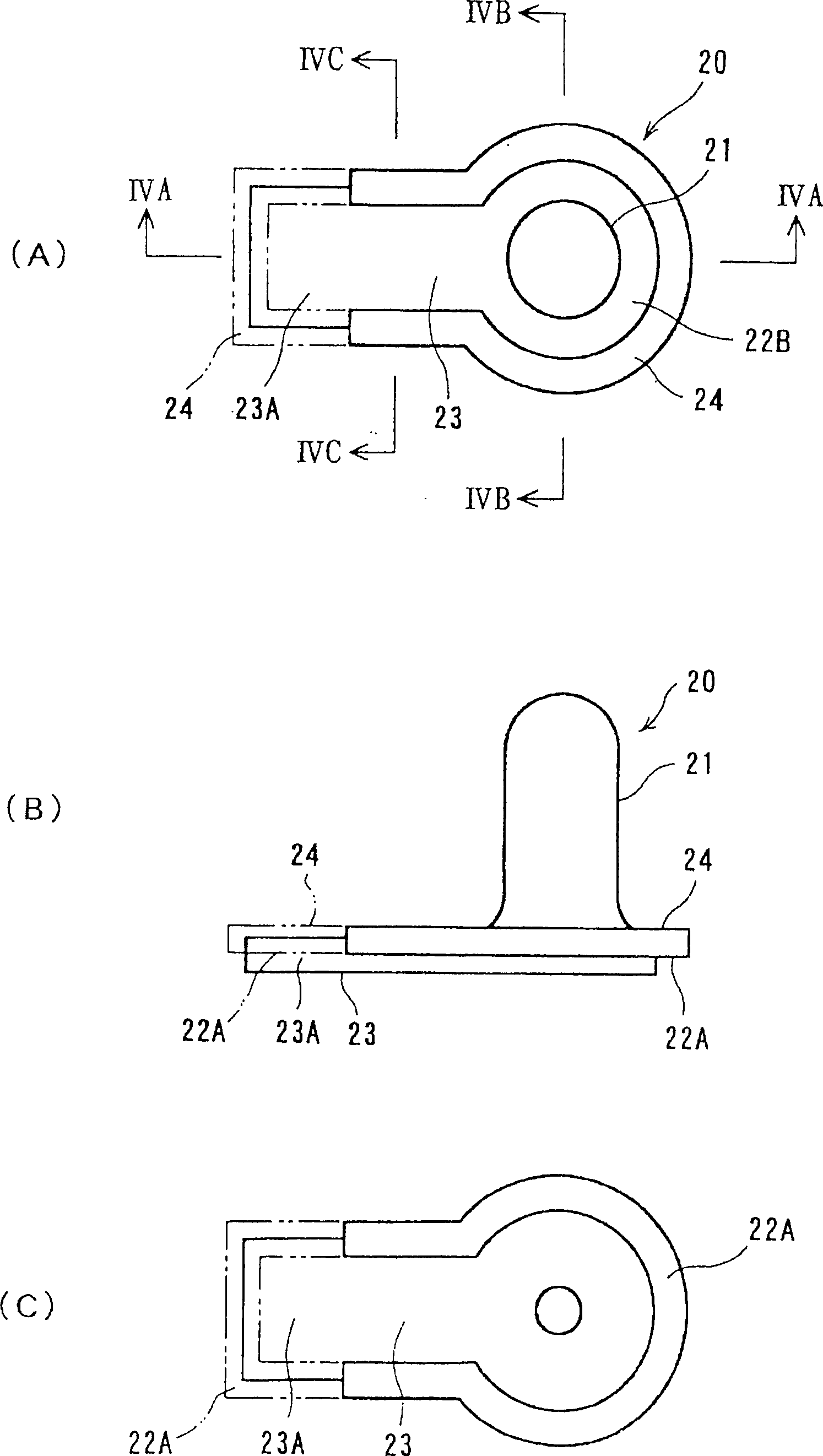

[0041] The following according to Figure 1 to Figure 15 , to describe the embodiment of the present invention.

[0042]

[0043] Figure 1 and figure 2 The coaxial connector 1 according to the first embodiment shown integrally holds the outer conductor 10 and the central conductor 20 via the medium 30 .

[0044]The outer conductor 10 has: a cylindrical cylindrical portion 11 having an axis in the mating direction with the counterpart connector; a leg portion 12 extending radially outward from the lower portion of the cylindrical portion 11, and is formed by placing a metal plate Formed by bending and forming. In this embodiment, the cylindrical portion 11 has a cylindrical shape, and a locking groove 13 is formed on the outer surface for locking with an external conductor of a counterpart connector (not shown) to prevent falling off. Also, the leg portion 12 is composed of leg portions 12A, 12B, and 12C extending from three positions in the circumferential direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com