Pre-flushing refined filtration oil filling circuit device

A preflushing and fine filtration technology, which is applied in the direction of fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve problems such as failure to ensure safety, out-of-control actuators, and unclear descriptions, etc., to achieve structural Compact, cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

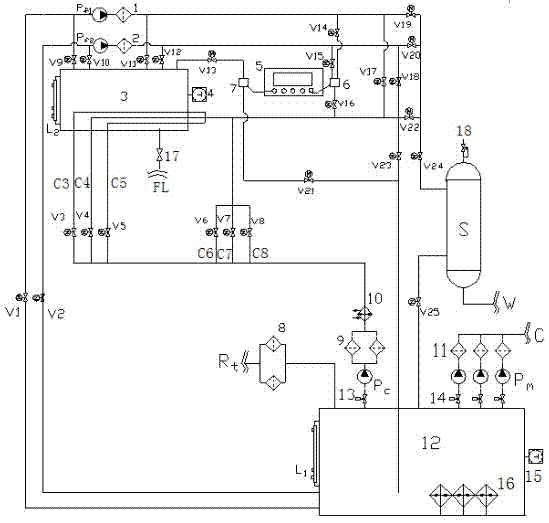

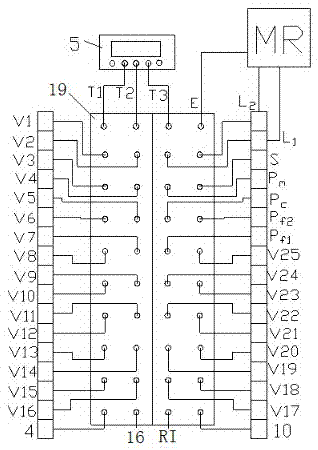

[0018] Embodiment 1: see figure 1 , a pre-flush fine filter oil-filling device, including a pre-flush oil tank 3, a large-flow flushing pump set P f1 ,P f2 , The first fine filtration filter group 1, the second fine filtration filter group 2, the pre-flush fuel tank temperature controller 4, the pre-flush fuel tank liquid level gauge L2, the refueling pipeline FL and the refueling valve 17, the electric control valve group V1~V25 , Particle moisture detector 5, detector inlet oil circuit integrated block 6, detector outlet oil circuit integrated block 7, oil-water-gas separator S, main oil tank 12, main system oil return filter group 8, main system circulating filter pump P c And circulation filter 9, main system main pump P m And oil outlet filter group 11, main circuit cooler 10, main oil tank temperature controller 15, main oil tank liquid level gauge L1, main oil tank heater 16, main control cabinet 19, pre-flush oil tank thermostat 4, pre-flush oil tank The liquid lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com