Rocker arm

一种钢材、残余奥氏体的技术,应用在机器/发动机、机械设备、发动机元件等方向,能够解决润滑状态严重等问题,达到防止异常磨损或纵摇、耐转动疲劳性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

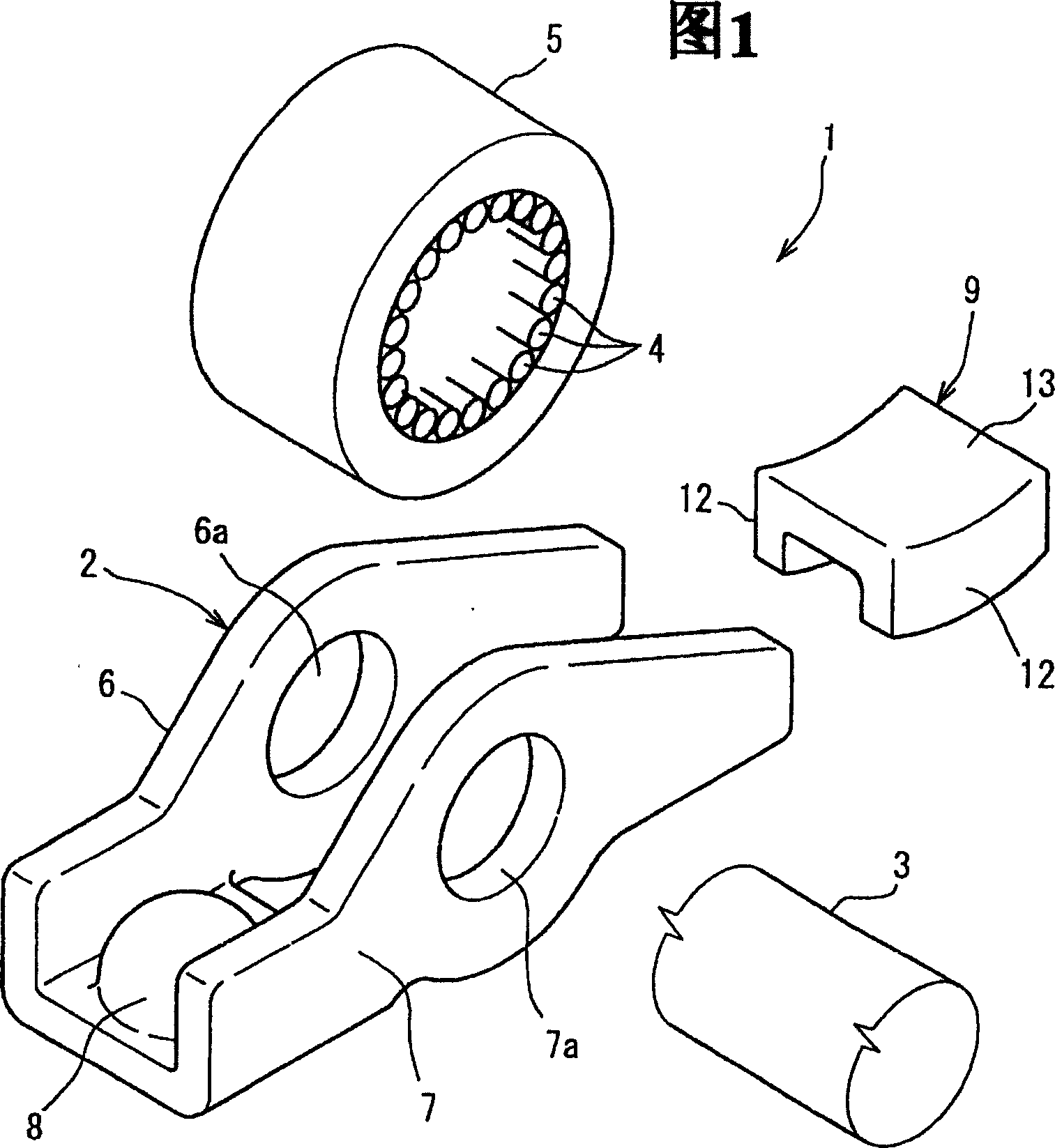

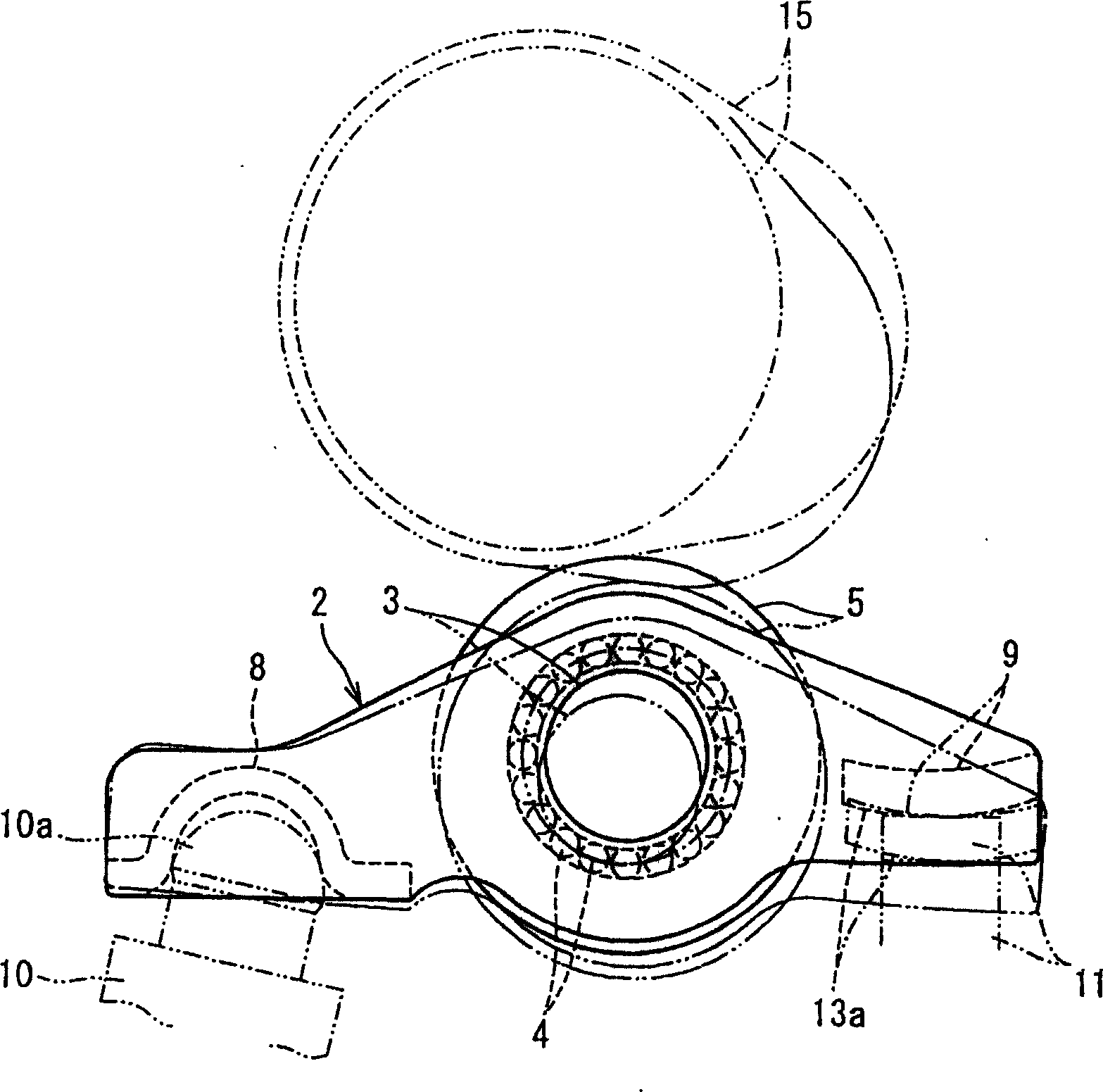

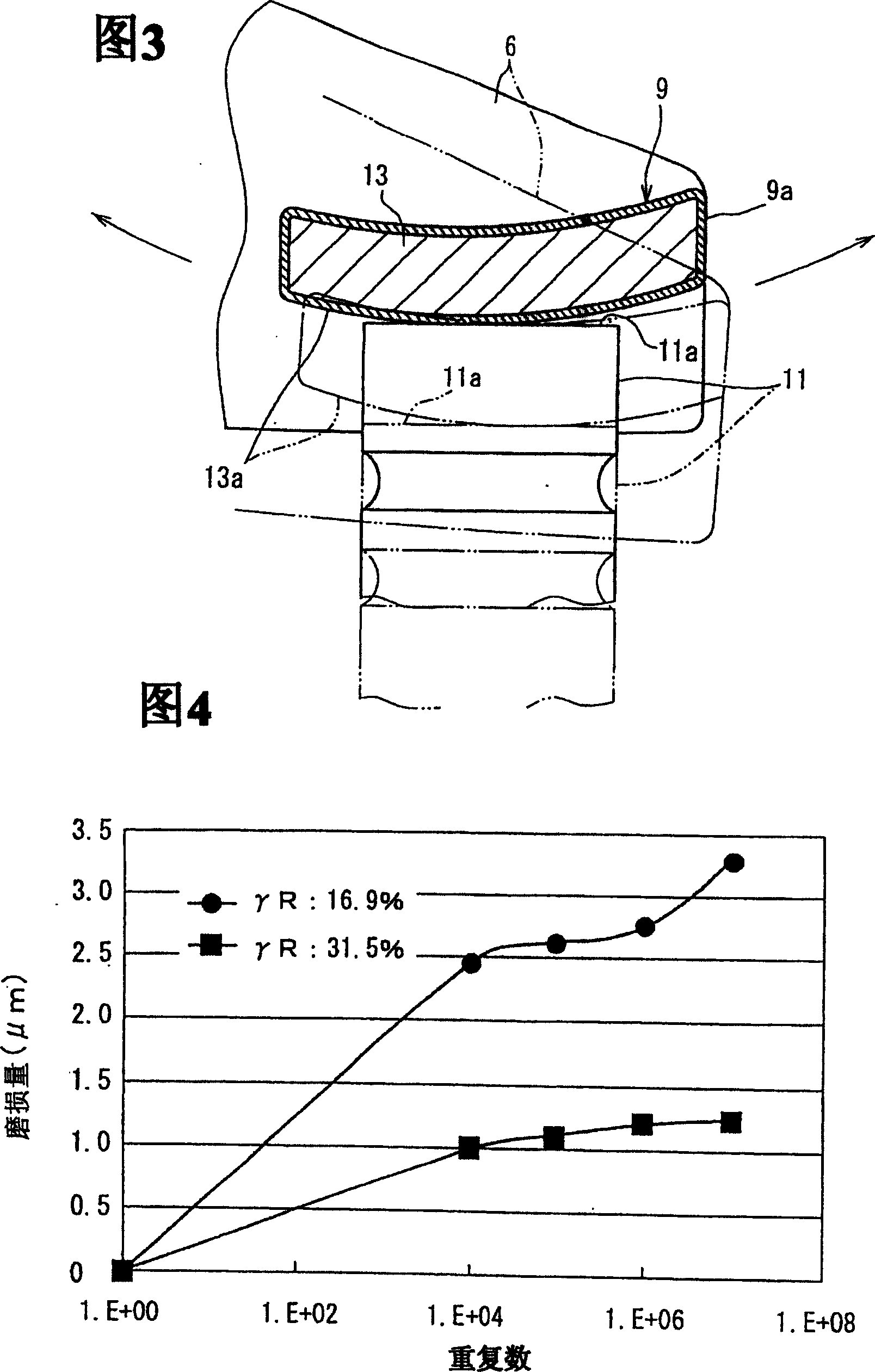

[0020] Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings. Fig. 1 is an exploded perspective view showing the overall configuration of a rocker arm made of sheet metal, figure 2 It is a cross-sectional view at the center of the width direction of the sheet metal rocker arm. FIG. 3 is an enlarged cross-sectional view showing the contact state between the connecting wall of the sheet metal rocker arm and the valve stem. FIG. 4 is a graph showing the relationship between the number of repetitions and the amount of wear .

[0021] Referring to these figures, 1 denotes a rocker arm made of sheet metal, and the rocker arm 1 made of sheet metal has a main body 2 . The body 2 has a pair of opposing side walls 6,7. In the central region in the longitudinal direction of each of the opposing side walls 6, 7, there are shaft holes 6a, 7a for supporting the support shaft 3. As shown in FIG. The ends of the support shaft 3 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com