Clamp for assembling annular extruding permanent magnet magnetic system and assembly method thereof

A permanent magnet magnetic system, annular technology, applied in the direction of hand-held tools, manufacturing tools, workpiece clamping devices, etc., can solve the problem of complex magnetic system, and achieve the effect of easy realization, good magnetic isolation, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

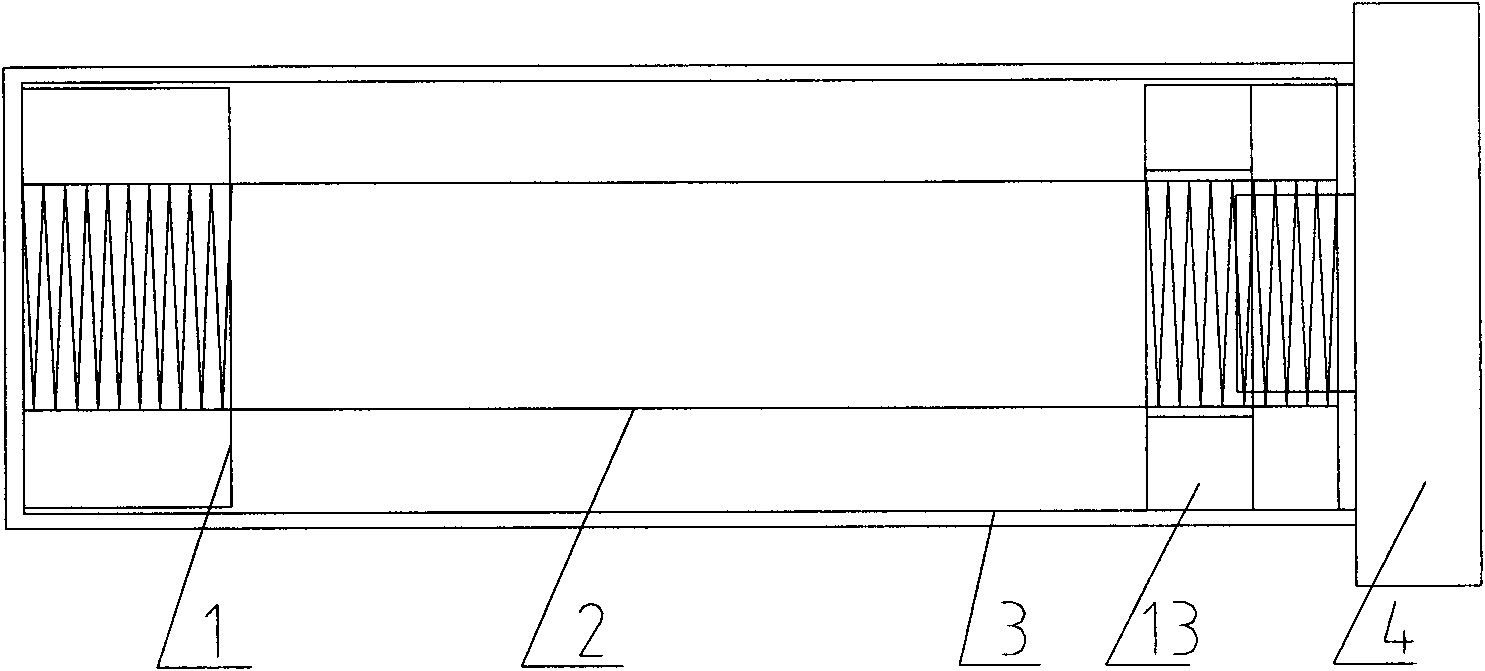

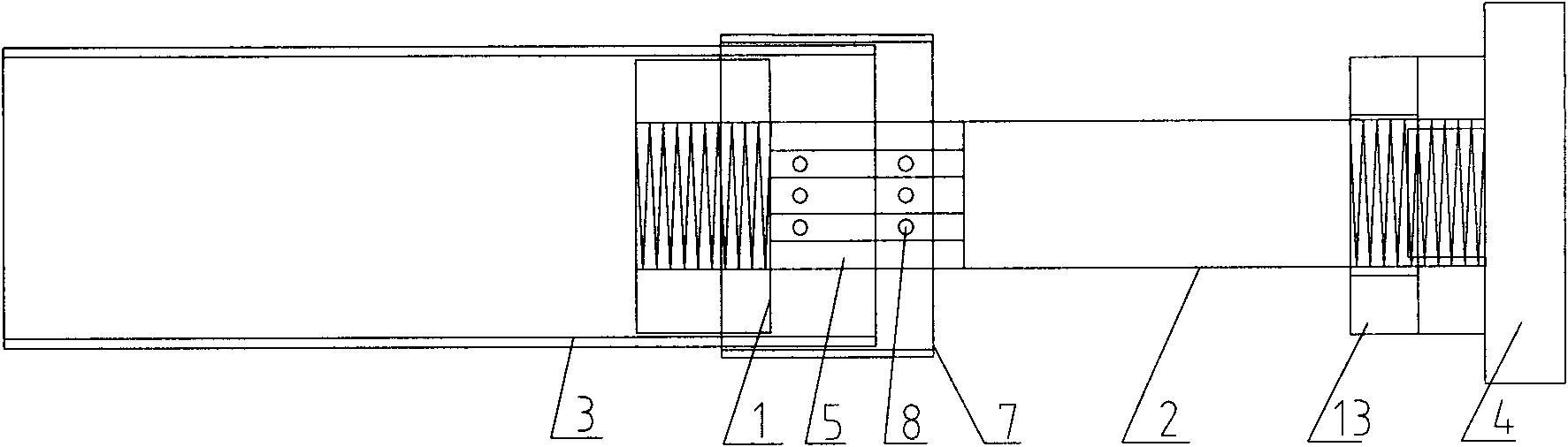

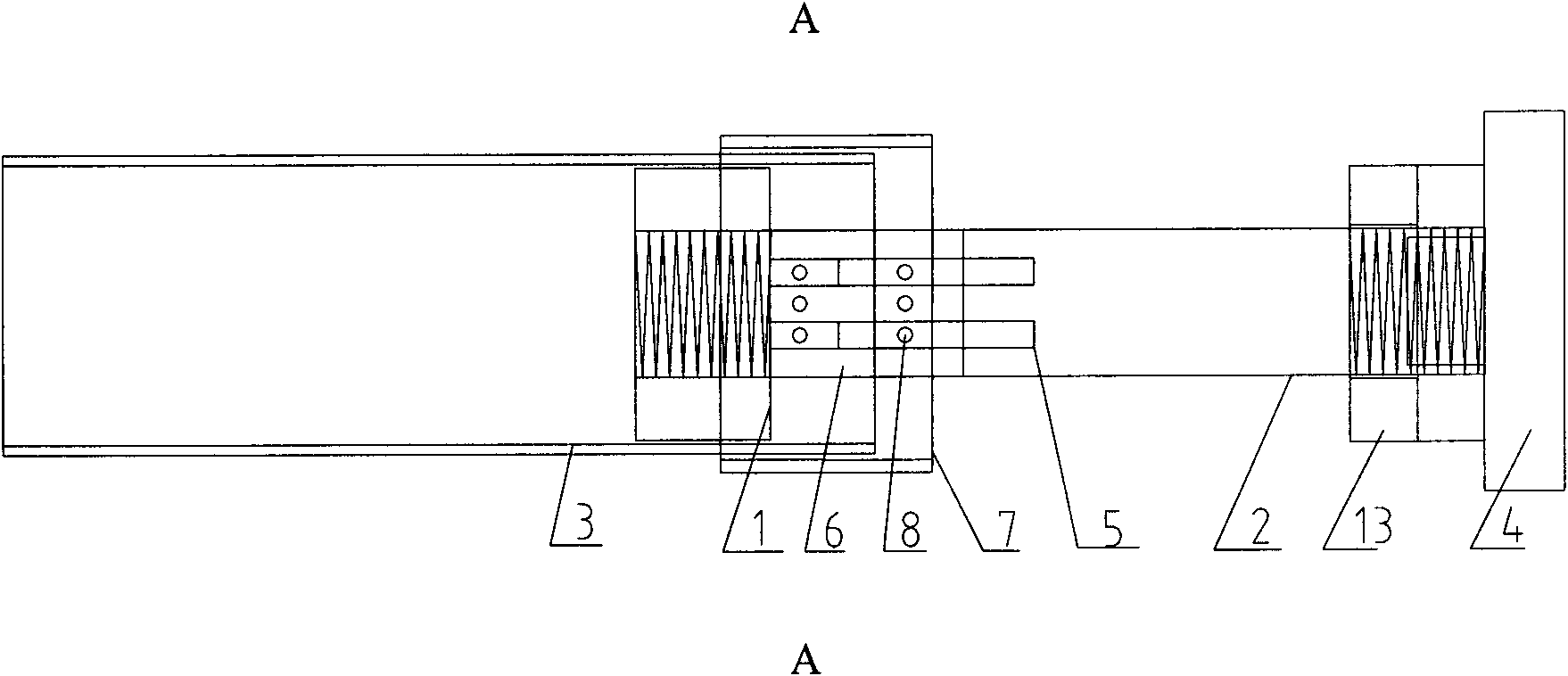

[0032] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

[0033] Such as figure 1 , figure 2 As shown, the fixture used for assembling the annular extruded permanent magnet system of the present invention includes an inner ring shaft 2 with external thread sections at both ends, several nylon sleeves 13 whose apertures are larger than the outer diameter of the inner ring shaft 2, and a An internally threaded nylon positioning sleeve 1 matched with the externally threaded section of the inner ring shaft, and a nylon positioning sleeve 1 with internally processed internally threaded and one end provided with an outer retaining ring 12 matched with the externally threaded section of the inner ring shaft Limiting sleeve 4 (see Figure 6 , Figure 6-1 ), a non-conductive magnetic steel protection cylinder 3 made of stainless steel that constitutes the outer roller sleeve part of the permanent magnet magnetic transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com