Shielded coil module and preparation method thereof

A technology for shielding coils and modules, applied in shielded loop antennas, antennas, antenna parts and other directions, can solve the problems of affecting the working performance of electronic equipment, affecting the shielding effect, low integration efficiency, etc. The effect of good magnetic isolation and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 (NFC module):

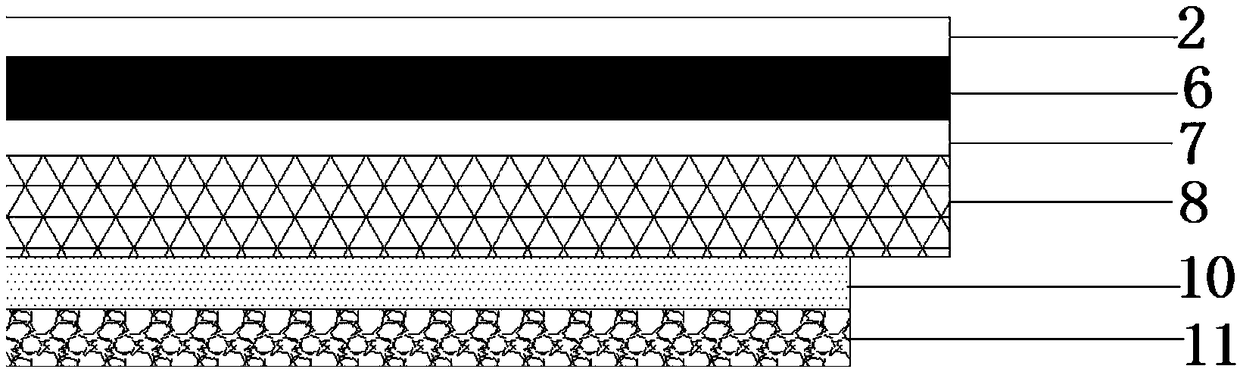

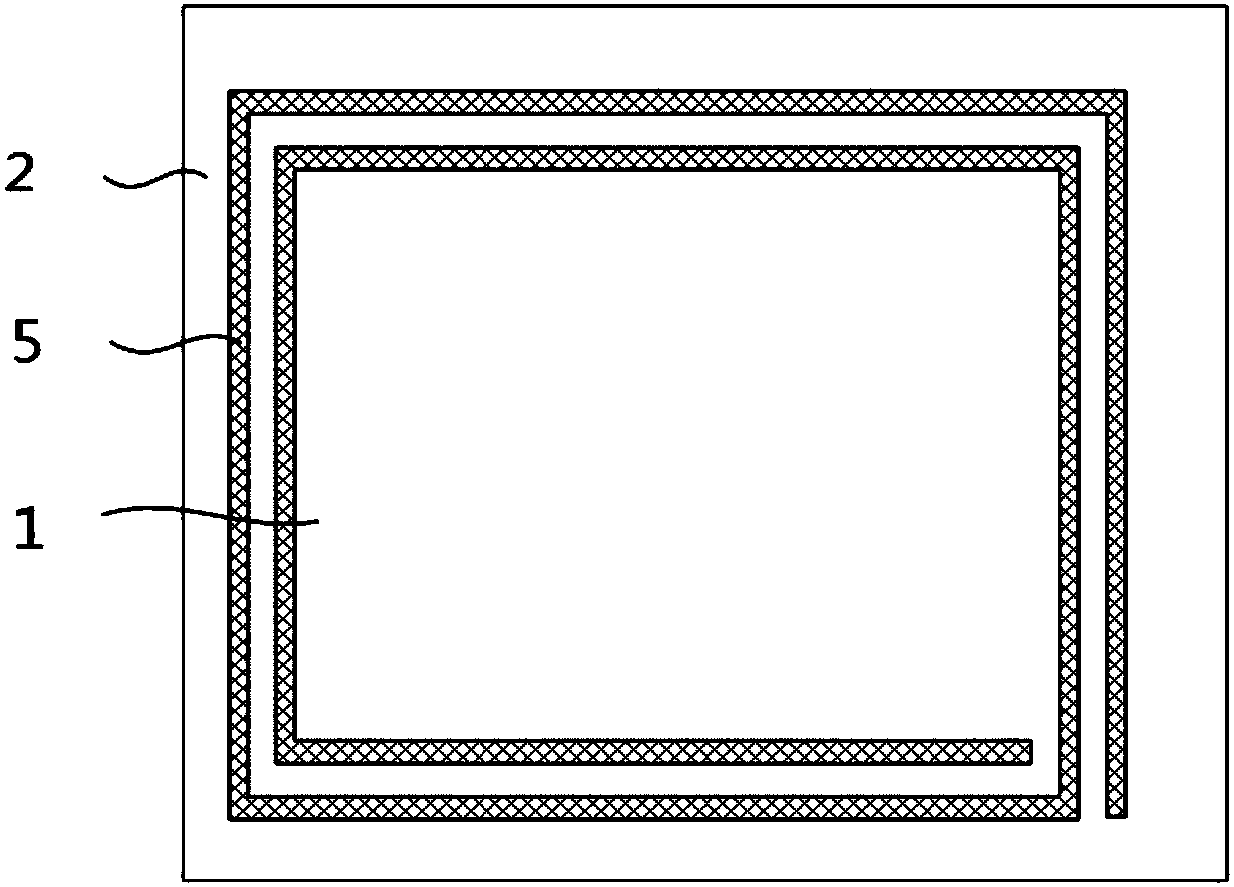

[0029] Such as figure 1 As shown, the present invention provides a shielding coil module 1. A shielding coil module 1 includes: a coil 5 formed on the upper surface of the base material 2, an insulating layer 10 formed on the upper surface of the coil 5 The shielding material layer 11 formed on the upper surface of the insulating layer 10 and the heat dissipation layer 13 formed on the upper surface of the shielding material layer 11 are placed on the battery metal plate 3; the manufacturing method includes the following steps:

[0030] A. A substrate 2 is provided, and a coil 5 is formed on the surface of the substrate 2;

[0031] Specifically, the substrate 2 is a PI single-sided adhesive substrate. An ink layer 12 is formed on the adhesive-free side of the substrate 2, and the ink layer 6 is obtained on the surface of the ink layer 12 through a printing process to form a micro-conductive layer 7 by light source irradiation. A conductiv...

Embodiment 2

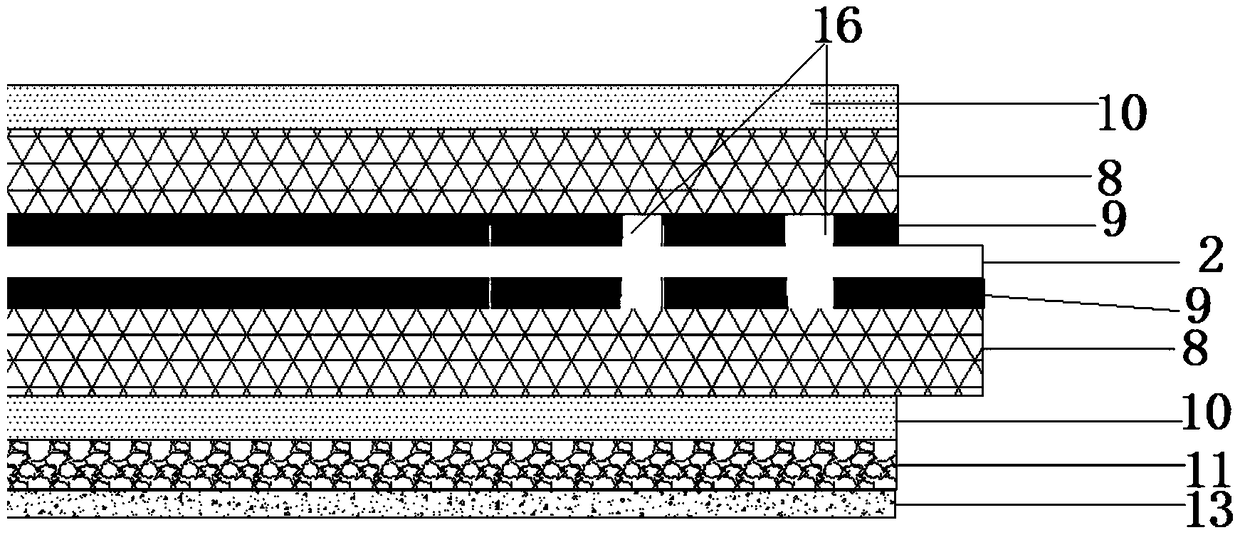

[0038] Such as image 3 Shown, preparation method of the present invention comprises the following steps at least:

[0039] A. A substrate 2 is provided, and a coil 5 is formed on the surface of the substrate 2 .

[0040] Specifically, the substrate 2 is an EMI absorbing material or a PI substrate. Such as figure 2 As shown, an ink layer 12 is formed on both sides of the substrate 2, and the coil catalytic ink layer 9 is obtained on the surface of the ink layer 12 by screen printing or coating process. Such as image 3 As shown, the electrolytic deposition method is used to form the conductive metal layer 8 on the surface of the catalytic ink layer 9 . Such as Figure 4 As shown, the coil 5 is formed.

[0041] B, forming an insulating layer 10 on the surface of the coil 5;

[0042] Specifically, the insulating layer 10 is formed by screen printing technology or coating technology, and the insulating layer 10 is located on the area of the coil 5. The thickness of the ...

Embodiment 3

[0047] Embodiment 3 (NFC+WPC)

[0048] Such as Figure 4 Shown, the present invention provides a kind of preparation method of shielded coil module, and described preparation method comprises the following steps at least:

[0049] A. A substrate 2 is provided, and a coil 5 is formed on the surface of the substrate 2 .

[0050] Specifically, the substrate 2 is an EMI absorbing material or a PI substrate. Such as figure 2 As shown, an ink layer 12 is formed on both sides of the substrate 2, and the coil catalytic ink layer 9 is obtained on the surface of the ink layer 12 by screen printing or coating process. Such as image 3 As shown, the electrolytic deposition method is used to form the conductive metal layer 8 on the surface of the catalytic ink layer 9 . Such as Figure 4 As shown, the coil 5 is formed.

[0051] B, forming an insulating layer 10 on the surface of the coil 5;

[0052] Specifically, the insulating layer 10 is formed by screen printing technology or coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com